Patents

Literature

130results about How to "Avoid problems such as cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Assembly integral shear wall building structure and building method

ActiveCN103669559AImprove the level of industrializationIncrease productivityWallsBuilding material handlingRebarHigh rise

The invention relates to an assembly integral shear wall building structure and a building method and belongs to the field of buildings and construction technologies of the buildings. The shear wall building structure is formed by connecting prefabricated concrete hollow components through steel bars and cast-in-place concrete, wherein the prefabricated concrete hollow components include prefabricated wall body components, floor board components, T-shaped wall pillar components, L-shaped wall pillar components, cross-shaped wall pillar components and wall body components with holes. Multiple parallel lengthwise through holes are formed in the prefabricated hollow components in the length direction and multiple parallel transverse non-through holes communicated with the lengthwise through holes are formed in the prefabricated hollow components in the width direction. Horizontal anchor connection steel bars inserted into the transverse holes are arranged among the different prefabricated components. Lengthwise anchor connection steel bars are arranged in the lengthwise holes, wherein one end of each lengthwise anchor connection steel bar protrudes out of the surface of the corresponding prefabricated component by a certain length. The concrete is filled into the lengthwise holes and the transverse holes to form a layer of structural unit or a single-layer building structure. Multiple structure units are connected to form a multiple-layer or high-rise assembly integrated shear wall structure. The assembly integral shear wall building structure and the building method can be applied to the multiple-layer or high-rise shear wall building structures and frame-shear wall building structures. Thus, the industrial level of the building structures can be improved, stress performance can be improved and resources are saved.

Owner:初明进

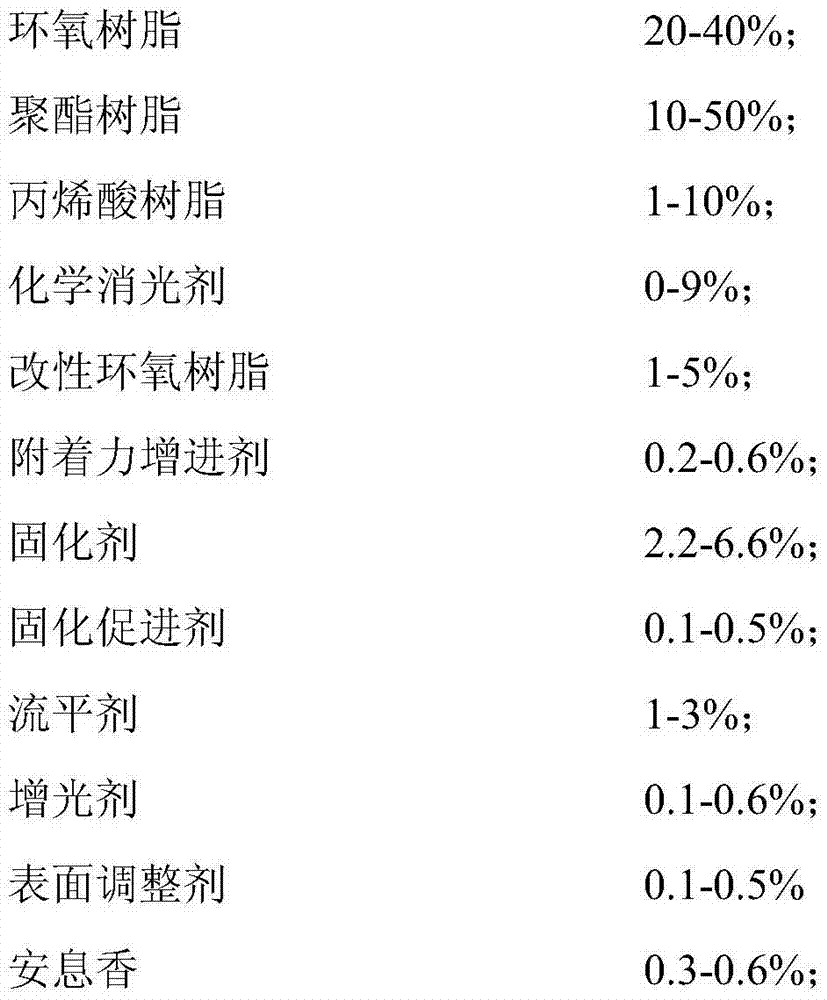

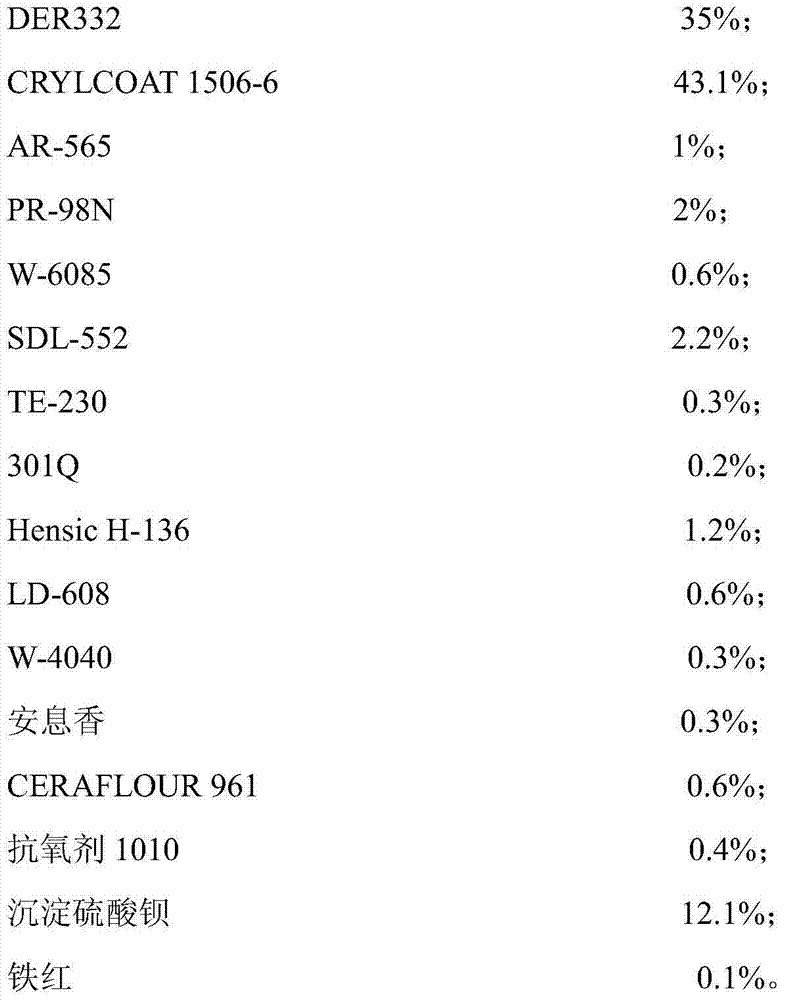

Super-levelling low-temperature curing powder coating for MDF

PendingCN104497797AAdjust glossImprove the level ofPowdery paintsEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of functional powder coatings, and particularly relates to a super-levelling low-temperature curing powder coating for an MDF. The powder coating is prepared from the following raw materials in percentage by weight: 20%-40% of epoxy resin, 10%-50% of polyester resin, 1%-10% of acrylic resin, 0-9% of a chemical flatting agent, 1%-5% of modified epoxy resin, 0.2%-0.6% of an adhesion promoter, 2.2%-6.6% of a curing agent, 0.1%-0.5% of a curing accelerator, 1%-3% of a flatting agent, 0.1%-0.6% of a gloss enhancer, 0.1%-0.5% of a surface conditioning agent, 0.3%-0.6% of benzoin, 0.2%-0.8% of a degassing agent, 0.3%-0.7% of an antioxidant, and 10%-20% of filler and pigment. According to the super-levelling low-temperature curing powder coating, the glossiness is adjusted by adjusting the amount of acrylic resin and the chemical flatting agent; highlight, matt and flat coats can be prepared; and the super-levelling low-temperature curing powder coating has the advantages of excellent levelling property, good adhesive force and low curing temperature.

Owner:山东朗法博粉末涂装科技有限公司

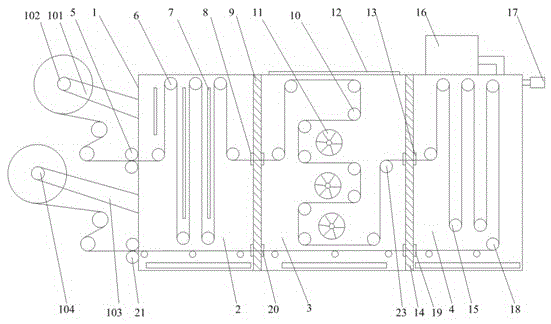

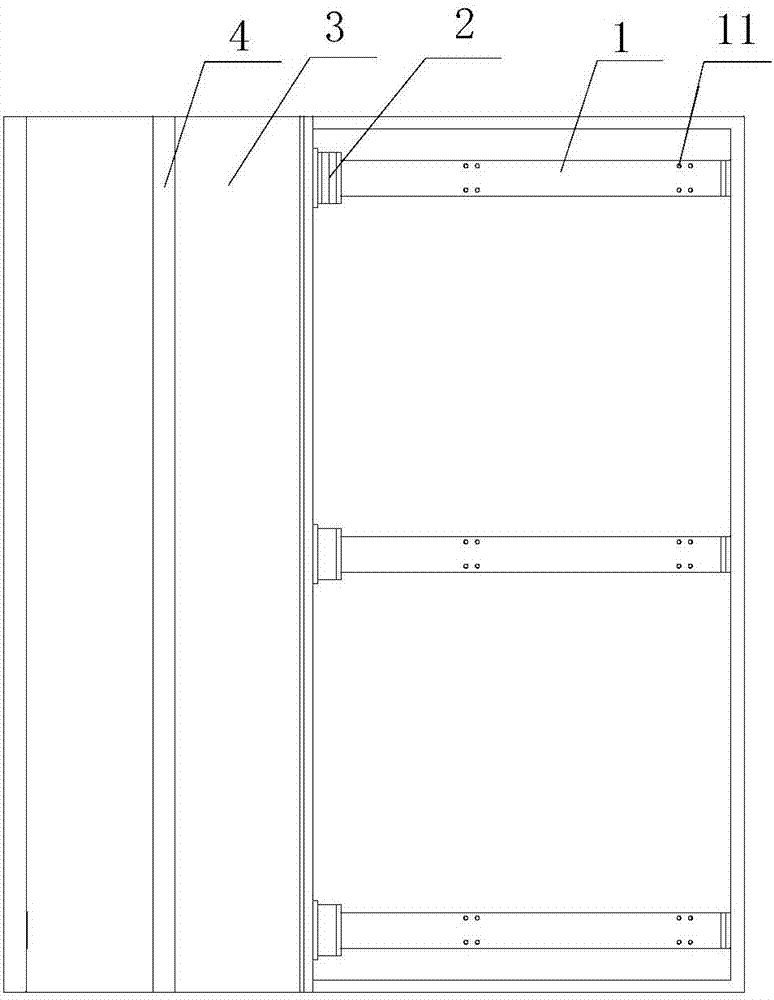

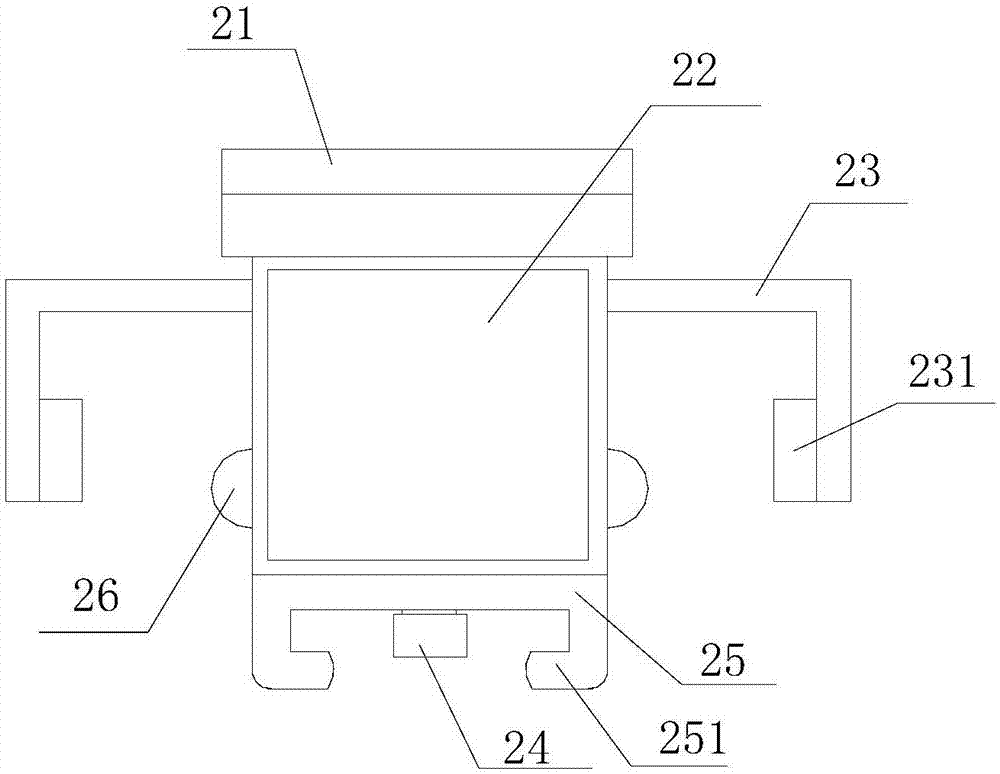

Lithium ion battery pole piece drying device

InactiveCN105486059AEasy to assembleEasy to moveDrying gas arrangementsDrying machines with progressive movementsElectrical batterySmall footprint

The invention relates to the technical field of lithium batteries and in particular to a lithium ion battery pole piece drying device. The lithium ion battery pole piece drying device comprises a cabinet. The cabinet is sequentially divided into a heating chamber I, a heating chamber II and a heating chamber III. Turning rolls I and infrared heaters are arranged in the heating chamber I. A first transmission port is formed in the upper end of the heating chamber I and formed in a heat insulation board I. Turning rolls II and fans are arranged in the heating chamber II. Turning rolls III are arranged in the heating chamber III and a vacuum pump and a vent valve are arranged at the upper end of the heating chamber III. A rotary roll is arranged at the lower end of the heating chamber III. The lithium ion battery pole piece drying device is safe, reliable, convenient to assemble and move, small in occupied area, high in drying speed and capable of solving the problem that bubbles, needle holes and chaps are generated and greatly improving production efficiency.

Owner:SHANDONG PEARSON POWER NEW ENERGY

Novel combined wallboard

The invention discloses a novel combined wallboard which comprises a panel base material, adjusting buckles, a locking clamping strip and hooks. A plurality of first installation grooves are formed in one side of the panel base material. The adjusting buckles are arranged in the first installation grooves and provided with clamping rings. The clamping rings are provided with adjusting rotary knobs. Each adjusting rotary knob is internally provided with a first installation hole. The adjusting buckles are installed in the first installation grooves through hinge pins. A second installation groove is formed in the other side of the panel base material. The locking clamping strip is arranged in the second installation groove and provided with a movable head. A guide rod is arranged below the movable head, and the guide rod is installed on a sleeve through a spring. Suspension grooves are formed in the two sides of the panel base material and matched with the hooks. The hooks are installed on a keel through bolts. Installation is convenient, and the construction amount is low. Moreover, the wallboards are connected firmly, and the problem of cracking of connection joints caused by wallboard deformation can be avoided.

Owner:YUYU

Heat treatment device for semi-closed tubular aluminum profiles

InactiveCN103882352AImprove physical performanceImprove stabilityFurnace typesHeat treatment furnacesMaterials scienceHeat treating

The invention relates to the technical field of aluminum profile production and particularly relates to a heat treatment device for semi-closed tubular aluminum profiles. The heat treatment device comprises an aluminum profile conveying track, wherein a locating track is fixed at a position, which is parallel to a conveying direction and is close to the middle of the aluminum profile conveying track, of the aluminum profile conveying track, and an internal aluminum profile heating device, an external aluminum profile heating device and a cooling device are arranged at one side of the conveying direction of the aluminum profile conveying track. According to the heat treatment device, various physical properties and internal structural stability of the aluminum profiles can be effectively improved.

Owner:HUZHOU JULI ALUMINUM

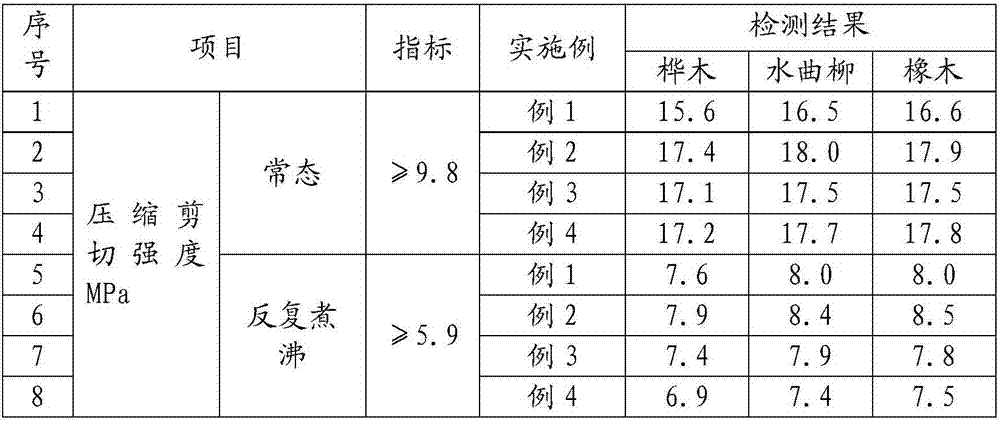

Laminated material laminating glue and preparation method thereof

ActiveCN106867427AImproved storage stabilityReduce dosageMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesDefoamerIsocyanate

The invention discloses laminated material laminating glue and a preparation method thereof. The laminated material laminating glue comprises components A and B. The component A comprises, by mass, 17.7% to 25.4% of deionized water, 39% to 63% of a water-based emulsion, 1% to 5% of a plasticizer, 2% to 4% of polyvinyl alcohol, 0.1% to 0.2% of a chelating agent, 0.1% to 0.2 % of a dispersant, 0.05% to 0.1% of a defoamer, 16% to 26% of calcium carbonate and 0.05% to 0.1% of a bactericide. The component B comprises polyaryl polymethylene isocyanate. The preparation method comprises preparing a modified polyvinyl alcohol solution from deionized water, polyvinyl alcohol and the chelating agent, orderly adding the water-based emulsion, the plasticizer, the dispersant and the defoamer into a dispersion kettle, slowly adding calcium carbonate into the dispersion kettle, carrying out dispersion to obtain uniform glue slurry, adding a polyvinyl alcohol modification solution and a bactericide into the glue slurry to obtain the component A and mixing the component A and the component B. The laminated material laminating glue is used for splicing of various laminated materials, has high splicing strength, a long application period, excellent heat resistance and excellent water resistance, resists water boiling and can reach the wood breaking strength.

Owner:北京市创新玮地科贸有限公司

Semi-closed tubular aluminium profile heat treatment device

InactiveCN108148984AIncrease heating rateImprove battery saving performanceCoil arrangementsFurnace typesEngineeringStructural stability

The invention relates to the technical field of aluminium profile production, in particular to a semi-closed tubular aluminium profile heat treatment device. The semi-closed tubular aluminium profileheat treatment device comprises an aluminium profile conveying channel; a locating track is fixed on a middle position, parallel to the conveying direction, of the aluminium profile conveying channel;and one side of the conveying direction of the aluminium profile conveying channel is provided with an aluminium profile internal heating device, an aluminium profile external heating device, and a cooling device, and various physical properties and internal structural stability of the aluminium profile can be effectively improved.

Owner:陈卫

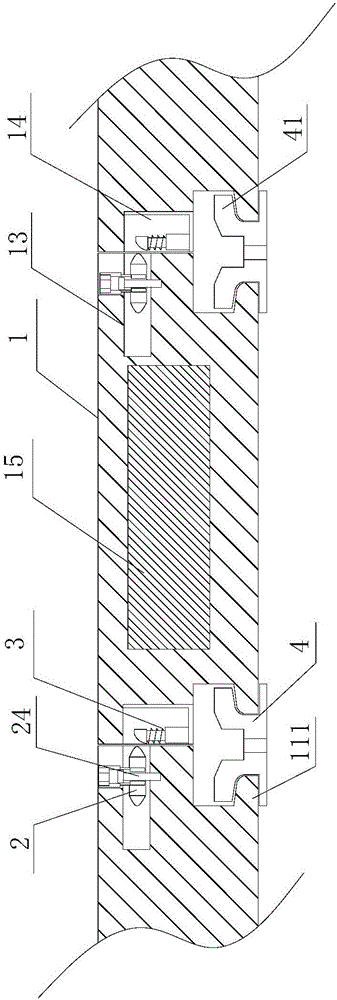

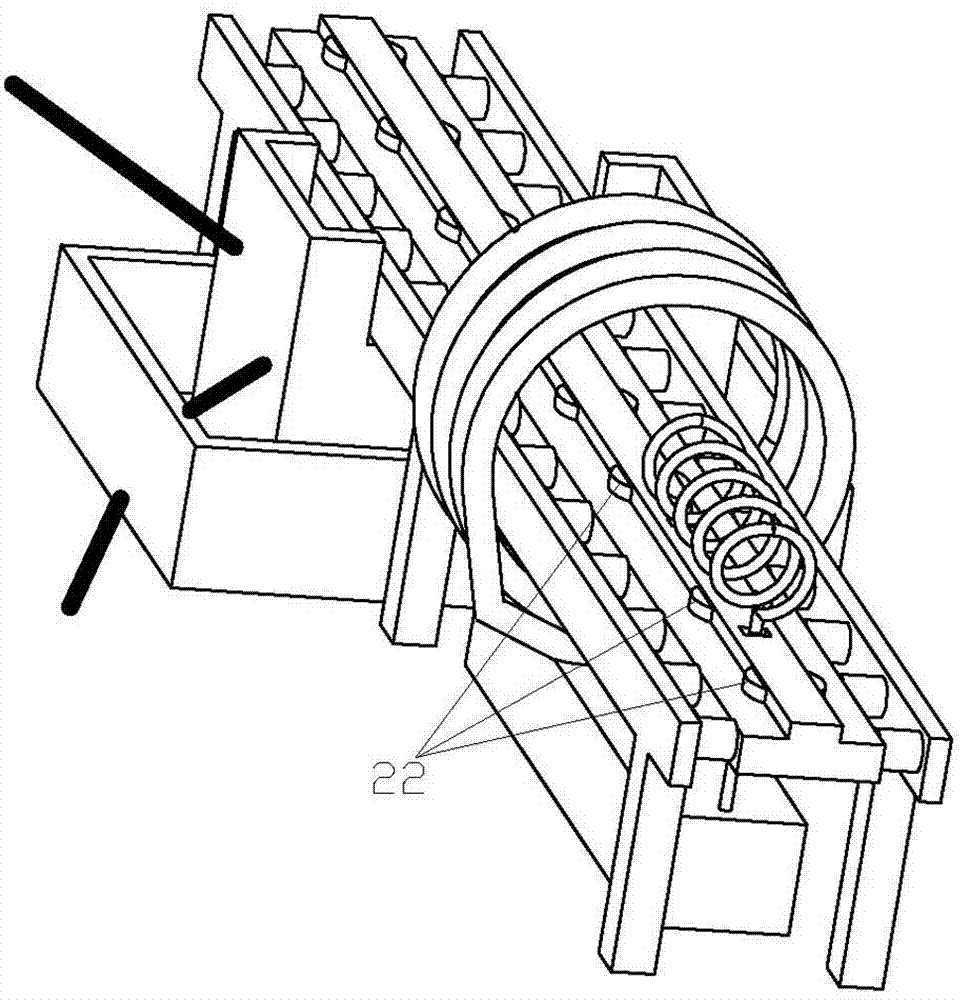

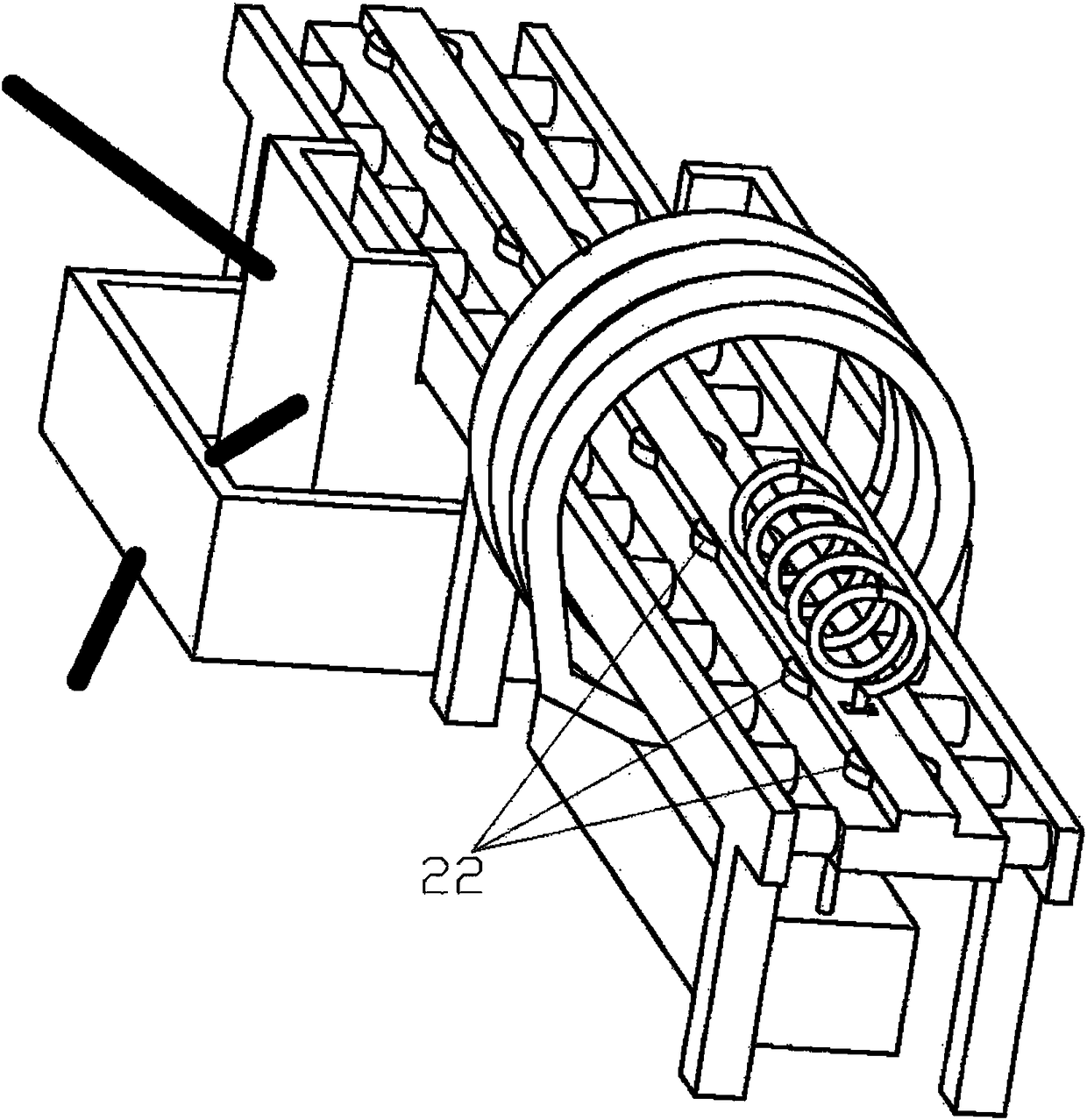

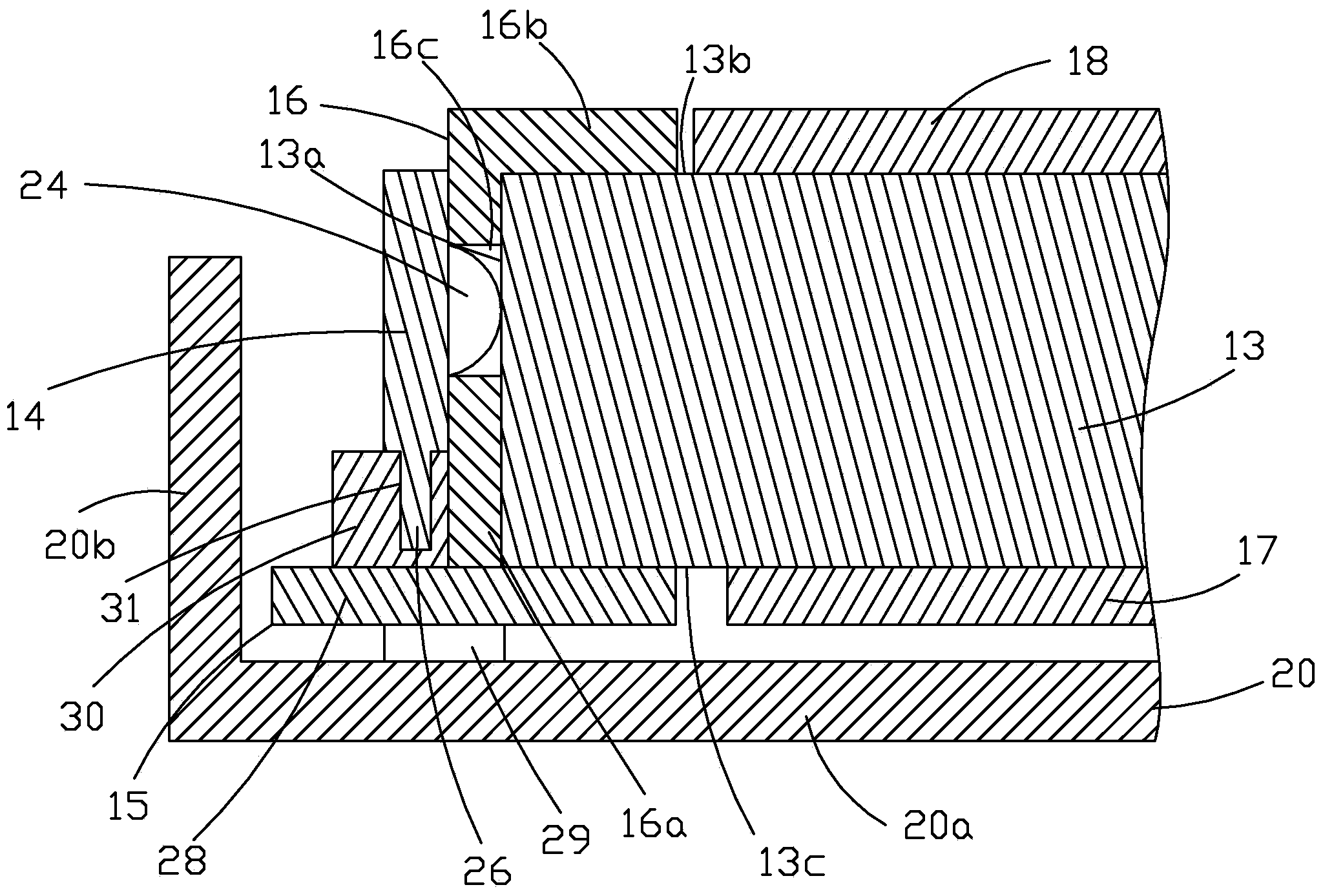

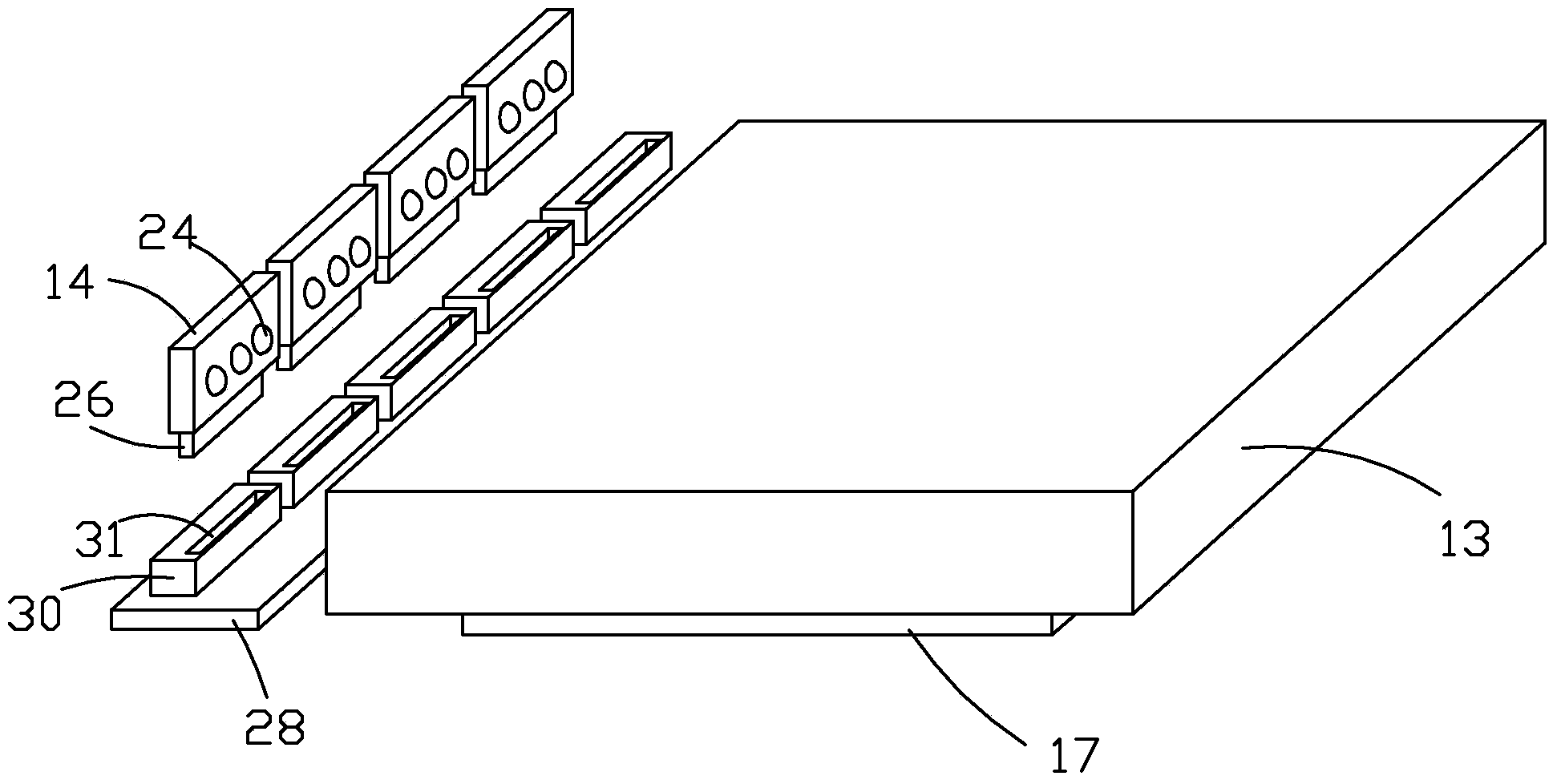

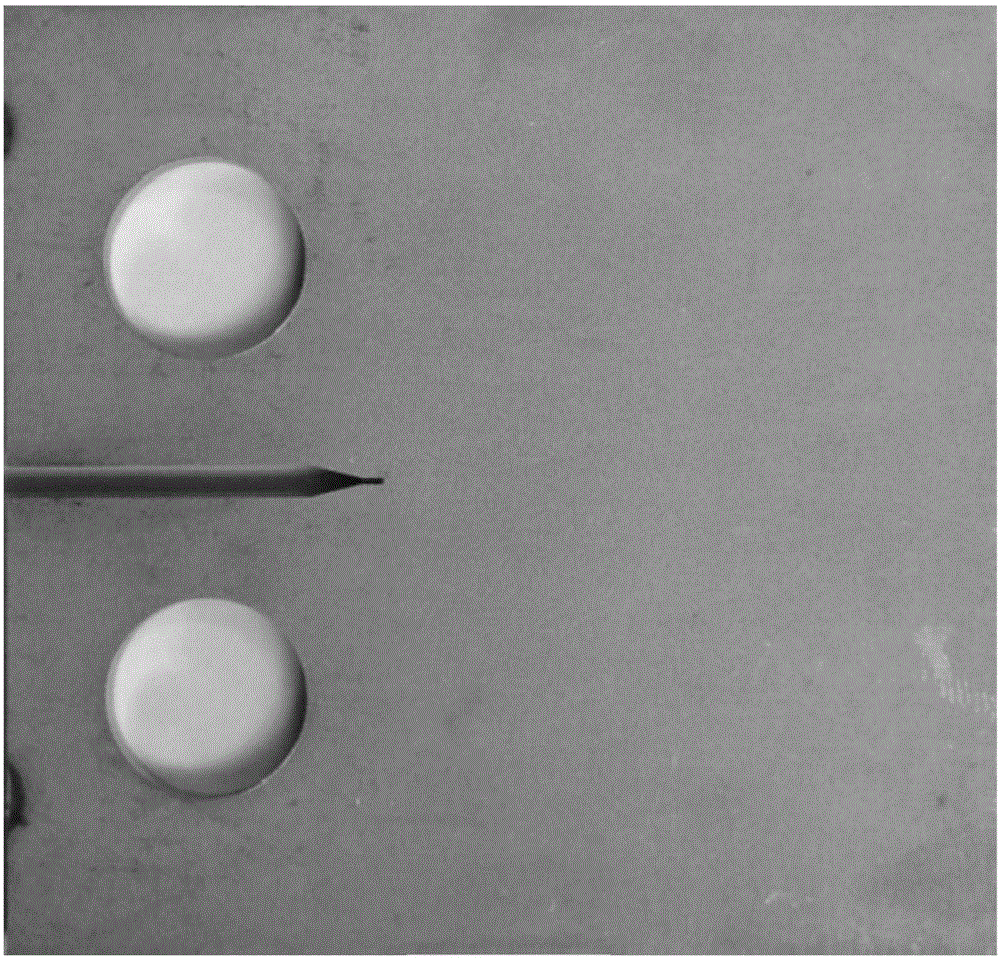

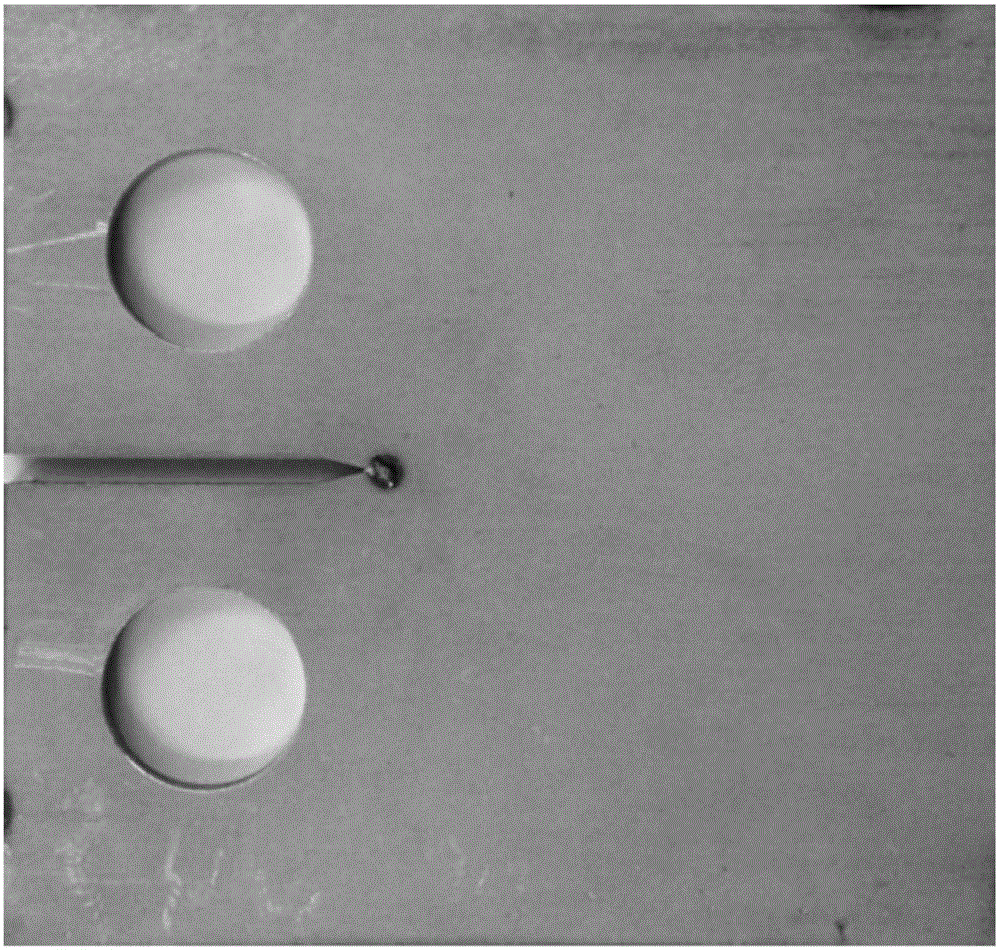

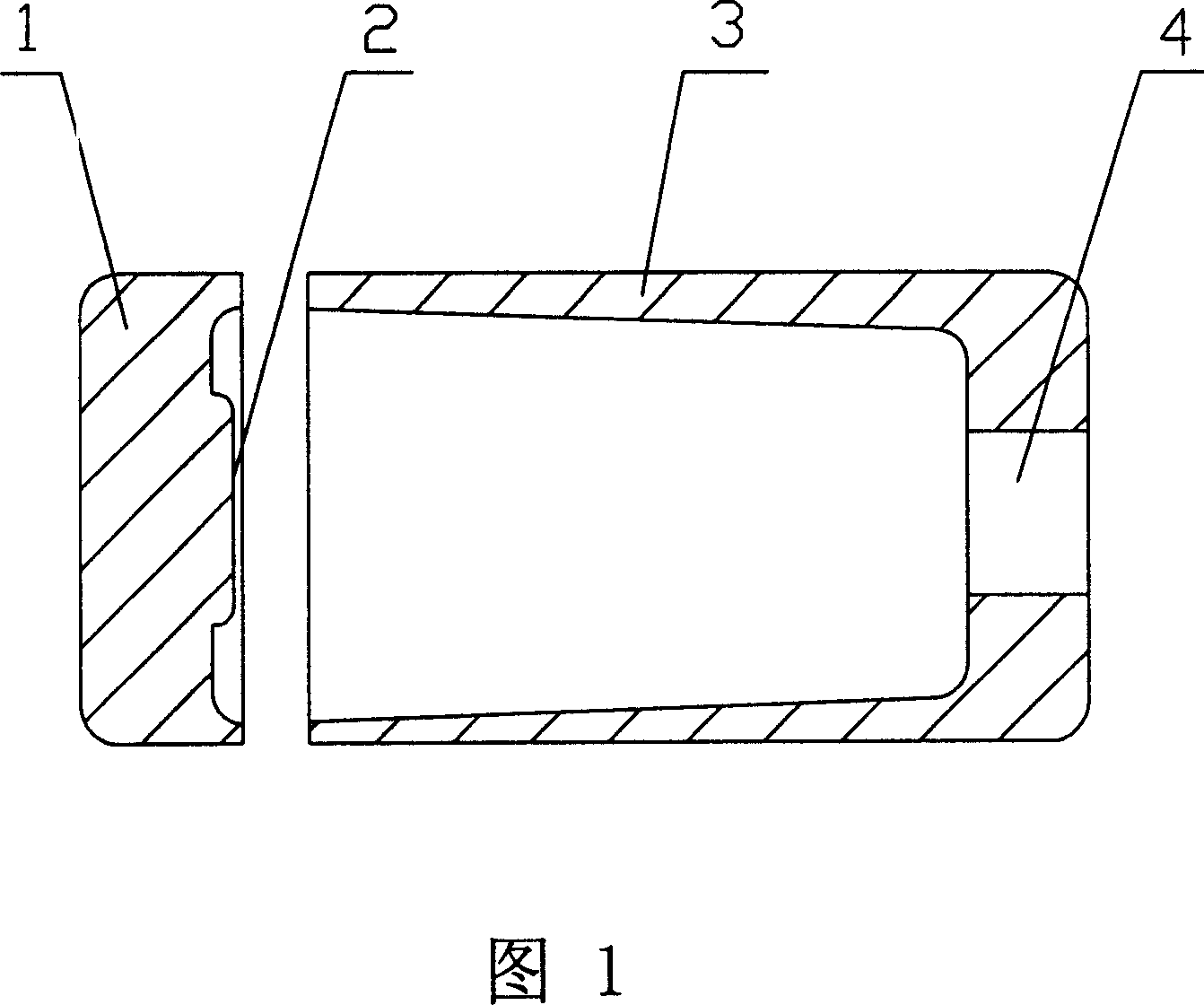

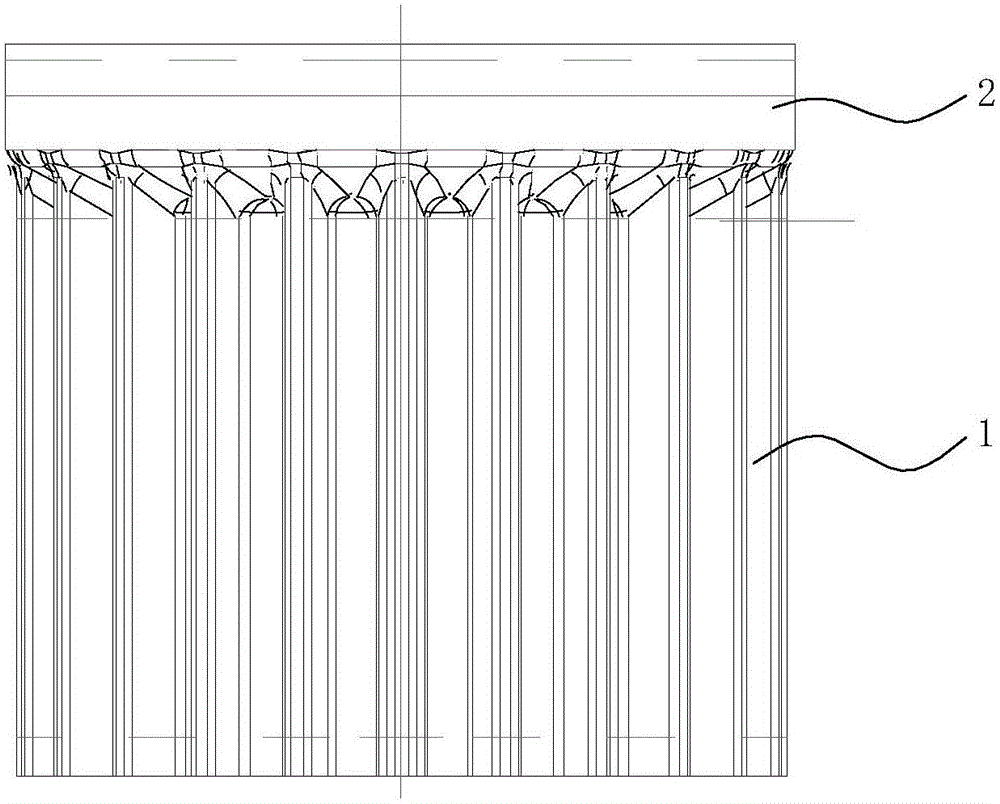

Precast concrete hollow component, and manufacturing method thereof

InactiveCN103628618AImprove the level of industrializationIncrease productivityStrutsConstruction materialReinforced concreteCross wall

The invention relates to a precast concrete hollow component, and a manufacturing method thereof, and belongs to the technical field of precast reinforced concrete structural components. The precast concrete hollow component comprises a precast wall plate component, a floor component, a T-shaped wall post component, an L-shaped wall post component, a cross wall post component and a wall body component provided with a hole; the precast concrete hollow component is internally provided with a plurality of longitudinal through holes along the length direction, and a plurality of horizontal non-through holes communicated with the longitudinal through holes along the width direction, wherein the longitudinal through holes are arranged parallelly to each other, and the horizontal non-through holes are arranged parallelly to each other. The manufacturing method comprises following steps: combining templates, such as a bottom die, a top die, a side die, a steel pipe inner die and the like, on a production field of precast slabs; arranging reinforcing meshes; then pouring concrete; drawing out a steel pipe after the strength of the concrete reaches to a certain degree; and dismounting the templates after the concrete reaches to an expected strength degree. The precast concrete hollow component can be used in multilayered, high-rise shear wall and frame-shear wall building structures, thus improving industrial level of the building structures, improving structural behaviors and saving sources.

Owner:初明进

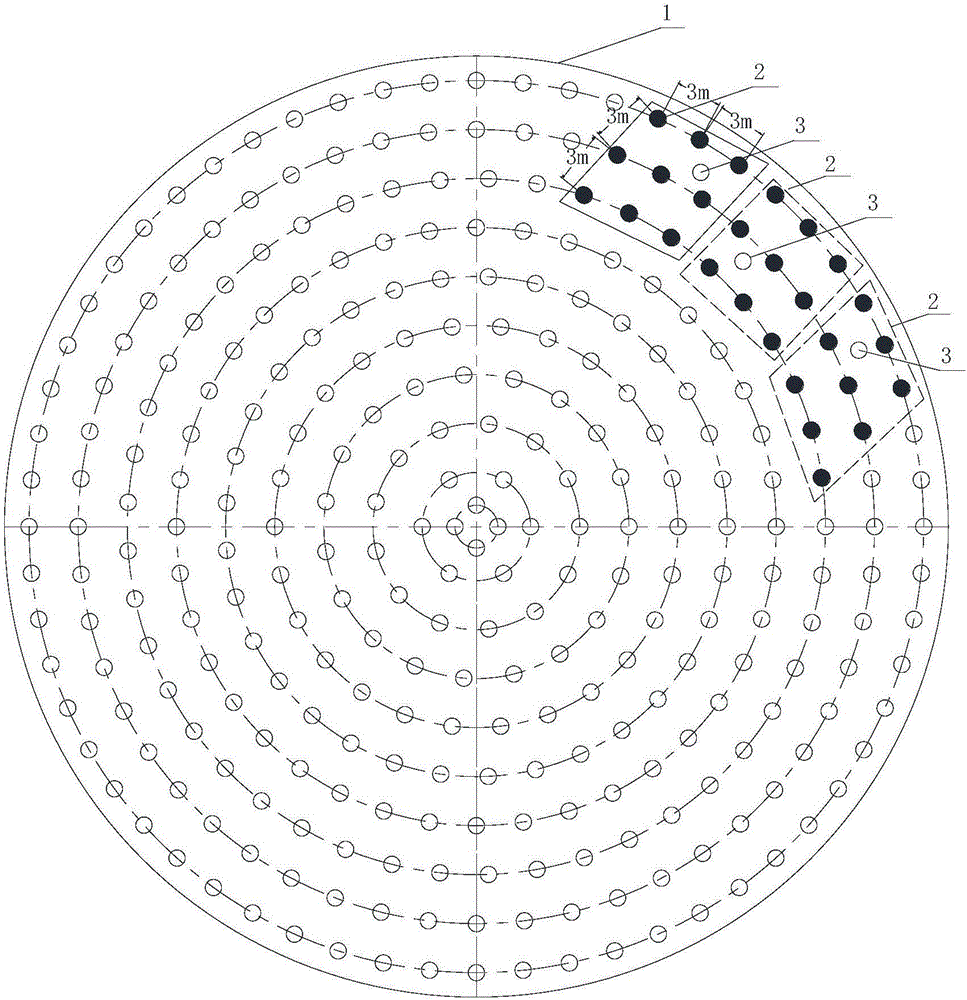

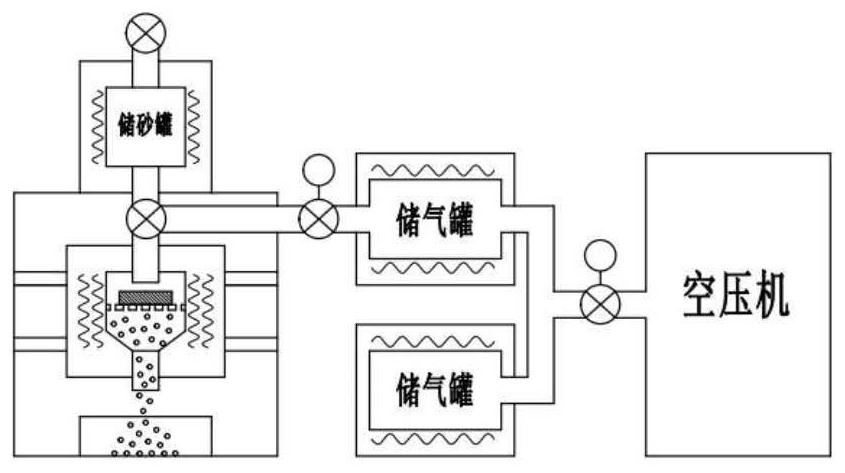

Quick pressure-relief gas discharge method for exposing super-thick and soft outburst coal seam in vertical wellbore

InactiveCN106321143AImprove breathabilityAccelerate gas emissionLiquid/gas jet drillingGas removalSingle holeDrill hole

The invention discloses a quick pressure-relief gas discharge method for exposing a super-thick and soft outburst coal seam in a vertical wellbore. The method comprises the following steps: designing discharge drilling holes in several circles along the contour of the wellbore heading face; dividing the drilling holes into a plurality of nine-hole thrusting units, and nine-hole injection units; drilling for each nine-hole thrusting unit and each nine-hole injection unit; conducting pressure test for drilling; thrusting coal of the 9 holes of the nine-hole thrusting units and the nine-hole thrusting units sequentially; constructing a gas inspection hole in the area of the nine-hole thrusting and nine-hole injection units in the thrusting, and measuring gas content; cementing the 9 drill holes of the nine-hole thrusting units and the nine-hole injection units after measuring the gas content; thrusting and cementing all the nine-hole thrusting units and the nine-hole injection units sequentially. The quick pressure-relief gas discharge method avoids the problem of cracking of the borehole wall after the change of the punching stress, and strengthens the coal, and increases the single hole discharge under the premise of ensuring the safety, and realizes the quick pressure-relief gas discharge of the super-thick and soft outburst coal seam.

Owner:CHINA UNIV OF MINING & TECH

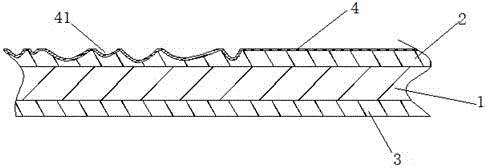

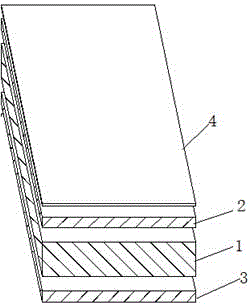

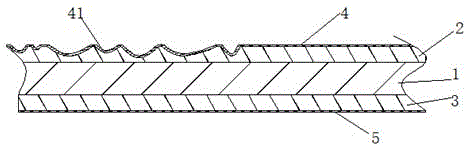

High-structural-strength three-dimensional solid wood composite board and forming method thereof

The invention discloses a high-structural-strength three-dimensional solid wood composite board which comprises a hard base layer and further comprises a first capacity layer group, a second capacity layer group and a surface layer, wherein the first capacity layer group and the second capacity layer group are arranged on the two sides of the base layer, wherein each of the first capacity layer group and the second capacity layer group is provided with at least one flexible capacity layer; the surface layer is arranged on the surface of the first capacity layer; a decoration groove is formed in the surface layer; and the bottom of the decoration groove is embedded into the first capacity layer group. The hard base layer can provide enough mechanical strength for the whole board and support the capacity layers and the surface layer in the board, so as to prevent the board from deforming in the process of making the decoration groove under high pressure. The solid wood composite board provided by the invention has a brand-new structure different from that of a conventional board, has the characteristics of stereoscopic vision, high mechanical strength and long service life, further has the advantages of low formaldehyde release amount and environment friendliness in use and can be widely applied to the fields of home decoration, artwork processing, commercial place decoration and municipal construction.

Owner:SHENZHEN SONGBOYU TIMBERING

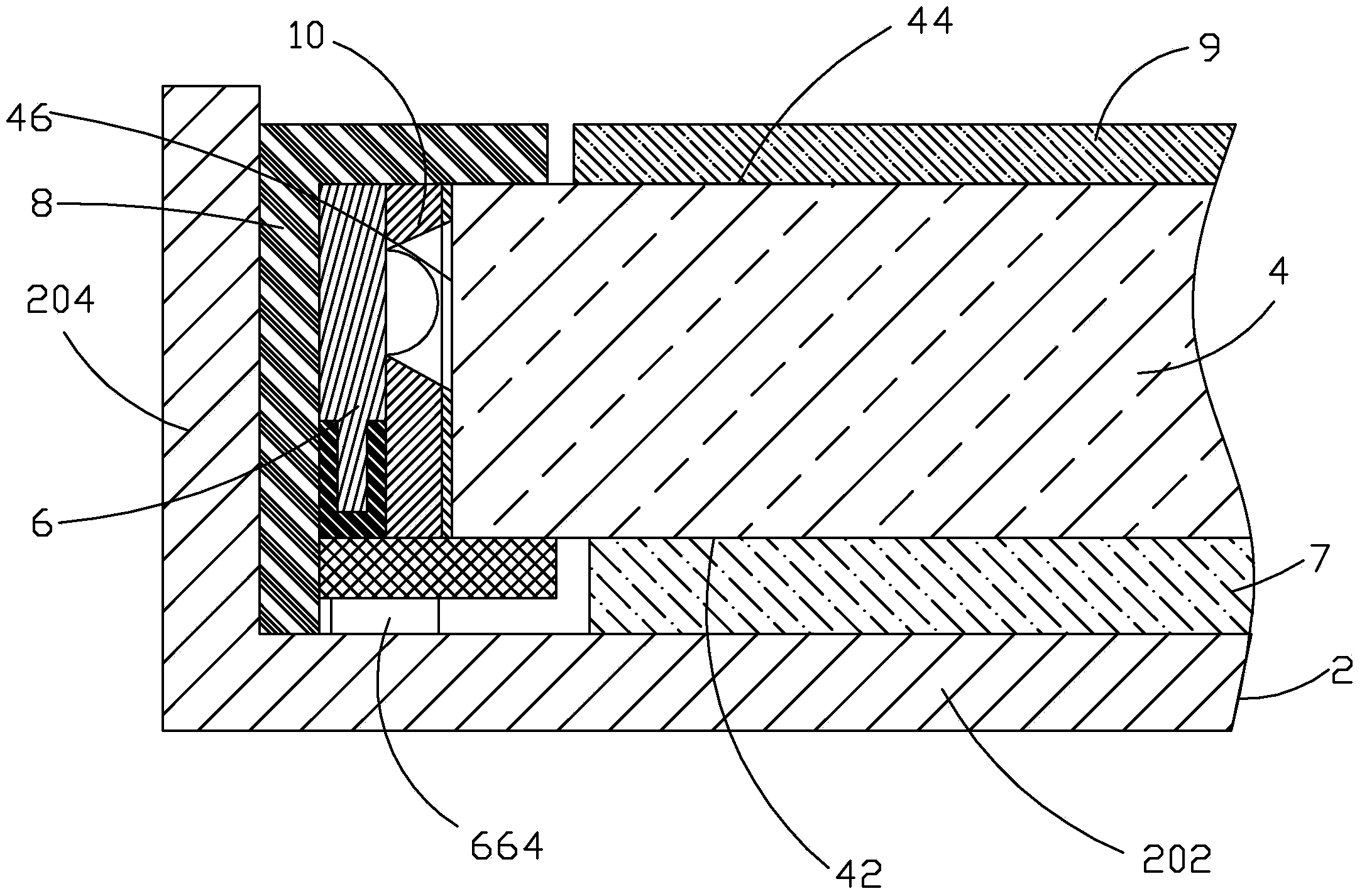

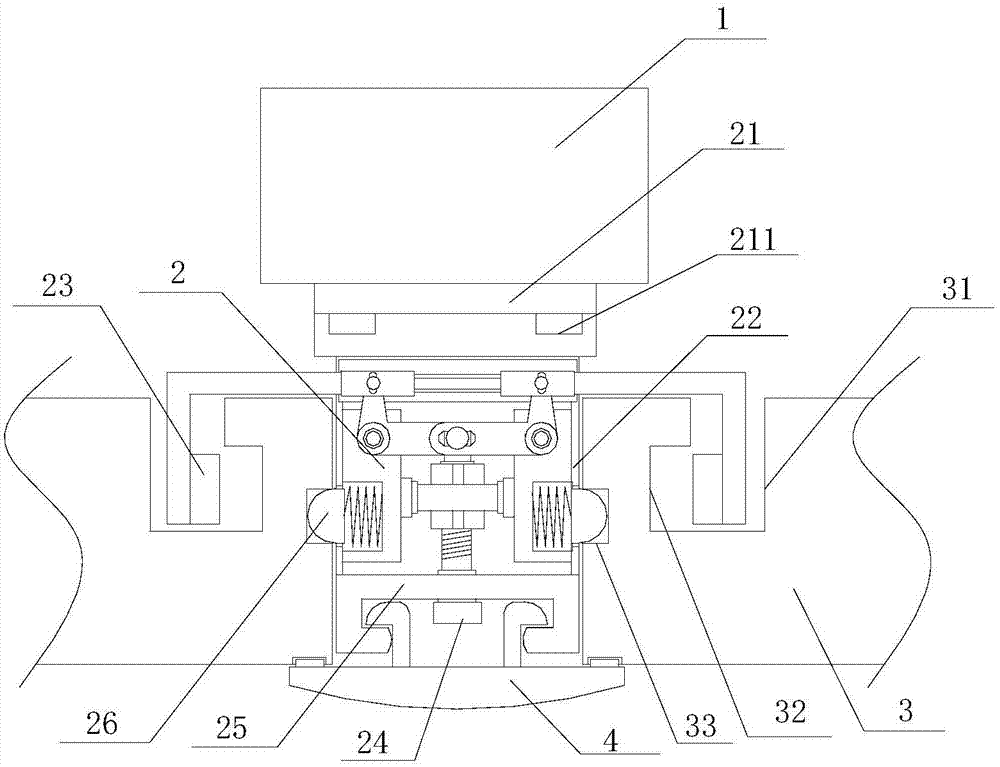

Backlight module

ActiveCN103672620AImprove cooling effectImprove qualityPoint-like light sourceLighting heating/cooling arrangementsLight guideOptoelectronics

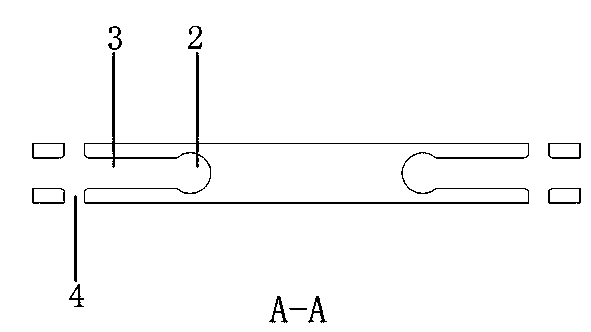

The invention provides a backlight module which comprises a back plate (2), a light guide plate (4), a backlight source (6), a light shield (8) and a side reflecting piece (10). The light guide plate (4) is arranged inside the back plate (2). The backlight source (6) is arranged inside the back plate (2) and located on one side of the light guide plate (4). The light shield (8) is arranged between the backlight source (6) and the back plate (2). The side reflecting piece (10) is arranged between the light guide plate (4) and the backlight source (6). The backlight source (6) comprises an LED substrate (62) and a plurality of LED lamps (64) installed on the LED substrate (62). The side reflecting piece (10) has elasticity. The side reflecting piece (10) is provided with a plurality of openings (102) corresponding to the LED lamps (64). The LED lamps (64) are contained inside the openings (102) and provide a light source for the light guide plate (4).

Owner:CHANGSHA HKC OPTOELECTRONICS CO LTD

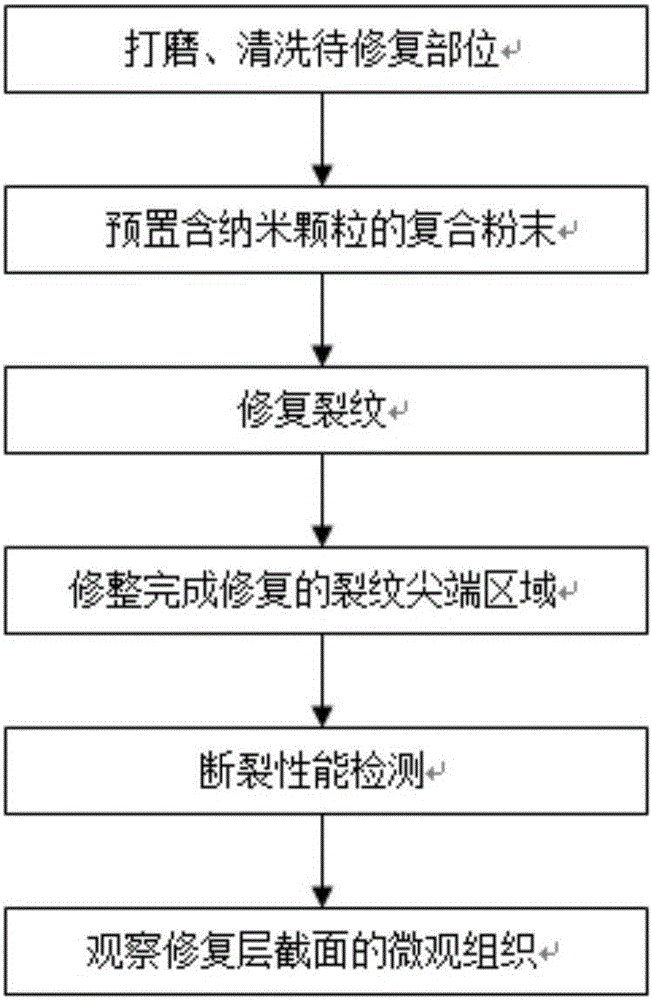

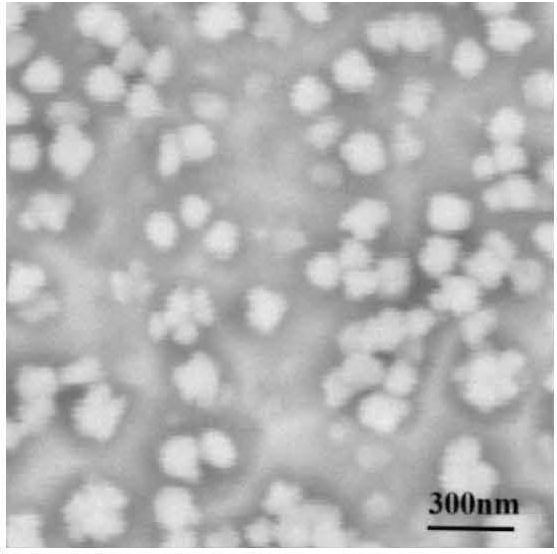

Method for repairing microcrack tip on stainless steel surface by means of nano-particles

ActiveCN105714286AImprove densification performanceExtended service lifeMetallic material coating processesHeat-affected zoneNanoparticle

The invention provides a method for repairing a microcrack tip on a stainless steel surface by means of nano-particles. The method is suitable for stainless steel with microcracks on the surface. The method comprises the steps that the to-be-repaired microcrack tip on the stainless steel surface is treated; composite powder containing the nano-particles is arranged on the microcrack tip in advance; the composite powder and a part of a matrix are fused by means of lasers; the repaired microcrack tip region is finished; and the fracture property of the stainless steel matrix obtained after repairing is detected, and the microstructure of the section of a repair layer is observed. The repairing method is high in flexibility, and repairing can be carried out many times; and meanwhile, the problems of large deformation, a large heat affected zone and the like in a conventional method are avoided in the repairing method. According to the repairing method, the microcrack tip is closed again, the matrix and the composite powder arranged on the microcrack tip in advance are in metallurgical bonding, and the defects of cracks, pores and the like do not exist in the bonding region; grains of the repair layer of the microcrack tip are refined, and the structural compactness is improved; and in addition, the fracture property generated after repairing is remarkably improved.

Owner:DALIAN UNIV OF TECH

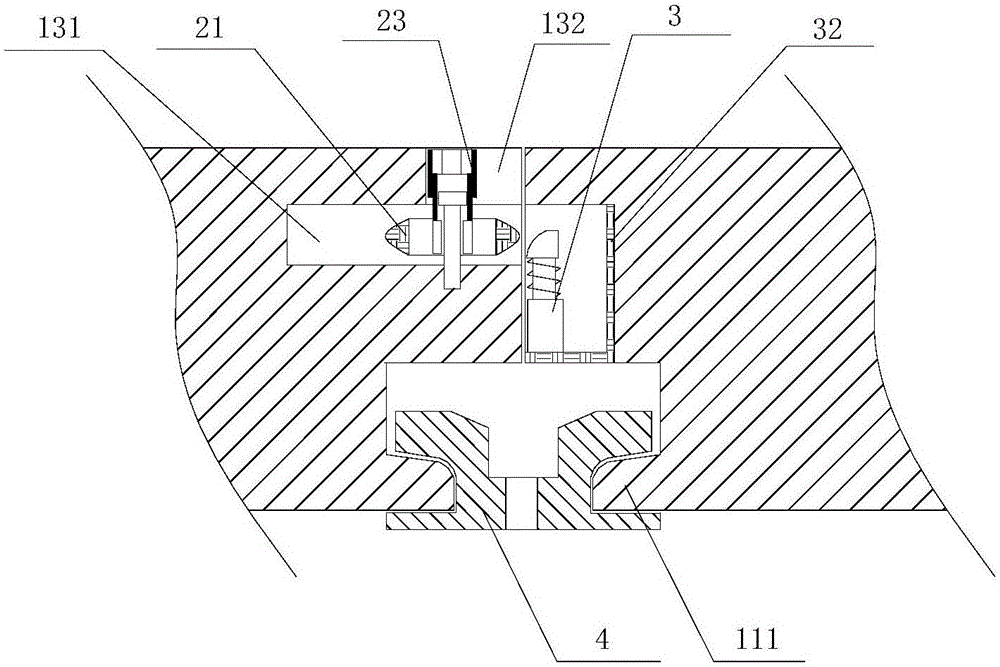

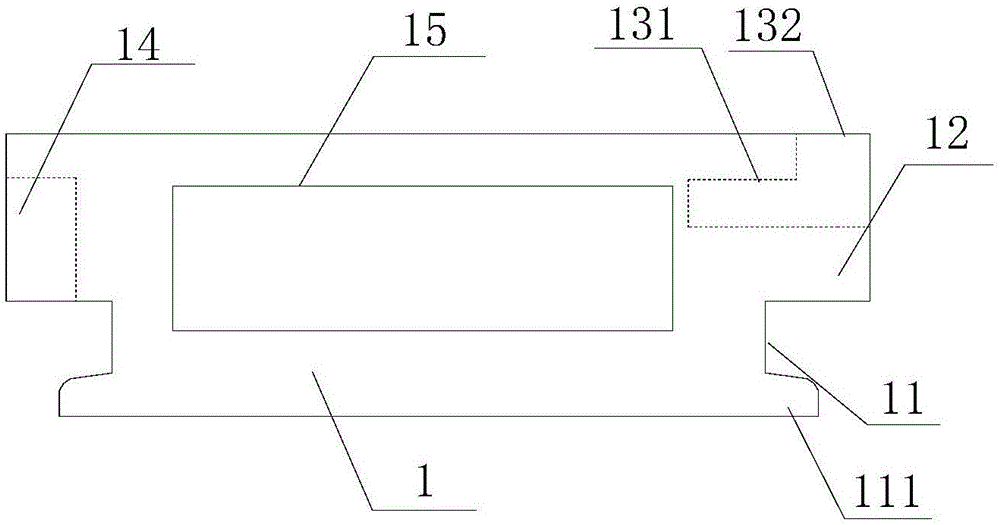

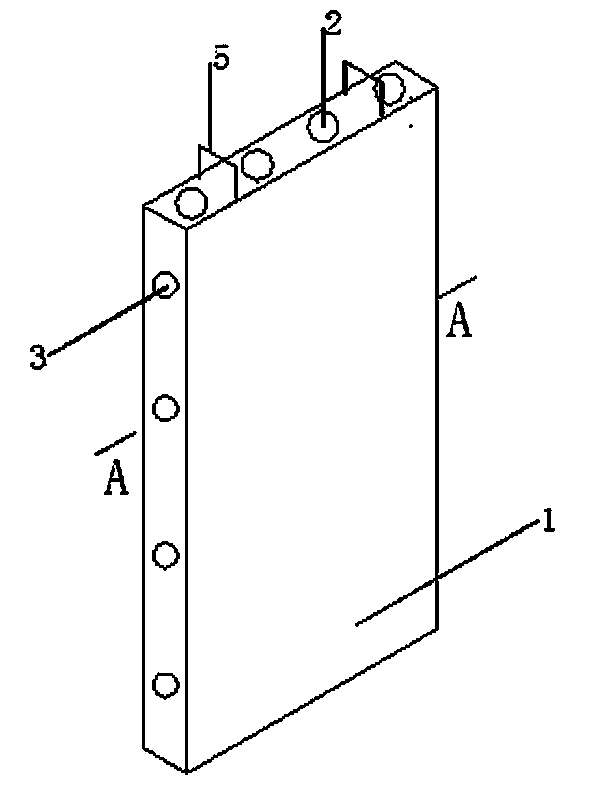

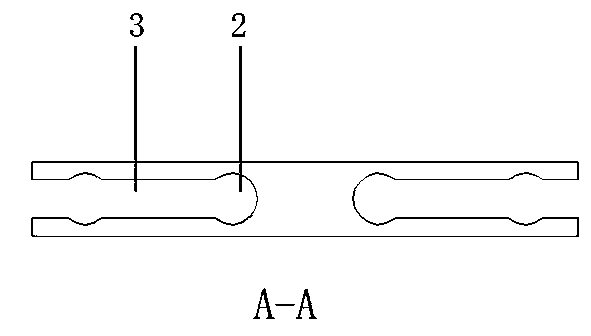

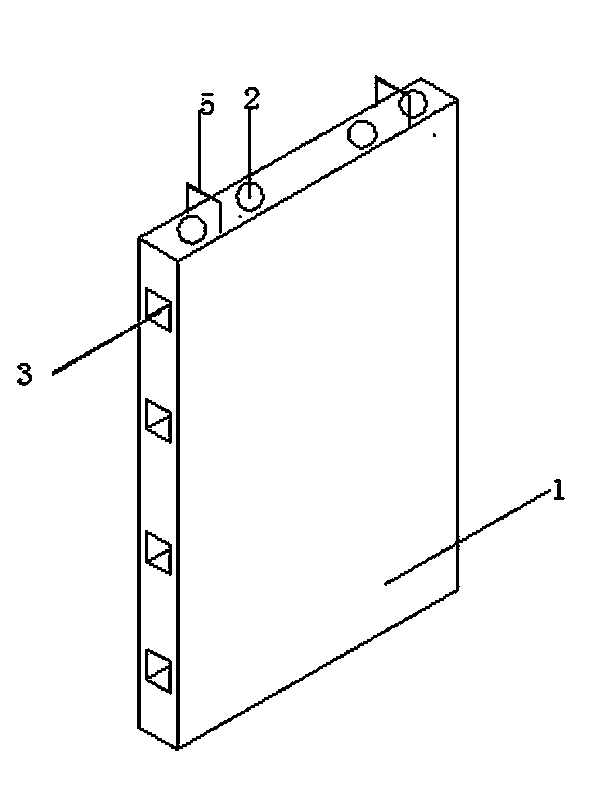

Prefabricated concrete hollow member and preparation method thereof

InactiveCN103628616AImprove the level of industrializationIncrease productivityConstruction materialRebarCoupling beam

The invention relates to a prefabricated concrete hollow member and a preparation method thereof, and belongs to the technical field of prefabricated reinforced concrete structure members. The prefabricated concrete hollow member comprises a prefabricated panel member, a floorslab member, a T-shaped wall column member, an L-shaped wall column member, a cross-shaped wall column member and a wall member with holes. The wall member with the holes comprises the holes, a coupling beam at the upper portion of the holes and walls on two sides of each hole. Multiple communicated and longitudinal holes are arranged in the prefabricated concrete hollow member along the length direction and are parallel to each other, and multiple non-through horizontal holes are arranged in the prefabricated concrete hollow member along the width direction. Board holes are arranged at the joints of the longitudinal holes and the horizontal holes. The prefabricated concrete hollow member can be applied in a multi-storey and high-rise shear wall building structure and a framework-shear wall construction wall, and therefore industrialization level of a building structure can be improved, stress property is improved, and resource is saved.

Owner:初明进

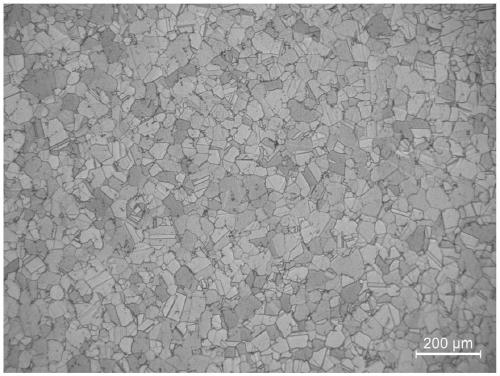

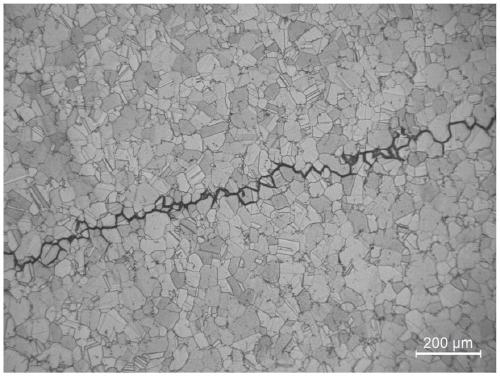

Hot working process of GH4738 nickel-based superalloy

PendingCN113560481AAvoid specimen crackingUniform tissueMetal-working apparatusWheelsVacuum induction meltingCrystallite

The invention discloses a hot working process of a GH4738 nickel-based superalloy. The process comprises the following steps that A, the GH4738 nickel-based superalloy is taken as a raw material, and is smelted by adopting a vacuum induction melting (VIM) process and a vacuum consumable remelting (VAR) process in sequence to obtain a vacuum consumable ingot; B, the vacuum consumable ingot is subjected to homogenization treatment and cogging forging treatment, and a GH4738 alloy bar blank is obtained; C, the GH4738 alloy bar blank is put into a gas furnace to be heated along with the furnace, flat anvil upsetting is conducted through a forging hammer after heat preservation, and a GH4738 alloy disc forge piece is obtained; and D, the GH4738 alloy disc forge piece is sequentially subjected to solution treatment, stabilizing treatment and secondary aging treatment, and the GH4738 nickel-based high-temperature alloy uniform in grain size and excellent in high-temperature erosion performance is obtained. According to the hot working process, the phenomena of mixed crystals, coarse crystals and the like in a GH4738 high-temperature alloy deformation structure can be avoided, the overall hardness and high-temperature erosion performance of a final forge piece are improved, and meanwhile the yield of the forge piece is increased.

Owner:INNER MONGOLIA UNIV OF TECH

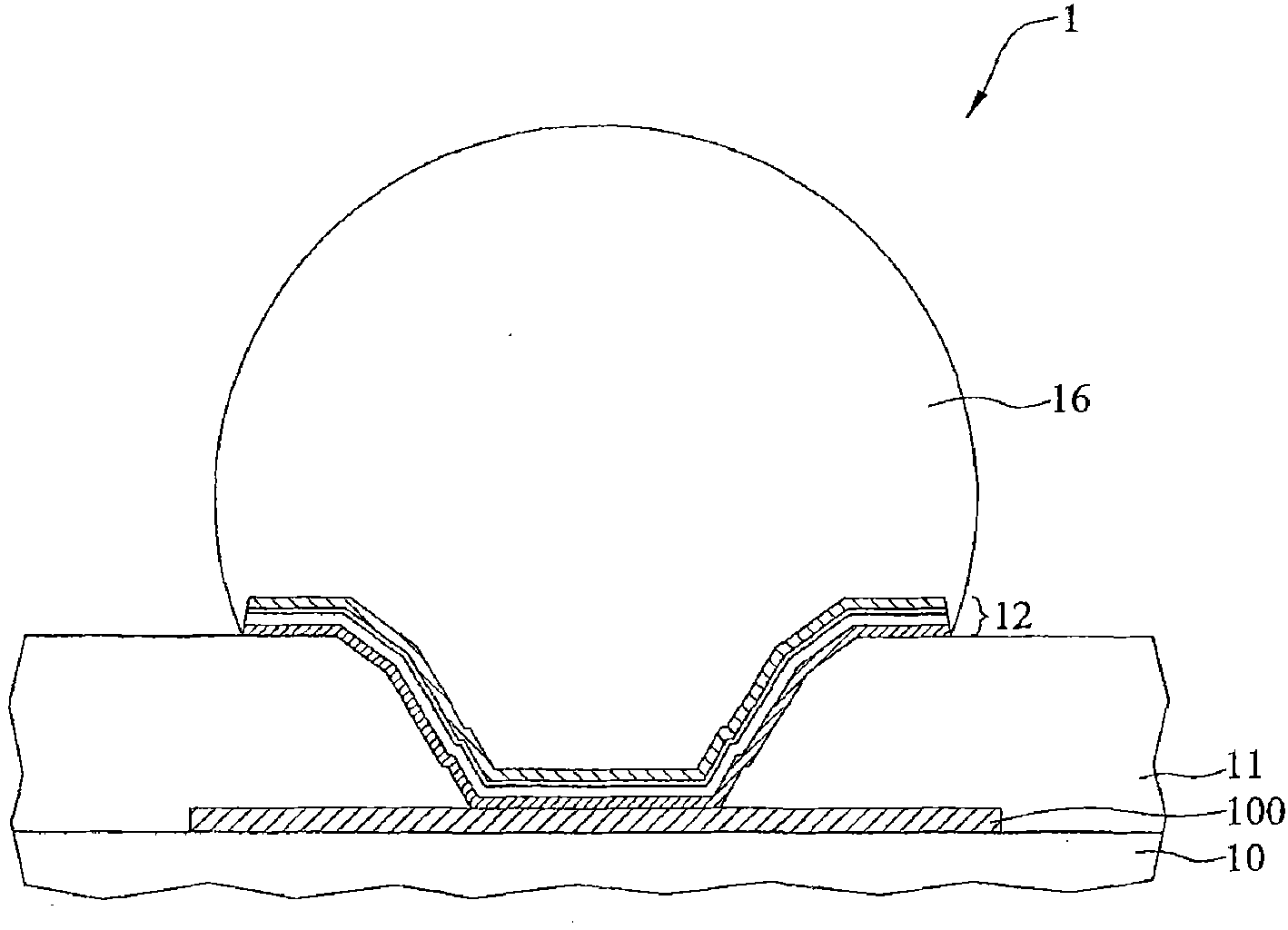

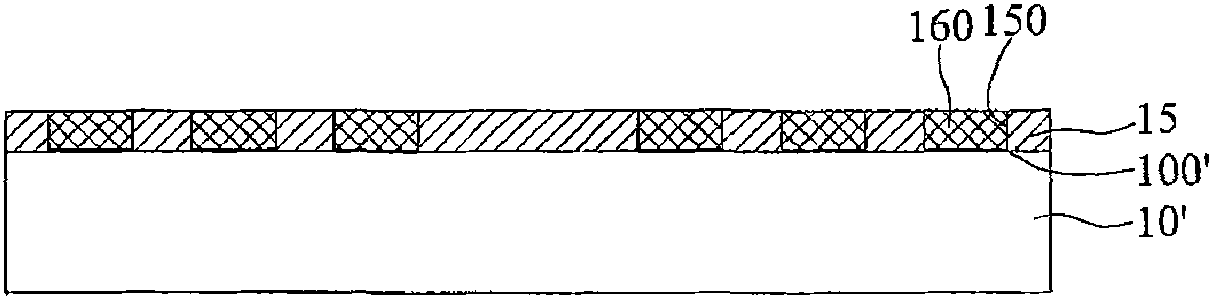

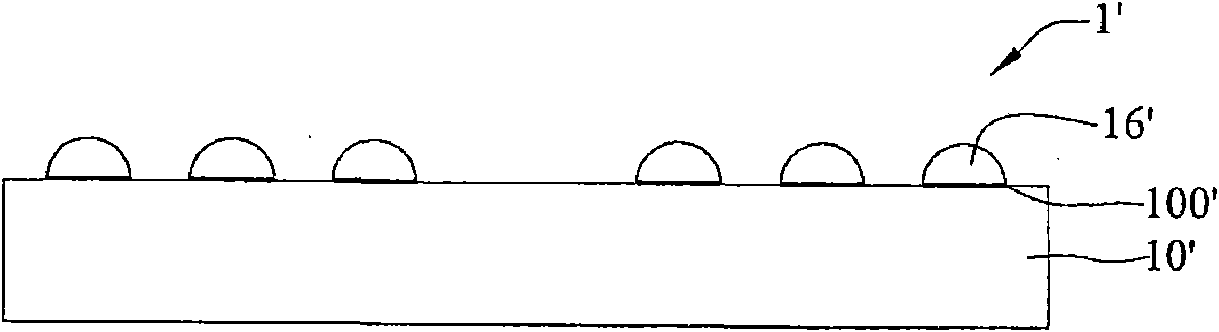

Semiconductor substrate and preparation method thereof

ActiveCN102487049AInhibit sheddingAvoid problems such as crackingSemiconductor/solid-state device detailsSolid-state devicesSolder ballSemiconductor

The invention relates to a semiconductor substrate and a preparation method thereof. The semiconductor substrate comprises a substrate, a first insulating protective layer, a metal layer, a second insulating protective layer, and a solder ball. More particularly, an electrical contact pad is arranged on the surface of the substrate; the first insulating protective layer is arranged on the substrate and enables the electrical contact pad to be exposed; the metal layer is arranged on the exposed electrical contact pad; the second insulating protective layer is arranged on the first insulating protective layer and enables a portion of the metal layer to be exposed; and the solder ball is arranged on the exposed metal layer. Because the second insulating protective layer is covered on a portion of the metal layer, when a temperature test is carried out on the semiconductor substrate, problems that the solder ball drops off or fractures and the like can be solved. Furthermore, the invention also provides a preparation method of the semiconductor substrate.

Owner:SILICONWARE PRECISION IND CO LTD

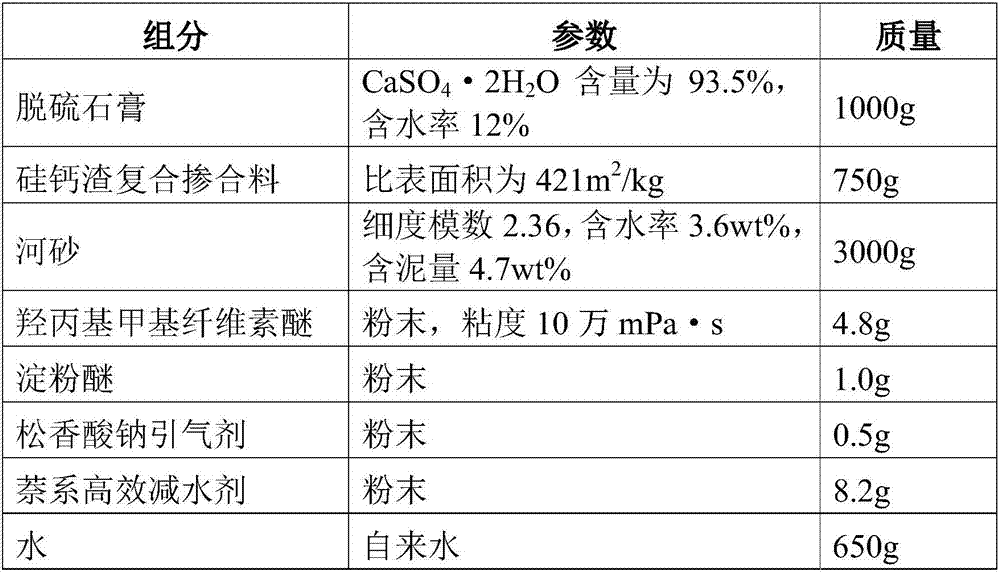

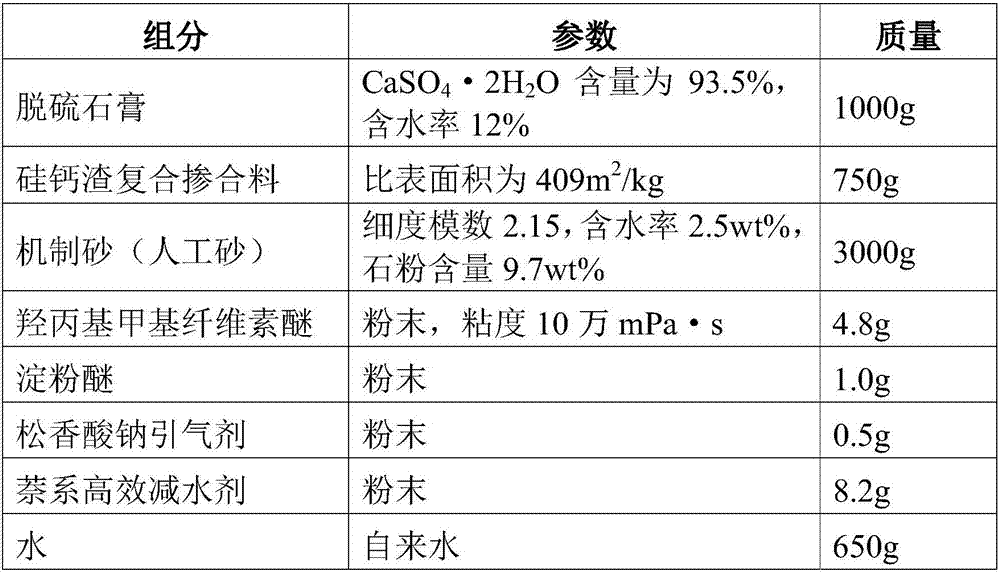

Cement-free desulfurized gypsum plastering mortar and preparation method thereof

The invention provides a cement-free desulfurized gypsum plastering mortar and a preparation method thereof. The cement-free desulfurized gypsum plastering mortar comprises the following components in parts by weight: 15-20 parts of desulfurized gypsum, 15-20 parts of silicon-calcium slag composite admixture, 60-70 parts of aggregate, 0.2-0.3 part of additive and 10-15 parts of water. The silicon-calcium slag composite admixture is composed of the following components in parts by weight: 40-50 parts of silicon-calcium slag, 1-5 parts of desulfurized gypsum, 30-35 parts of fly ash, 15-25 parts of granulated blast-furnace cinder and 0.05-0.08 part of grinding aid. The cement-free desulfurized gypsum plastering mortar is free of any cement and directly adopts the desulfurized gypsum, silicon-calcium slag and other industrial solid wastes as the basic components, so that the prepared cement-free desulfurized gypsum plastering mortar can satisfy requirements in related standards, and does not need to perform drying, calcination, milling and other processes on the desulfurized gypsum, thereby lowering the energy consumption and pollution in the desulfurized gypsum plastering mortar working process.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

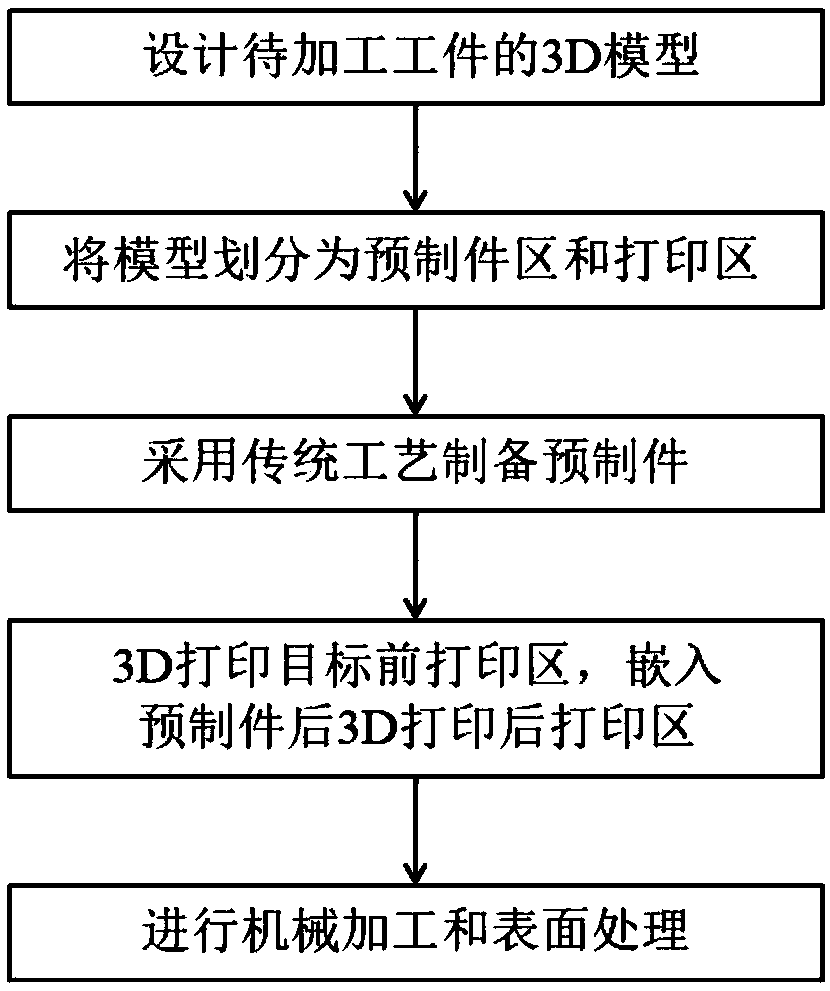

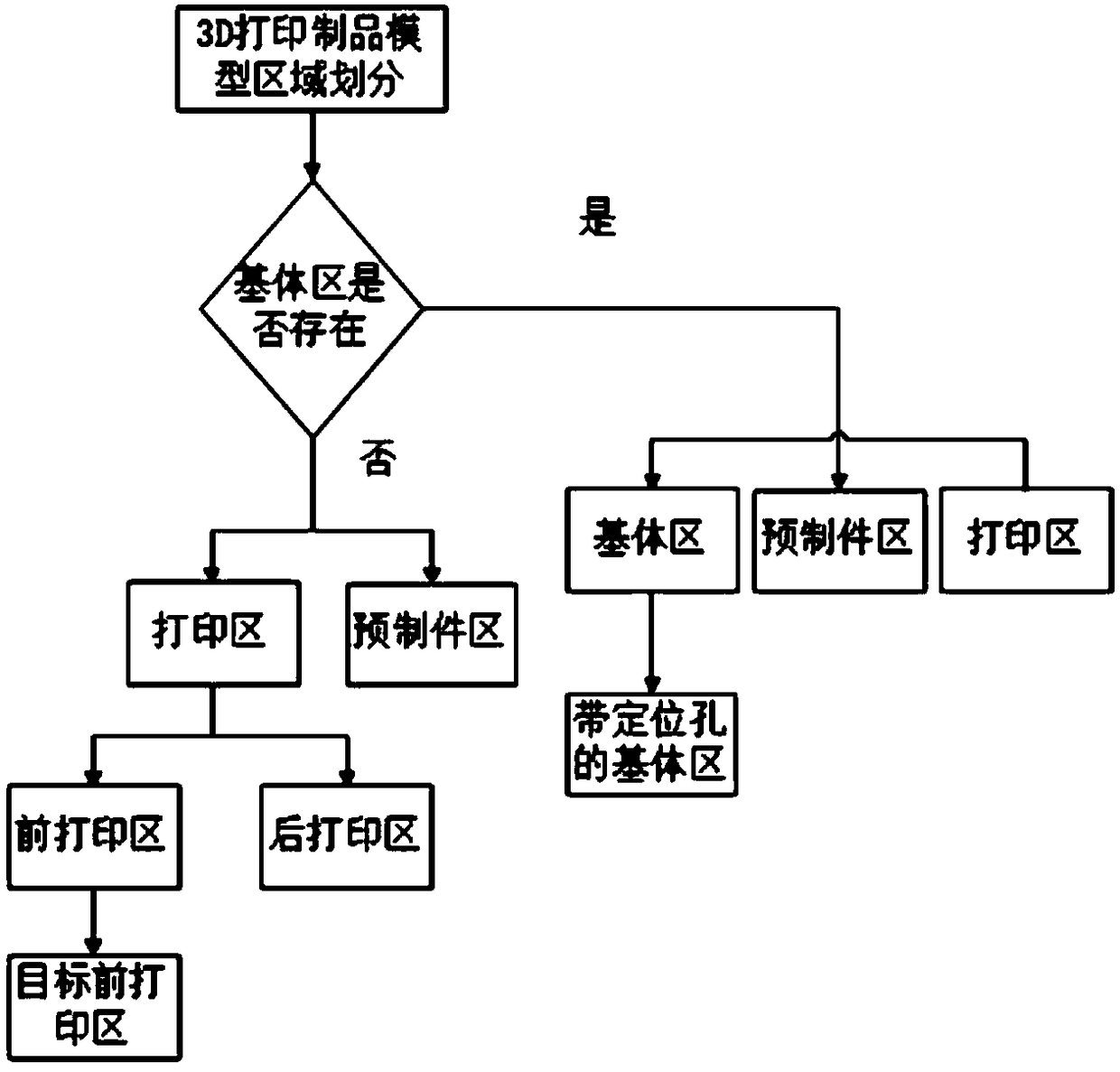

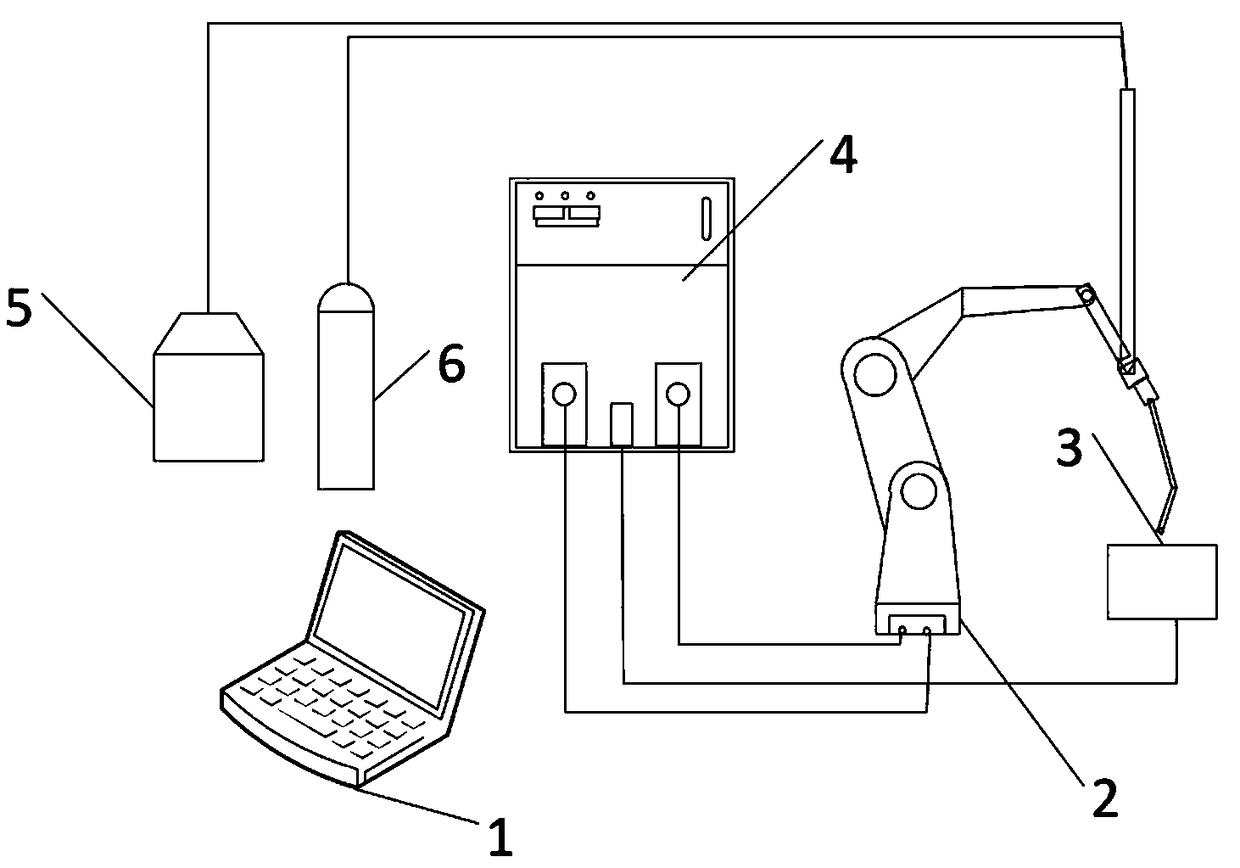

Metal workpiece processing method embedded with preform

ActiveCN109128162AAvoid cloggingAvoid problems such as crackingAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing cost reductionMachining

The invention belongs to the technical field of 3D printing and relates to a metal workpiece processing method embedded with a preform. The method includes the following steps: firstly, a model of theworkpiece is designed, and a proper internal pipe is designed; then the model is divided into a preform area and a printing area, and the preform is prepared by traditional technology. 3D printing isadopted to process a pre-printing area of the target, and a post-printing area is processed after the perform is embedded; at last, the workpiece with a complex inner pipe and / or a complex local areais obtained by mechanical processing and surface treatment. The invention adopts the traditional processing technology to preset the internal pipeline in advance, thus avoiding the problems of blockage and cracking of the internal pipeline, etc. The local complex area of the mould is prepared by the traditional machining technology through the way of preform, which not only ensures the manufacturing precision of the mould, but also optimizes the performance of the local area. In addition, the 3D printing method of the invention has a wide range and good adaptability. The manufacturing cost can be effectively reduced and the production efficiency can be improved by partition manufacturing.

Owner:HUAZHONG UNIV OF SCI & TECH

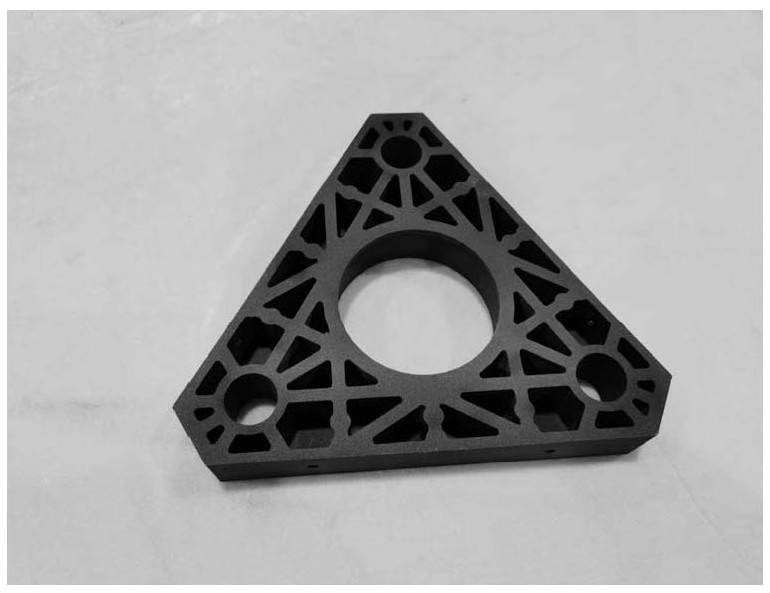

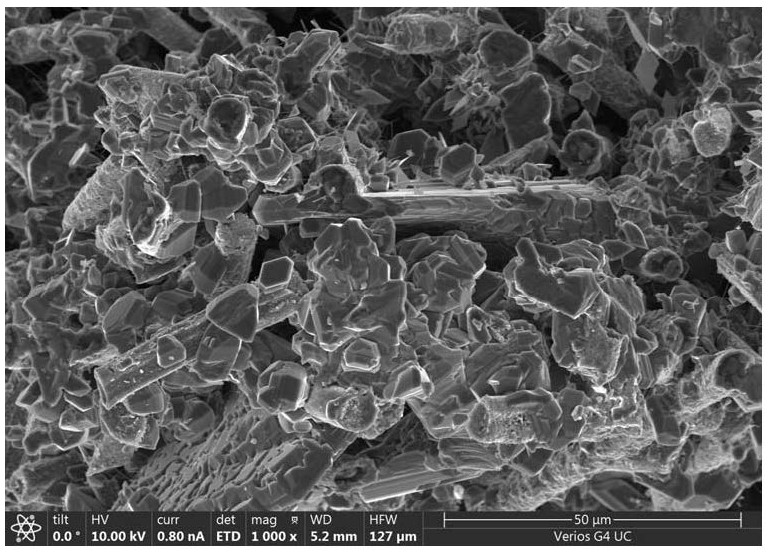

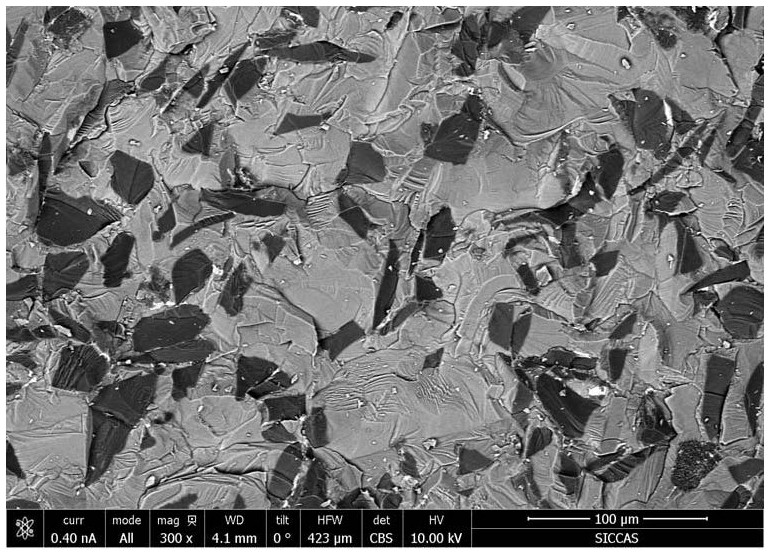

Preparation method of laser 3D-printed complex-configuration silicon carbide composite part

ActiveCN112624777AImprove performanceSave on high costsAdditive manufacturing apparatusCarbide siliconFiber

The invention discloses a preparation method of a laser 3D-printed complex-configuration silicon carbide composite part. The preparation method comprises the following steps that (1) preparing composite raw powder for laser 3D printing, wherein the composite raw powder comprises, by volume percent, 10-70% of chopped carbon fibers, 20-70% of silicon carbide, 20-50% of organic resin with a carbon residue rate larger than 35%, and 5-20% of carbon black; (2) molding the composite raw powder into a silicon carbide composite biscuit with a complex configuration by adopting a laser 3D printing method; (3) degreasing the biscuit in a vacuum atmosphere to crack and carbonize the organic resin and form a degreased biscuit completely composed of inorganic matters; and (4) carrying out liquid-phase reaction siliconizing on the degreased biscuit in a vacuum environment to obtain the laser 3D-printed complex-configuration silicon carbide composite part.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

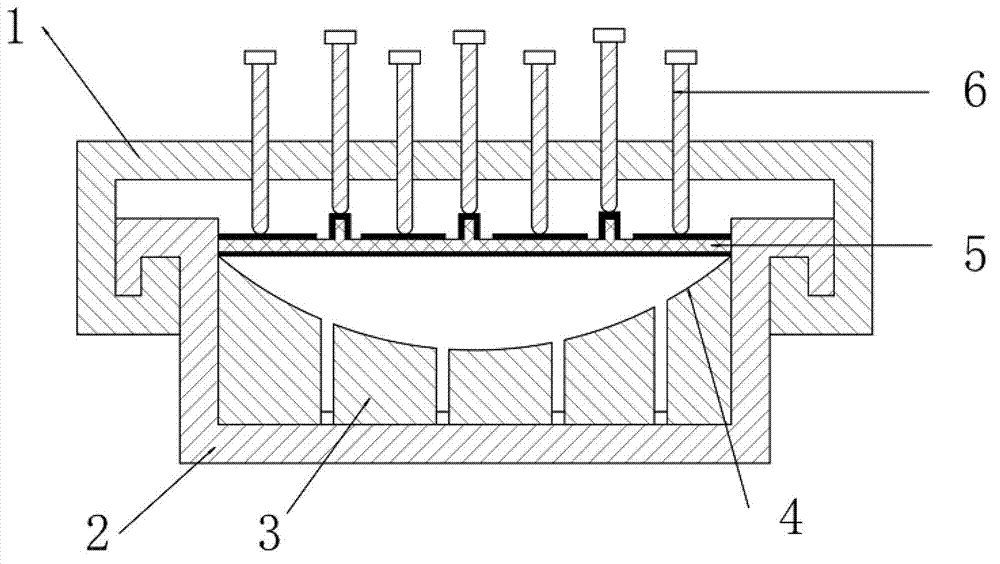

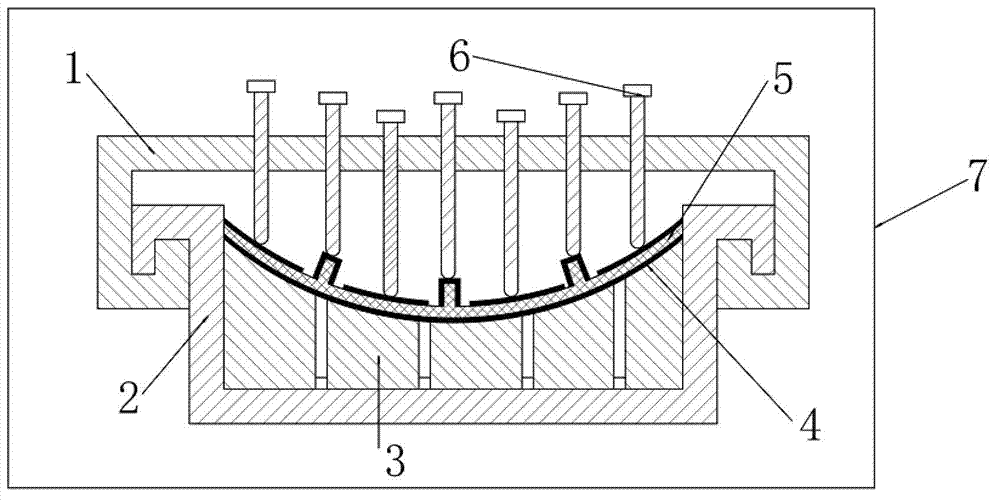

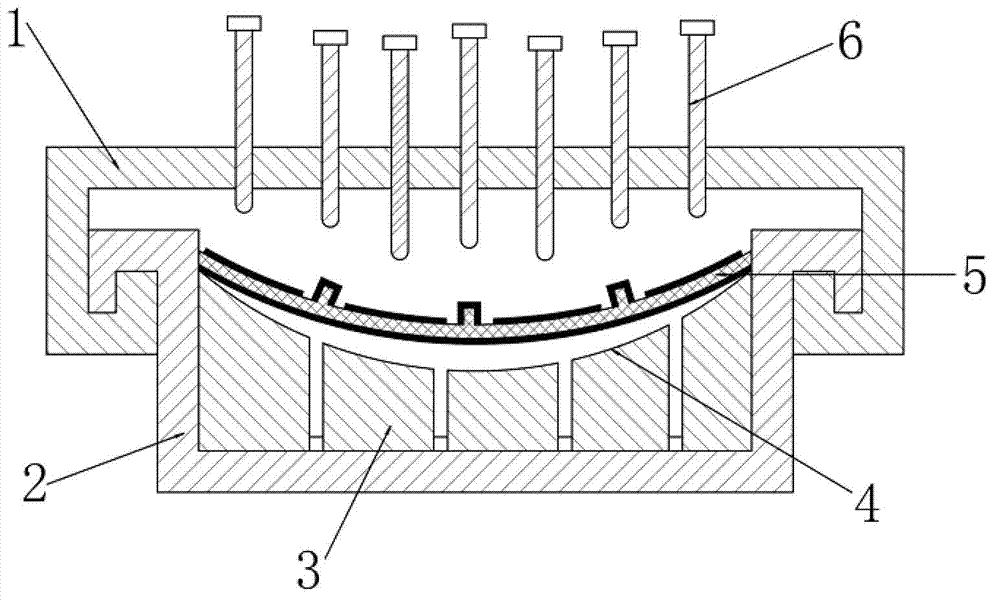

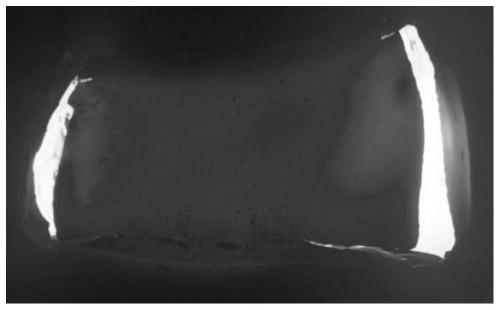

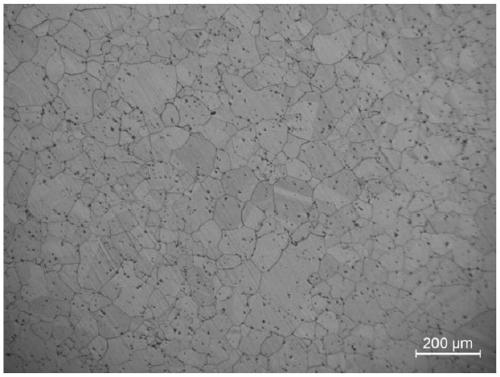

Age forming method and mould for aluminum lithium alloy welding structural wallboard

InactiveCN103194699ARealize formingAvoid problems such as crackingStress relaxationUltimate tensile strength

The invention relates to an age forming method and mould for aluminum lithium alloy welding structural wallboard and relates to the formation of integral aluminum lithium alloy welding structural wallboards and satisfied T8 state requirements on mechanical property and fracture toughness. The method is characterized in that a synchronous continuous heating and pressurizing method is utilized so that the integral aluminum lithium alloy welding structural wallboard has a stress age forming effect, so as to separate out a strengthening phase, the performances of strength and fracture toughness of the integral wallboard are improved, and moreover, the integral aluminum lithium alloy welding structural wallboard has stress relaxation and permanently deforms accordingly. The wallboard is prepared according to the following steps: 1, designing a forming mould shape; 2, clamping parts; 3, age forming; and 4, local correcting. The forming method provided by the invention has the characteristics of simple forming process, convenience in operation and good repeatability; a problem that the aluminum lithium alloy cannot be easily form a T8 state is effectively solved; and moreover, by utilizing the method, the forming precision of the integral wallboard can be improved, and the production period is shortened.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Smelting preparation method of large-sized titanium-aluminum intermetallic ingot

The invention provides a smelting preparation method of a large-sized titanium-aluminum intermetallic ingot. The method comprises the following steps: smelting raw materials in a cold crucible vacuum induction suspension smelting furnace for multiple times; repeatedly pouring into a relatively large-sized ingot mold; and connecting by means of the diffusion effect between liquid-state molten metal and solidified alloy in the ingot mold to obtain a large-sized ingot. According to the method, an induction suspension smelting technology is sufficiently utilized to prepare the alloy with uniform ingredients and high purity; the limitation of the induction suspension smelting technology for volumes of raw materials can be overcome, and the large-sized alloy ingot can be prepared by utilizing the diffusion effect between high-temperature liquid-state metal and solid-state metal; molten metal is diluted in the large-diameter ingot mold by means of multiple times of small-amount repeated pouring and is uniformly contracted in the cooling process, so that occurrence of large-sized sinkholes can be avoided. The method is an optimal choice for smelting preparation of large-sized titanium-aluminum intermetallic ingots.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

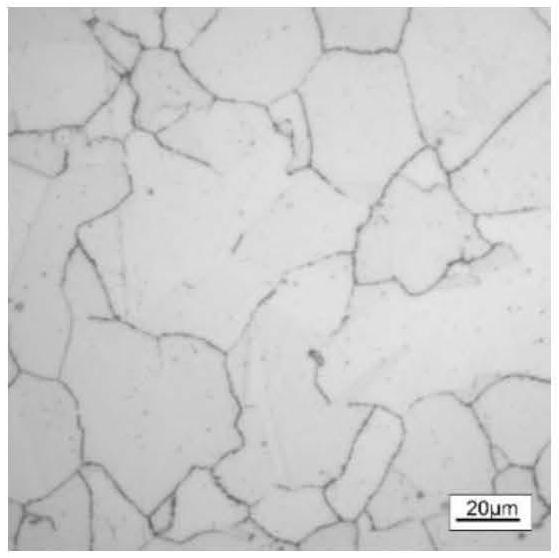

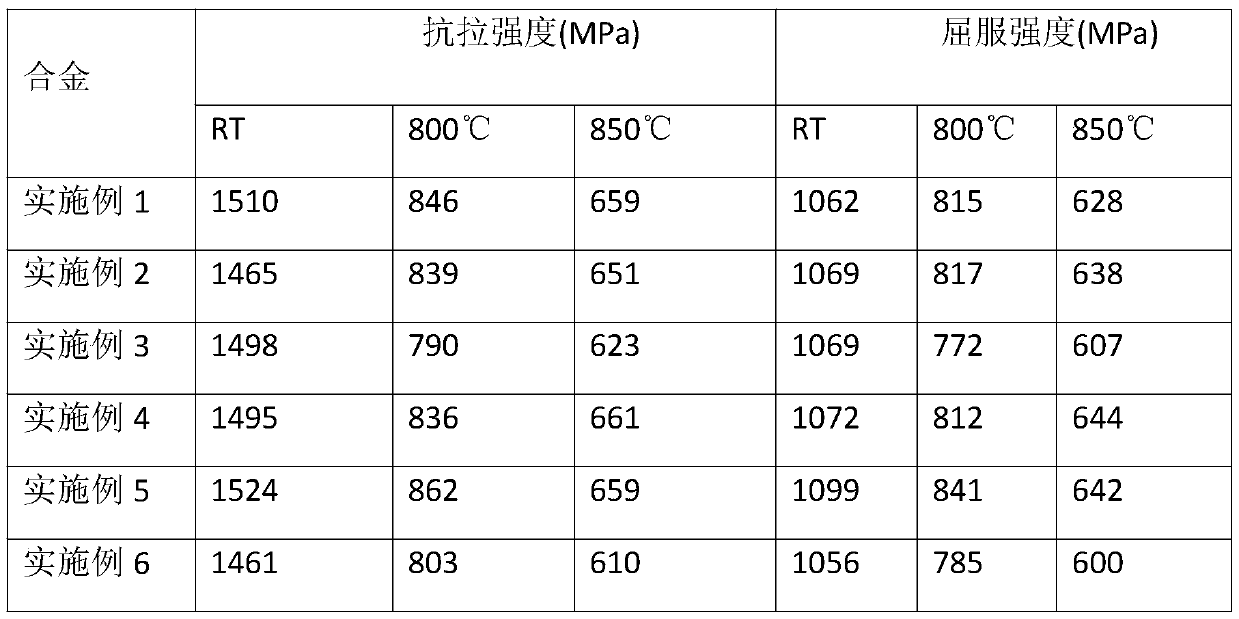

Preparation process for nickel-based high-tungsten polycrystalline high-temperature alloy

The invention relates to a preparation process for a nickel-based high-tungsten polycrystalline high-temperature alloy. The preparation process comprises the following steps that alloy smelting is carried out, specifically, the following components of, in percentage by mass, 15%-18% of Cr, 15%-20% of Co, 0.5%-1.5% of Ti, 3.5%-4.5% of Al, 7.0%-8.5% of W, less than or equal to 0.5% of Si, less thanor equal to 0.5% of Mn, 0.5%-1.5% of Nb, 0.03%-0.08% of C, and the balance Ni are smelted under the vacuum degree of 0.3-0.5 Pa and the protection of argon, and then refining is carried out by adopting an electroslag remelting process to obtain a ingot casting; then hammer cogging is carried out; high-temperature rolling is carried out; and final heat treatment is carried out. According to the preparation process, the alloy is completely recrystallized after being subjected to heat treatment, the grain size of the alloy is 30-50 mm, Ni3Al phases are dispersedly distributed in a crystal, the volume fraction of the Ni3Al phases is not lower than 35%, and the yield strength of the alloy is not lower than 700 MPa under the condition of 850 DEG C.

Owner:CHINA HUANENG GRP CO LTD +1

Forming process of large conic roller blank

InactiveCN101020199AGood tissue densityImprove processing efficiencyExtrusion diesExtrusion control devicesEngineeringForming processes

The present invention discloses forming process of large conic roller blank, and belongs to the field of cold extrusion forming technology. The forming process includes the steps of: cutting the metal rod into the material sections in required size, external grinding to required size, extruding in an extruder at pressure of 200-800 tons, and pushing out the extruded large conic roller blank. The forming process is superior to turning process, and has high steel material utilization rate, high production efficiency, improved material structure and other advantages.

Owner:王建昌

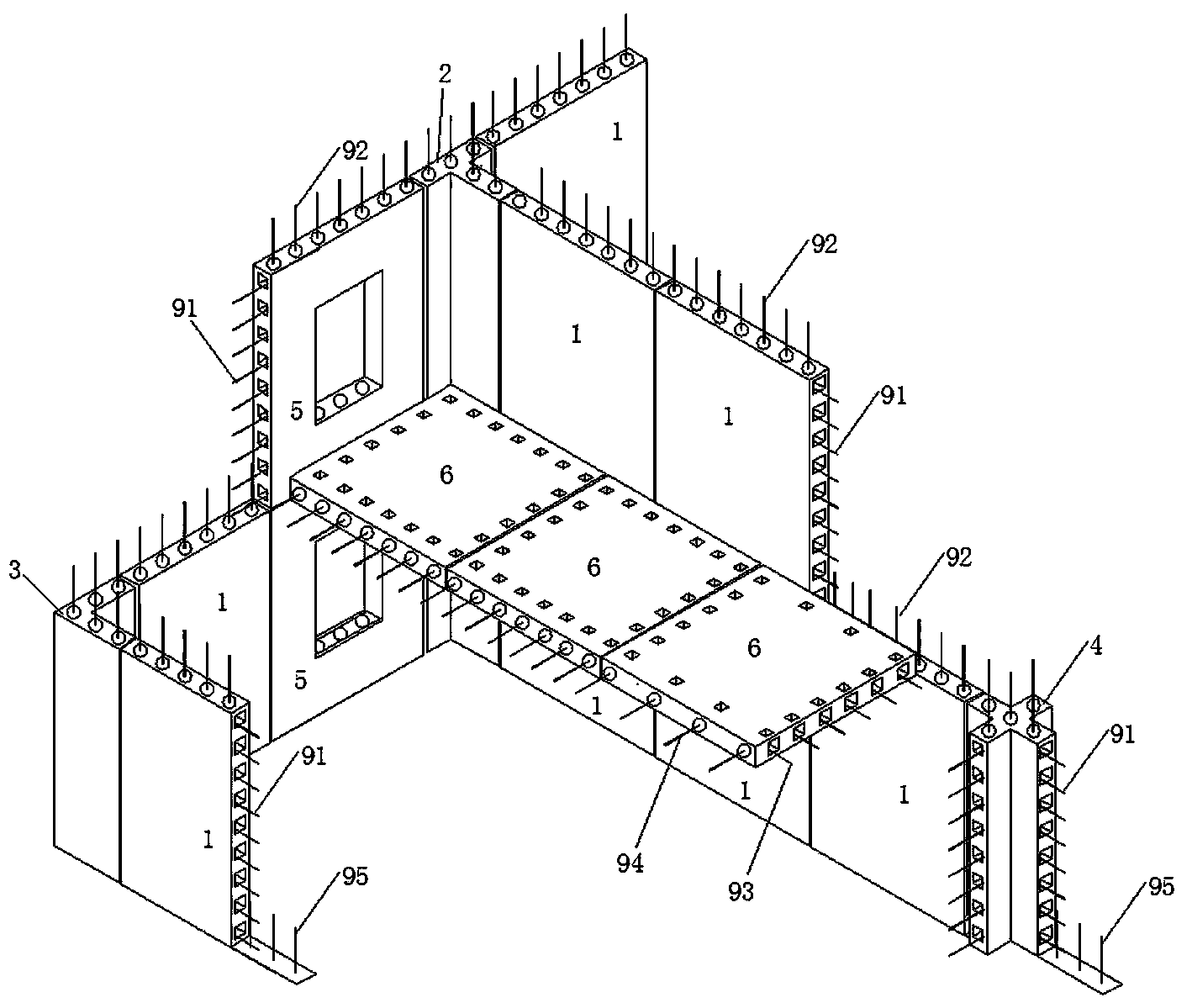

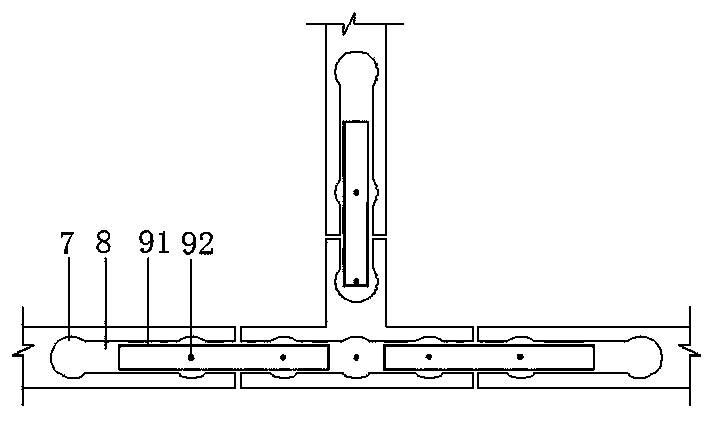

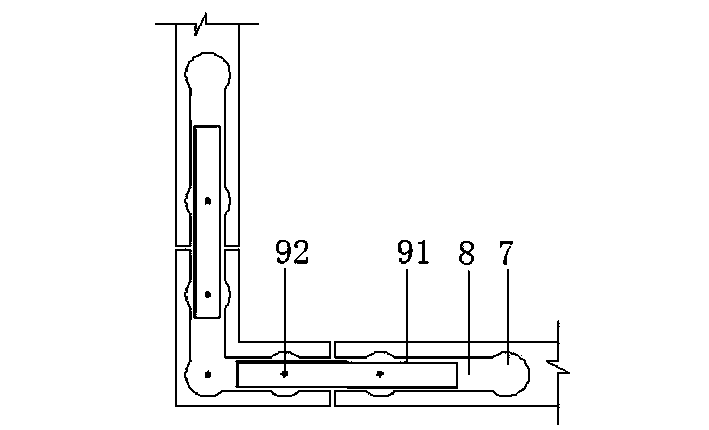

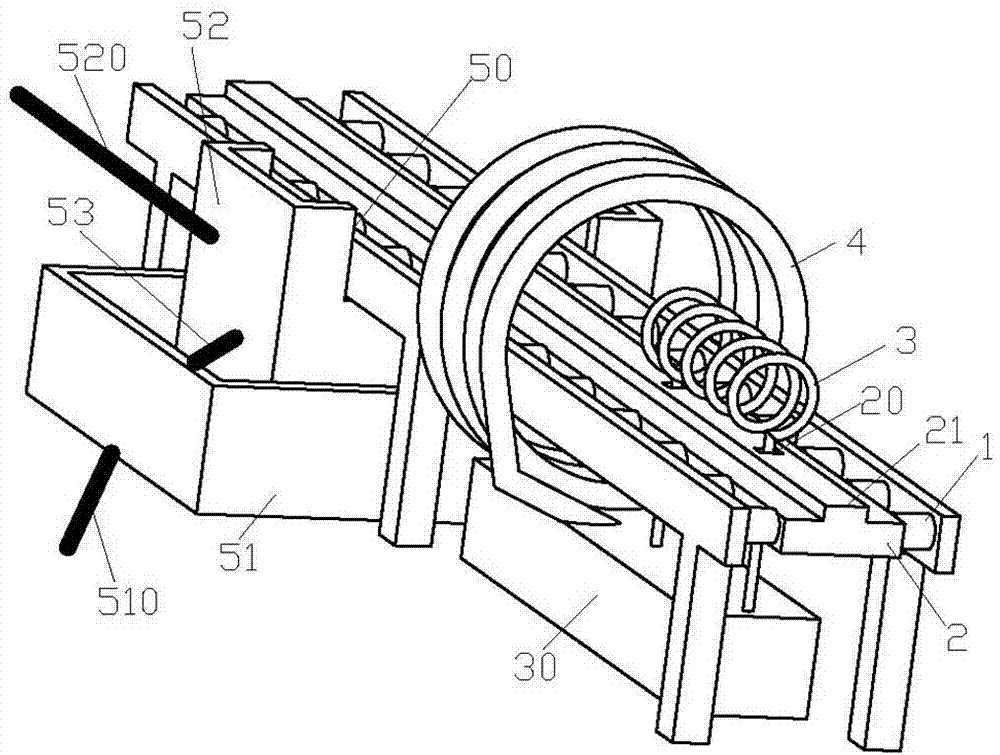

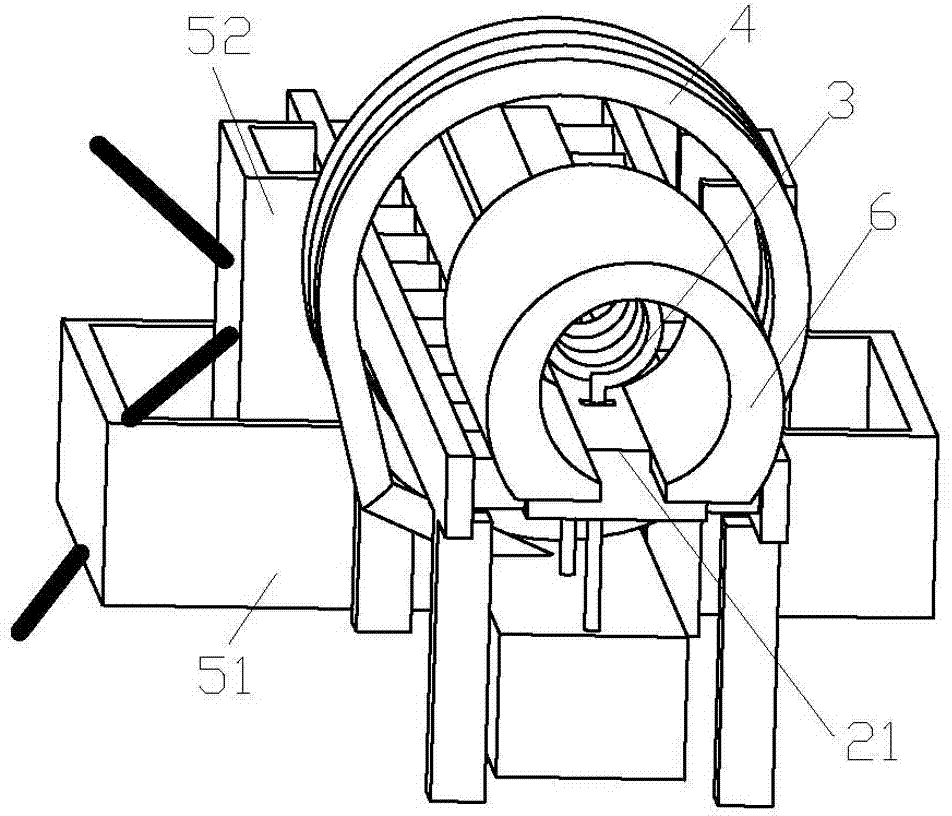

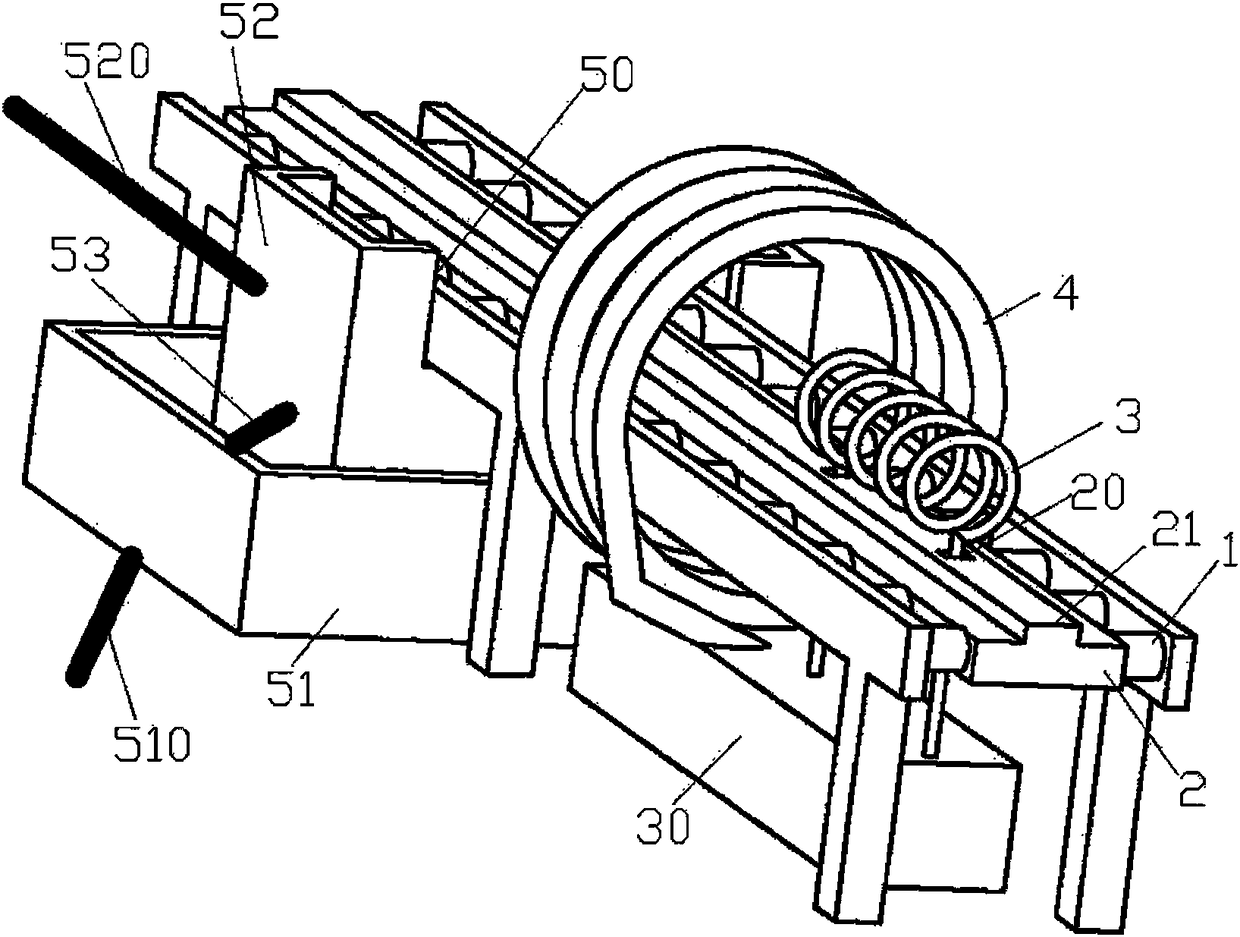

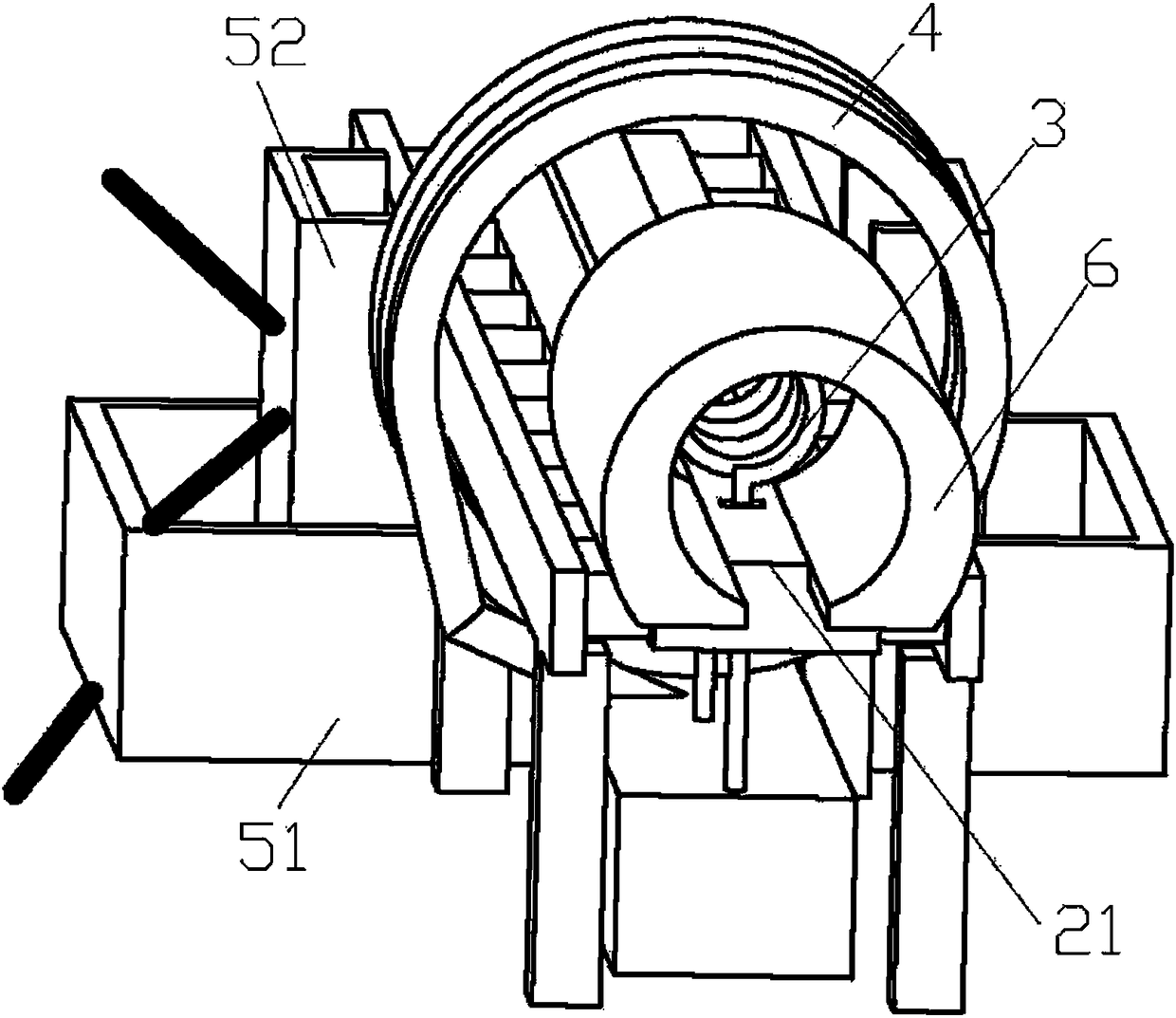

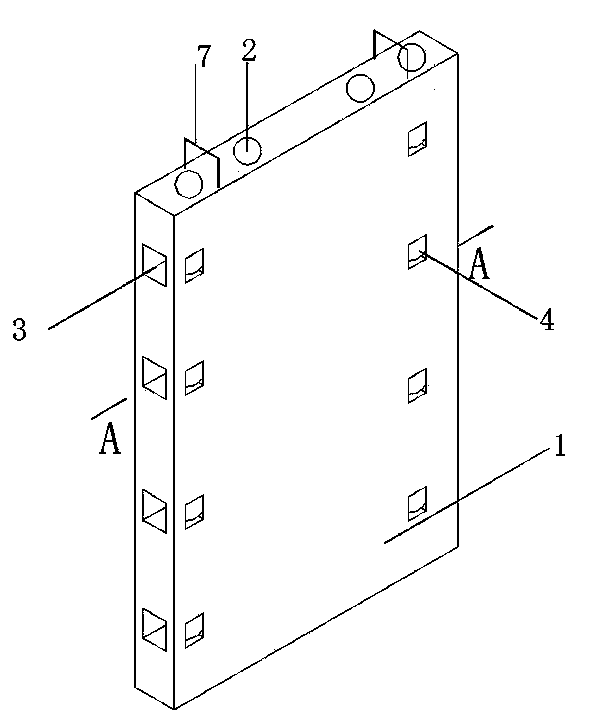

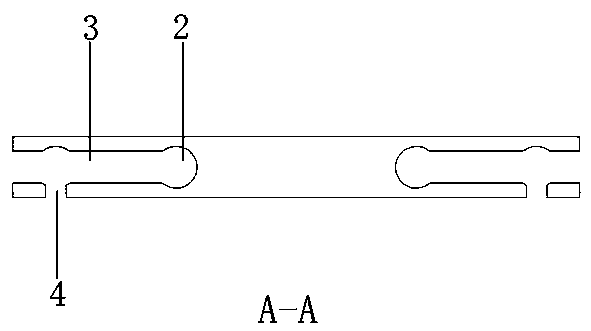

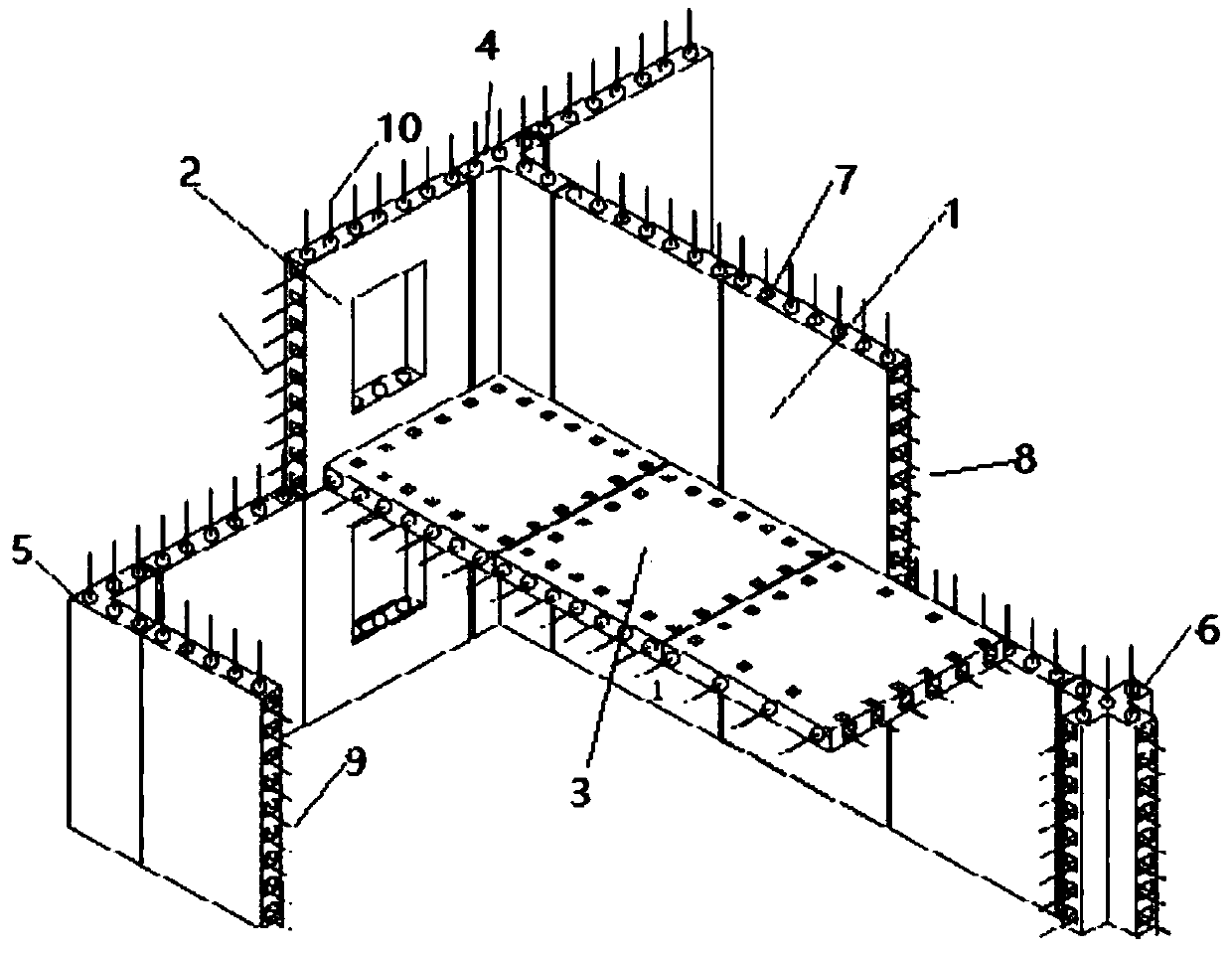

Assembled monolithic shear wall building structure and construction method thereof

InactiveCN109594649AEasy seam connectionReliable seam connectionWallsBuilding material handlingTransverse grooveEngineering

The invention provides an assembled monolithic shear wall building structure and a construction method thereof. The assembled monolithic shear wall building structure comprises prefabricated walls (1)without windows, prefabricated walls (2) with windows, floor boards (3), first wall columns (4), second wall columns (5) and third wall columns (6), wherein each prefabricated wall (2) with windows comprises a window reserving frame, window reserving frame beams and walls on two sides of the window reserving frame; a plurality of parallel full-length connecting vertical holes (7) are formed in the prefabricated walls (1) without windows, the prefabricated walls (2) with windows, the floor boards (3), the first wall columns (4), the second wall columns (5) and the third wall columns (6) in theheight direction, and a plurality of full-length transverse grooves (8) are formed in the width direction; transverse main reinforcements (9) are arranged in the full-length transverse grooves (8), and vertical main reinforcements (10) are arranged in the full-length connecting vertical holes (7). The assembled monolithic shear wall building structure has the characteristics of high constructionspeed, reliable quality and good anti-seismic property.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Attapulgite binder for light strips used for building walls

The invention discloses an attapulgite binder for light strips used for building walls. The binder is composed of the following raw materials by weight parts: 120-150 parts of 32.5 rapid-hardening aluminum sulfate cement, 10-15 parts of copolymer rubber powder of styrene and butadiene, 100-150 parts of quartz sand, 4-6 parts of vegetable fibers, 3-5 parts of alum stone powder, 4-8 parts of limestone powder, 15-20 parts of instant powdered sodium silicate, 5-10 parts of dolomite powder, 10-15 parts of the attapulgite and 4-8 parts of slag powder. The attapulgite binder for the light strips used for the building walls is strong in bond strength, and can reduce layering and spalling, guarantee engineering quality, prevent problems of hollowing, cracking and other problems after a long-term use, and thus improve endurance. The binder provided by the invention is pre-mixed in a dry way, is stable in quality, can be added with a proper amount of water to stir for using, and thus is simple and convenient to construct. The binder effectively utilizes the slag powder and other waste materials, is free of poisonous and harmful additives, totally meets requirements of environmental protection, and is safe and non-polluted.

Owner:CHIZHOU BANZHU TECH

Combined wall plate

ActiveCN107268922AEasy to installExtended service lifeCovering/liningsPhotovoltaic energy generationKeelEngineering

The invention discloses a combined wall plate comprising a main keel, lock catch assemblies, wall plate base materials and sealing strip assemblies. The main keel is transversely mounted on a wall body and provided with the multiple lock catch assemblies. The wall plate base materials are fixed to the main keel through the lock catch assemblies, and the lock catch assemblies are symmetrically provided with locking buckles and internally provided with driving assemblies. The driving assemblies drive the locking buckles to horizontally move, first clamping grooves are formed in the two ends of the wall plate base materials and matched with the locking buckles, and the sealing strip assemblies are arranged between the wall plate base materials. Connecting buckles are arranged on the lock catch assemblies, and the sealing strip assemblies are matched with the connecting buckles. Mounting is convenient, connecting between wall plates is firm, the two adjacent wall plates are locked through the lock catch assemblies, the problem that connecting seams crack due to wall plate deformation can be avoided, the connecting gap between the wall plates is sealed, and the service life of the wall plate is prolonged.

Owner:嘉兴天美环保集成墙面有限公司

Segregation-enhanced type deforming high-temperature alloy and preparation process thereof

The invention provides a segregation-enhanced type deforming high-temperature alloy and a preparation process thereof. The segregation-enhanced type deforming high-temperature alloy is prepared from components in percent by mass including 0.03%-0.07% of C, 11%-14% of Cr, 10%-15% of Co, smaller than or equal to 0.5% of Mn, smaller than or equal to 0.5% of Si, 1.5%-2.0% of Nb, 2.5%-3.5% of Mo, 1.5%-3.0% of W, 2.0%-3.0% of Ti, 4.0%-4.5% of Al, smaller than or equal to 0.1% of Ta, smaller than or equal to 0.003% of B, smaller than or equal to 0.03% of Zr and the balance Ni. It is guaranteed that the alloy has good high-temperature strength in a segregation enhancing manner, meanwhile, the contents and the relative proportions of the elements such as Cr, W, Mo, Al and Ti are controlled, and itis guaranteed that the alloy has good structure stability and avoids segregation of harmful phases in the high-temperature service period. The alloy has good structure stability, and the grain size ofthe alloy is 50 micrometers-70 micrometers. Meanwhile, the alloy has excellent strength performance.

Owner:CHINA HUANENG GRP CO LTD +1

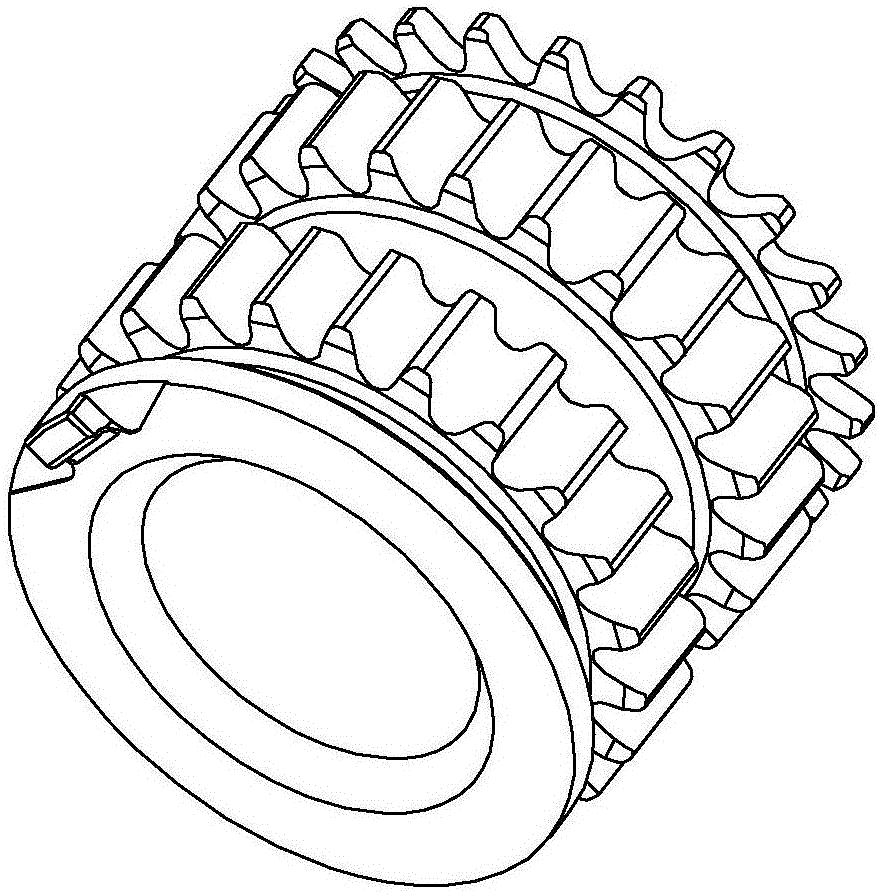

Preparing method for automobile chain wheel

The invention relates to a preparing method for an automobile chain wheel. According to the method, round steel or a hollow pipe material is subjected to a series of treatment such as annealing, shot blasting and saponification of phosphorus, the performance of a blank can be primarily improved through annealing and shot blasting, after an inner layer protection film and an outer layer lubricating film are formed on the surface of the blank through saponification of phosphorus, cold extrusion is conducted, and the problems of blank surface cracking and the like in the cold extrusion process can be solved. After the component appearance meeting the requirement is obtained through the procedures of extrusion, inner hole turning, groove cutting, positioning structure machining and the like, a component is subjected to carburizing and quenching and tempering treatment, the hardness of a workpiece is further improved, and the metallographic structure of the workpiece can meet the QC / T262-1999 requirement. A gear part structure is directly machined in the cold extrusion process. Compared with the prior art, adopted equipment is relatively simple, and the production efficiency is effectively improved. Due to the fact that the hardness of the workpiece is improved step by step in the whole component preparing process, the abrasion of a tool is effectively avoided, and the production cost is reduced.

Owner:QIJING MACHINERY

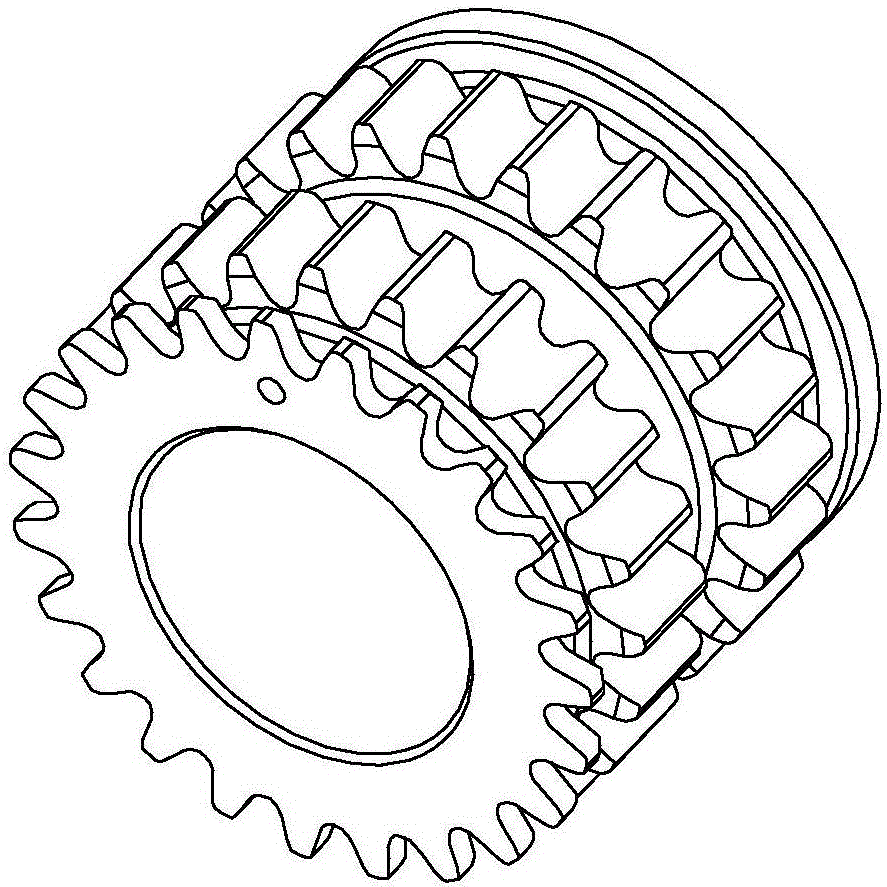

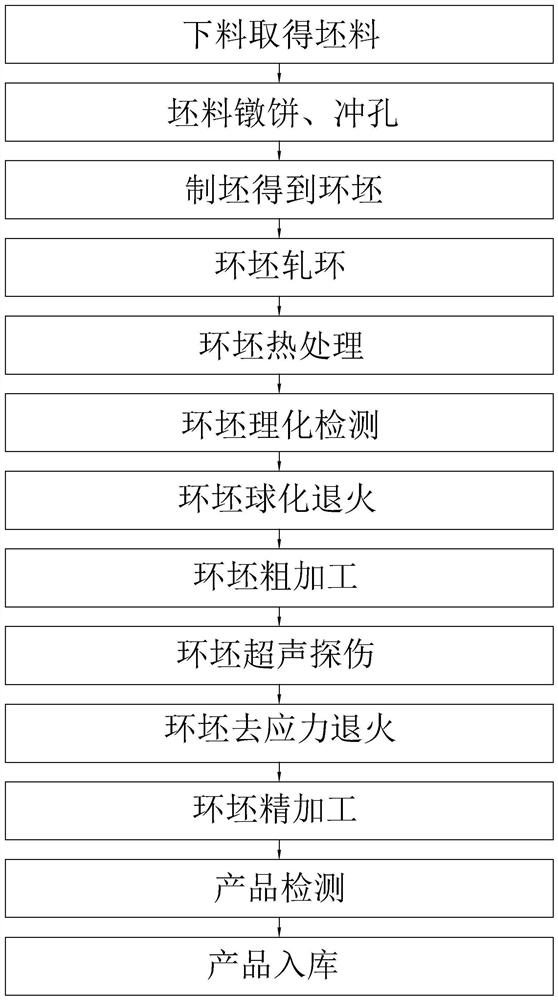

Forming method of large-diameter thin-wall high-barrel type ultrahigh-strength steel D406A ring forging

PendingCN112853079AImprove deformation abilityHigh precisionFurnace typesHeat treatment furnacesPunchingStress relief

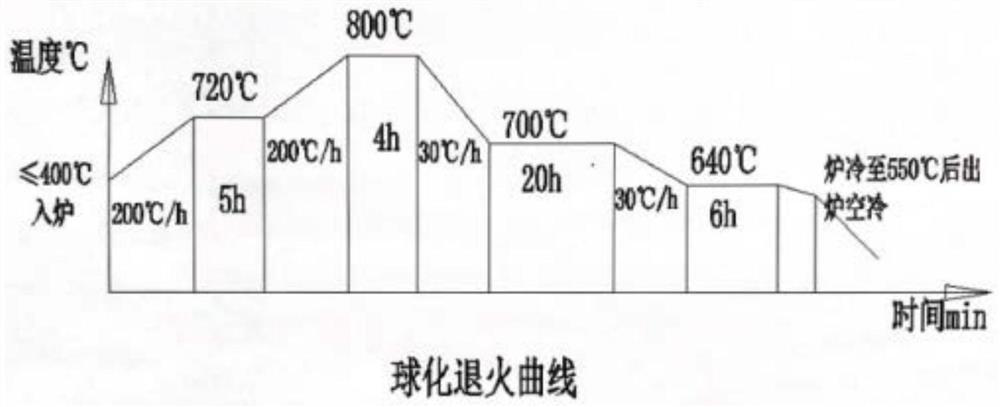

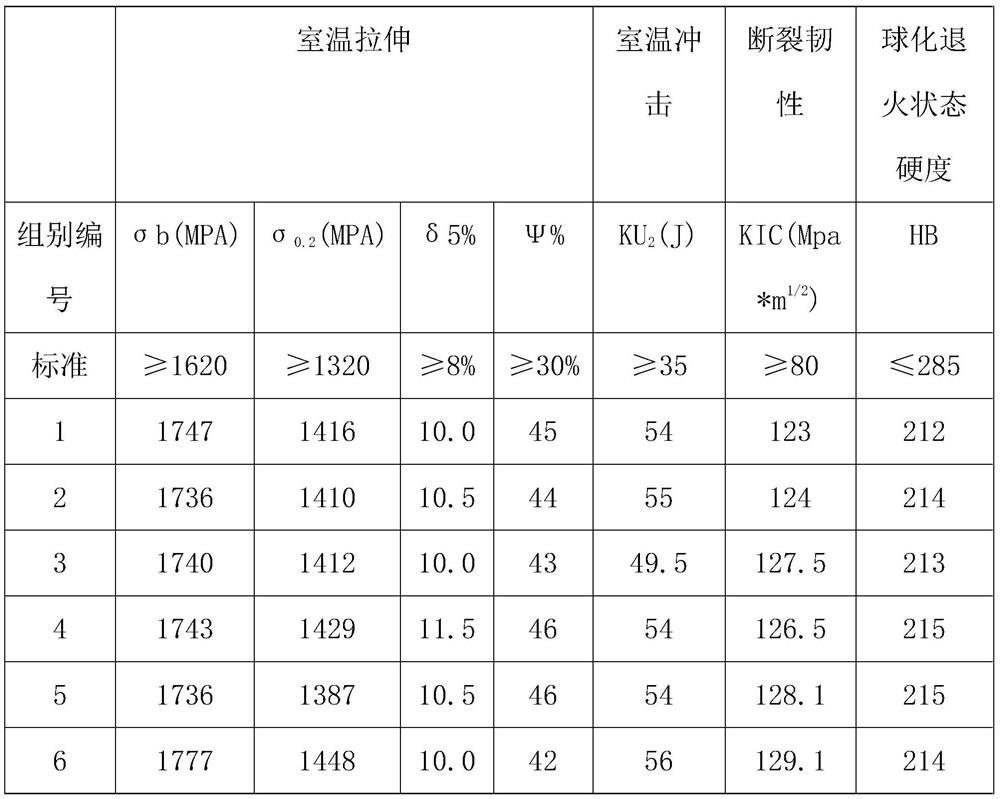

The invention discloses a forming method of a large-diameter thin-wall high-barrel type ultrahigh-strength steel D406A ring forging, and belongs to the technical field of high-strength steel forming. According to the technical scheme, the method is characterized by comprising the following steps that S1, blanking is performed, and a blank is obtained; S2, the blank is upset into a cake, and punching is performed; S3, a ring blank is obtained through blank making; S4, the ring blank is rolled into a ring; S5, heat treatment is performed on the ring blank; S6, physical and chemical detection is performed on the ring blank; S7, spheroidizing annealing is performed on the ring blank; S8, rough machining is performed on the ring blank; S9, ultrasonic flaw detection is performed on the ring blank; S10, stress relief annealing is performed on the ring blank; S11, finish machining is performed on the ring blank. The method has the advantage that the accuracy, the quality stability and the reliability of the ring forging are improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

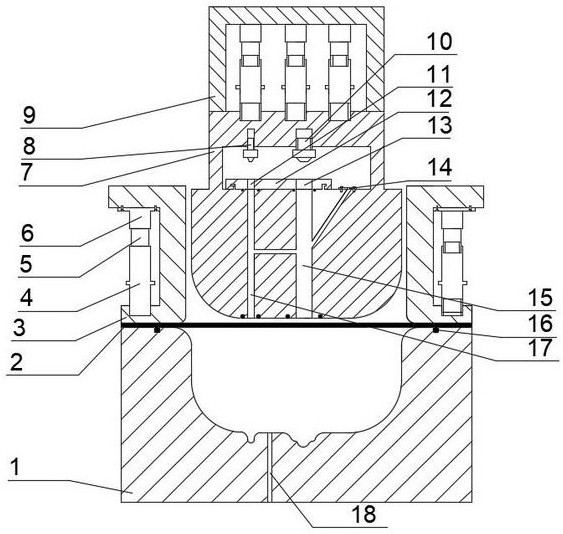

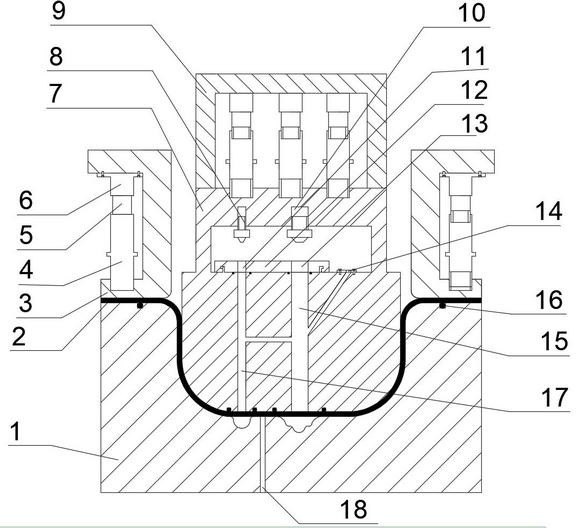

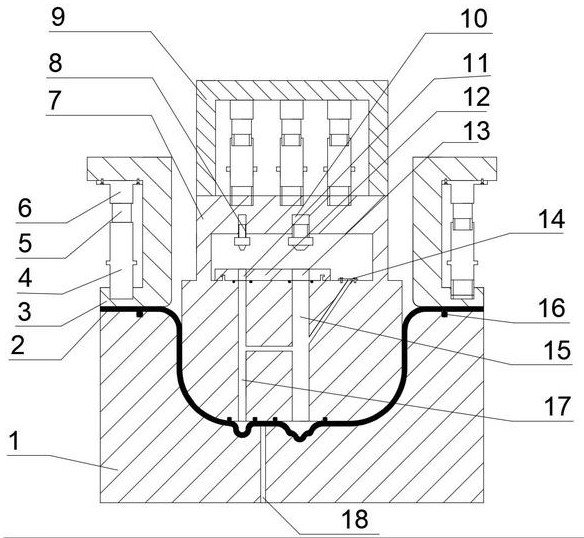

Thin-wall component variable-speed liquid filling-ultrasonic-laser composite forming method and system

ActiveCN114505395AImprove stress statusSimple wayShaping toolsIncreasing energy efficiencyUltrasonic vibrationAerospace

The invention relates to a variable-speed liquid filling-ultrasonic-laser composite forming method and system for a thin-wall component, which is used for forming a metal or composite material ultra-deep cavity complex feature component, forming an ultra-deep cavity feature by utilizing an ultrasonic vibration coupling passive liquid filling forming technology, and forming a complex small feature by utilizing a laser coupling high-speed liquid filling forming technology. According to the method, the forming limit, the forming quality and the complexity of the thin-wall component can be effectively improved, and the defects of cracking, wrinkling and the like in the forming process are reduced. The method has wide application prospects in the high-speed carrying fields of aerospace, automobiles and the like, especially in the aspect of integrated forming of ultra-deep-cavity thin-wall components with multiple complex characteristics, the forming performance of the plate is greatly improved, the blank in the forming field of the ultra-deep-cavity components is filled, the complexity of the formed components is widened, and the forming quality is improved.

Owner:HEBEI UNIV OF TECH

Light board attapulgite binder for building partition walls

The invention discloses a light board attapulgite binder for building partition walls. The binder is composed of the following raw materials: by weight, 120-150 parts of 32.5 rapid hardening aluminum sulfate salt cement, 40-50 parts of pure acrylic emulsion, 4-6 parts of polyvinyl alcohol, 3-4 parts of diethylene glycol, 2-3 parts of hydroxyethyl methyl cellulose, 100-150 parts of silica sand, 4-6 parts of plant fiber, 3-5 parts of alunite powder, 4-8 parts of benzenesulfonyl hydrazide, 5-10 parts of dolomite powder, 10-15 parts of attapulgite, 4-8 parts of furnace slag powder, 1-2 parts of sodium borate, 5-8 parts of triethanolamine, 0.5-1 parts of 3-aminopropyl trimethoxy silane. The light board attapulgite binder for building partition walls has strong adhesion, reduces chances of delamination and spalling, guarantees engineering quality, avoids the problems of hollowing and cracking after long-term usage, and therefore raises the durability.

Owner:ANHUI GUODIAN ENERGY EQUIP ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com