Acid-corrosion-free and high electric insulation red phosphorus flame retarded reinforced nylon and production method thereof

A technology of acid corrosion and nylon, applied in the field of engineering plastics, can solve the problems of reducing the electrical insulation safety performance of nylon materials, affecting the expansion of the application range of materials in the electrical field, and achieving the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

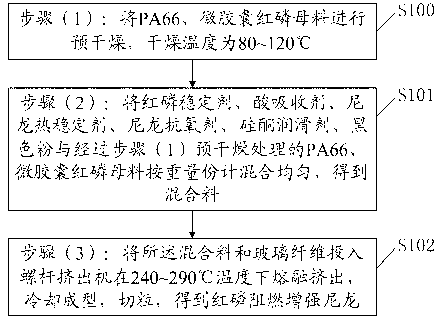

[0072] Such as figure 1 As shown, the embodiment of the present invention also provides a preparation method of red phosphorus flame-retardant reinforced nylon without acid corrosion and high electrical insulation, including:

[0073] S100, step (1): pre-dry PA66 and microcapsule red phosphorus master batch, and the drying temperature is 80~120℃;

[0074] Preferably, the pre-drying treatment in step (1) includes:

[0075] Dry PA66 at a drying temperature of 100~120℃ for no less than 4 hours;

[0076] Dry the microcapsule red phosphorus masterbatch at a drying temperature of 80~90℃ for not less than 2 hours.

[0077] It should be noted that since water is not only a necessary reactant for the hydrolysis of red phosphorus, but also an important factor affecting the electrical insulation safety of the material, the water content of the raw materials must be controlled before processing. The auxiliary materials and additives in the formula do not contain crystal water, and generally do no...

Embodiment 1

[0120] Pre-dry PA66 at a drying temperature of 100°C for 6 hours, and pre-dry the microcapsule red phosphorus master batch at a drying temperature of 80°C for 3 hours; 1 part of red phosphorus stabilizer, 4 parts of acid absorbent, and 1 part of nylon are heat stabilized Mixing agent, 0.3 parts of nylon antioxidant, 0.5 parts of silicone lubricant, 1.2 parts of black powder, 51 parts of PA66 and 18 parts of microcapsule red phosphorus masterbatch after pre-drying treatment in parts by weight to obtain a mixture ; Put the mixture and 23 parts of glass fiber into the screw extruder, use the bimodal processing temperature to control the melting temperature to melt and extrude at 240 ~ 290 ℃, and use the vacuum pump to vacuum during the melt extrusion process, and to the screw The extruder barrel is injected with inert gas, and finally, it is cooled to form and pelletized to obtain red phosphorus flame-retardant reinforced nylon.

Embodiment 2

[0122] Pre-dry PA66 at a drying temperature of 115°C for 5 hours, and pre-dry the microcapsule red phosphorus master batch at a drying temperature of 85°C for 2.5 hours; 4 parts of red phosphorus stabilizer, 2 parts of acid absorbent, and 0.7 parts of nylon are heat stabilized Mixing agent, 0.5 parts of nylon antioxidant, 0.8 parts of silicone lubricant, 2 parts of black powder, 53 parts of PA66 and 16 parts of microcapsule red phosphorus masterbatch which have undergone pre-drying treatment in parts by weight to obtain a mixture; The mixture and 21 parts of glass fiber are put into the screw extruder, and the bimodal processing temperature is adopted to control the melting temperature to melt and extrude at 240~290℃, and the vacuum pump is used to vacuum during the melt extrusion process while extruding to the screw The barrel of the machine is injected with inert gas, and finally, it is cooled to form and pelletized to obtain red phosphorus flame-retardant reinforced nylon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com