Patents

Literature

73results about How to "Guaranteed anti-seepage effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-seepage air-permeable pot culture container and preparation method thereof

ActiveCN102475041APrevent extravasationGuaranteed breathabilityReceptacle cultivationLiquid waterPhysical chemistry

The invention relates to an anti-seepage air-permeable pot culture container. The pot culture container is provided with an open cavity, aggregate particles and water-repellent binder are stuck together to form the pot culture container, and pores through which air molecules rather than liquid water molecules can pass are formed between the neighboring aggregate particles. The aggregate particles are one of quartz sand, slag, ceramsite and glass beads or the mixture of any of quartz sand, slag, ceramsite and glass beads. The invention also discloses a preparation method for the anti-seepage air-permeable pot culture container. Since the invention applies the material with good anti-seepage and air-permeable properties to the pot culture container, the moisture for pot culture is effectively retained, so that the moisture needed by a plant is maintained, and moreover, while proofing water, the pot culture container also has the air-permeable property. The anti-seepage air-permeable pot culture container can be widely applied to the plantation of various potted plants, garden nursery transplantation and the plantation of crops in arid regions.

Owner:BEIJING RECHSAND SCI & TECH GRP

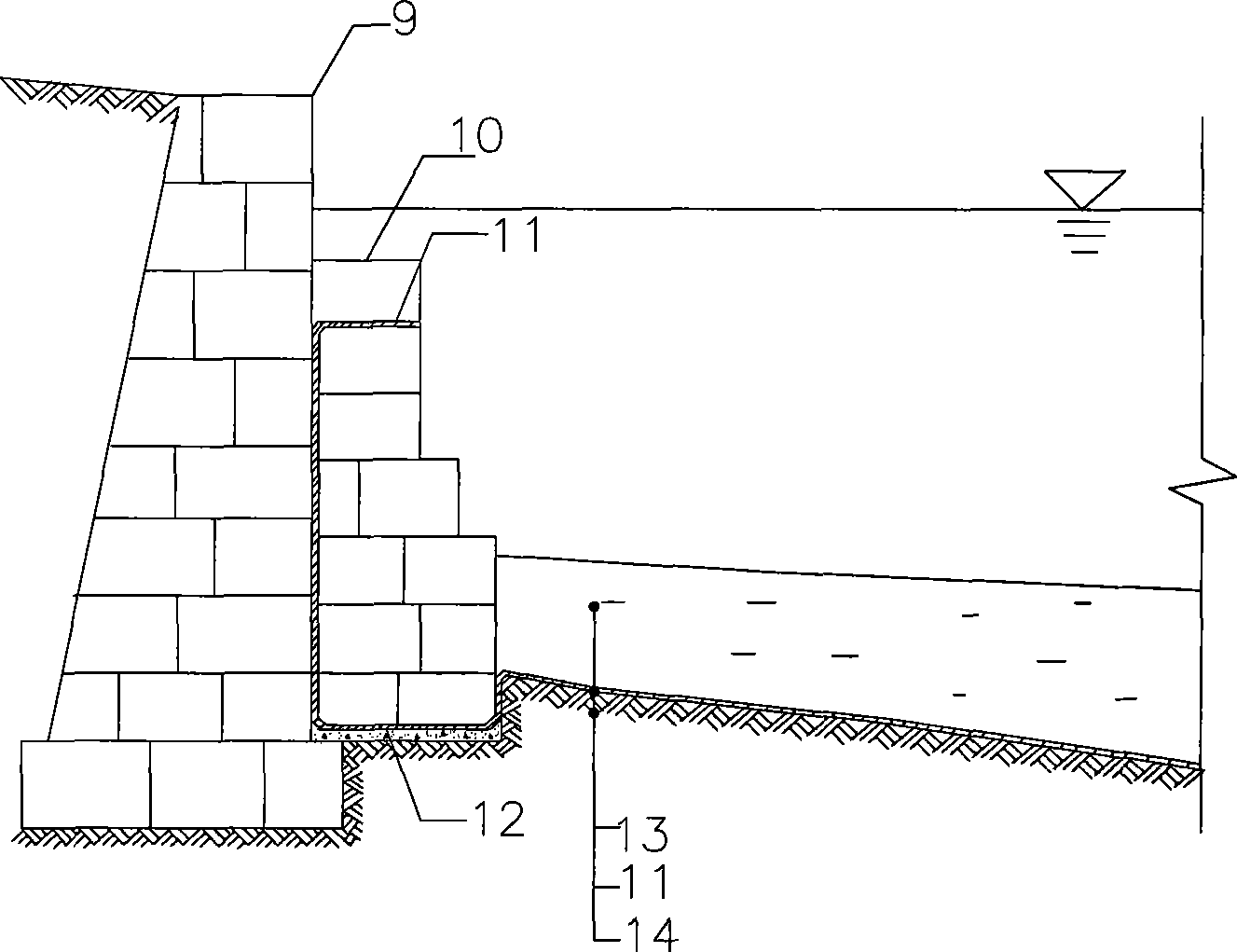

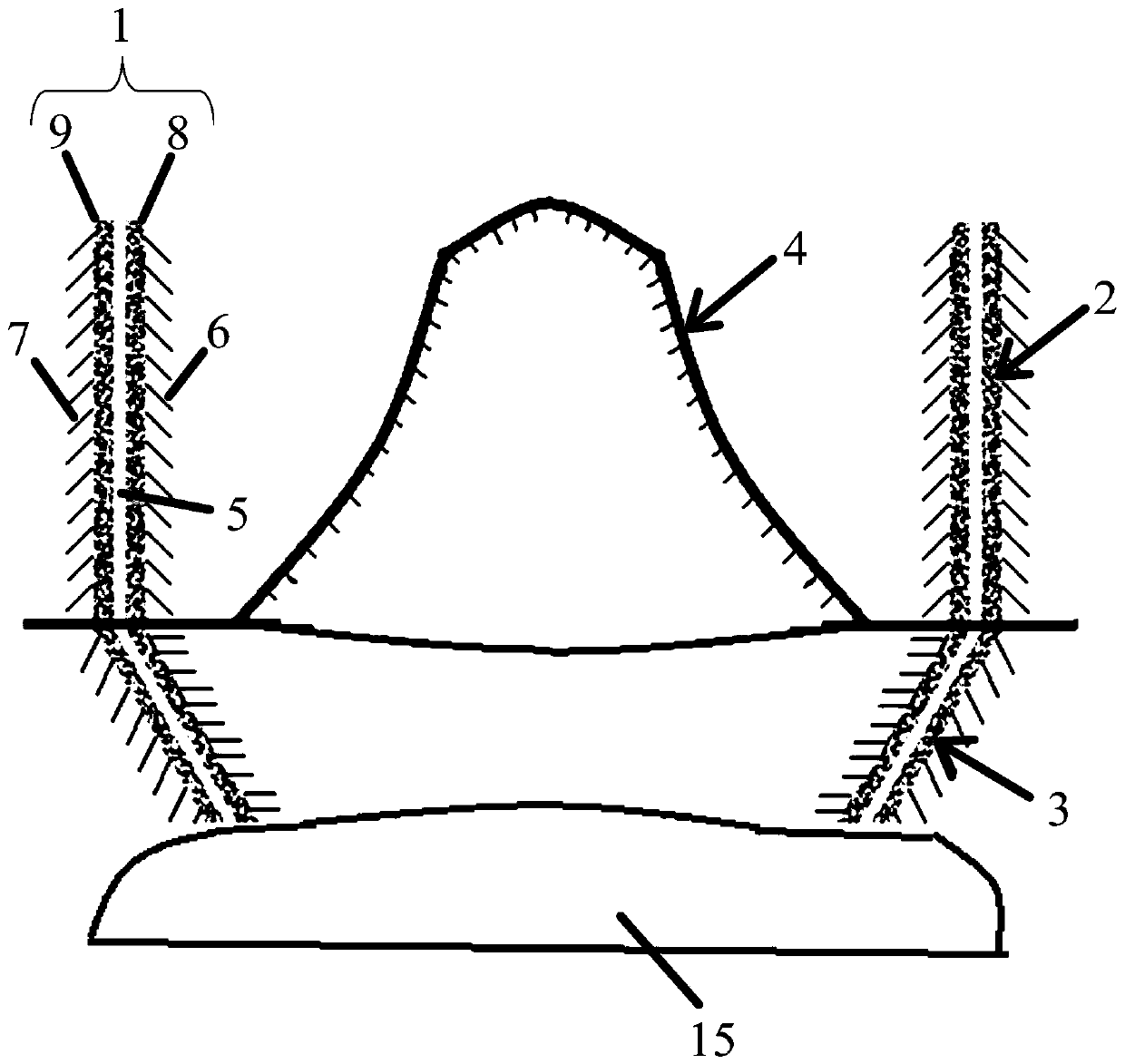

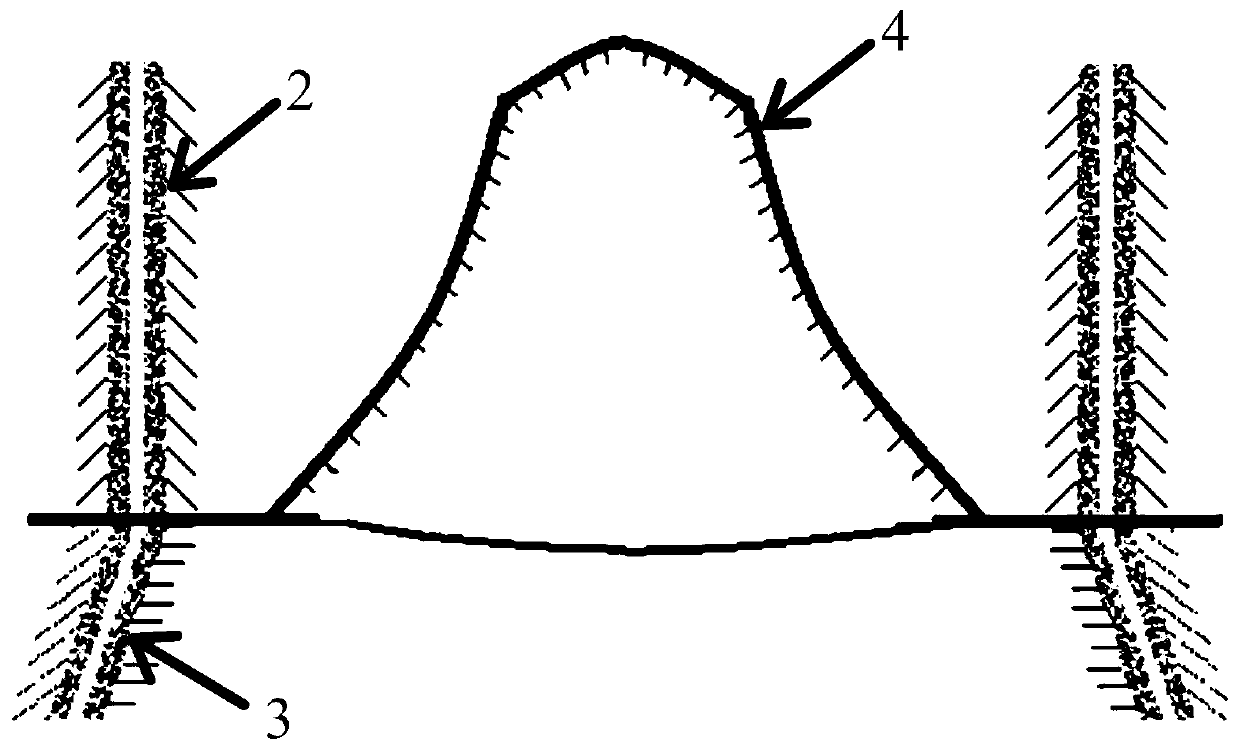

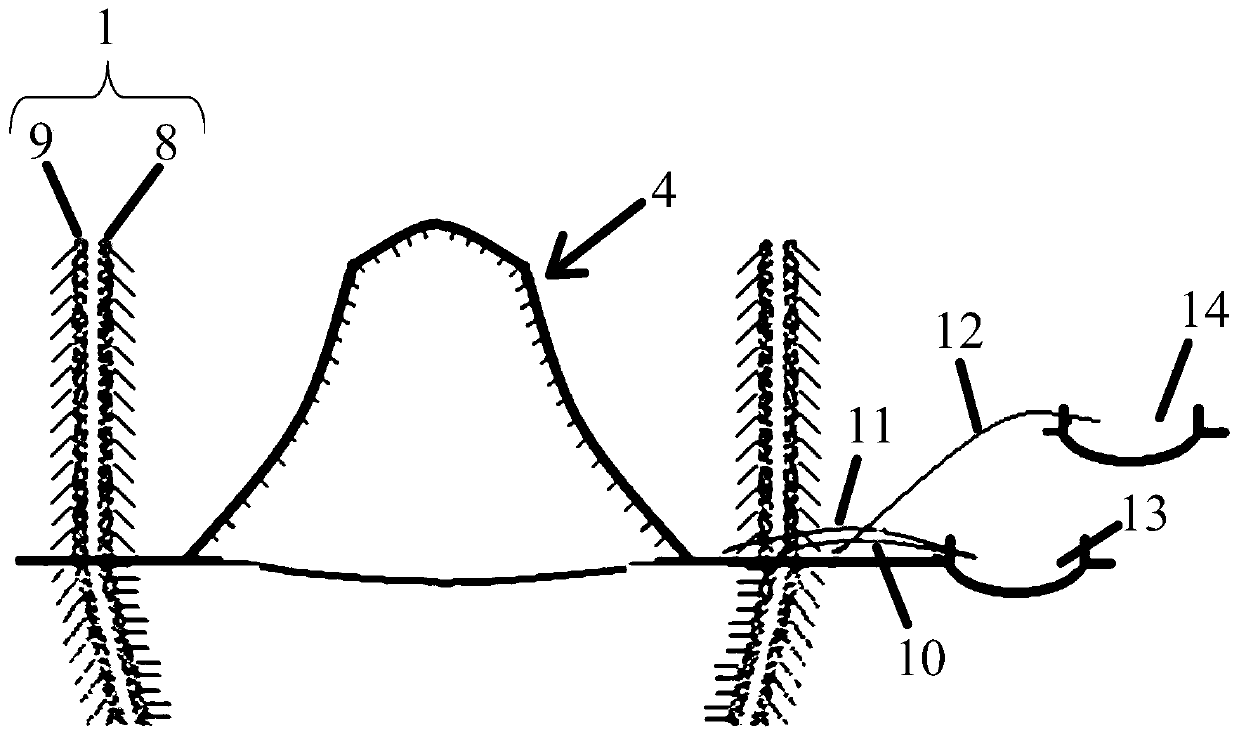

Impermeable water stopping structure for hydraulic engineering

ActiveCN103628451APrevent penetrationAvoid scourMarine site engineeringStructural engineeringHydraulic engineering

The invention relates to an impermeable water stopping structure for hydraulic engineering. The impermeable water stopping structure comprises a dam body. One side of the water stopping face of the dam body is provided with a step-shaped dam body impermeable layer extending from the dam top to the dam bottom. A dam foundation impermeable layer is arranged in a dam foundation of the bottom of the dam body. An impermeable connecting layer is arranged between the dam foundation impermeable layer and the step-shaped dam body impermeable layer. The dam foundation impermeable layer is of a combined structure comprising a concrete impermeable wall and a grouting curtain. One side of the water stopping face of the dam body is provided with the step-shaped dam body impermeable layer extending from the dam top to the dam bottom, and therefore permeating, washing and wearing of the surface of the dam body from water can be effectively prevented. As the dam foundation impermeable layer is arranged in the dam foundation, the impermeable water stopping structure can effectively prevent seepage of water in a dam, and therefore the impermeability and the durability of the whole dam and the foundation can be ensured.

Owner:日照市三联调水有限公司

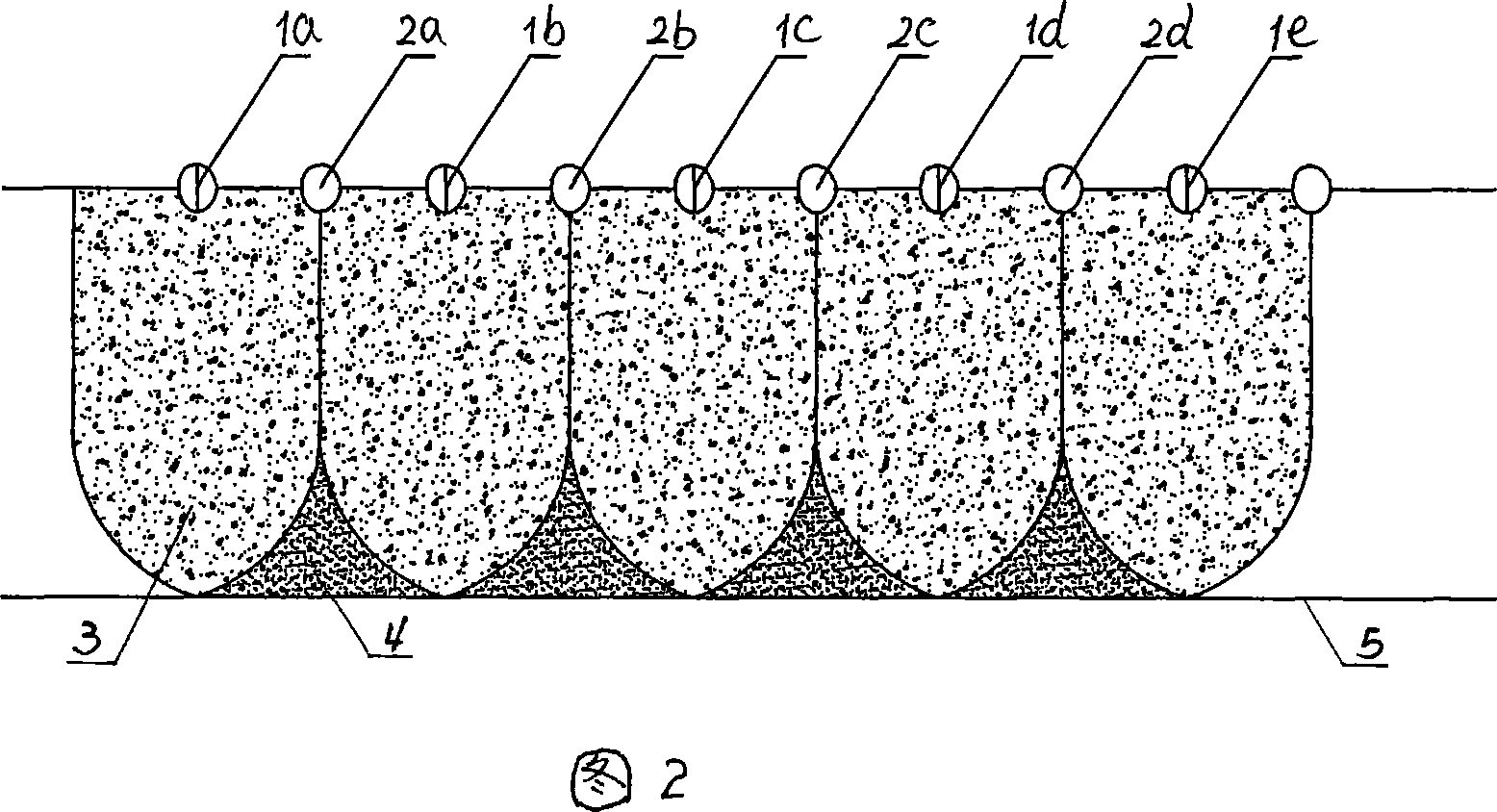

Air-permeable fish tank and its manufacturing method

ActiveCN102850075AGuaranteed breathabilityImprove breathabilityPisciculture and aquariaCeramicwareLiquid waterFishery

The invention discloses an air-permeable fish tank. The fish tank comprises a cavity with an opening and is formed by bonding hydrophobic substance-coated aggregate particles and hydrophobic binder; voids, through which air molecules can pass through and liquid water molecules can not pass through under high pressure, are formed among adjacent aggregate particles; and diameters of the voids are of 0.002-0.086 mm. The invention also discloses a manufacturing method of the fish tank. The fish tank effectively solves the problem that existing ordinary fish tanks can not have both of anti-seepage and air-permeable performances. The fish tank has the advantages of low cost, simple manufacture and simple appearance, and it is suitable for various occasions suitable for fish culture.

Owner:BEIJING RECHSAND SCI & TECH GRP

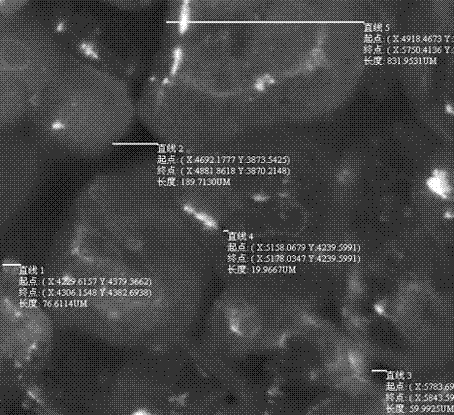

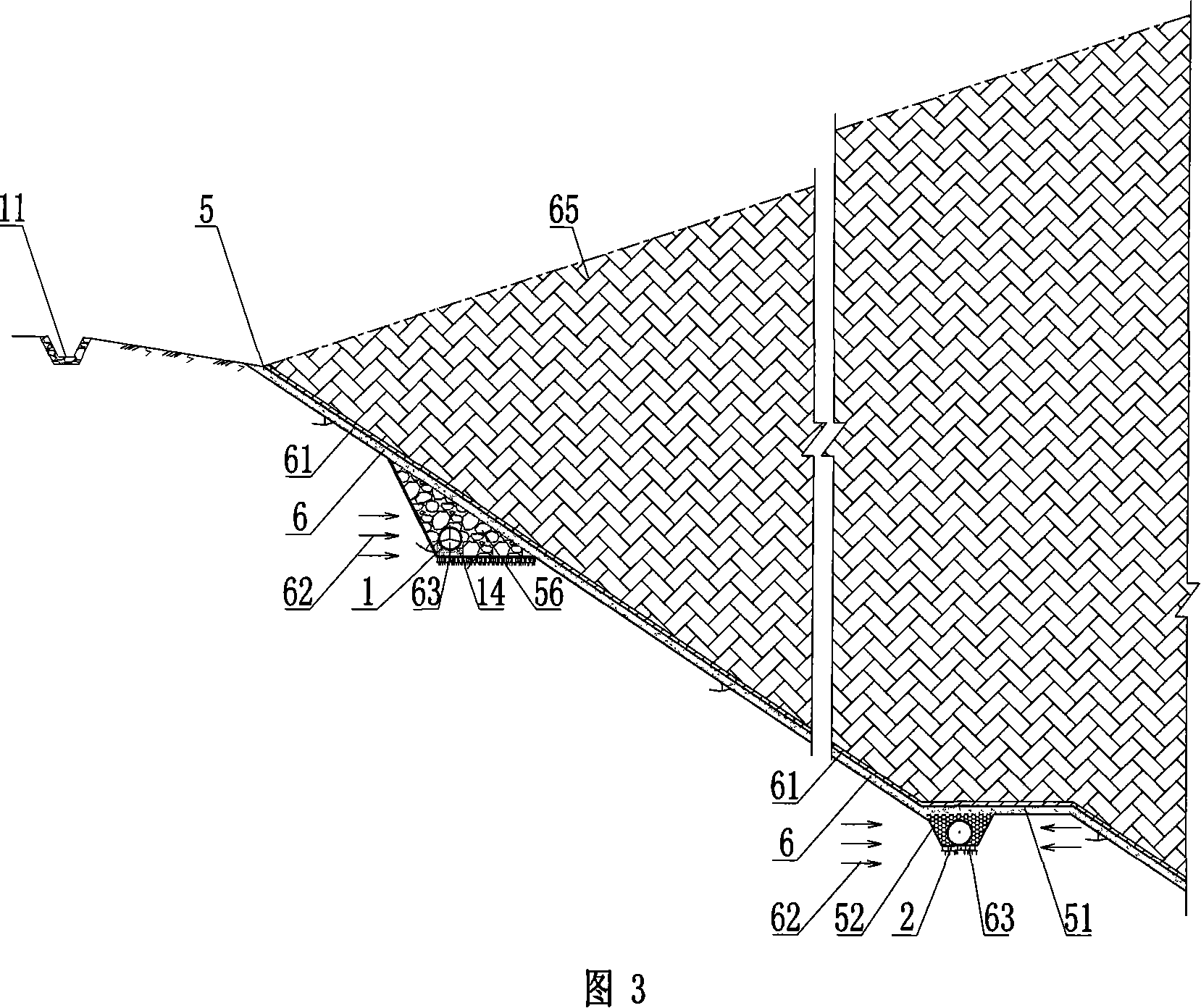

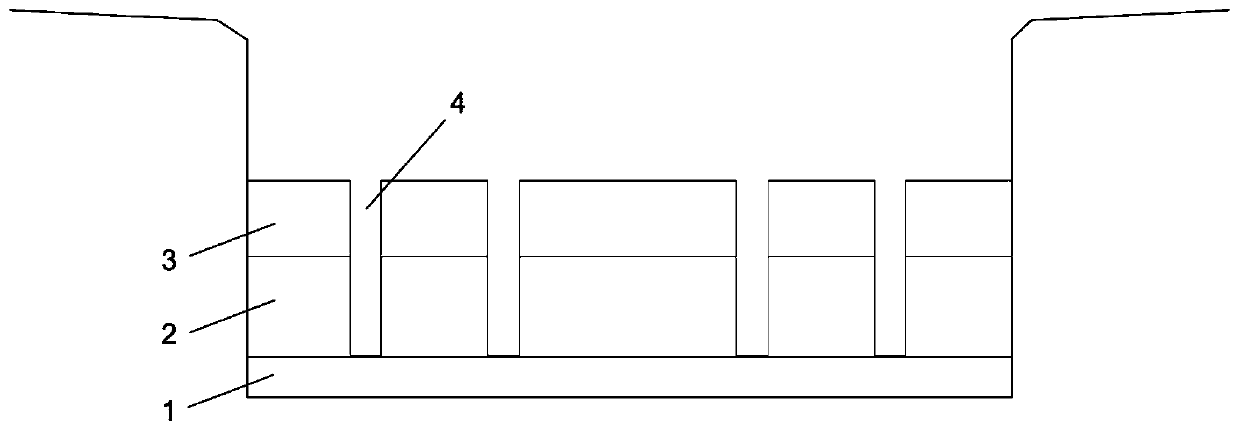

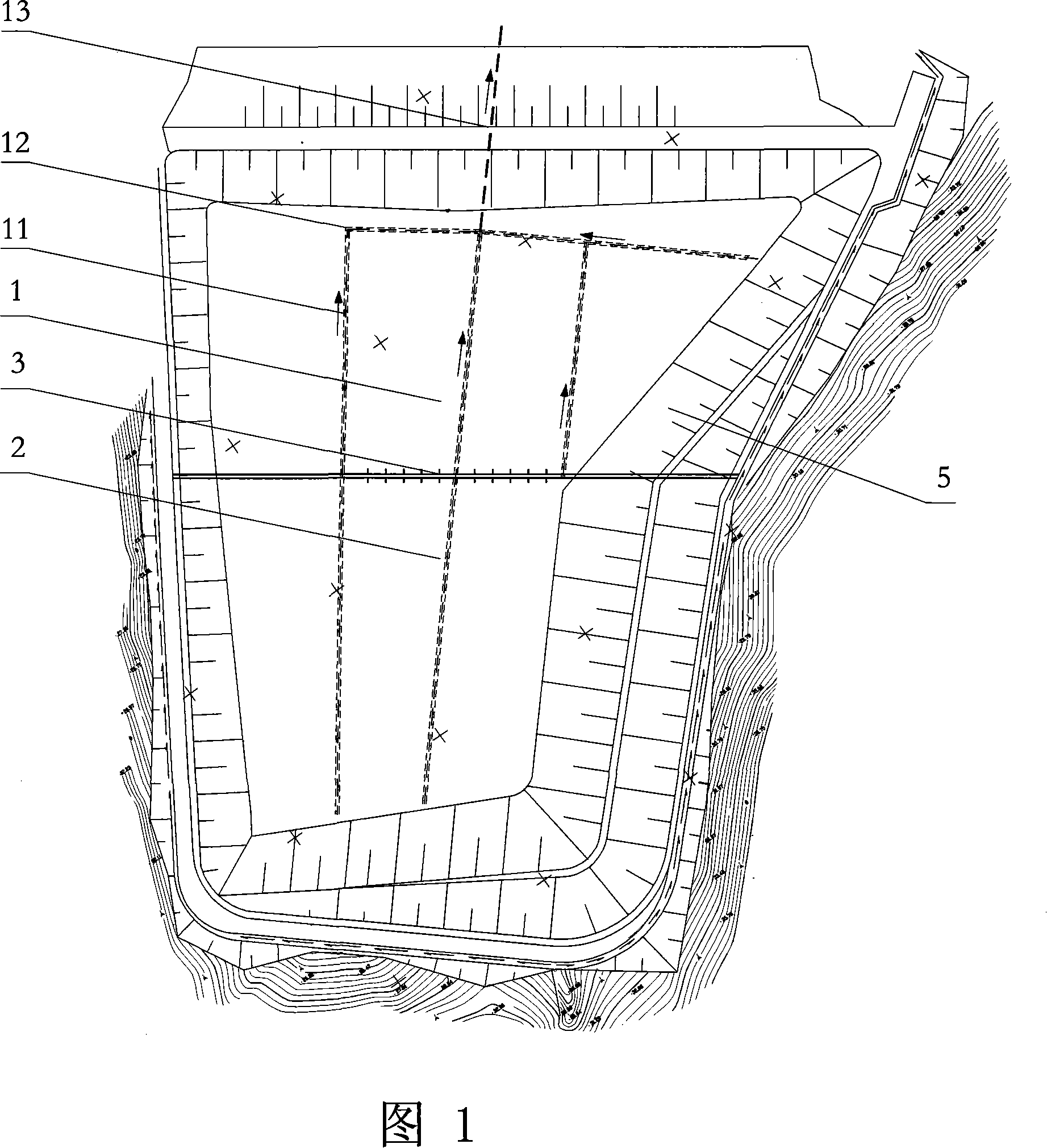

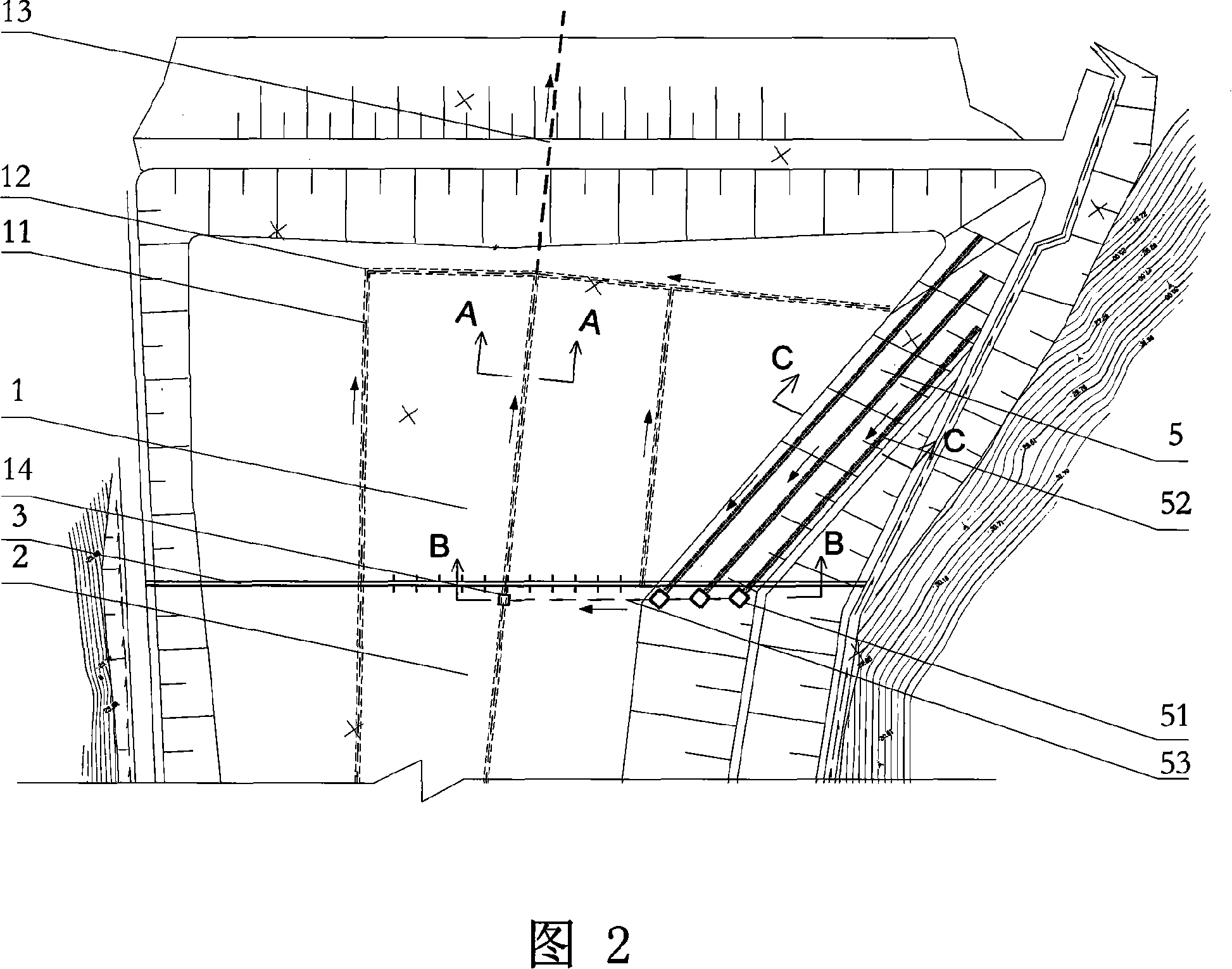

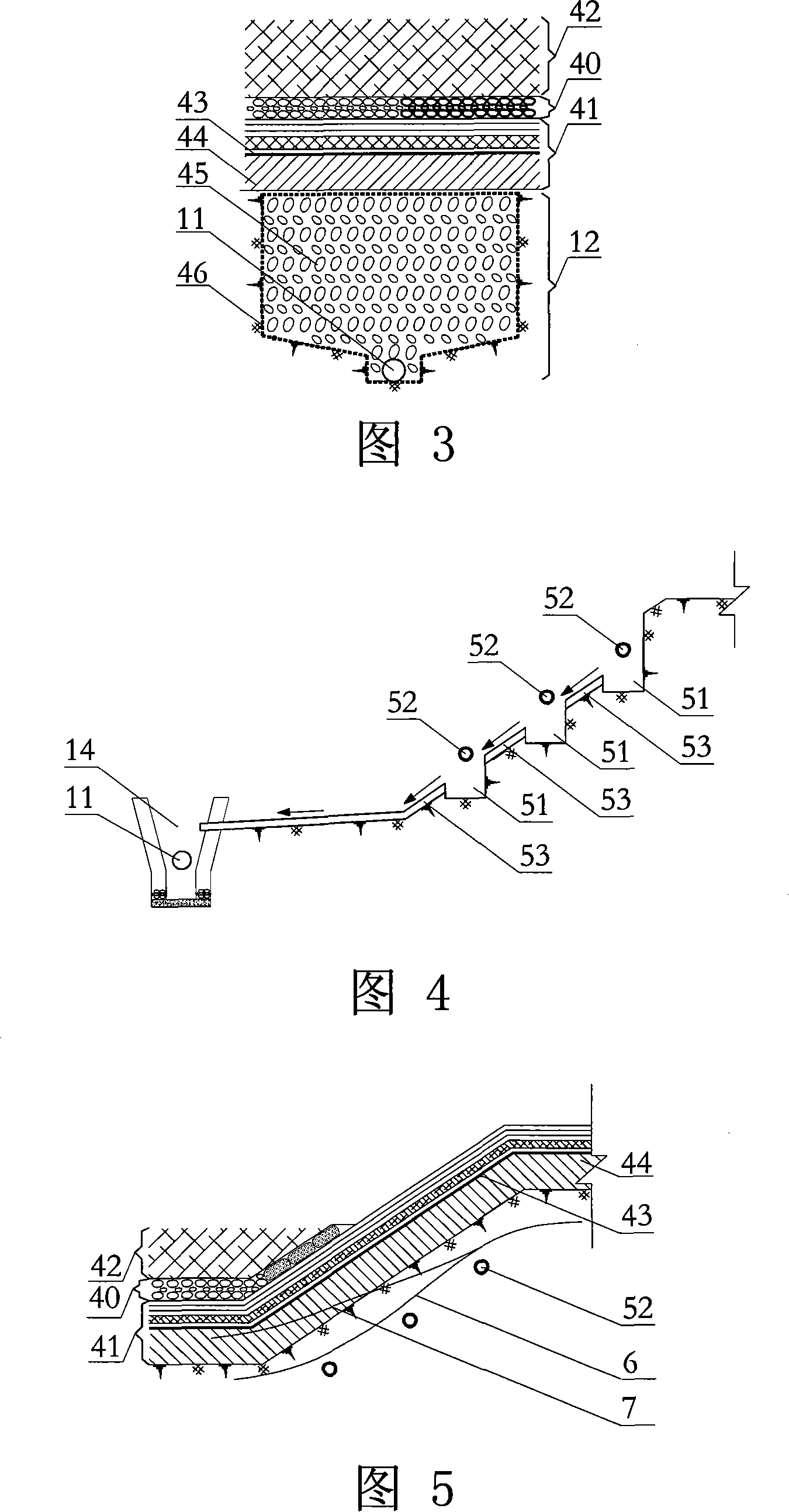

Stereo drainage system structure for landfill underground water

ActiveCN101148885ARapid evacuationPrevent damage to the anti-seepage layerFoundation engineeringWater flowEngineering

The stereo underground water draining system for landfill includes one upper water flow cutting off structure set in the top of the slope in landfill, one bottom water draining structure set in the bottom of landfill, and water cutting off open ditches. The upper water flow cutting off structure includes permeated water cutting off pipes around the landfill; the water cutting off open ditches dug in the periphery of the landfill have outlet in the downstream of the landfill; and the permeated water cutting off pipes are communicated to outside landfill or to the bottom water draining structure. The water draining system may have also middle water flow cutting off structure and foot water flow cutting off structure communicated mutually. The water draining system can drain underground water and surface water effectively to ensure the antiseepage effect of the impervious barrier.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

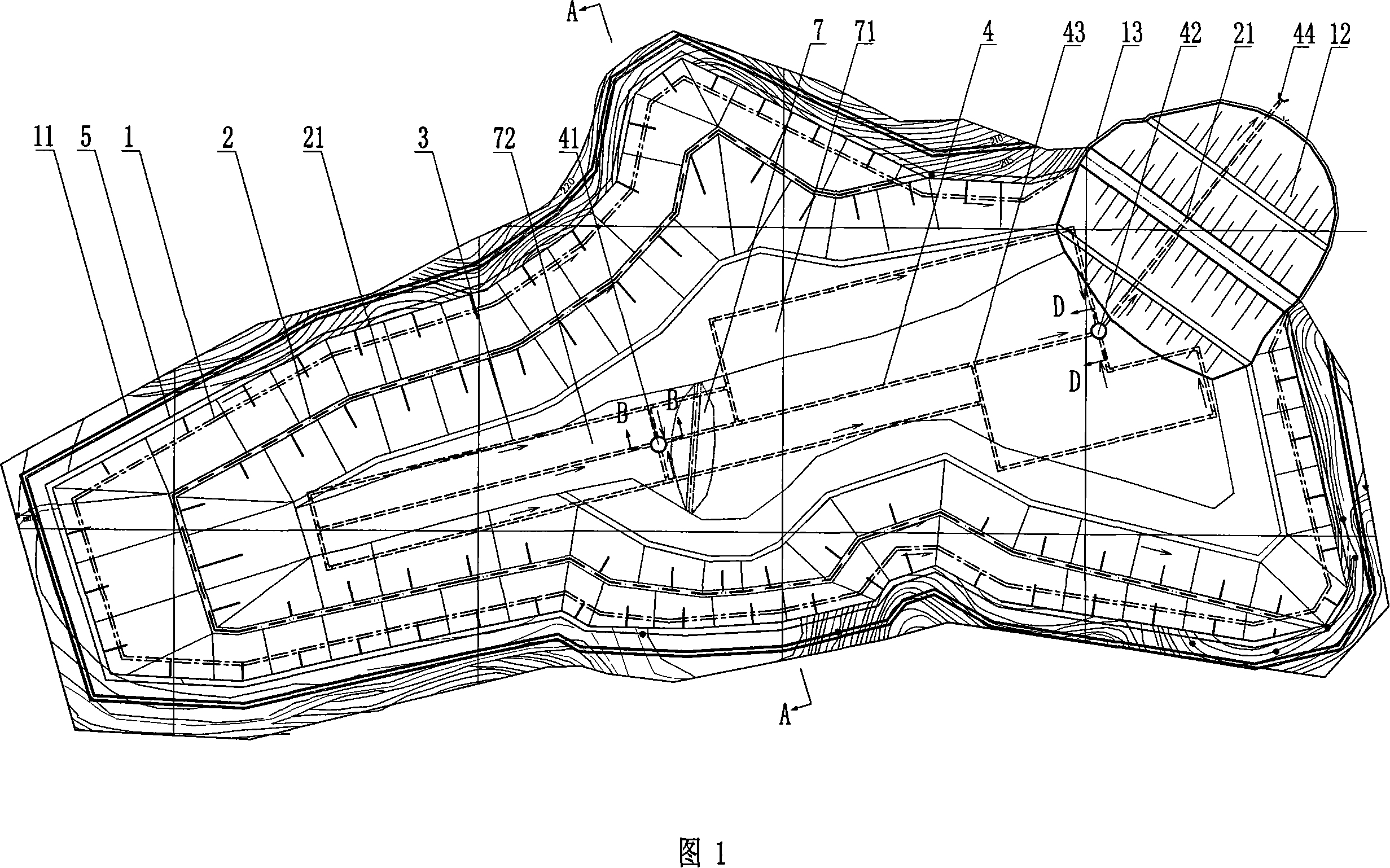

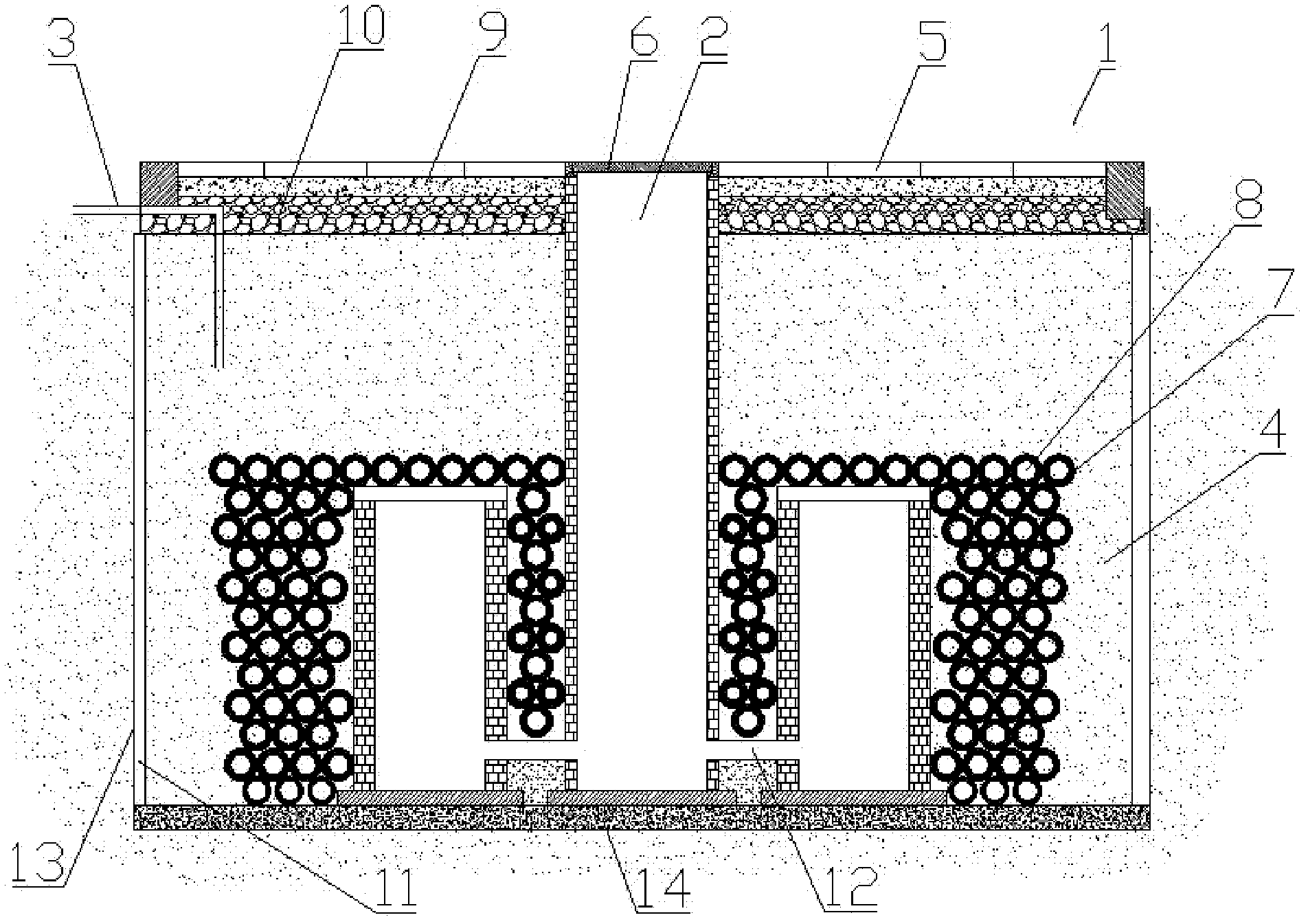

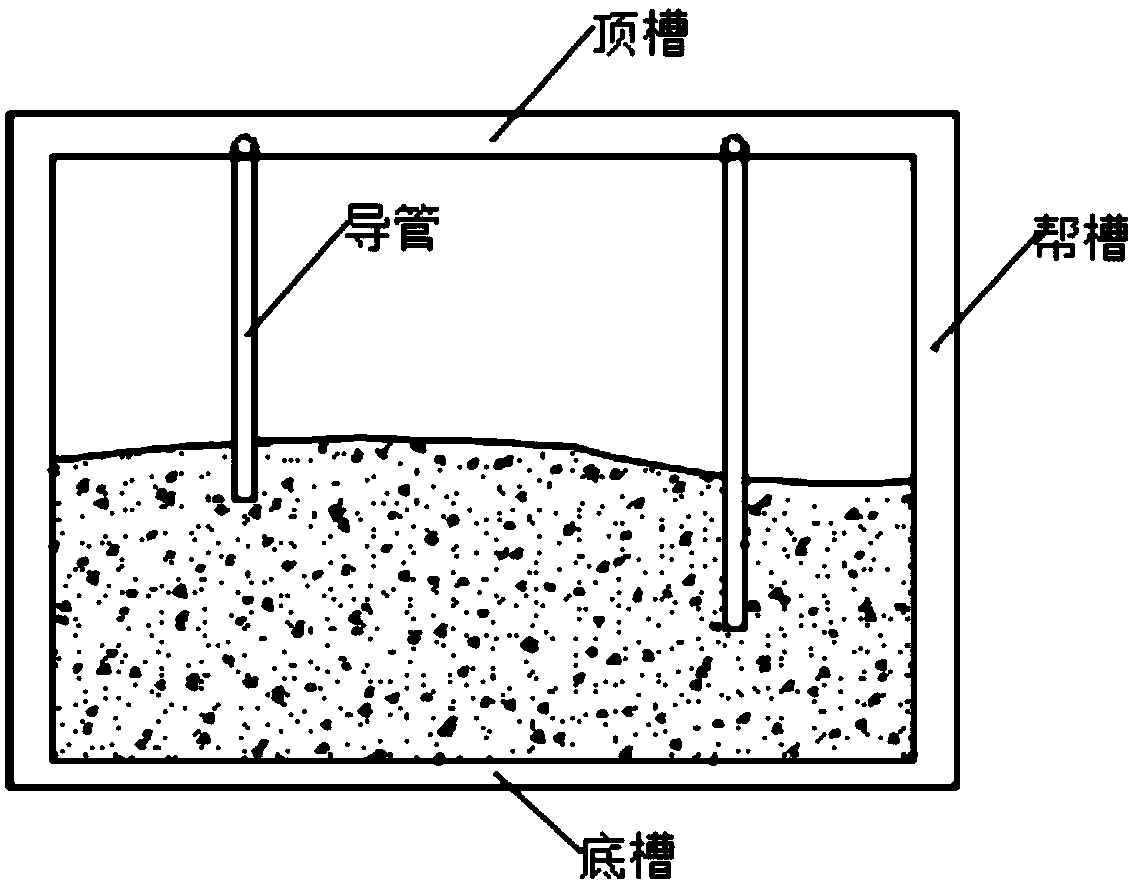

Water storage system

ActiveCN103174189AGuaranteed anti-seepage effectGuaranteed air permeabilitySewerage structuresGeneral water supply conservationWater storageWater quality

The invention relates to a water collection and purification system, in particular to a water storage system which is firm in building and easy to construct. The water storage system comprises a water storage container, a water collection well and water permeability padding which is filled between the water collection well and the water storage container, water is filled into the water storage container through a water inlet pipe or a water permeability surface layer paved above the padding, the container wall is a seepage prevention air permeability wall which is composed of seepage prevention air permeability particles, the boundary of the seepage prevention air permeability wall is limited through air permeability wall bags, and fine sand particles are piled up on two sides of the seepage prevention air permeability wall to fix the seepage prevention air permeability wall in a squeezing mode. The container wall of the water storage system adopts the air permeability wall bags and are filled with the seepage prevention air permeability particles, thin sand are filled on two sides of the side wall to squeeze and reinforce the side wall, the water can be prevented from being leaked outwardly through seepage prevention performance of the seepage prevention air permeability particles, so that the seepage prevention performance of the water storage system is ensured, meanwhile, an air permeability degree of the whole water storage system is also ensured through the air permeability performance of the seepage prevention air permeability particles, and the stored water is enabled not to go bad easily.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

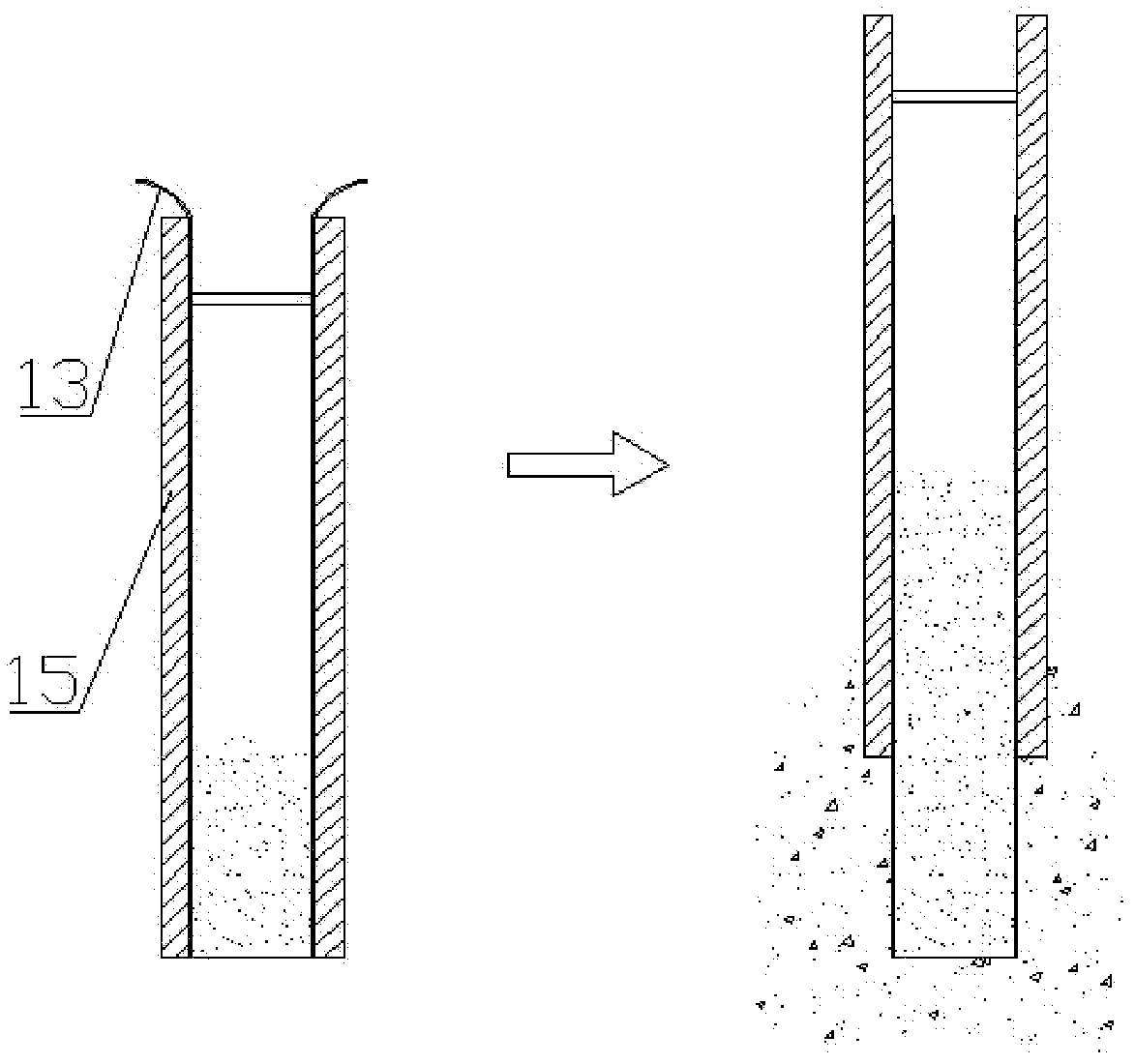

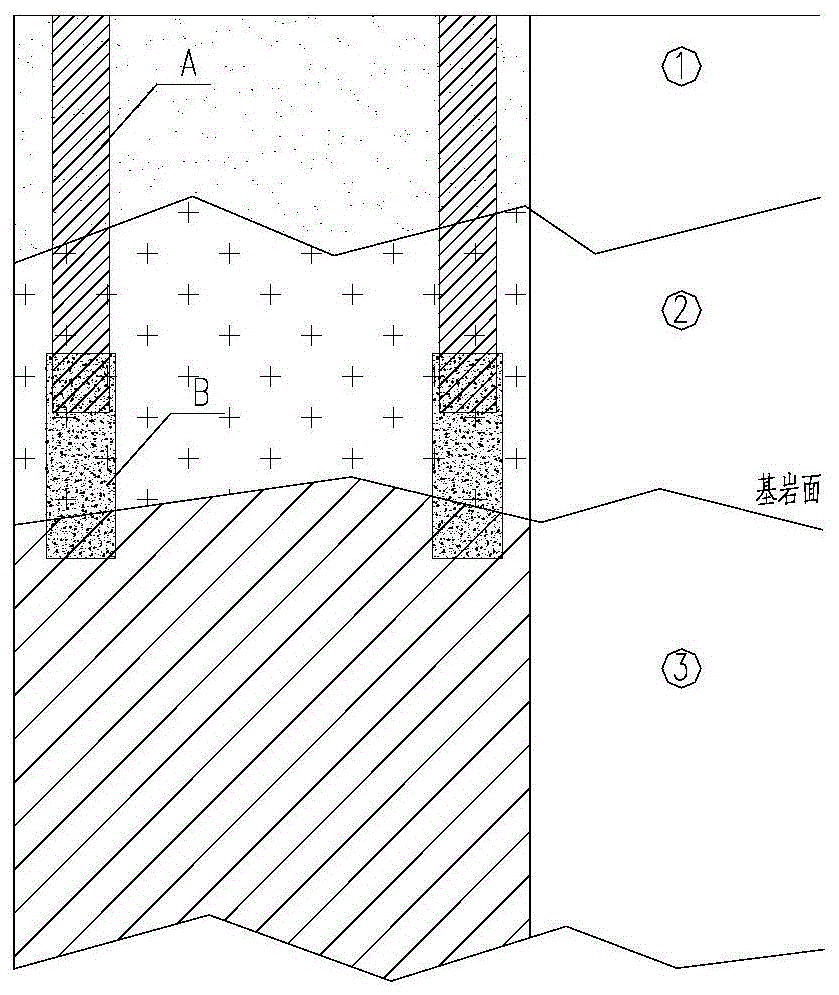

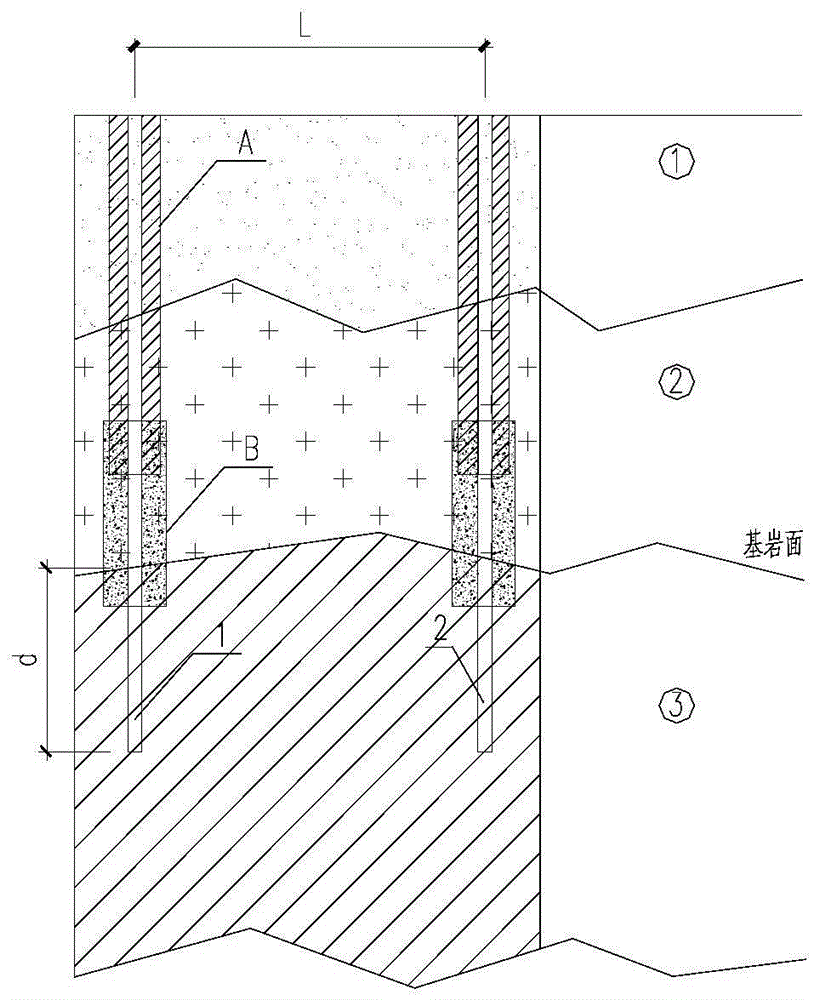

Construction method of high-strength sealing wall with anti-seepage function in mine roadway

The invention relates to a construction method of a high-strength sealing wall with an anti-seepage function in a mine roadway and belongs to the field of protection measures for mine water disasters.The method includes the steps of 1, forming grooves in a top plate and a bottom plate in a sealed place and the two sides of the sealed place and removing waste on the site; 2, determining the positions and size of three holes; 3, constructing a brick wall, installing anchoring rods in grooves formed in a concrete wall and constructing a steel bar framework; 4, before construction of a wall body,filling the holes, adopting a vertical guide pipe insertion method for pouring of the concrete wall until pouring of the concrete wall is finished, and spraying slurry after construction of the wallbody is finished. An anti-seepage concrete wall construction process of a dam is combined, and through installation of an underground anti-seepage high-strength sealing device, the anti-seepage high-strength sealing wall which is convenient in construction, small in seepage amount and high in safety and reliability and can achieve sealing in a water permeation period is provided. The sealing walladopts a combined wall body structure composed of the brick wall, a filling layer and the concrete wall and solves the problem that water can permeate when a water influx accident happens under a welland it is needed to construct a waterproof sealing wall.

Owner:LIAONING TECHNICAL UNIVERSITY

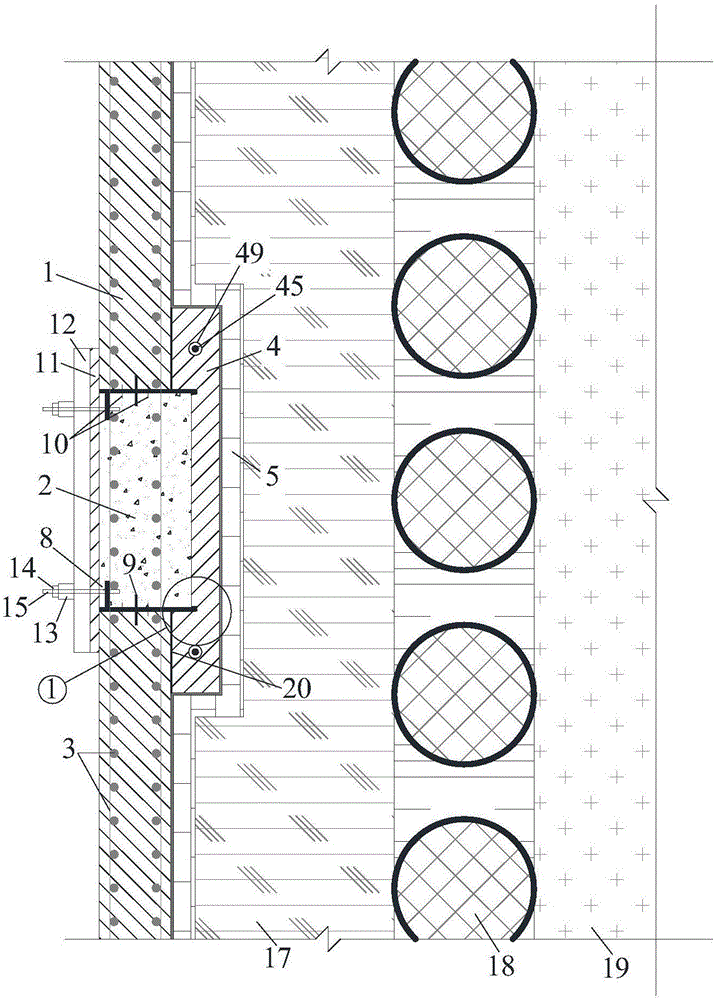

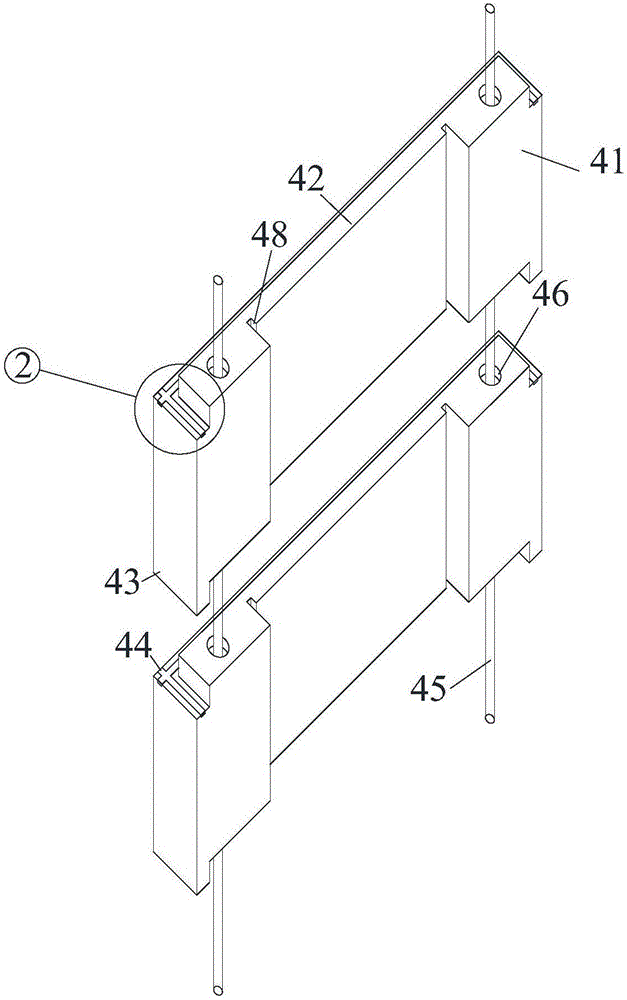

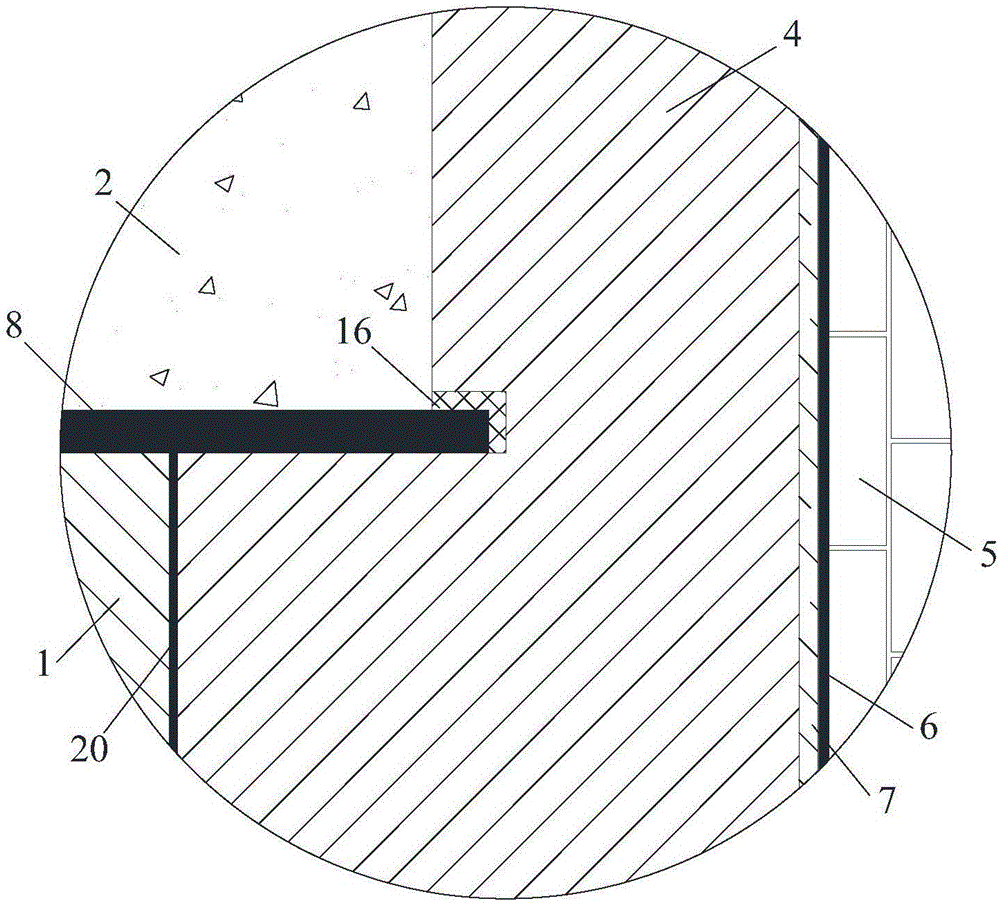

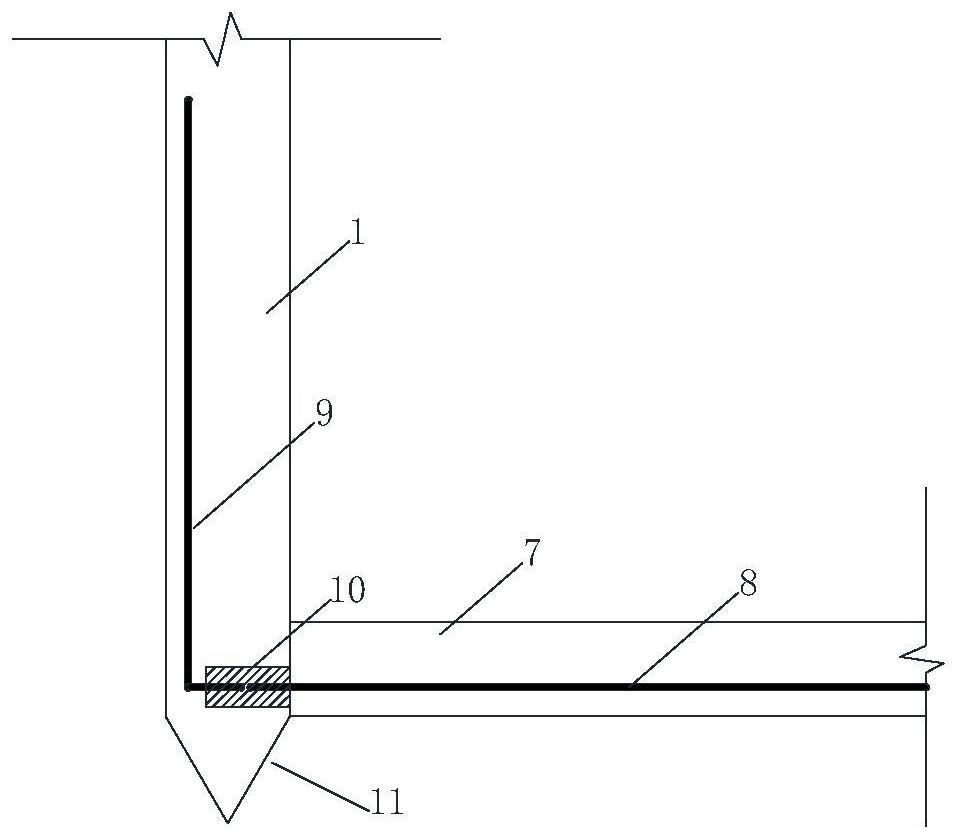

Basement exterior wall post-cast strip advanced sealing structure and basement exterior wall post-cast strip construction method

ActiveCN106120870AWaterproof and anti-seepageAvoid the impact of constructionArtificial islandsProtective foundationRebarSteel plates

The invention relates to a basement exterior wall post-cast strip advanced sealing structure. The basement exterior wall post-cast strip advanced sealing structure is characterized by comprising a sealing plate (4), a brick masonry protection layer (5), a waterproof layer (6), a mortar leveling layer (7), a connecting steel plate (8), a water stop steel plate (9), connecting cotters (10) and the like; the sealing plate (4) is assembled on the outer side of the mortar leveling layer (7), protruding bars (43) at the upper end of the sealing plate (4) are embedded in grooves (44) in the lower end of the sealing plate (4) and are connected with the grooves (44) in the lower end of the sealing plate (4) into a whole through connecting ribs (45) in the perpendicular direction; one end of the connecting steel plate (8) is clamped in clamping grooves (48) in the sealing plate (4) and are provided with reinforcing steel bar penetrating holes, and horizontal bars penetrate in the reinforcing steel bar penetrating holes and are welded to the connecting steel plate (8); and the other end of the connecting steel plate (8) is provided with post-cast strip formwork fixing and connecting screw rods (15). The basement exterior wall post-cast strip advanced sealing structure belongs to the field of basement exterior wall and post-cast strip construction in industrial and civil construction body structures and has the beneficial effects that advanced water stop and soil retaining effects are good, and the construction speed is high; and good technological and economic benefits are achieved.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

River bottom microbial grouting ecological anti-seepage system and construction method thereof

InactiveCN110106826ARealize anti-seepage treatmentGuaranteed anti-seepage effectStream regulationPlant cultivationLoamEnvironmental geology

The invention provides a river bottom microbial grouting ecological anti-seepage system and a construction method thereof. The anti-seepage system comprises compacted clay layers and ecological layerswhich are laid at the bottom of a riverway layer by layer; the ecological layers are loam layers, a plurality of grouting holes are formed in the upper surfaces of the ecological layers, and the holebottoms of the grouting holes extend to the bottoms of the compacted clay layers; and during working, the grouting holes are grouted with microbial mixed liquid. The construction method of the anti-seepage system comprises the steps of laying-covering of compacted clay, laying of the ecological layers, arrangement of the grouting holes, grouting of the microbial mixed liquid and the like. According to the anti-seepage system, by controlling the factors such as the hole spacing of the grouting holes and the grouting pressure, anti-seepage treatment in various conditions can be achieved, construction is convenient, and good ecological performance is achieved.

Owner:CHONGQING JIAOTONG UNIVERSITY

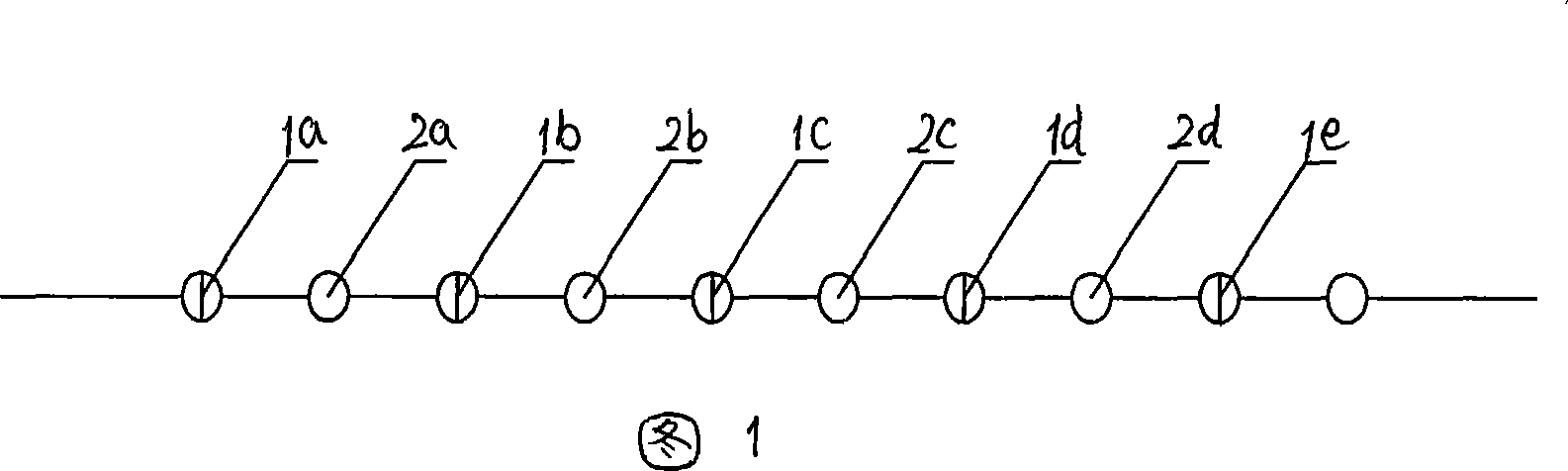

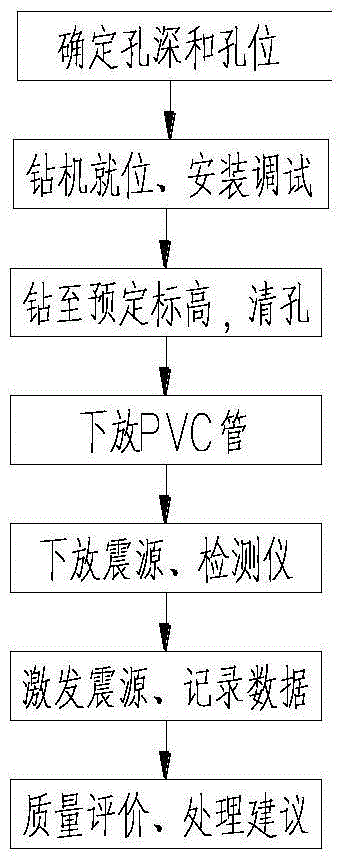

Rapid construction method for prevention seepage integrating vibrating-jetting with controlled cement grouting

InactiveCN101063309AIncrease lossIncrease investmentFoundation engineeringMarine site engineeringHigh pressureMaterials science

The invention relates to the soft base anti-seepage quick construct method of the vibrating spraying and controlling cement grouting integration, belongs to the anti-seepage body construct field, the steps are as follows, a. The driller is used to drill equally-spaced in the stratum, and the anti-seepage body is formed in a single row, the hole distance is 1-1. 25m, and the vibrating spraying hole and the controlling cement grouting hole is interval arranged. b. The vibrating spraying hole is high pressure injected with cement grouting. c. After the vibrating holes on the two sides are constructed, the base hole is to be dragged, water pumped and controlled injected with cement grouting. The invention could effectively save the single construct period, to decrease the single construct cost, to decrease the single construct investment, the construct effect is good.

Owner:中国安能集团第三工程局有限公司

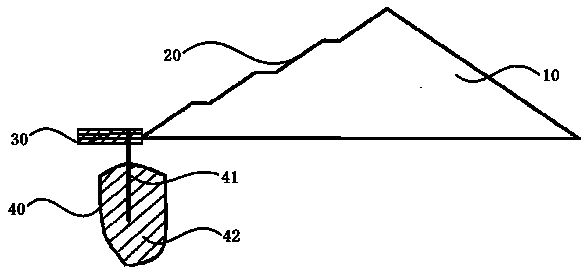

Drainage treatment structure for working landfill slope underground water

ActiveCN101148887AAvoid destructionGuaranteed anti-seepage effectFoundation engineeringPipingEngineering

The slope underground water draining structure for landfill includes one bottom underground water draining system below the antiseepage layer, and foundation pits in the landfill slopes causing so-called 'water bag' at different heights and communicated to the bottom underground water draining system. The foundation pits have horizontal holes to inside the slope with drained underground water. The slope underground water draining structure can eliminate so-called 'water bag' effectively to ensure the antiseepage effect of the impervious system in the landfill.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

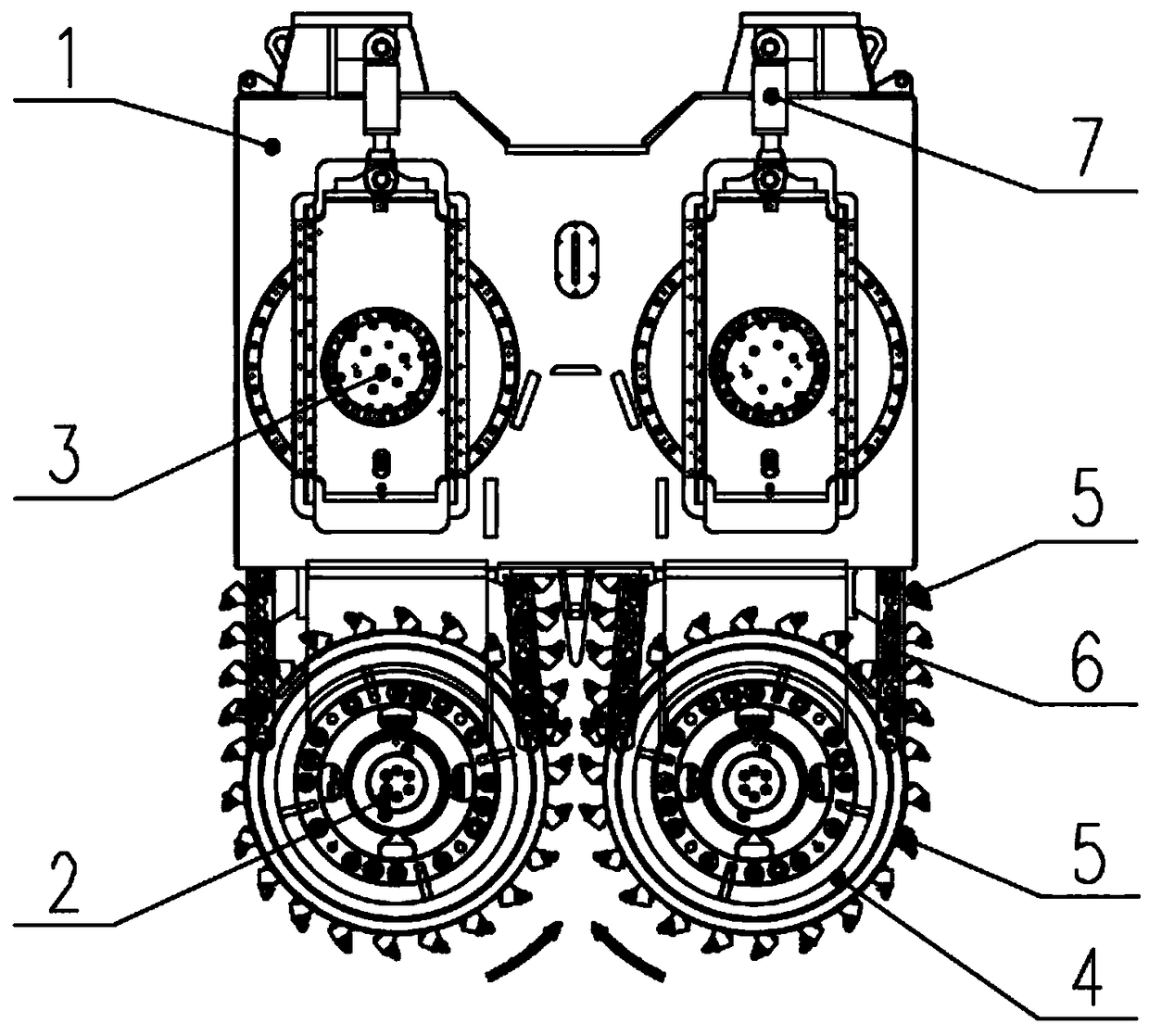

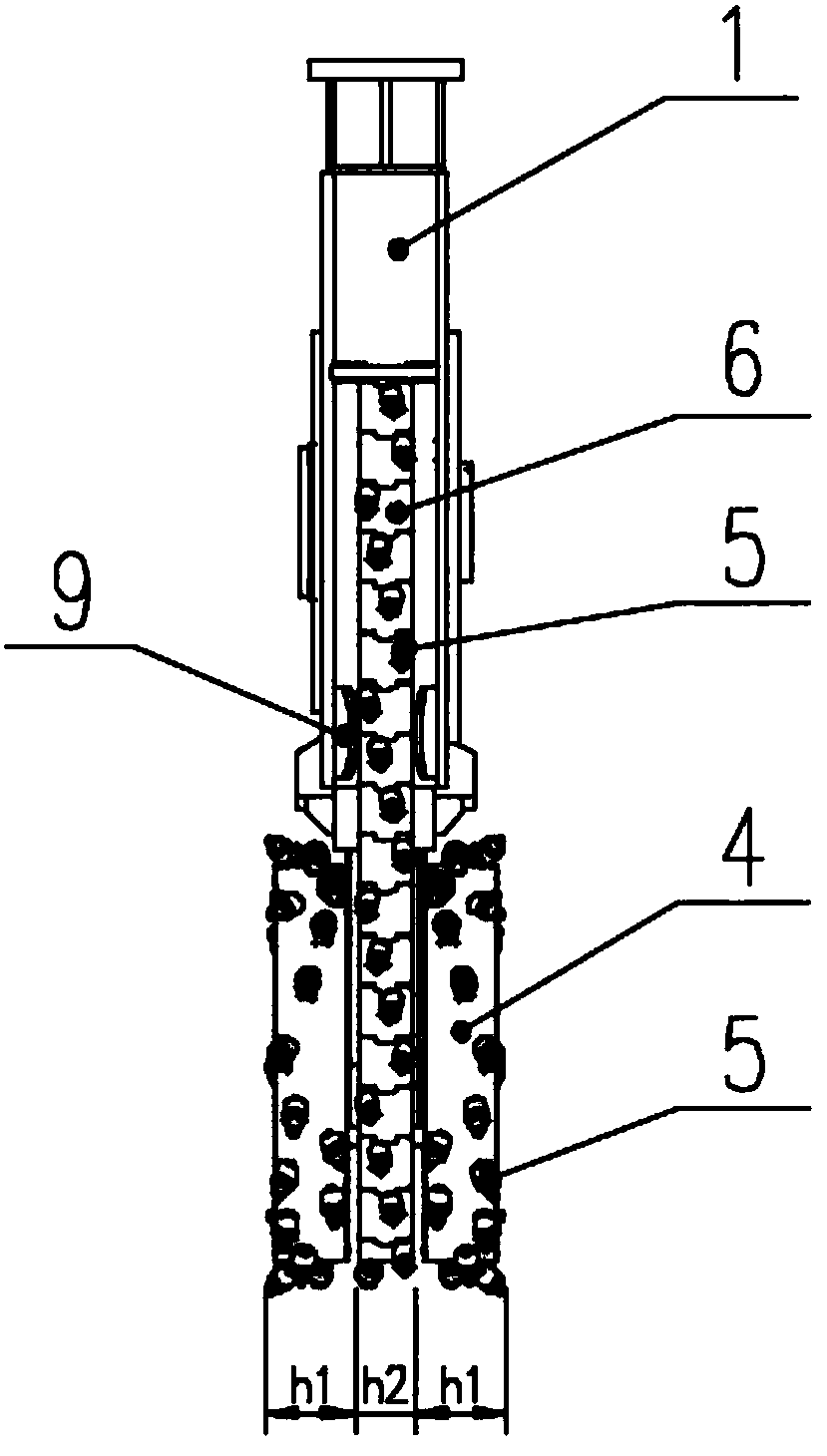

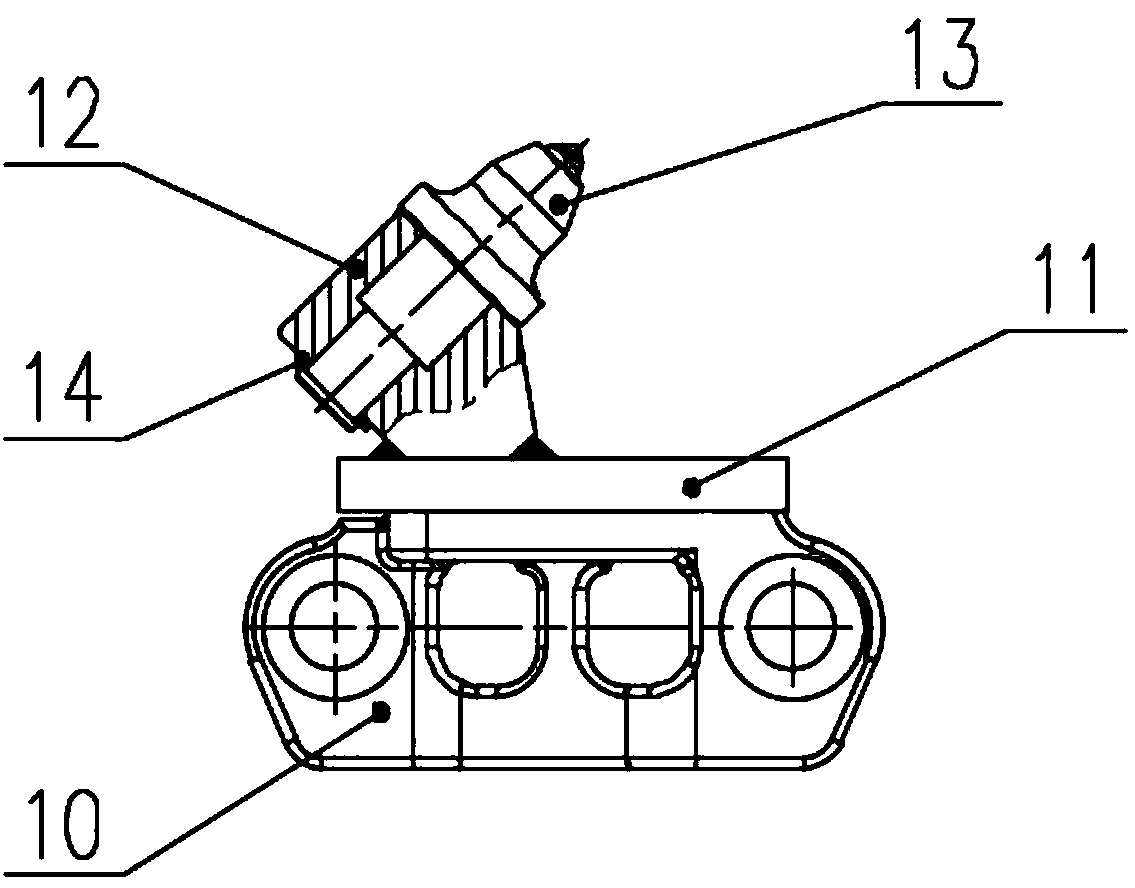

Double-wheel slot milling machine based on sprocket transmission and milling, and slot forming method

PendingCN108086381AIncreased shear strengthImprove anti-seepage performanceMechanical machines/dredgersBulkheads/pilesDrive wheelBraced frame

The invention discloses a double-wheel slot milling machine based on sprocket transmission and milling, and a slot forming method. The double-wheel slot milling machine at least comprises a support frame, a rotary milling wheel, a driving wheel, milling wheel hubs, a milling cutter gear, a sprocket, a sprocket tensioning device and a sprocket wheel. The sprocket tensioning device pulls the drivingwheel to move up and down. The sprocket is connected with the driving wheel and the rotary milling wheel in a surrounding mode to achieve driving. A plurality of milling teeth are welded on the peripheral edge of the sprocket. The milling wheel hubs are arranged on two sides of the rotary milling wheel. A plurality of milling teeth are arranged on the circumferences of the milling wheel hubs at intervals. The sprocket wheel is located on the inner side of the sprocket to eject the sprocket outwardly during mounting. The double-wheel slot milling machine has the advantages that technical problems in the prior art are solved, rock stratums below the support frame can be milled completely, smoothness of the side wall of a milling groove is guaranteed, and slurry and rock debris are discharged quickly; triangular grooves can be formed in two sides of the milling groove respectively, and shearing strength and seepage-proofing effect at casted continuous wall joints after slotting are improved greatly.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

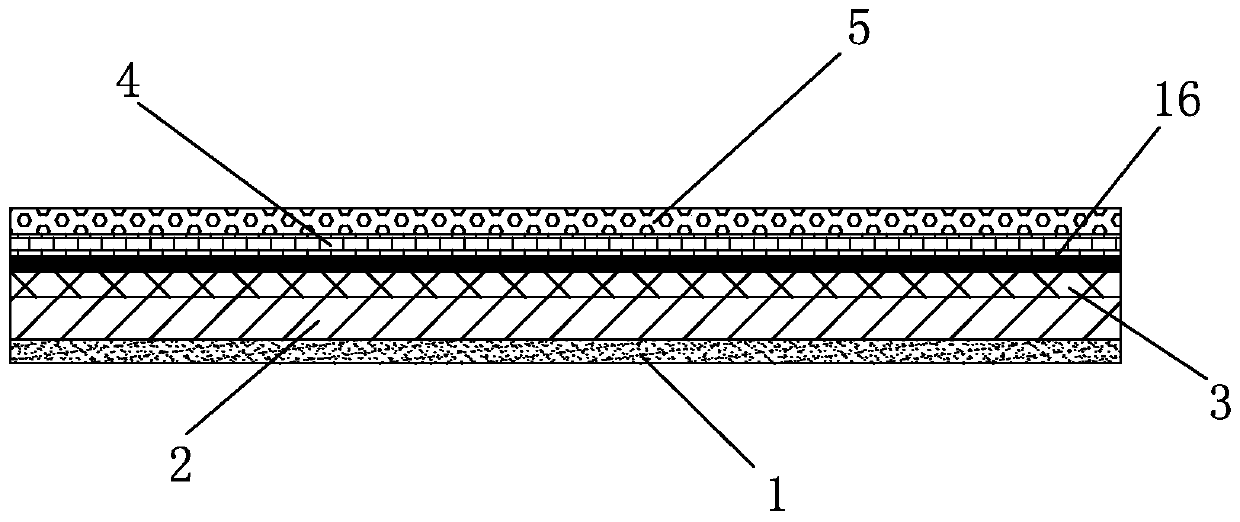

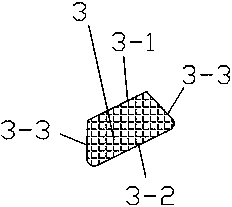

Hot-melting glue-spraying type processing technique of geosynthetic clay liner

InactiveCN104441922ANot easy to spillSmooth appearanceLaminationLamination apparatusChemical storageFiber

The invention relates to a hot-melting glue-spraying type processing technique of a geosynthetic clay liner. The processing technique comprises the steps of unwinding, spreading and dispersing bentonite by taking woven geotechnical cloth, bentonite and non-woven geotechnical cloth as raw materials, carrying out composite needling and hot melting, spraying glue, overlocking and winding. According to the geosynthetic clay liner prepared by the composite needling after hot melting, glue spraying and overlocking, inter-tangled fiber nets have flat appearance after being rolled and shaped by a heat roller, the entanglement strength of the needled fiber net after the glue spraying process is enhanced, the peeling strength is improved, and is better than that of a product by the traditional process; and finally, the product is subjected to overlocking to stitch the periphery of the product, the bentonite in the middle layer cannot run off easily in production, transportation and laying processes, the seepage-proofing effect of the product can be well ensured, and the geosynthetic clay liner is suitable for the anti-seepage projects such as artificial lake waterscapes, refuse landfills, underground garages, green roofs, water pools, oil depots, chemicals storage yards.

Owner:HONGXIANG NEW GEO MATERIAL

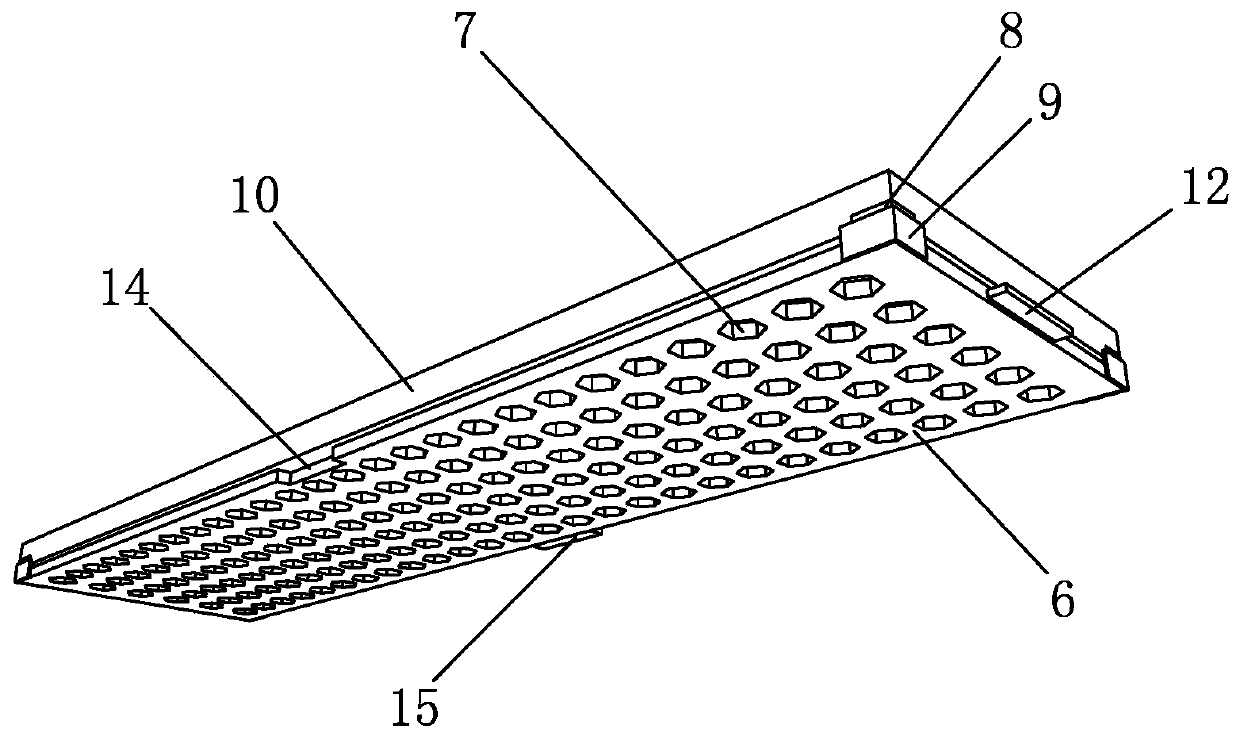

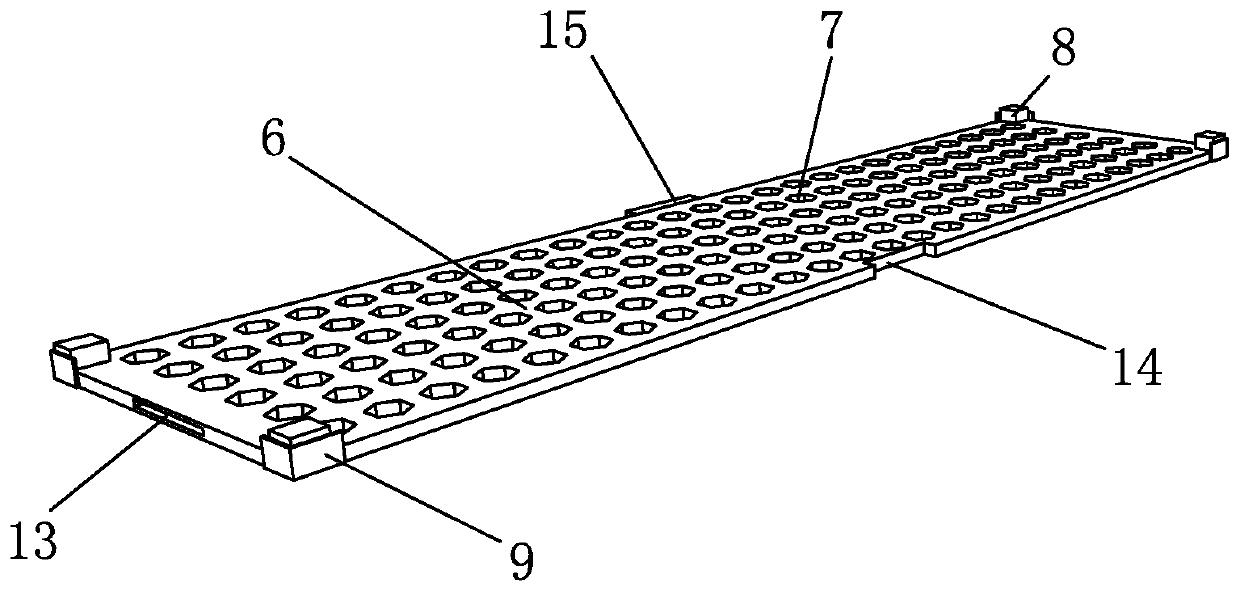

Anti-seepage structure for balcony and construction method of anti-seepage structure

InactiveCN110005049AStable structureNot easy to deform and misplaceBalconiesBuilding insulationsEngineeringProtection layer

The invention discloses an anti-seepage structure for a balcony. The anti-seepage structure comprises a waterproof coating layer, a coiled material waterproof layer, an anti-seepage film layer and a protecting layer, the protecting layer comprises a supporting plate layer and a ceramic tile layer which are arranged from bottom to top, the supporting plate layer is formed by supporting plates in anassembled mode, clamping blocks are arranged on the corners around the top face of each supporting plate correspondingly, the ceramic tile layer is formed by ceramic tiles in an assembled mode, clamping grooves are formed in the corners around the bottom face of each ceramic tile correspondingly, and the clamping blocks and the clamping grooves are matched. A construction method comprises the following steps of (1) base layer treatment, (2) treatment of the waterproof coating layer, (3) laying of the coiled material waterproof layer, (4) layering of the anti-seepage film layer and (5) layingof the protecting layer. The anti-seepage structure for the balcony is ingenious and reasonable in overall structural design, through the anti-seepage structure, the anti-seepage effect of the balconycan be improved effectively, the protecting layer is divided into the supporting plate layer and the ceramic layer, the waterproof effect of the balcony can be further improved under the situation ofensuring the surface attractive degree of the balcony, and the upper ceramic tile layer can also be conveniently laid through the supporting plate layer.

Owner:ZHEJIANG COLLEGE OF CONSTR

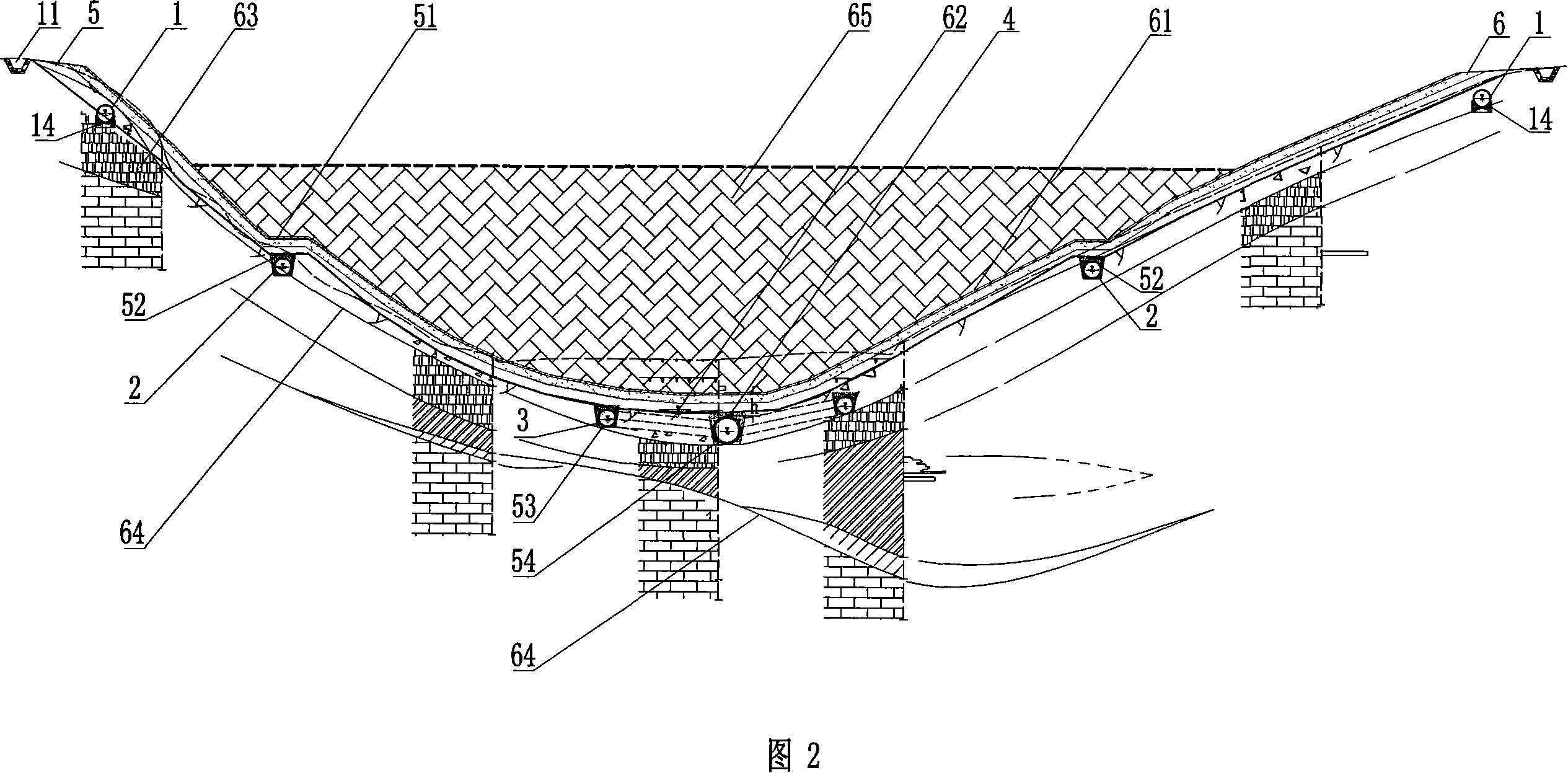

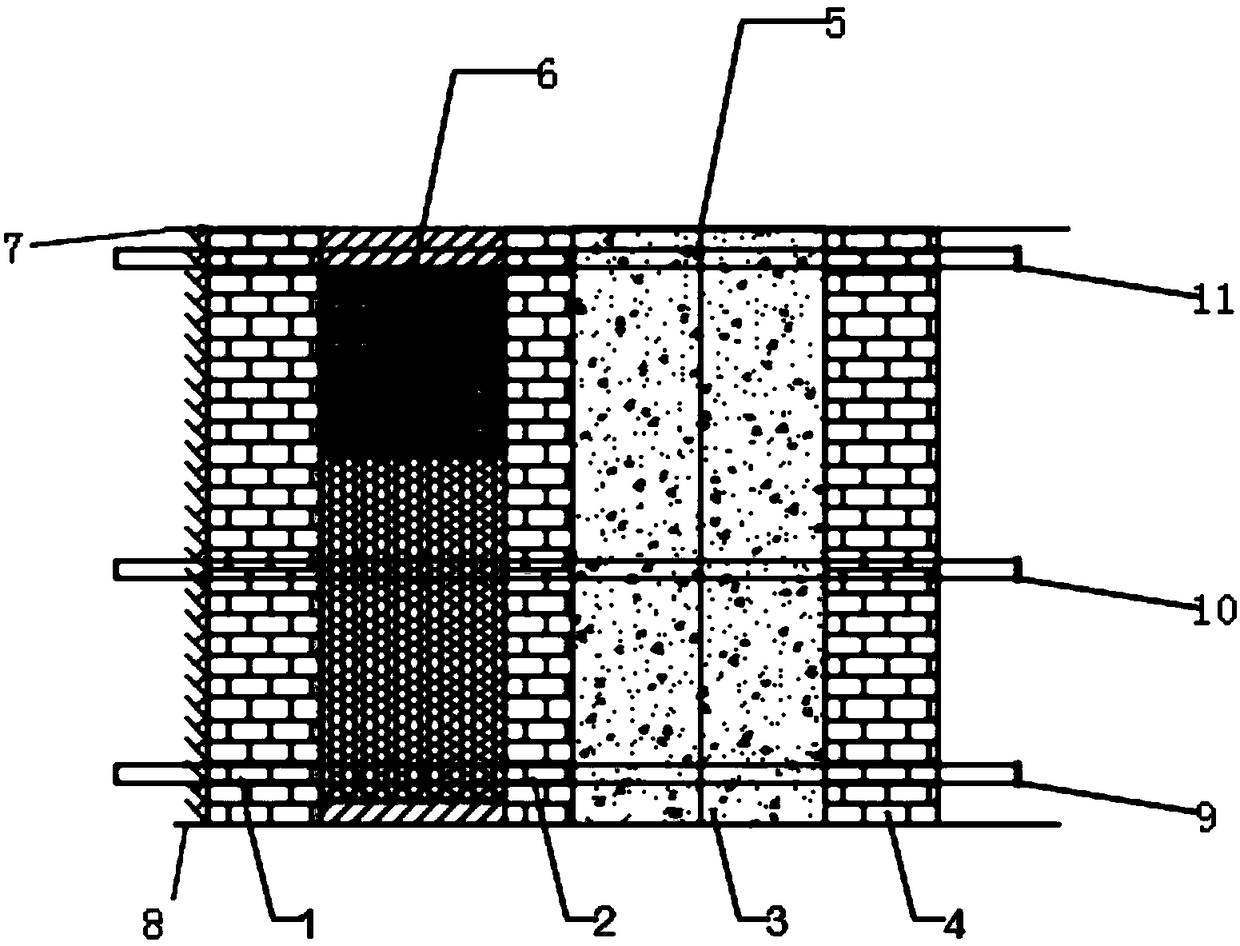

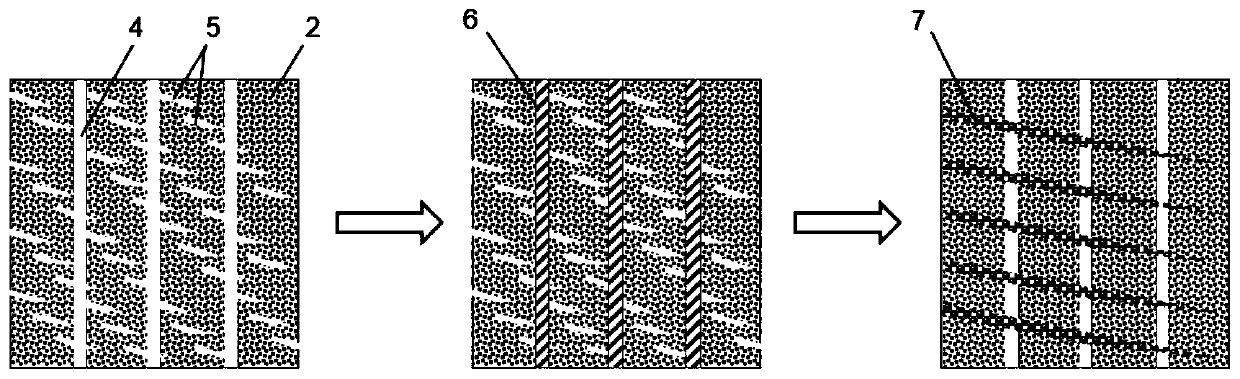

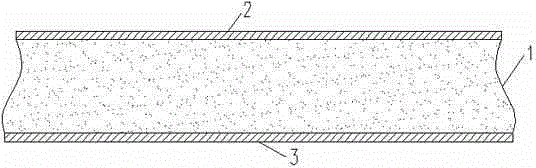

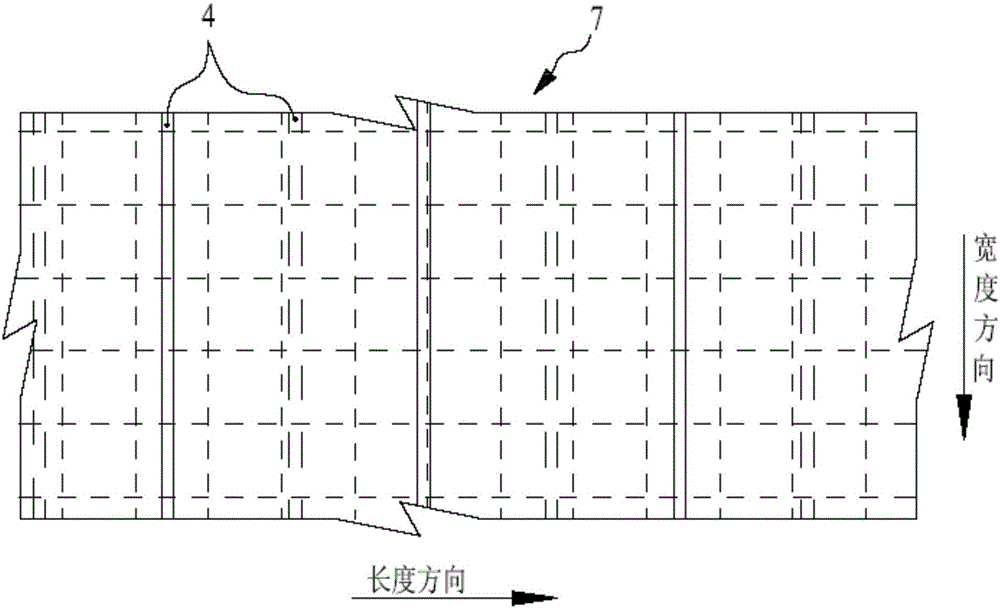

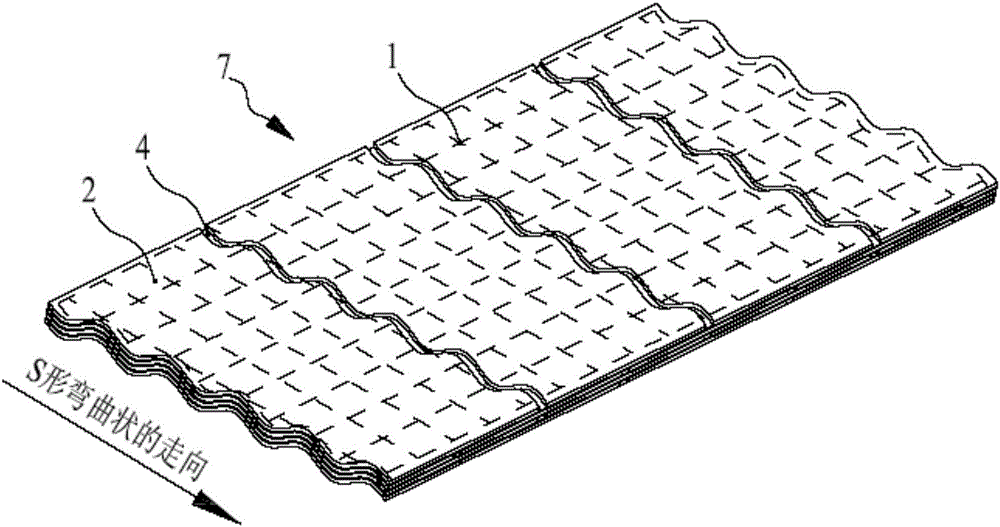

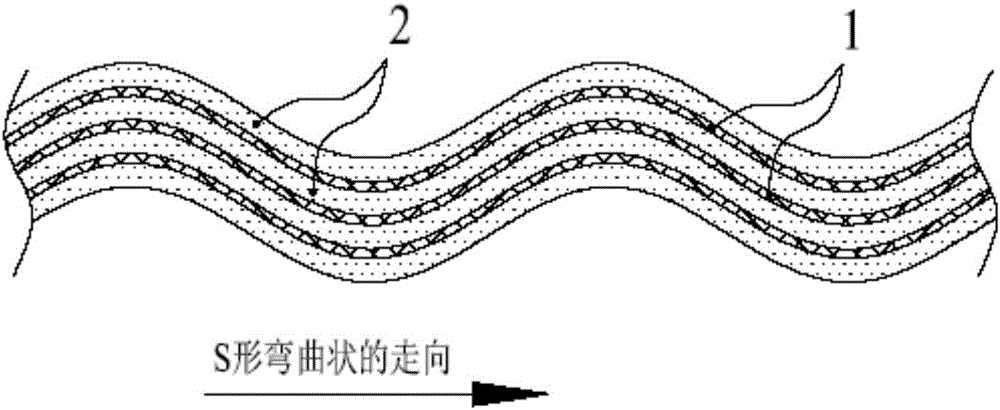

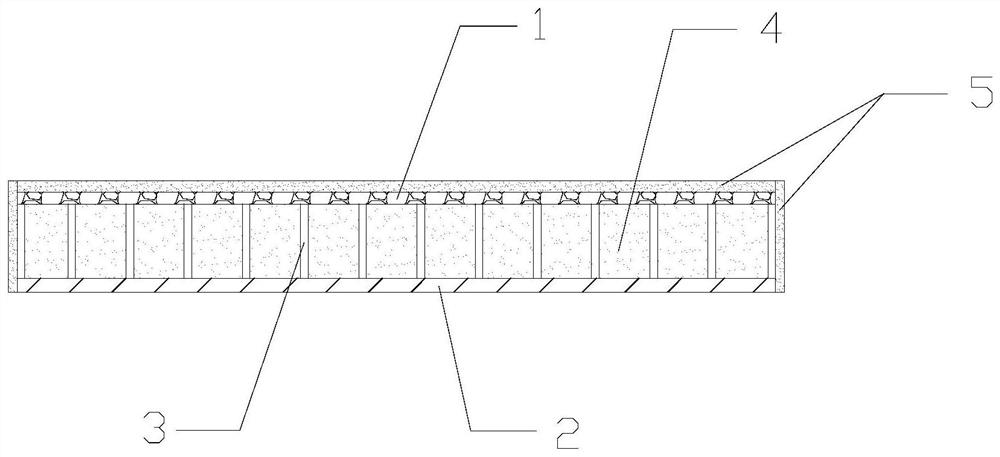

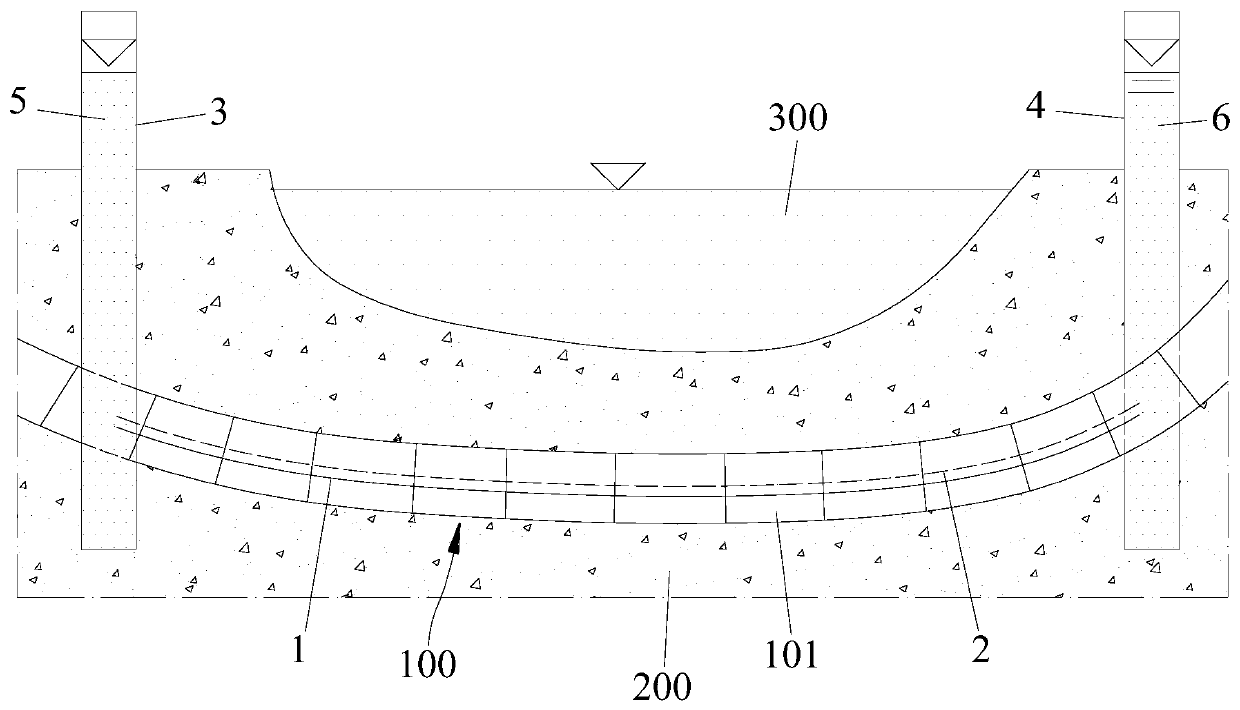

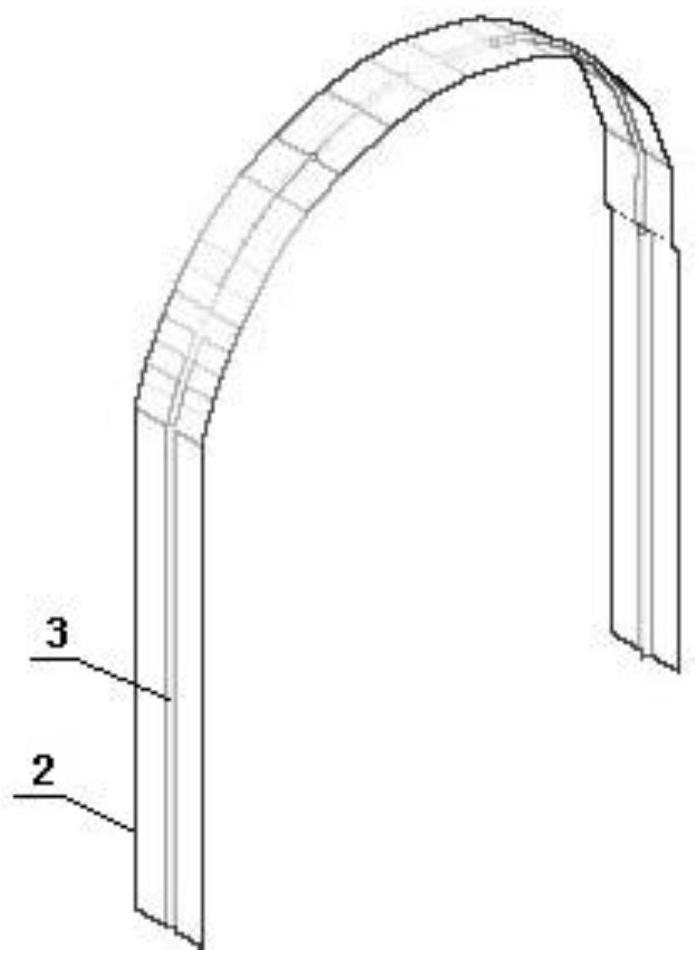

Laminar composite for dam body seepage prevention, dam body seepage prevention structure and construction method thereof

ActiveCN106245590AGuaranteed anti-seepage effectImprove the efficiency of anti-seepage constructionSynthetic resin layered productsMarine site engineeringHydropower engineeringEngineering

The invention discloses a laminar composite for dam body seepage prevention, a dam body seepage structure and a construction method thereof, belongs to the field of water conservancy and hydropower engineering, and provides a laminar composite for dam body seepage prevention and a dam body seepage prevention structure. The problem that the seepage prevention structure deforms along with the dam body and is cracked can be solved, and then the seepage prevention effect of a dam is ensured. By adopting the mode that a flexible skeleton layer and a flexible packing layer are arranged in an interlayered mode, when used for dam seepage prevention, the laminar composite can deform along with the deformation of the dam, and the problem that the seepage prevention body is cracked can be effectively avoided, so that the seepage prevention effect of the dam can be ensured. The laminar composite can also be produced in batches in a factory, so that the dam seepage prevention construction efficiency can be effectively improved, and the construction cost can be lowered. In addition, the laminar composite and the dam material have the good interconnectivity, and the layering phenomenon can be effectively avoided; the material can also be used for a seepage prevention structure for concrete surface crack repairing.

Owner:POWERCHINA CHENGDU ENG

Cement-based composite material blanket based on sandwich mesh cloth and preparation method of blanket

PendingCN112297528AEasy to assemble and disassembleGood flexibilityLamination ancillary operationsRoof covering using flexible materialsAluminatePortland cement

The invention discloses a cement-based composite material blanket based on sandwich screen cloth and a preparation method of the blanket. The cement-based composite material blanket comprises the sandwich screen cloth, the sandwich screen cloth comprises a mesh surface layer evenly provided with meshes, a plain cloth bottom layer and connecting monofilaments for connecting the mesh surface layer and the plain cloth bottom layer, the sandwich screen cloth is filled with a curable dry powder material, and the top surface and the two sides of the sandwich screen cloth are coated with waterproof polymer cement layers. The dry powder material is formed by mixing cement and sand according to the mass ratio of 1:1, the cement comprises 20% of sulphoaluminate cement and 80% of Portland cement, andthe sand is dry river sand and / or sea sand. The meshes can be firmly fixed after the polymer cement is condensed, so that the cement material is difficult to move or leak in a mesh cloth body. The polymer cement material has good flexibility and waterproof effect, has good interface property with a cement material matrix and is bonded, so that the polymer cement material is solidified into a firmwhole, and the anti-seepage effect of the material blanket is guaranteed. The preparation method is simple, reliable and convenient to install and construct.

Owner:阿米乃麦合木提

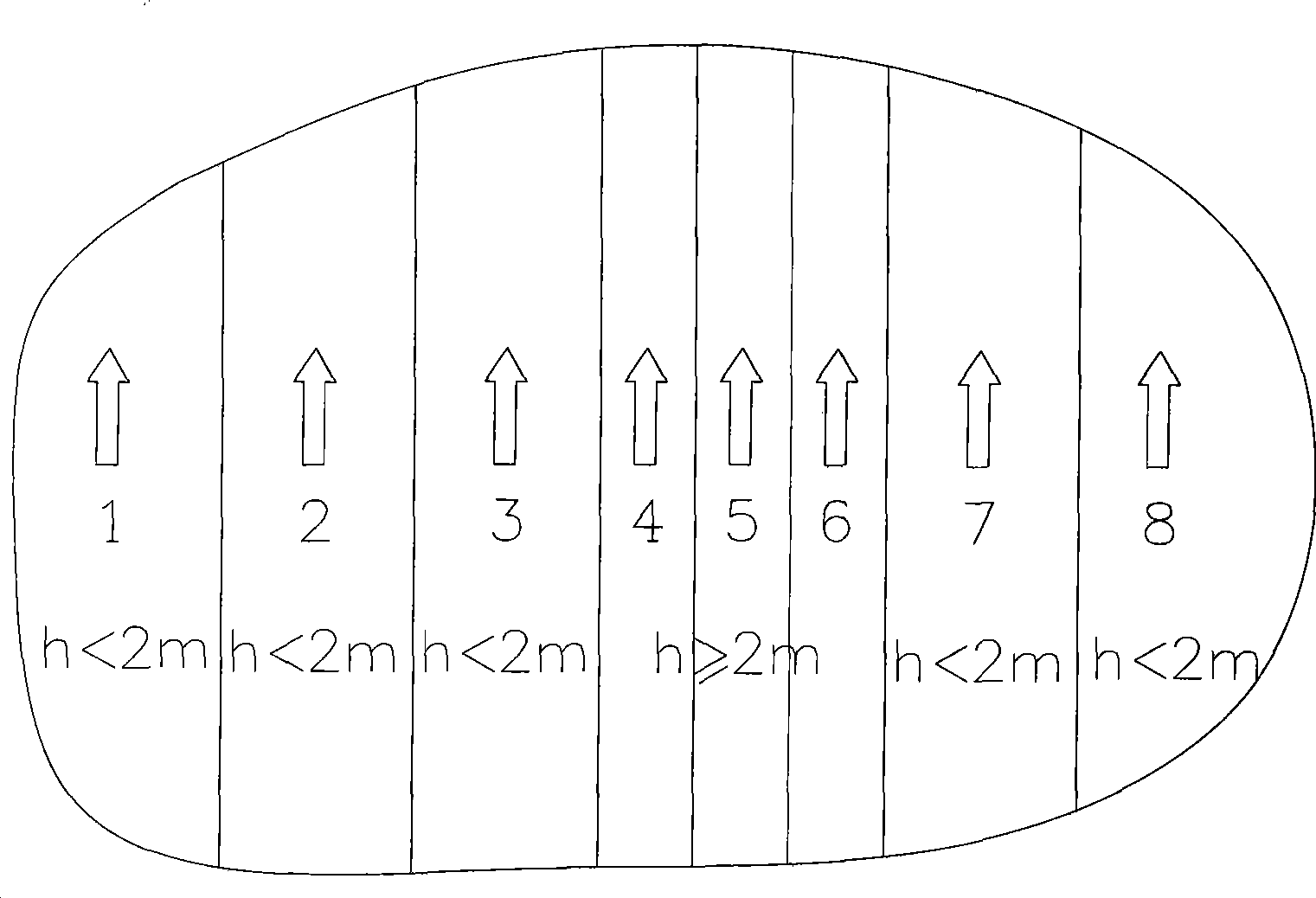

Geomembrane anti-seepage processing method for city landscape lake

InactiveCN101435189ADoes not affect appearanceTroubleshoot hard-to-clean problemsExcavationsMarine site engineeringGeomembraneExcavator

The invention relates to a geomembrane antiseepage treatment method for landscape lake, including a substrate antiseepage treatment and a vertical sidewall antiseepage treatment: in the substrate antiseepage treatment, excavate units are divided vertical to the geomembrane laying direction, for the place with the depth of silt less than two meters, the width of two geomembranes is made as one excavate unit, for the place with the depth of silt more than or equal to two meters, the width of one geomembranes is made as one excavate unit, each unit is excavated along the geomembrane laying direction, the excavated silt is put in the unit beside the construction unit, the unit is laid with the geomembrane immediately after the unit is excavated, the silt is backfilled after the laying and welding of the geomembrane is finished, and the geomembrane antiseepage treatment can be performed under the condition of not removing the silt; and in the vertical sidewall antiseepage treatment, an excavator is adopted to trim the stones on the periphery of the lake bottom, then revetment foundation trenches are excavated, new strip stone protection wall is built in the foundation trenches after the laying of geomembranes, then the flanges of the geomembrane are fixed among the top layer of strip stone, and thereby solving the defaults that the vertical side antiseepage geomembrane is not easy to retract edges and the edges are exposed outside.

Owner:CHONGQING UNIV

Anti-seepage blocking wall and construction method thereof

The invention discloses an anti-seepage blocking wall and a construction method of the anti-seepage blocking wall. The anti-seepage blocking wall and the construction method especially aim at a slag yard or a storage tailing yard with Karst landform. The anti-seepage blocking wall comprises a blocking wall body, a first anti-seepage blocking layer and a second anti-seepage blocking layer. The blocking wall body comprises an upper-layer wall body part and a lower-layer wall body part, wherein the upper-layer wall body part is located above the earth surface, and the lower-layer wall body part is located below the earth surface, so that a pollution source is isolated from the outside. The first anti-seepage blocking layer is located on one side, facing the slag yard or the tailing storage yard, of the blocking wall body to prevent solid-liquid pollutants in the slag yard or the tailing storage yard from seeping outwards. The second anti-seepage blocking layer is positioned on one side, far away from the slag yard or the tailing storage yard, of the blocking wall body, so that solid-liquid mixtures such as spring water and rainwater outside the slag yard or the tailing storage yard are prevented from entering the slag yard or the tailing storage yard. The purpose is to solve the problems that in the prior art, the anti-seepage blocking effect of an anti-seepage blocking wall is poor, and serious environmental pollution can be caused.

Owner:中节能大地环境修复有限公司 +1

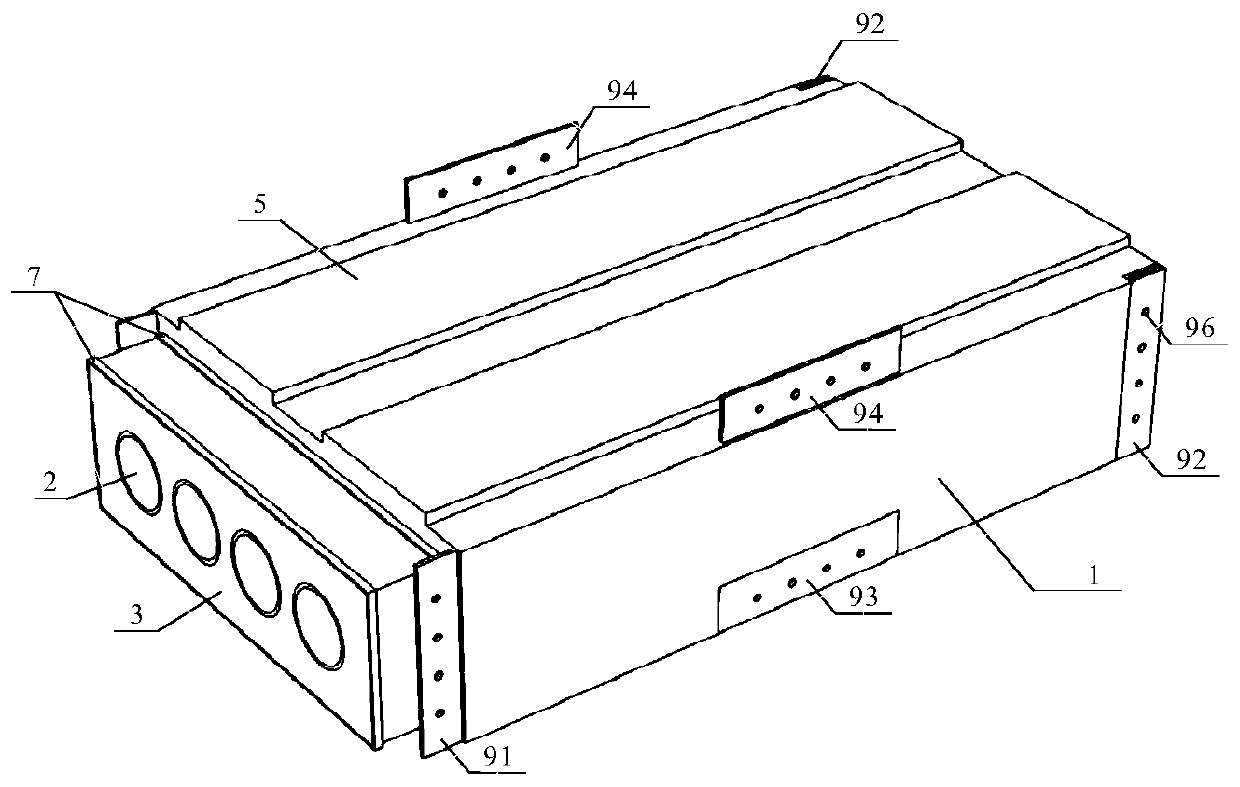

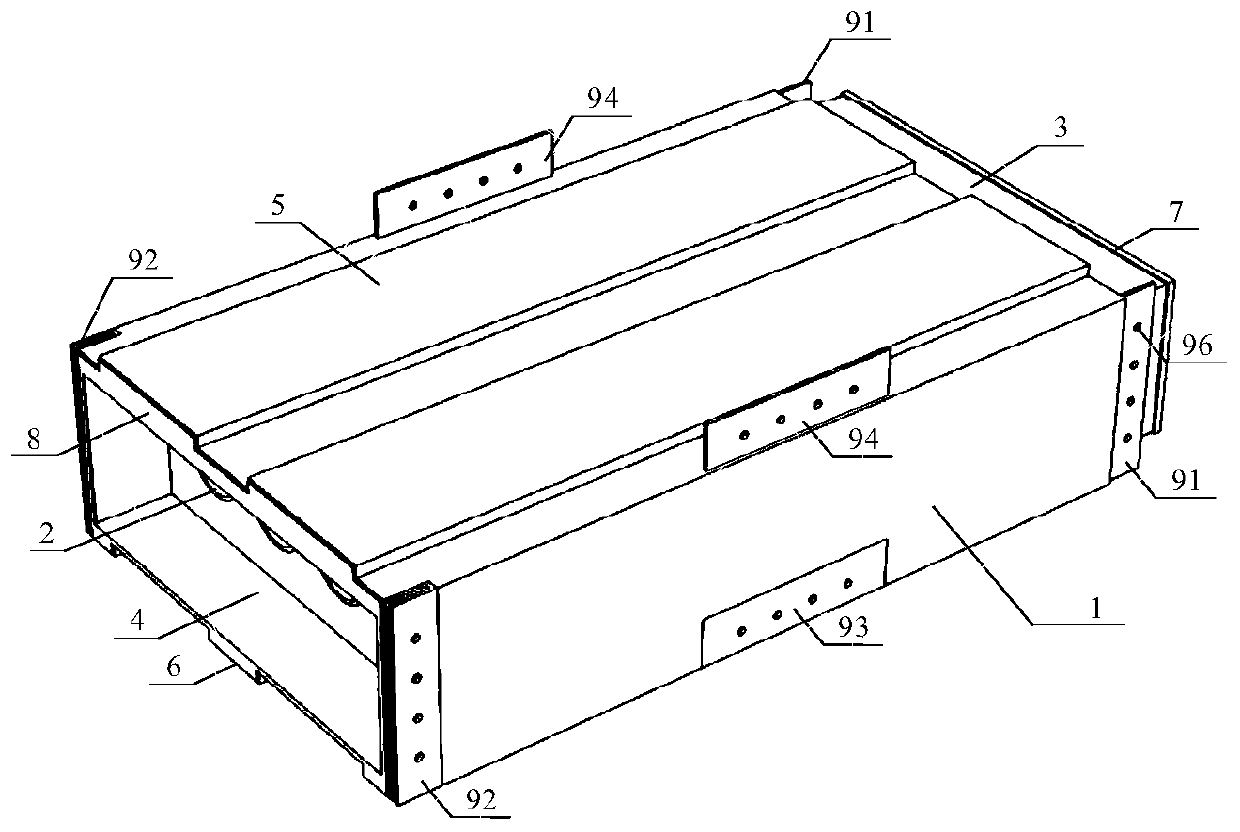

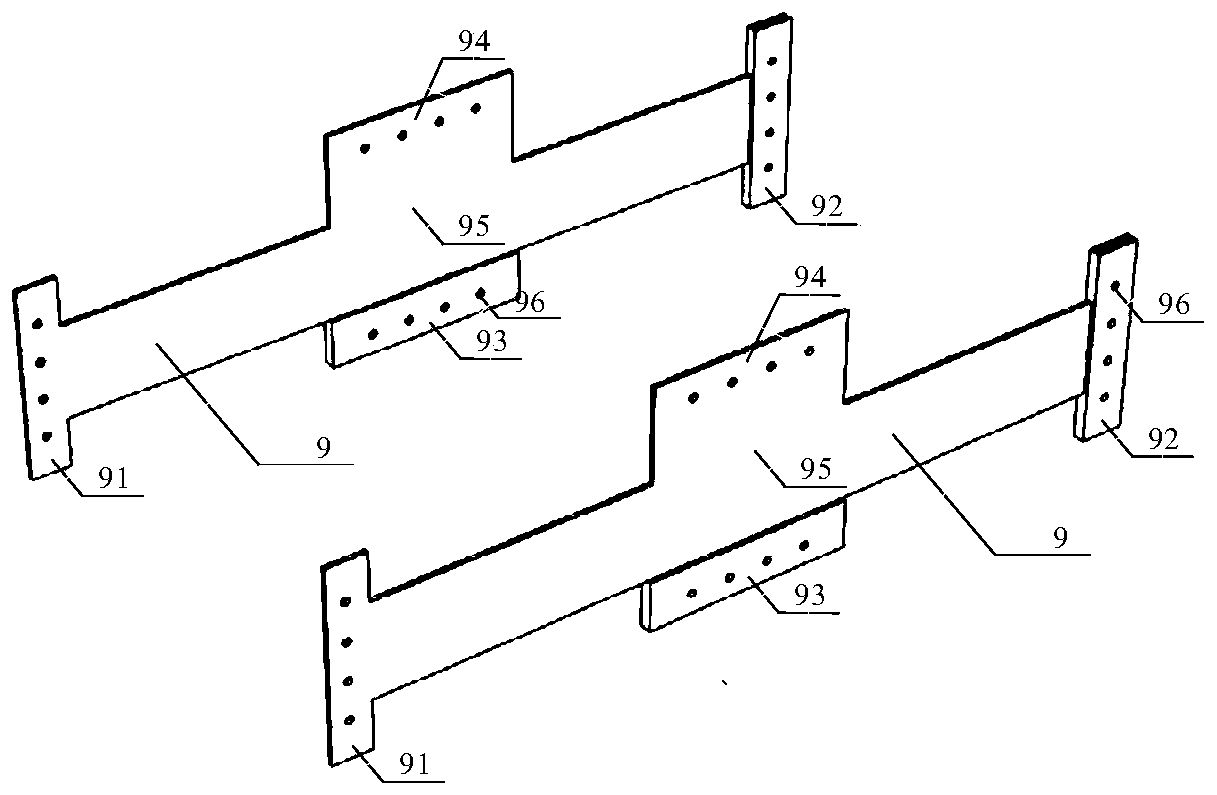

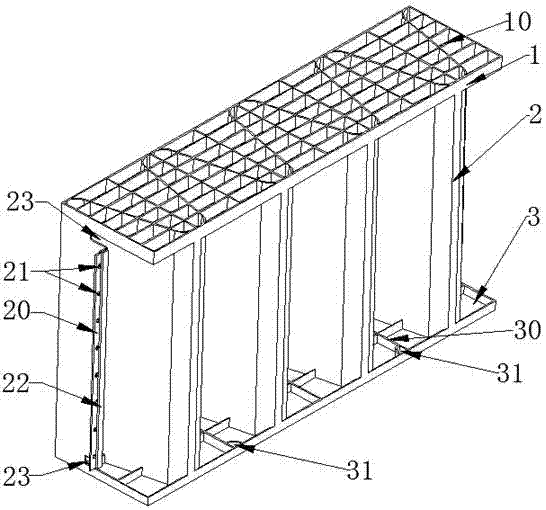

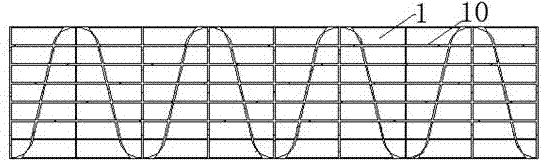

Structure reinforced cable duct module

PendingCN110233465AImprove bearing capacityIncrease stiffnessCable installations in underground tubesButt jointBearing capacity

The invention discloses a structure reinforced cable duct module. The front end and the rear end of the structure reinforced cable duct module in the longitudinal direction are respectively provided with a socket and a bell mouth for longitudinal butt joint positioning; the upper surface and the lower surface of the structure reinforced cable duct module are respectively provided with matched concave-convex groove structures for vertical butt joint positioning; the profile steel is arranged on the two longitudinal sides of the structure reinforced cable duct module respectively, matched tenonsor grooves are formed at the upper portion and the lower portion of the profile steel, matched tenons or grooves are also formed at the left portion and the right portion of the profile steel, and corresponding bolt holes are formed in the tenons and the grooves. The structure reinforced cable duct module can achieve modular production and modular assembly, thereby greatly simplifying the designprocess; in addition, the modularized cable duct can be constructed mechanically, is convenient to transport and stack, has a fast engineering progress, does not need to support a formwork and cast concrete, does not need to maintain the concrete, and greatly saves the construction time; and moreover, the profile steel framework spliced together on two sides of the cable duct structure ensures therigidity of the joint and greatly improves the bearing capacity performance and the overall rigidity of the cable duct structure.

Owner:SOUTH CHINA UNIV OF TECH

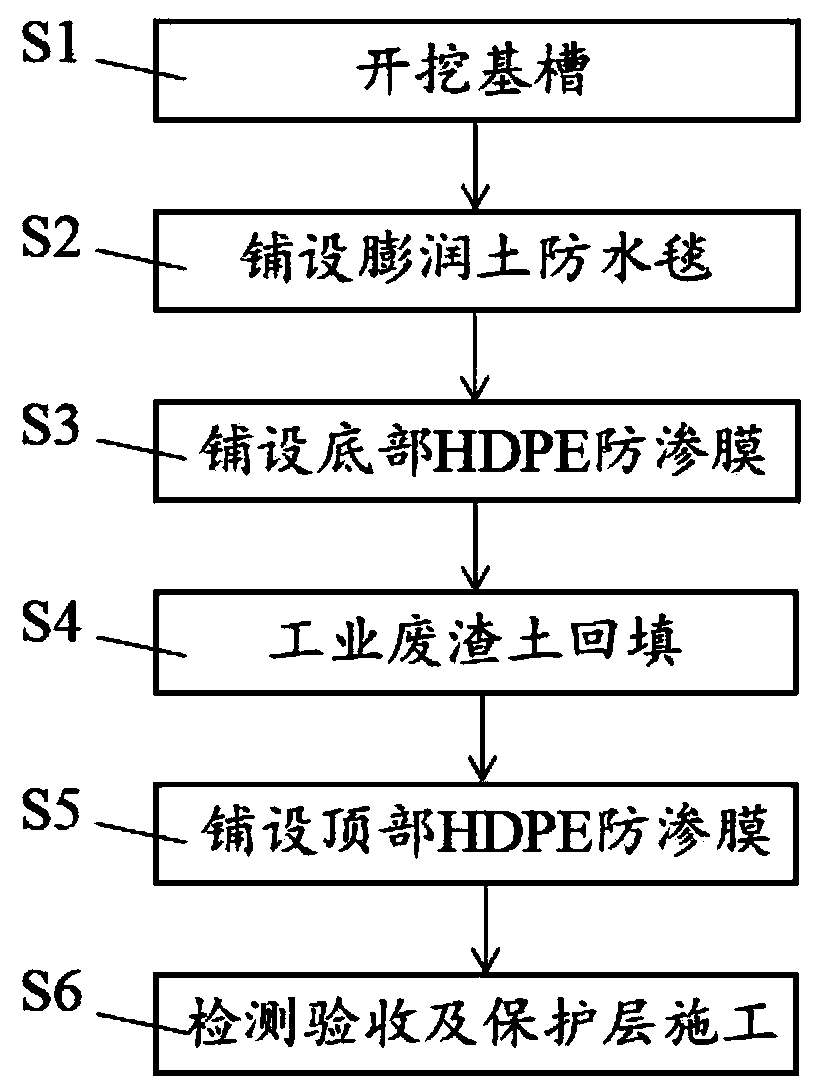

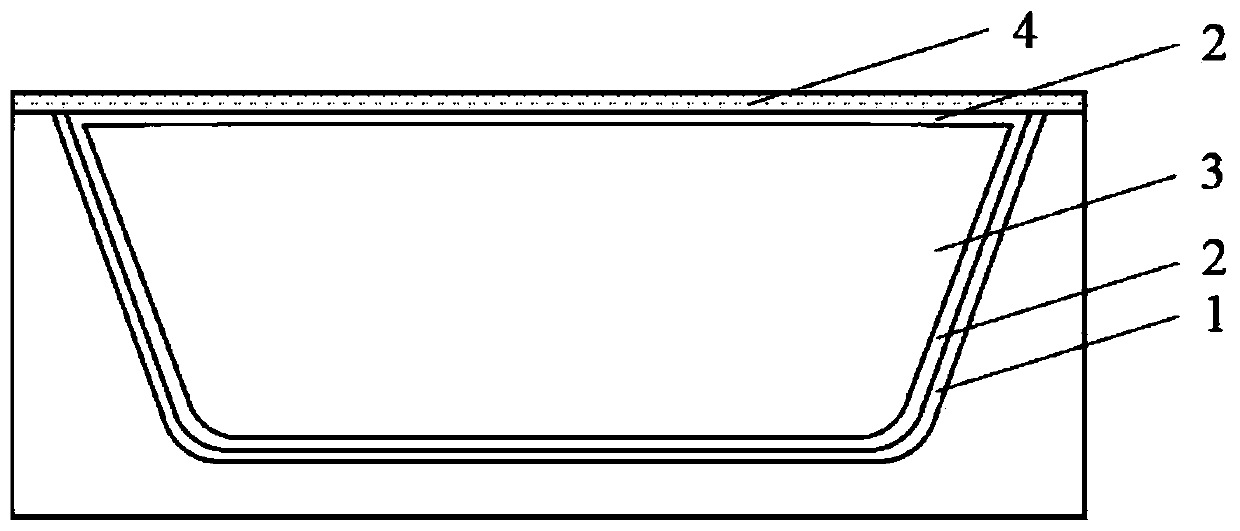

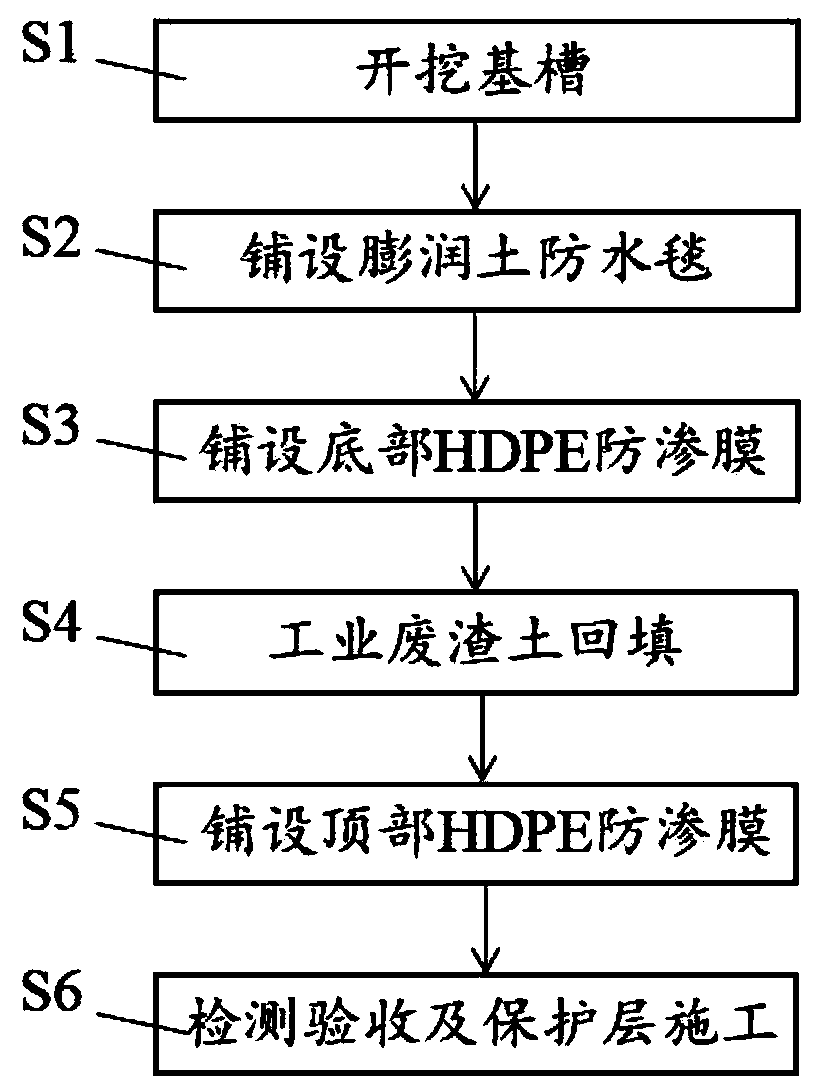

Construction method of HDPE film for road embankment seepage prevention

InactiveCN109706811AGuaranteed reliabilityGuaranteed anti-seepage effectRoadwaysSeam weldingIndustrial waste

The invention relates to a construction method of HDPE film for road embankment seepage prevention, comprising the steps that a foundation trench is excavated, and a groove is provided within the range of land for roads; bentonite waterproof blankets are paved, and the foundation trench is paved with a layer of bentonite waterproof blanket by adopting a manner of directly overlapping; bottom HDPEimpermeable film is paved, and the bentonite waterproof blankets are paved with the HDPE impermeable film, and the lap joint width between films is no less than 15cm, and the seams are welded by meansof three-seam welding manner; industrial waste is backfilled, and the foundation trench is divided into two layers for conducting industrial waste filling and compaction; top HDPE impermeable films are paved, and the industrial waste is paved with the HDPE impermeable films, and sealing welding is conducted on the bottom HDPE impermeable film and the top HDPE impermeable film; checking and accepting, and construction of an insulation protection layer are conducted: checking and accepting are conducted after construction is completed, results are recorded after the accepting is qualified, andthe construction of an insulation protection layer is immediately conducted. The invention is advantageous in that with the construction method, good waterproof effect and quite long service lifetimecan be guaranteed.

Owner:江苏控华建工有限公司

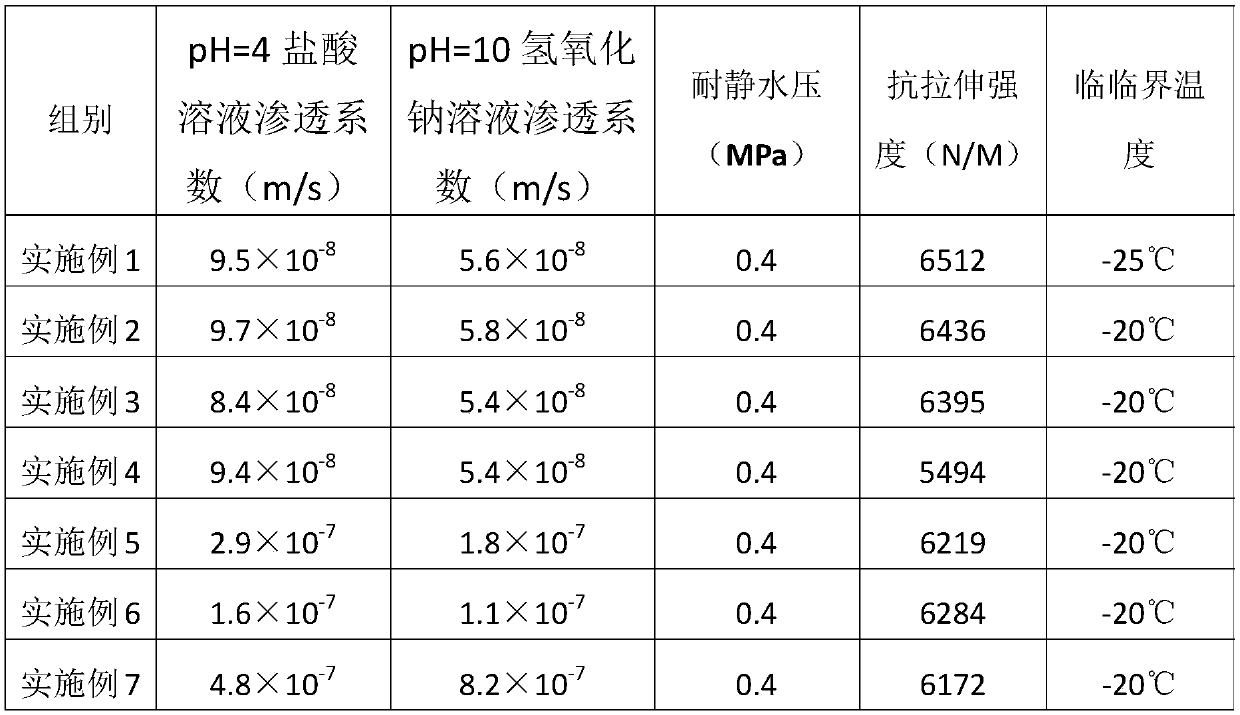

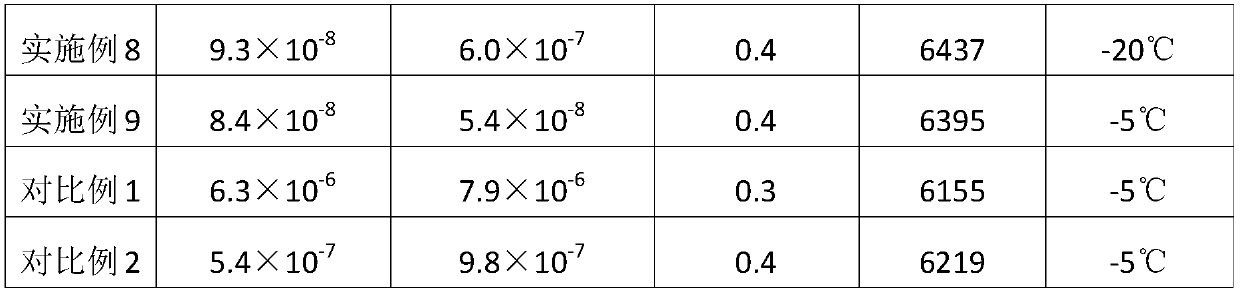

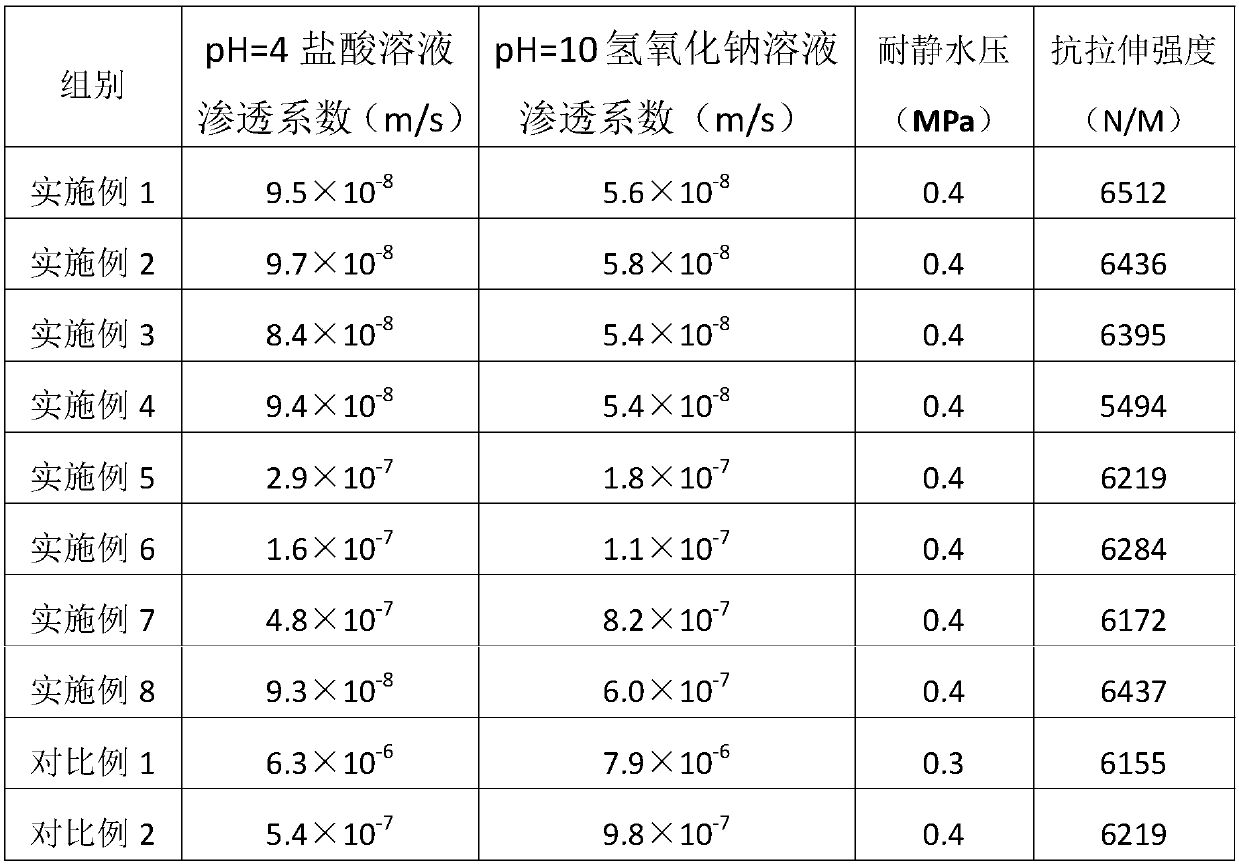

Anti-freeze high-corrosion-resistance prehydration mineral impermeable material and preparation method thereof

PendingCN109677040ANot easy to tearAvoid breakingSynthetic resin layered productsLaminationBasalt fiberBasalt

The invention provides an anti-freeze high-corrosion-resistance prehydration mineral impermeable material. The material comprises a basalt fiber layer, a mineral impermeable layer and an impermeable film which are sequentially arranged from top to bottom, wherein the basalt fiber layer is a grid shaped material which is knitted through basalt fibers; the mineral impermeable layer comprises bentonite, kaolin, a high-molecular polymer and an antifreeze agent; and the impermeable film is an HDPE film. The invention also provides a preparation method of the anti-freeze high-corrosion-resistance prehydration mineral impermeable material. The anti-freeze high-corrosion-resistance prehydration mineral impermeable material is high in corrosion resistance, tensile strength and impermeable effect, and can be constructed at the temperature below subzero 10 DEG C.

Owner:中国非金属矿工业有限公司

Geomembrane anti-seepage layer protection structure of constructed wetland

ActiveCN108178316AGuaranteed anti-seepage effectAvoid problems such as crackingSustainable biological treatmentMarine site engineeringConstructed wetlandGeomembrane

The invention relates to a geomembrane anti-seepage layer protection structure of a constructed wetland. The geomembrane anti-seepage layer protection structure comprises an anti-settling structure unit disposed at the bottom of the constructed wetland and a geomembrane protection structural unit disposed on the inner side of the bottom of the wall of the constructed wetland, the anti-settling structure unit comprises a first wire mesh layer, a spherical stone expansion layer and a second wire mesh layer laid in sequence from bottom to top, the geomembrane protection structural unit comprisesa bottom plate mechanism, a top plate mechanism, a support column mechanism and a composite geomembrane, and the composite geomembrane and the support column mechanisms are sealed by a sealing rubberring nested on the support column mechanism. Through construction of an anti-anti-settling structure e and an anti-seepage layer protection structure at the bottom of the constructed wetland, when settlement occurs at the bottom of the constructed wetland, the problems of wetland structural damage and bottom leakage caused by soil layer settlement and geomembrane tensile cracking can be effectively prevented.

Owner:BEIJING ORIENT LANDSCAPE

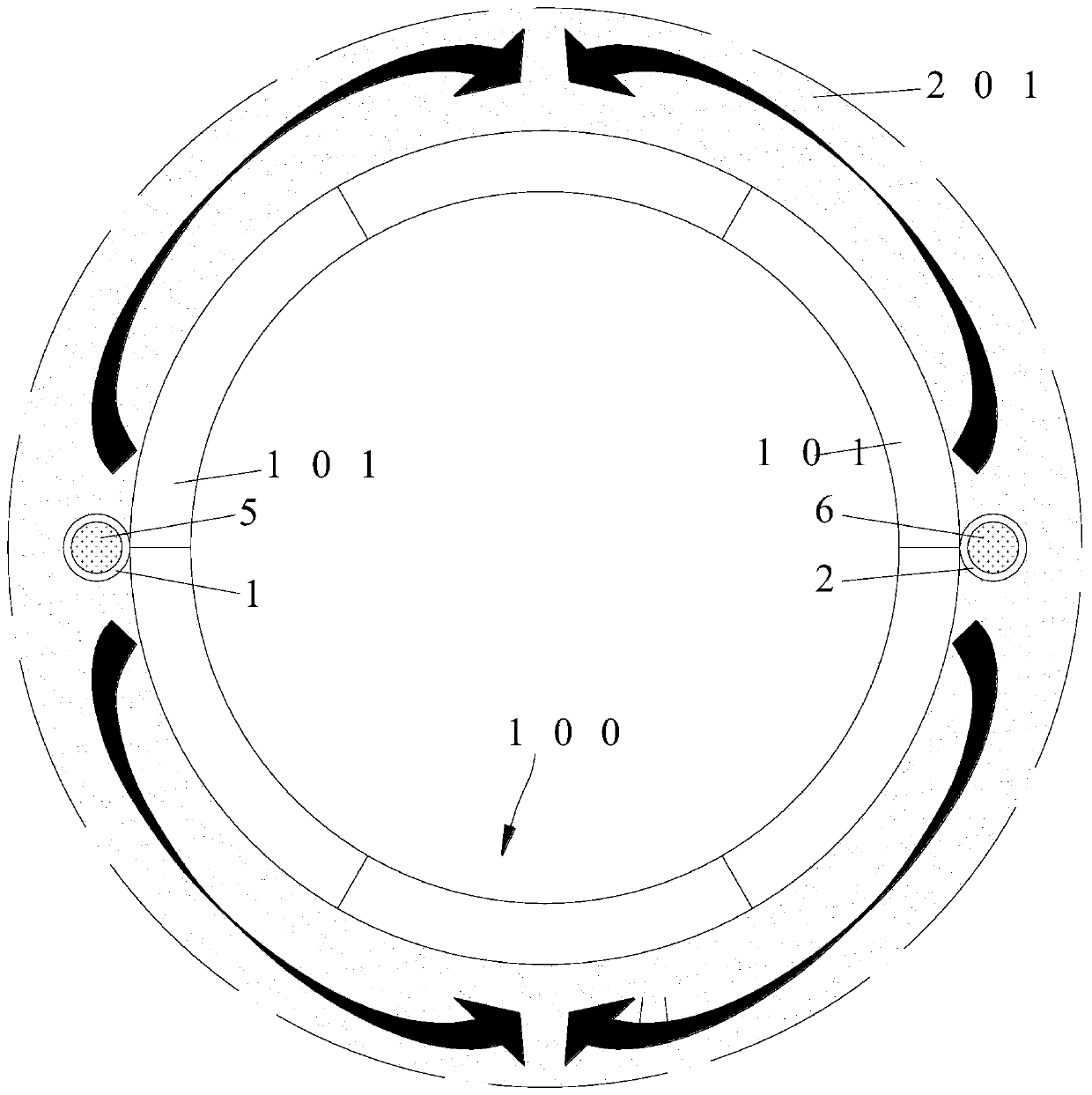

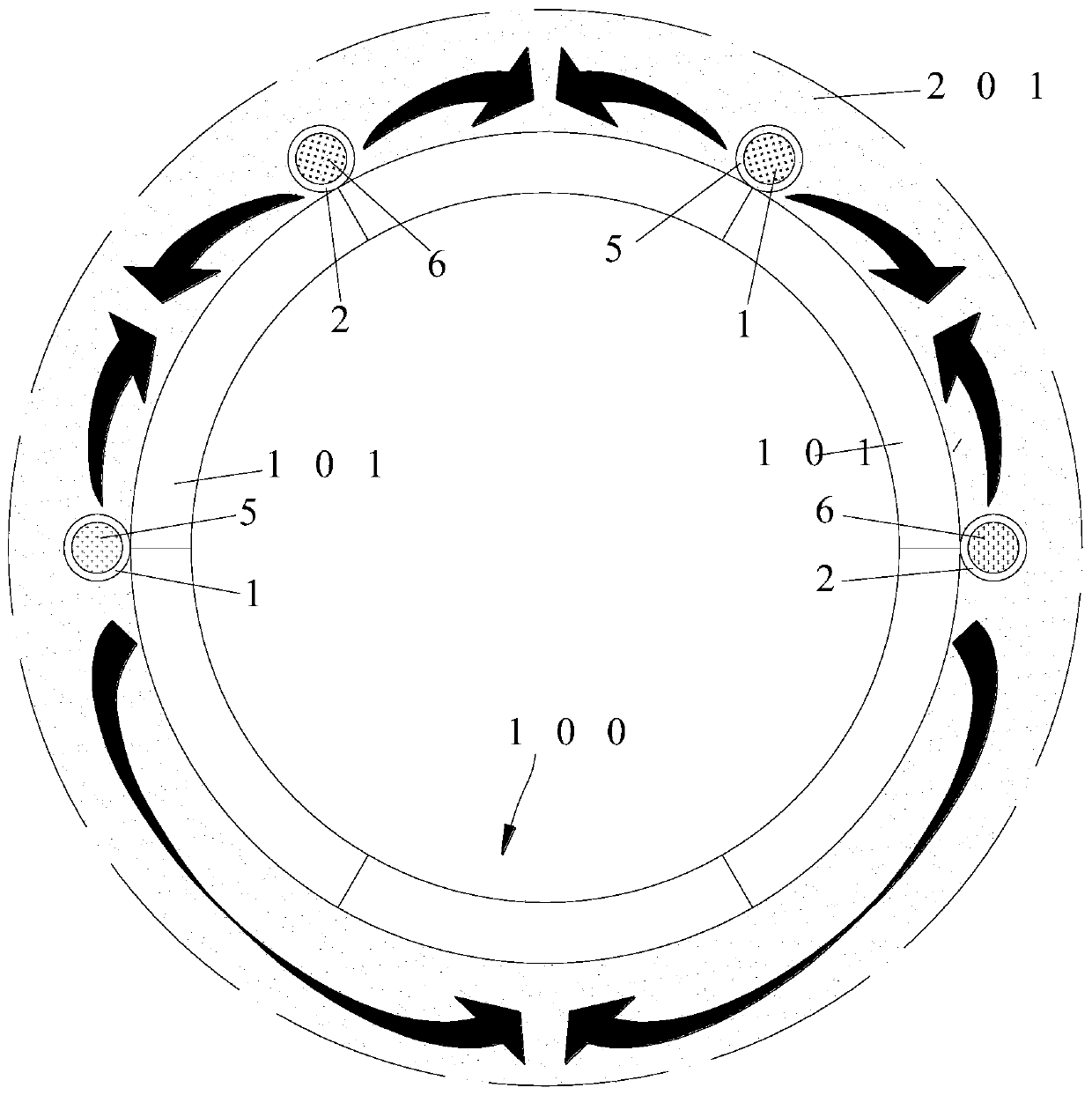

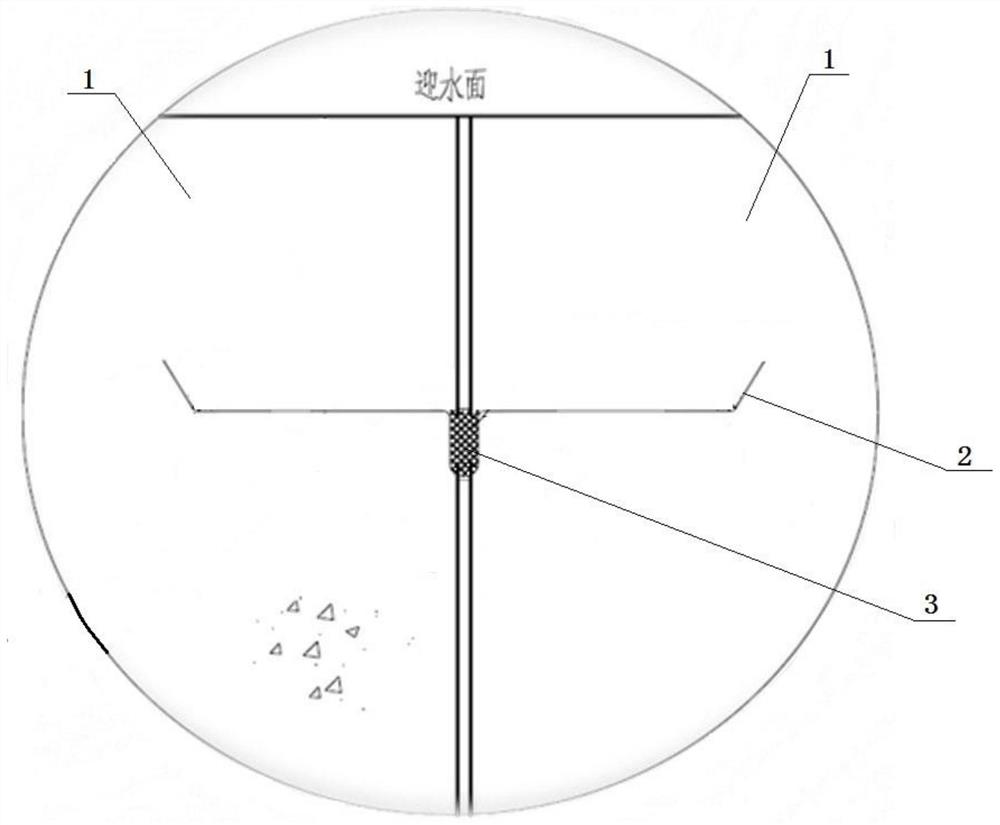

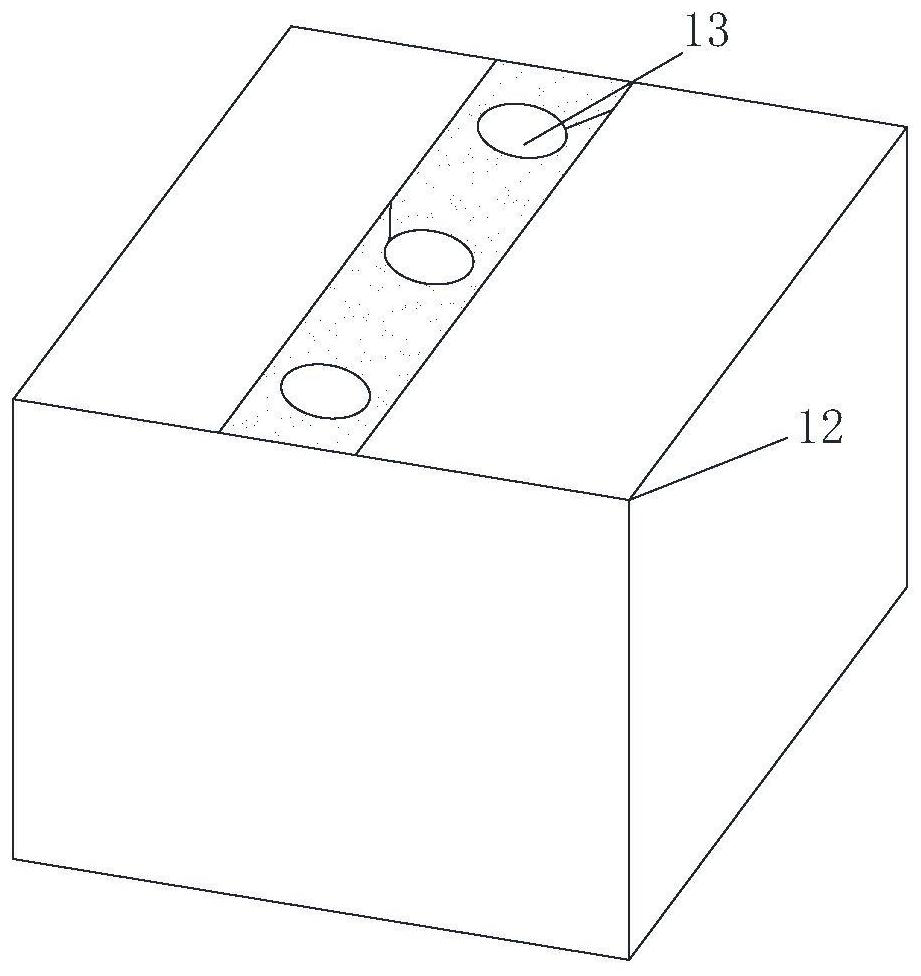

Microorganism seepage-proofing grouting device and method of lining segment of river-crossing tunnel

ActiveCN111411646AGuaranteed anti-seepage effectImprove the safety of useArtificial islandsProtective foundationMicroorganismStructural engineering

The invention discloses a microorganism seepage-proofing grouting device and method of a lining segment of a river-crossing tunnel. A first conveying pipe and a second conveying pipe are arranged in aperipheral water-rich soil layer of the river-crossing tunnel, wherein one end of the first conveying pipe communicates with a first container, one end of the second conveying pipe communicates witha second container, and the other end of the first conveying pipe and the other end of the second conveying pipe are sealed. A first grouting hole and a second grouting hole are formed in the positions, at least corresponding to the to-be-blocked lining segment area, of the first conveying pipe and the second conveying pipe. In the grouting process, though the water head differences between the interiors of the first container and the second container and river water corresponding to the positions of the river-crossing tunnel, a first mixed solution and a second mixed solution are promoted toflow into the peripheral water-rich soil layer of the river-crossing tunnel through the first grouting hole and the second grouting hole and are slowly annularly diffused and mixed along the peripheryof the river-crossing tunnel, finally microorganism slurry in the first mixed solution and a nutrient solution in the second mixed solution react so as to form a layer of annular biogel reinforcementband wrapping the lining segment from the periphery, and therefore gaps between the lining segments are blocked.

Owner:SUN YAT SEN UNIV

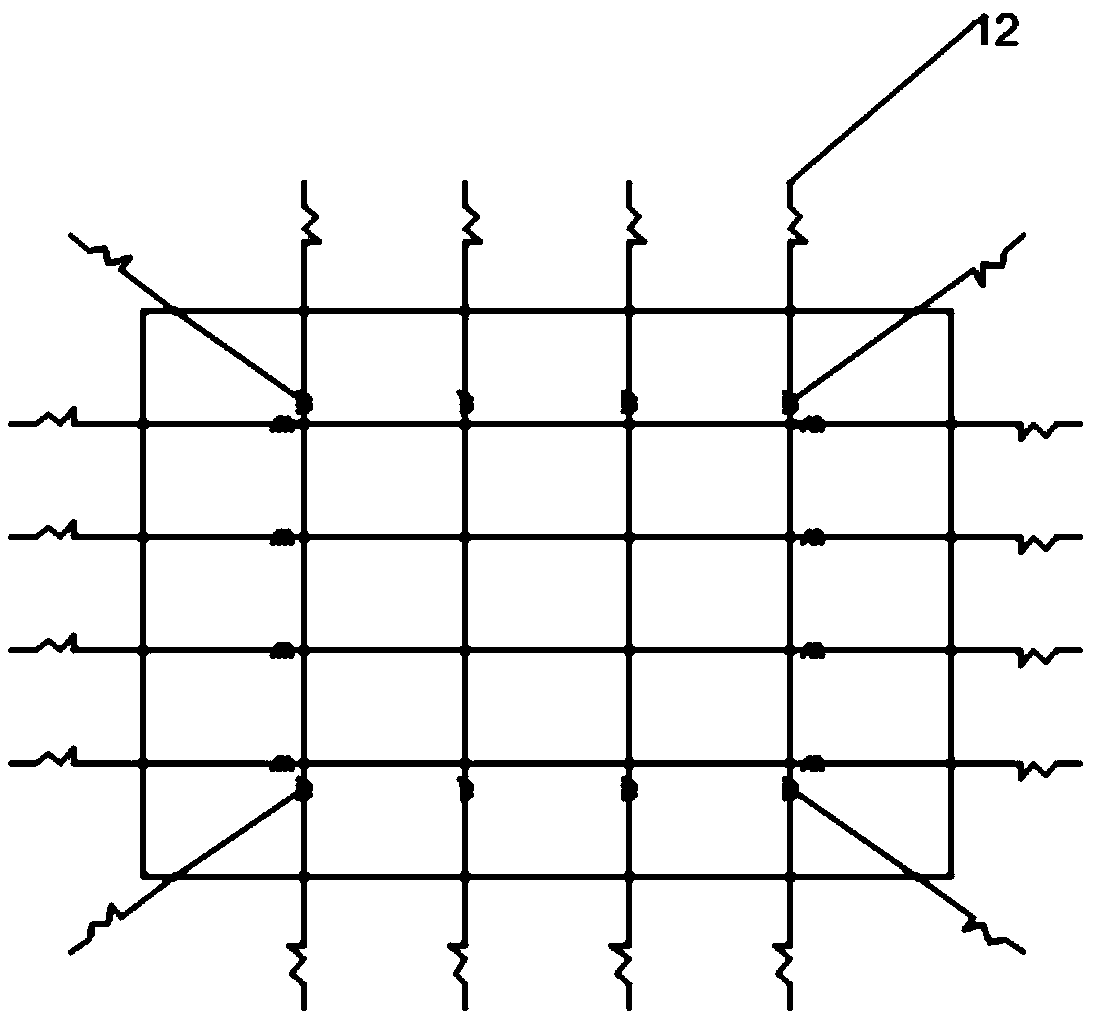

Novel semi-burying ridge structure

PendingCN107027366APlace stableGuaranteed stabilityDamsDykesAgricultural engineeringStructural engineering

The invention discloses a novel semi-burying ridge structure. The semi-burying ridge structure comprises a walking passageway end face, a water-blocking supporting vertical face, a pluck-prevention embedding end face and a cross connecting piece, the walking passageway end face is connected with the upper end of the water-blocking supporting vertical face, the pluck-prevention embedding end face is connected with the lower end of the water-blocking supporting vertical face, and the cross connecting piece can be connected with the end of the water-blocking supporting vertical face. A dense plane grid structure is adopted in the walking passageway end face, a sparse plane grid structure is adopted in the pluck-prevention embedding end face, connecting plates are arranged at the two ends of the water-blocking supporting vertical face, connecting holes are uniformly formed in the connecting plates, the two sides of each connecting plate are provided sealing strips separately, the upper end and the lower end of each connecting plate are provided with deformation compensation gaps, and the corner of the sparse plane grid structure of the pluck-prevention embedding end face is provided with a drill rod land preformed hole. The novel semi-burying ridge structure is utilized in the field, the arable area of the land is increased, the grain yield is increased, the field passing-through environment is improved, the maintenance cost of ridges is also lowered, besides, adaptive goods are provided for rice cultivation.

Owner:长春市锐达筑路材料有限公司

High-corrosion-resistance pre-hydrated mineral impermeable material and preparation method thereof

PendingCN109572093ANot easy to tearAvoid breakingLamination ancillary operationsSynthetic resin layered productsBasalt fiberBasalt

The invention provides a high-corrosion-resistance pre-hydrated mineral impermeable material. The high-corrosion-resistance pre-hydrated mineral impermeable material comprises a basalt fiber layer, amineral impermeable layer and an impermeable membrane which are sequentially arranged from top to bottom, the basalt fiber layer is a latticed material woven by basalt fibers; the mineral impermeablelayer comprises bentonite, kaolin and high-molecular polymers; the impermeable membrane is an HDPE (high-density polyethylene) membrane. The invention further provides a preparation method of the high-corrosion-resistance pre-hydrated mineral impermeable material. The high-corrosion-resistance pre-hydrated mineral impermeable material has the advantages of high corrosion resistance, high tensile strength and an excellent impermeable effect.

Owner:中国非金属矿工业有限公司

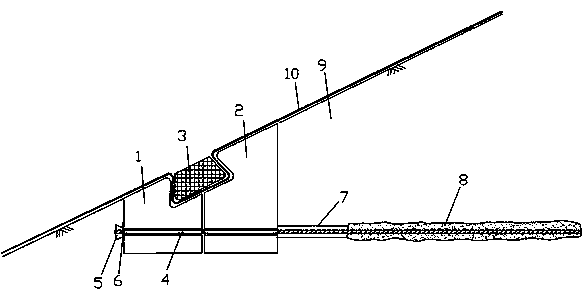

Anti-seepage structure of corridors at structural joint of rolling dam and construction method of anti-seepage structure

PendingCN112746598AEasy constructionShorten the construction periodBarrages/weirsWater stopArchitectural engineering

The invention discloses an anti-seepage structure of corridors at a structural joint of a rolling dam and a construction method of the anti-seepage structure, and belongs to the technical field of water conservancy and hydropower engineering. The structure comprises a water stop part and two corridors A, wherein the two corridors A are connected through the water stop part, the two corridors A are formed by one-time concrete pouring, and the water stop part is integrally manufactured and formed and is prefabricated with the two corridors A. The corridors A are formed by one-time concrete pouring, and the water stop part is integrally manufactured and formed, so that the construction is simplified, the construction period is shortened, and the construction efficiency is improved. The water stop part is reliably connected with the corridors A, the ductility of the water stop part is good, the anti-seepage effect of the anti-seepage structure of the corridors is effectively guaranteed, and the water seepage treatment cost of the anti-seepage structure of the corridors in the later period is reduced. The concrete is prevented from entering a water stop groove through a chloroprene rubber rod, so that the water stop part is ensured to keep good flexibility, and water leakage at the butt joint of the two corridors A is avoided.

Owner:SINOHYDRO BUREAU 9

Geomembrane fixing device laid on slope

ActiveCN111188367AIntegrity guaranteedReduce slope lengthCoastlines protectionProtective foundationSoil scienceGeomembrane

The invention provides a geomembrane fixing device laid on a slope and belongs to the technical field of earthwork synthetic materials. The geomembrane fixing device comprises a clamp A, a clamp B, aclamp block and a geomembrane. A notch of the clamp A and a notch of the clamp B define a groove-shaped space. The clamp block matched with the groove-shaped space is arranged in the groove-shaped space. An oblique line formed by the upper end face formed after splicing of the clamp A, the clamp B and the clamp block has the consistent angle with the slope. The geomembrane is arranged between theclamp A, the clamp B and the clamp block. On the premise of not changing the continuity of the slope, the geomembrane is fixed to a slope foundation in a segmented mode, and the load-bearing length ofthe geomembrane is reduced equivalently, the geomembrane can be protected against breakage, and the anti-seepage effect can be ensured. As rivets are not adopted, the geomembrane is fixed without damage, and the anti-seepage function of the geomembrane is not destroyed.

Owner:SHENYANG POLYTECHNIC UNIV

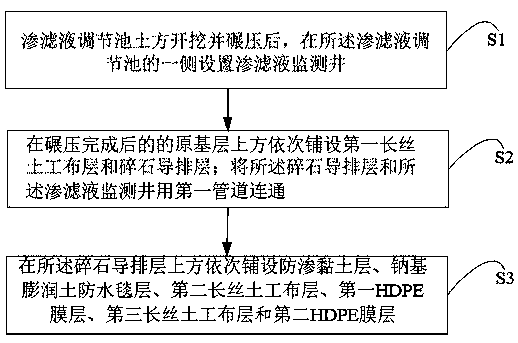

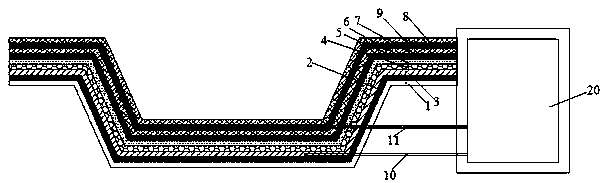

Construction method of leachate adjusting system

InactiveCN110644585AImprove water qualityNot destroyedProtective foundationGeotextilesSoil scienceCrushed stone

The invention provides a construction method of a leachate regulating system. The method comprises the following steps that after leachate regulating tank earth is excavated and rolled, a leachate monitoring well is set on one side of a leachate adjusting tank; a first filament geotextile layer and a gravel guiding and discharging layer are sequentially laid on an original base layer after rollingis completed; the gravel guiding and discharging layer communicates with the leachate monitoring well through a first pipeline; and an anti-seepage clay layer, a sodium-based geosynthetic clay linerlayer, a second filament geotextile layer, a first HDPE film layer, a third filament geotextile layer and a second HDPE film layer are sequentially laid on the gravel guiding and discharging layer. According to the method, the gravel guiding and discharging layer is laid on the original base layer, and the pipeline is connected between the guiding and discharging layer and the monitoring well so that underground water can be well drained; and the HDPE film layers are used as the main impermeable layers, and the rest is used as transition layers to filter the polluted underground water seepage,so that water in the adjusting tank can be effectively prevented from permeating downwards and the polluted underground water is prevented from permeating into the tank.

Owner:CHINA FIRST METALLURGICAL GROUP

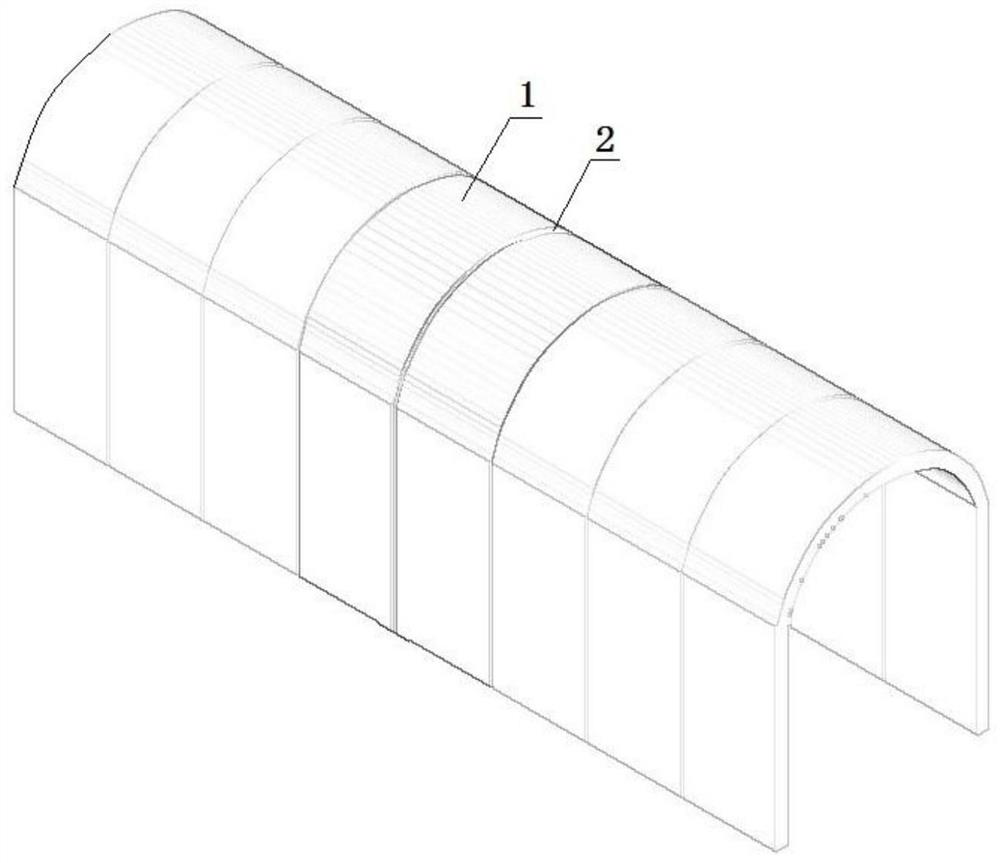

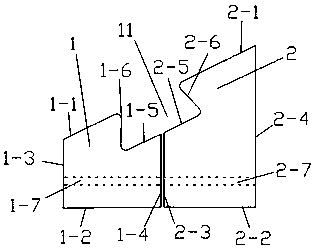

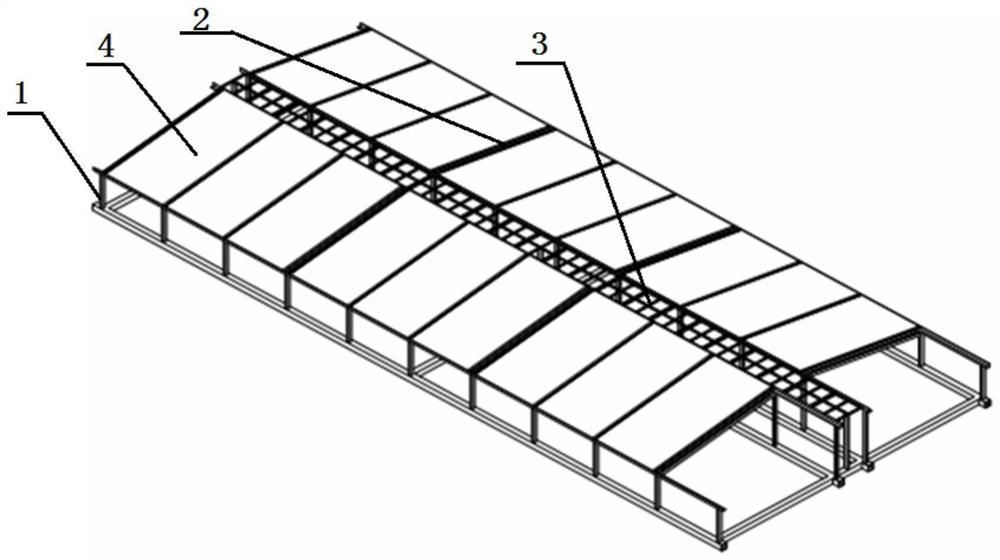

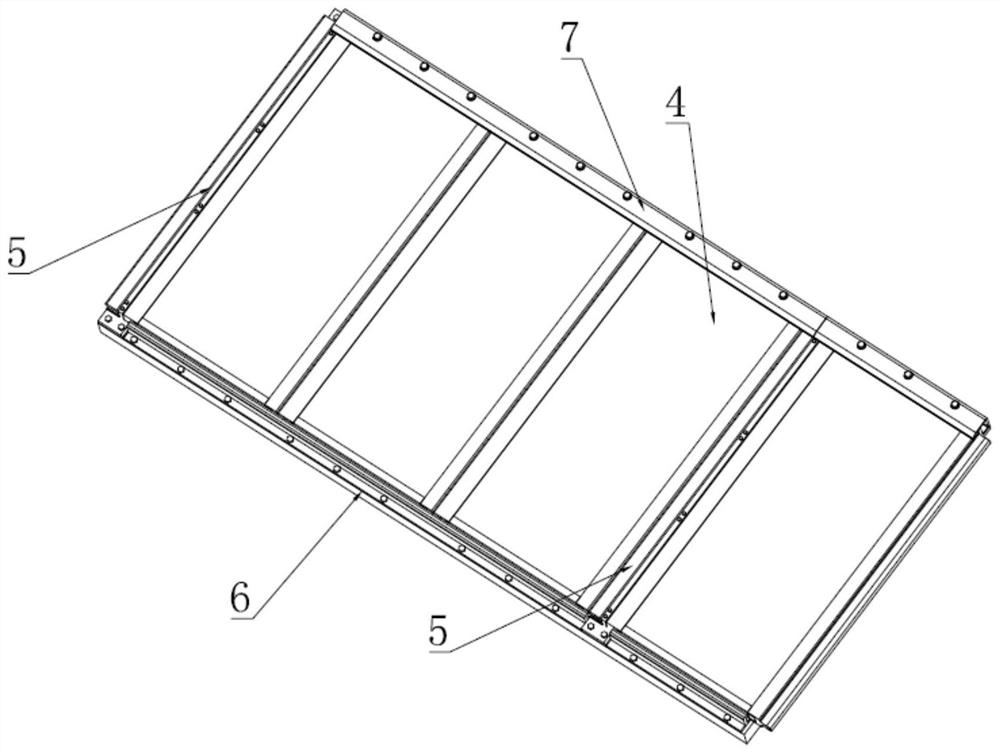

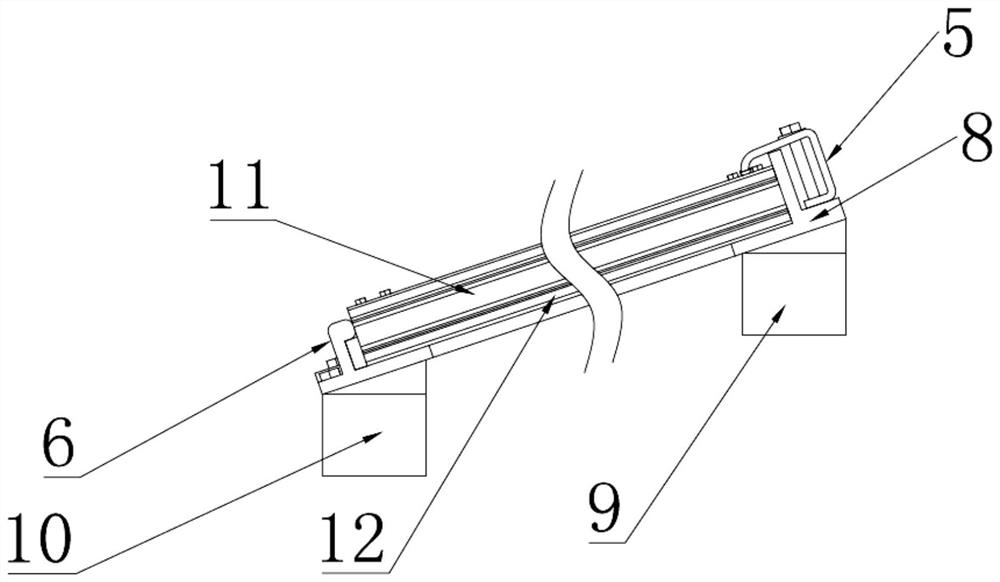

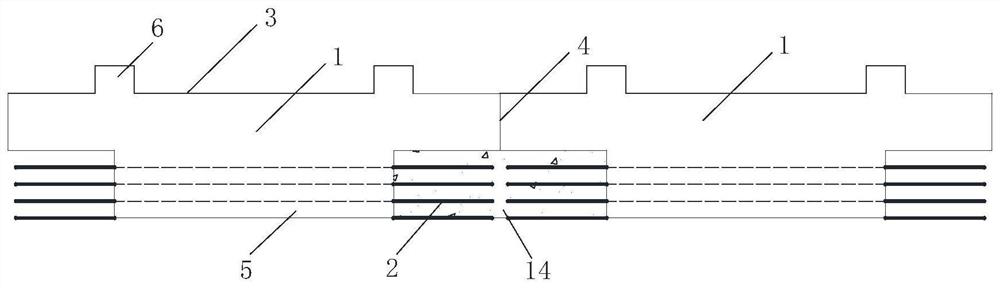

Photovoltaic building integrated corridor

ActiveCN112854432APrevent slippingSimplify the installation processPhotovoltaic supportsSolar heating energyBuilding integrationArchitectural engineering

The invention discloses a photovoltaic building integrated corridor. The photovoltaic building integrated corridor comprises a steel frame structure, a wallboard and an obliquely arranged roof panel, wherein the roof panel is a photovoltaic module panel; a plurality of oblique brackets are uniformly distributed on the top structure of the steel frame structure in the longitudinal direction of the corridor; a plurality of groups of photovoltaic module panels are sequentially laid between the adjacent oblique brackets in the longitudinal direction of the corridor; each group of photovoltaic module panels comprises a plurality of first-class photovoltaic module panels and a second-class photovoltaic module panel; the first-class photovoltaic module panels are connected with the adjacent photovoltaic module panels through inserting structures; the first-class photovoltaic module panels are connected with the oblique brackets through inserting structures; the second-class photovoltaic module panels are connected with the oblique brackets through oblique plane pressing structures; water-resisting strips are arranged between the opposite side surfaces of the oblique plane pressing structures and the second-class photovoltaic module panels; and water-resisting strips are also arranged between the opposite surfaces in the inserting structures. According to the photovoltaic building integrated corridor, the mounting steps are simplified on the premise of ensuring the anti-seepage effect of the roof, the mounting time required by mounting personnel on the roof is reduced, and the risk is reduced.

Owner:安徽海螺新能源有限公司

A static pressure prefabricated pool and its construction method

ActiveCN110359525BConstruction adaptationAvoid large excavation schemesSewerage structuresWater supply tanksArchitectural engineeringRebar

The invention discloses a static pressure prefabricated assembly type water tank and a construction method thereof. The construction method comprises the following steps of: dividing a tank wall structure into lath-shaped precast blocks for processing and prefabrication; locating a construction site, and excavating a guide pressure relief hole; sequentially pressing the lath-shaped precast blocksof the tank wall into a soil layer by using a static pressure machine, and forming a tank wall prototype; excavating internal soil, and arranging a support; eliminating the soil at connecting positions of the precast blocks, carrying out steel bar abutting joint, and carrying out cast-in-place construction at the connecting positions; and casting a bottom plate in place, and removing the support.A static pressure technology is applied to the construction of the water tank structure, can greatly reduce the earth excavation and backfilling amount in the conventional water tank construction process, reduces the deformation and uneven settlement of surrounding buildings, is suitable for construction in a narrow space, reduces the requirements on a construction site, accelerates the construction of the water tank, and shortens the construction period; and by adopting the static pressure technology, the noise is low during the construction period, and the construction can be performed on sites with surrounding residential areas. Meanwhile, the static pressure technology can greatly improve the friction resistance of the side wall of the water tank, which is beneficial to the reduction of anti-floating cost.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com