Method for repairing microcrack tip on stainless steel surface by means of nano-particles

A micro-crack and nano-particle technology, applied in the coating process and coating of metal materials, can solve the problems of easy occurrence of thermal cracks, large heat input, shrinkage and deformation, etc., to prolong the service life and achieve uniform and fine grain structure. , the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

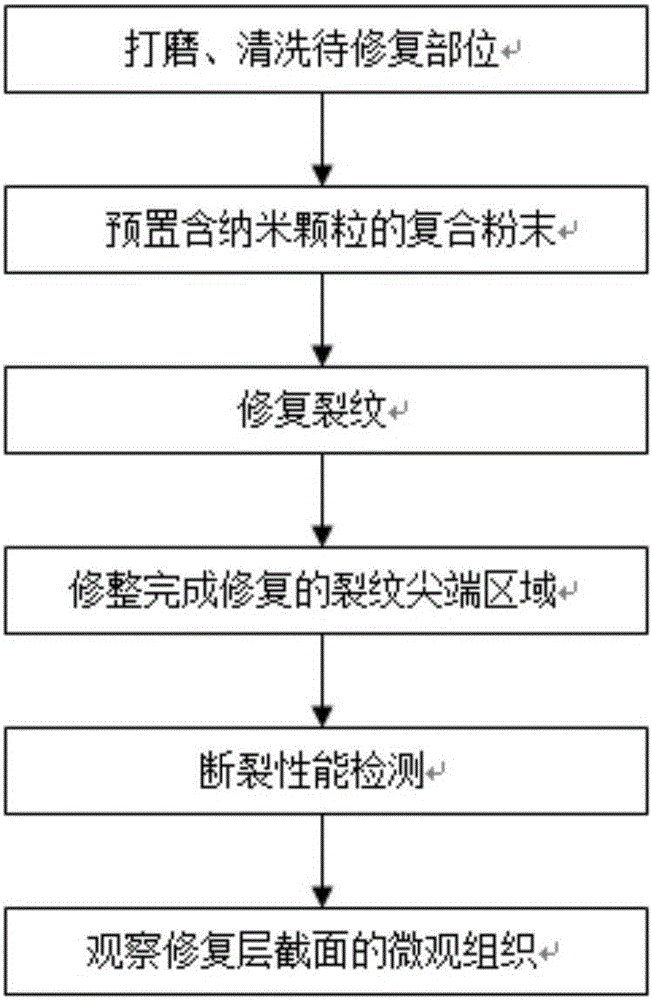

[0022] specific implementation plan

[0023] The present invention is further illustrated below through specific implementation examples.

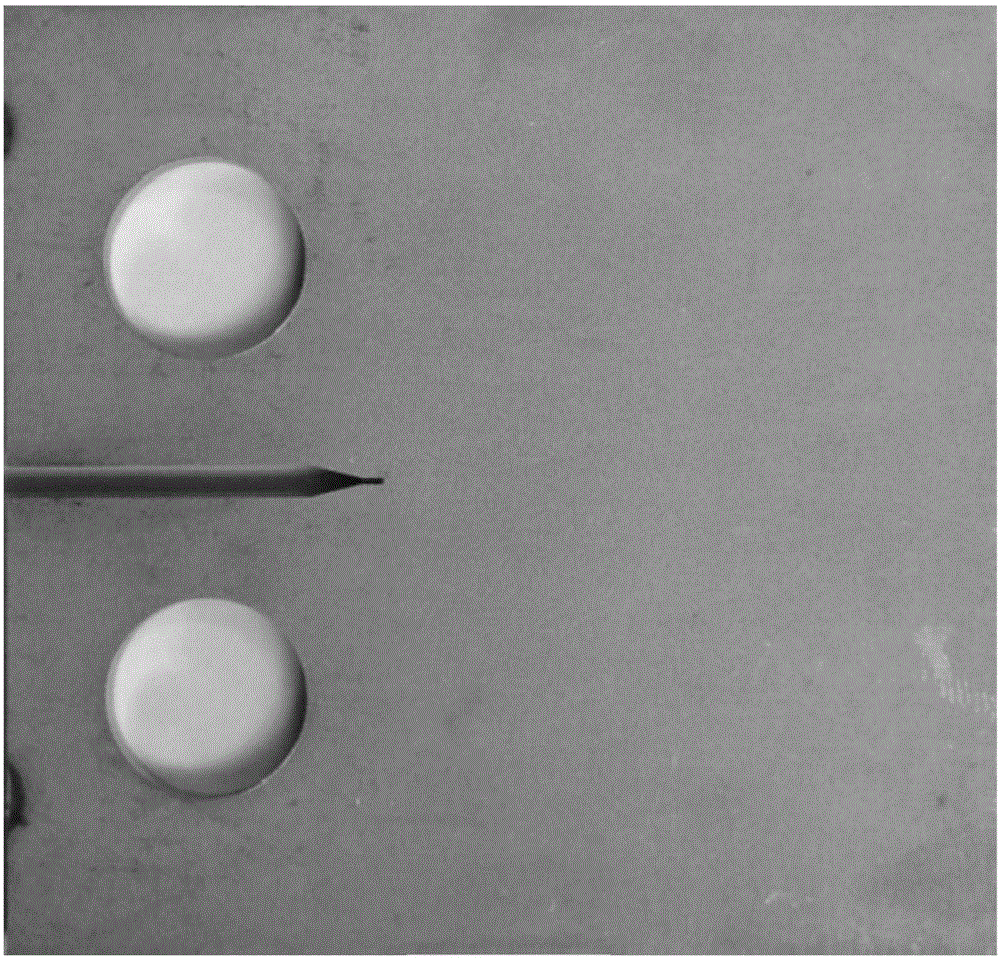

[0024] First, the tip of the tiny crack on the surface of 304 stainless steel is treated, polished with sandpaper, then cleaned with absolute ethanol, and then dried.

[0025] Secondly, blend the composite powder containing nano-WC and micron 304 stainless steel powder with absolute ethanol, and evenly pre-place it on the surface of the base stainless steel. The pre-powder area is about 100mm 2 , the thickness is 1mm, and the mass of the powder is about 2g, which ensures smooth surface and low porosity.

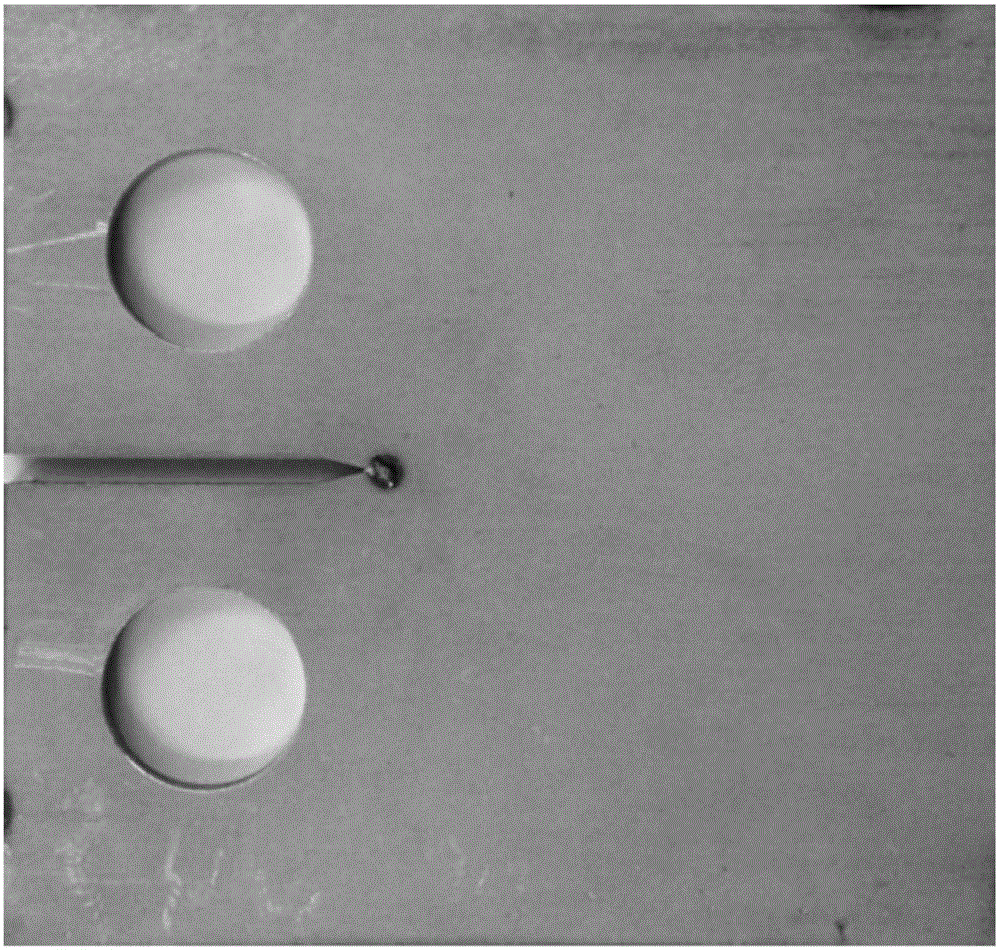

[0026] Then, the high energy density of the laser beam is used to rapidly condense the composite powder and the matrix material, so that the composite powder and the matrix are metallurgically bonded and tightly bonded together, thereby completing the repair of the crack. Finally, remove the excess powder remaining at the tip of the tin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com