Double-wheel slot milling machine based on sprocket transmission and milling, and slot forming method

A double-wheel milling and sprocket technology, which is applied to mechanically driven excavators/dredgers, infrastructure engineering, earth movers/shovels, etc., can solve the problem of reducing construction efficiency, affecting construction efficiency, and disturbing the normal operation of peripheral equipment. Work and other problems, to achieve the effect of reducing construction procedures, improving shear strength and anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

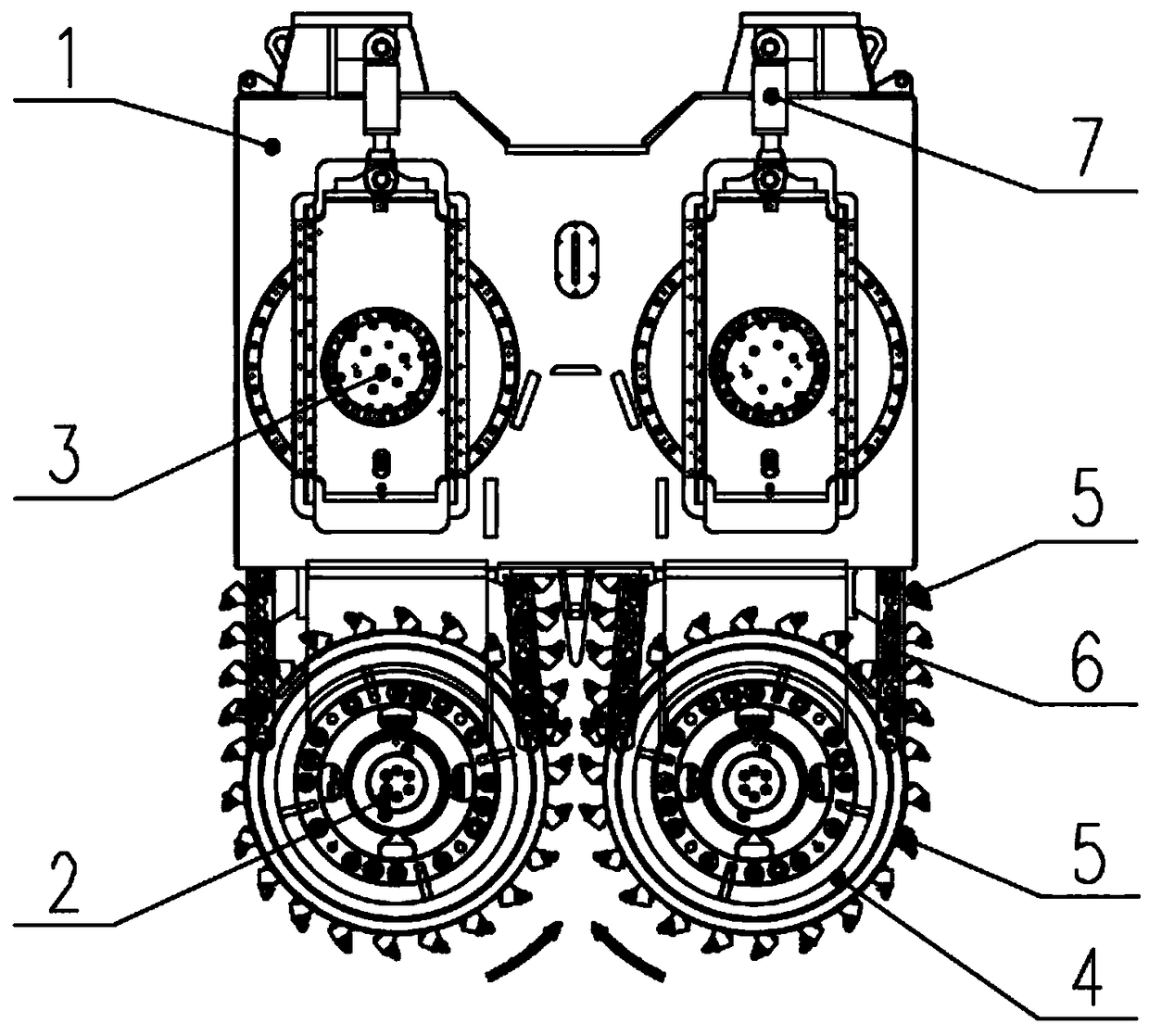

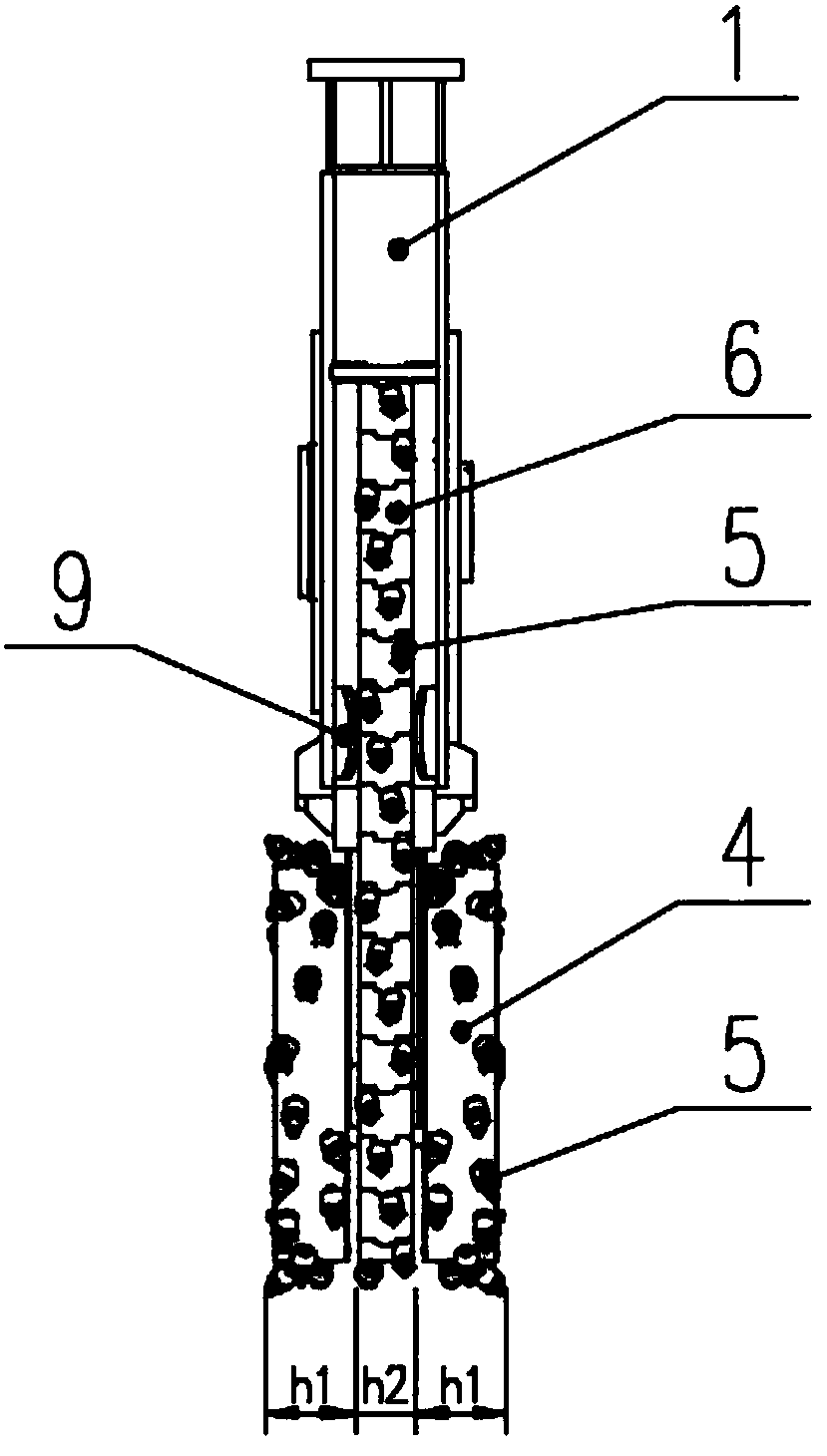

[0035] see figure 1 and 2 , shows the double-wheel milling machine based on sprocket transmission and milling of the present invention.

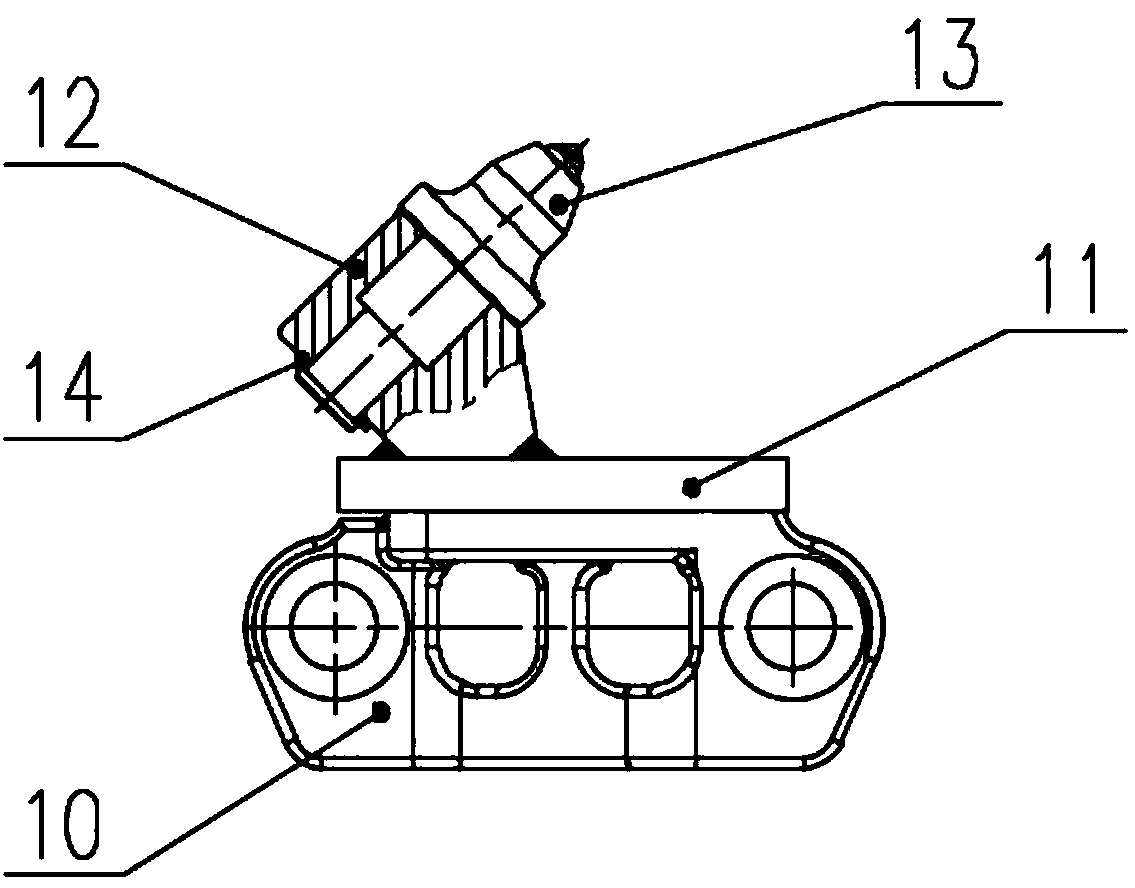

[0036] The two-wheel milling machine based on sprocket transmission and milling at least includes a support frame 1, a rotating milling wheel 2, a driving wheel 3, a milling wheel hub 4, a plurality of milling cutter teeth 5, sprockets 6, and a sprocket tensioning device 7 and a sprocket roller 8, the rotary milling wheel 2 is two and symmetrically arranged on the left and right sides of the support frame 1, and the driving wheel 3 is also two and symmetrically arranged above the rotary milling wheel 2, the There are two sprocket tensioning devices 7 and they are arranged symmetrically above the driving wheel 3. Each sprocket tensioning device 7 is respectively connected to the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com