Patents

Literature

54results about How to "Improve fracture performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Complex metallographic structured steel and method of manufacturing same

ActiveUS20090098408A1Castability is degradedFormability deterioratesHot-dipping/immersion processesFurnace typesSheet steelYield ratio

A multi-phase steel sheet having microstructure having in combination ferrite, martensite of between 3% and 65% by volume, and at least one microstructure selected from the group consisting of, bainite and retained austenite, and having fine complex precipitates selected from the group of TiC, NbC, TiN, NbN, (Ti.Nb)C, (Ti.Nb)N, and (Ti.Nb)(C.N) particles having at least 50% smaller than 20 nm in size, and physical properties having tensile strength greater than about 780 megapascals and at least one of the properties of elongation greater than about 10%, yield ratio greater than about 70%, and hole expansion ratio greater than about 50%.

Owner:NUCOR CORP

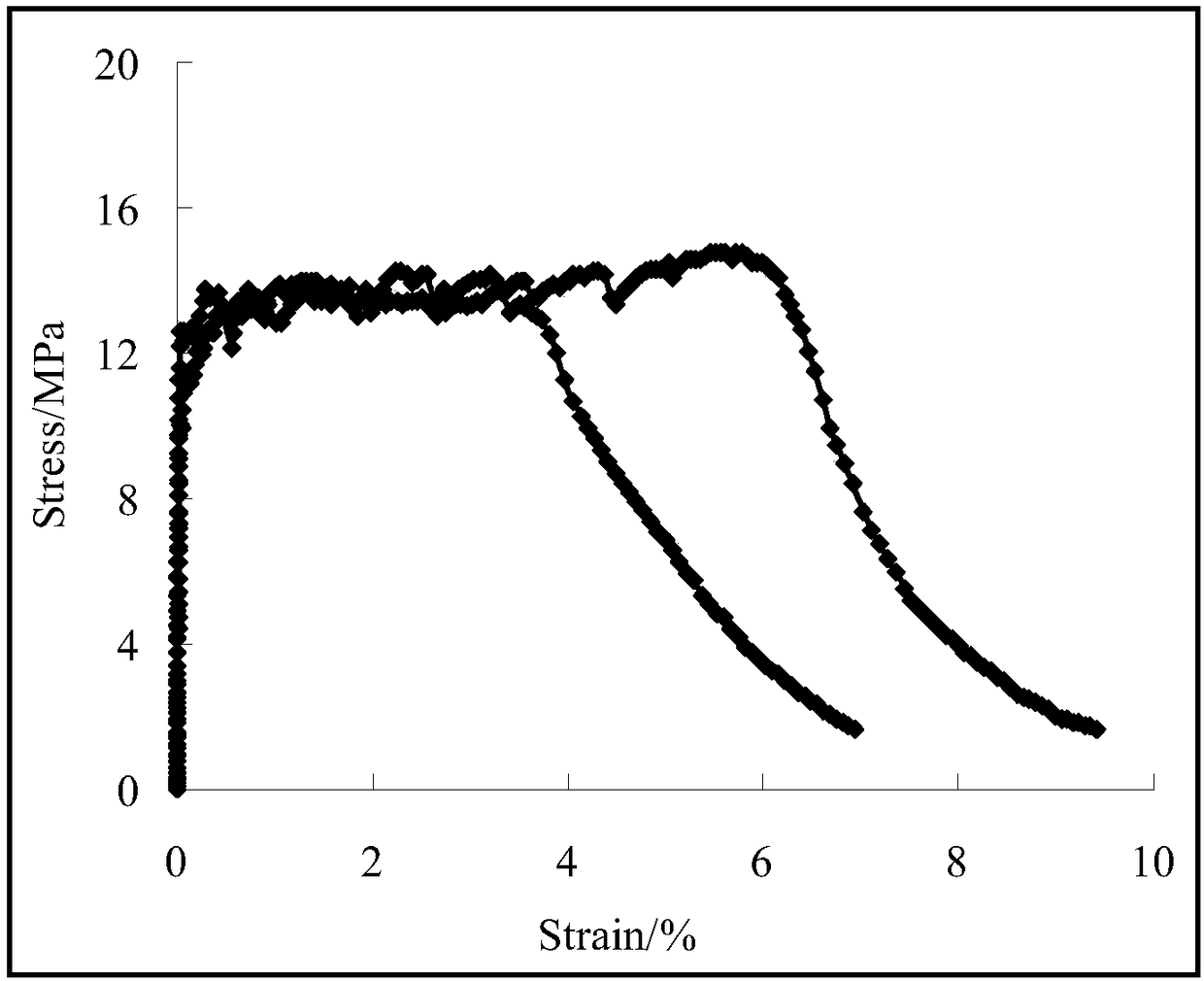

Hybrid fiber toughened ultrahigh-strength and ultrahigh-ductility cement-based material

The invention relates to a hybrid fiber toughened ultrahigh-strength and ultrahigh-ductility cement-based material which comprises the following ingredients in parts by weight: 700-1250 parts of 525 ordinary Portland cement, 200-300 parts of silica fume, 200-750 parts of mineral powder, 400-500 parts of quartz sand, 200-230 parts of water, 20-30 parts of a polycarboxylic acid high efficiency waterreducer, 5-20 parts of ultra-high molecular weight polyethylene fiber and 39-117 parts of ultrahigh-strength steel fiber. Compared with the prior art, the cement-based composite with maximum compressive strength of 200MPa, direct tension strength near 15MPa, tensile ductility near 10% and slump of greater than 180mm is obtained by mixed use of the ultra-high molecular weight polyethylene fiber and the steel fiber, and can be pumped and cast in place.

Owner:TONGJI UNIV

Modified natural rubber masterbatch and method for production thereof, and rubber composition and tire

InactiveCN101084258AImprove filler dispersibilityImprove wear resistanceSpecial tyresMasterbatchPolymer science

This invention provides a method for producing a modified natural rubber masterbatch, which comprises the step of mixing a modified natural rubber latex, which is formed by adding a polar group-containing monomer to a natural rubber latex to graft-polymerize the polar group-containing monomer onto a natural rubber molecule in the natural rubber latex, with a slurry solution formed by previously dispersing a filler into water, and a modified natural rubber masterbatch produced by the method and capable of highly improving a low loss factor, a wear resistance and fracture characteristics of a rubber composition.

Owner:BRIDGESTONE CORP

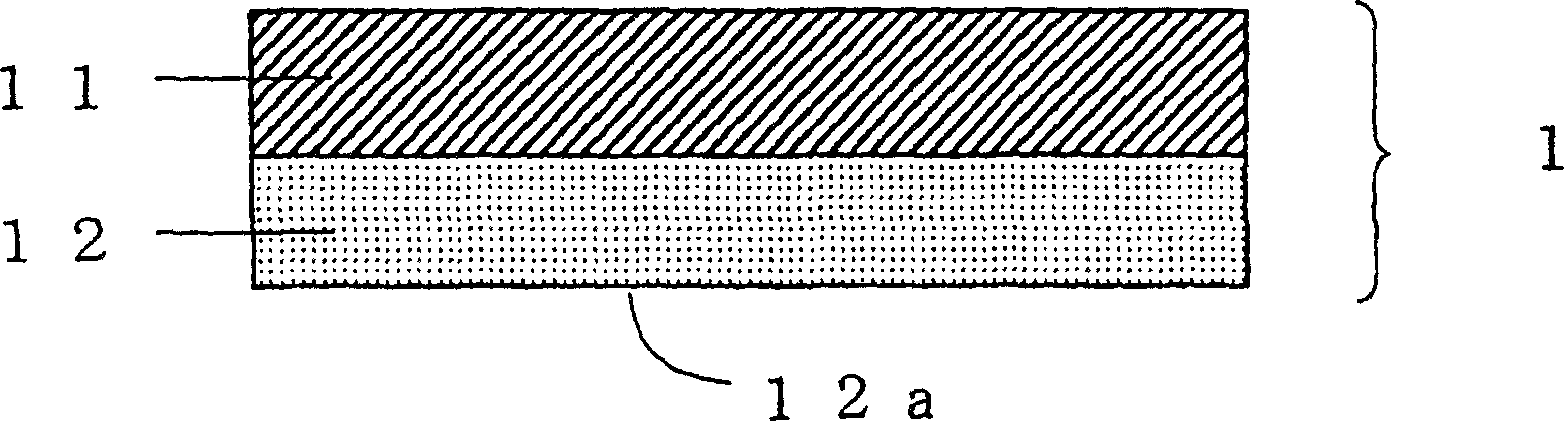

Impact-absorbing sheet

InactiveCN1760564AImprove fracture performanceAvoid enteringAdhesive articlesSynthetic resin layered productsEngineeringMono layer

Owner:NITTO DENKO CORP

Aluminum alloy for subway station ceiling and preparing method of aluminum alloy

The invention relates to an aluminum alloy for a subway station ceiling and a preparing method of the aluminum alloy. The aluminum alloy is characterized by comprising chemical components, including by mass percent, 0.45% to 0.6% of Mg, 0.3% to 0.5% of Si, 0.1% to 0.3% of Mn, 0.1% to 0.2% of Cr, 0.1% to 0.3% of Zr, 0.1% to 0.3% of Hf, 0.05% to 0.2% of Ta, 0.05% to 0.15% of Cu, not larger than 0.05% of Zn, not larger than 0.20% of Fe, not larger than 0.05% of Ti, and the balance Al, wherein the single content of other impurity elements is not larger than 0.05%, and the total content of other impurity elements is not larger than 0.15%. The aluminum alloy is obtained through the preparing method of smelting, refining, casting and homogenizing. Through optimizing of alloy components, adjustment is carried out, the trace of Zr, Hf and Ta is added, and the strength, the heat dissipation, corrosion resistance, humidity resistance, fatigue resistance, static electricity resistance, recrystallization resistance capacity and breaking resistance performance of the aluminum alloy can be obviously improved.

Owner:ALNAN ALUMINIUM CO LTD

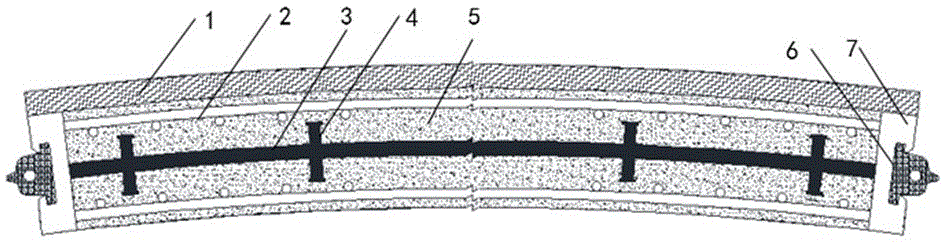

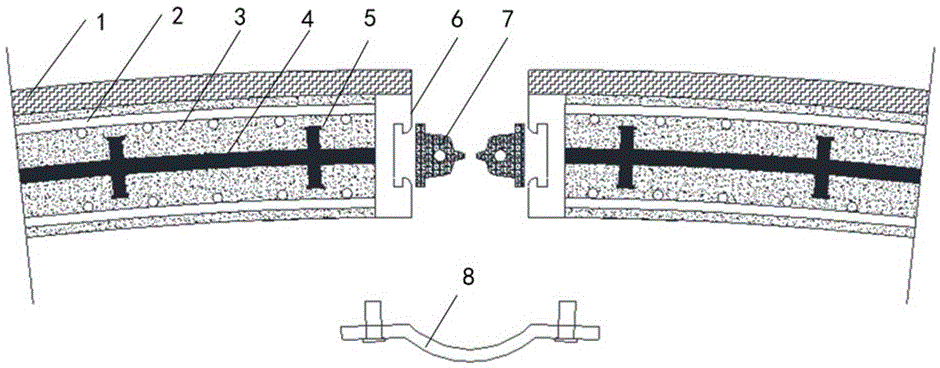

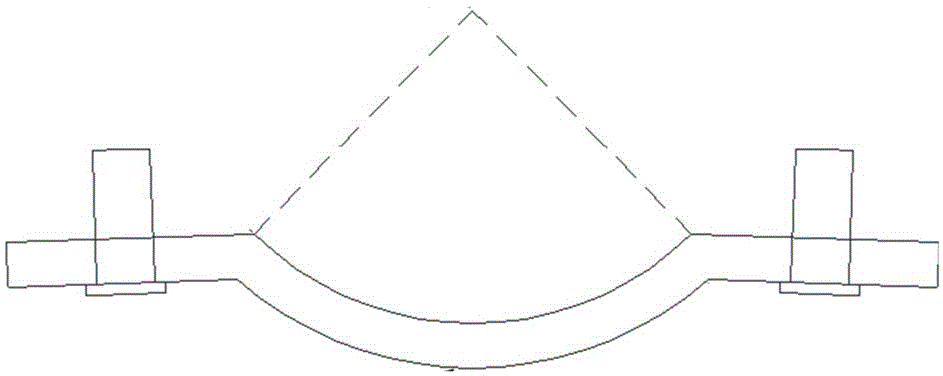

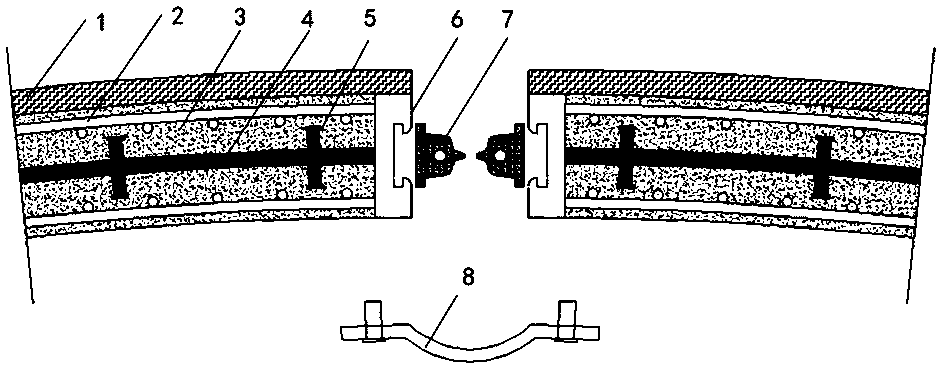

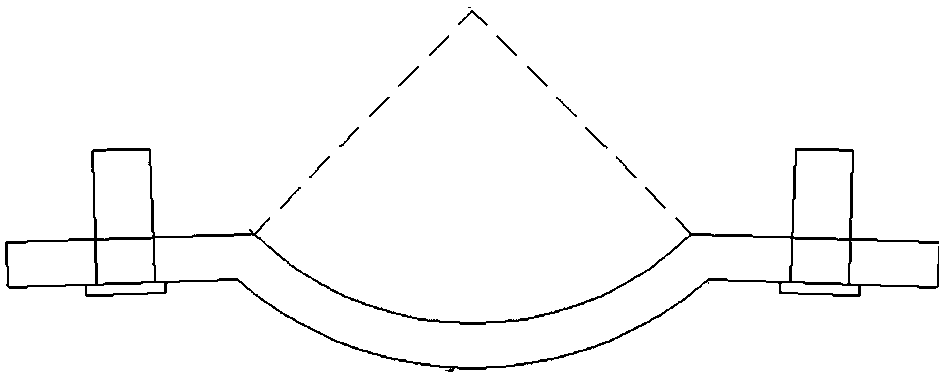

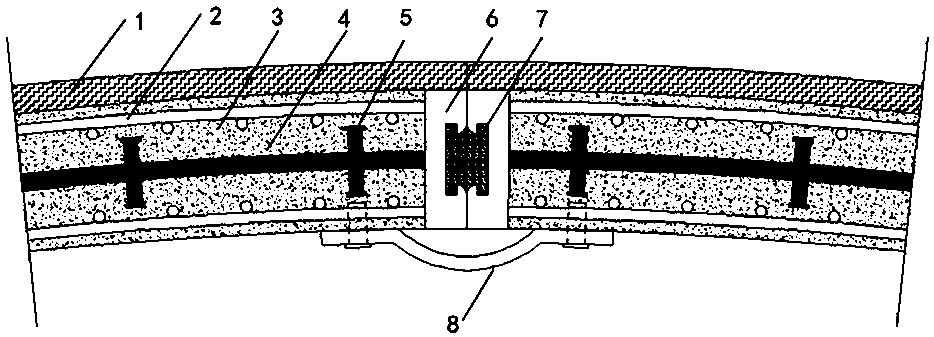

Shield tunnel segment structure and connecting structure thereof

The invention discloses a shield tunnel segment structure and a connecting structure thereof. The shield tunnel segment structure comprises a segment body and is characterized in that the segment body is mainly composed of a steel plate layer, a concrete layer wrapping the steel plate layer, and steel mesh reinforcements which are located on the two sides of the steel plate layer correspondingly and embedded in the concrete layer; the lateral edges of the segment body are fixedly provided with metal connectors, the outer sides of the metal connectors are provided with grooves for containing water stops, and the water stops are installed inside the grooves; and an outer protecting layer is arranged on the outer side of the segment body, and the outer protecting layer is a polyurea layer combined on the outer side surface of the segment body. The connecting structure is composed of two adjacently arranged shield tunnel segment structures and a connecting part for connecting the two shield tunnel segment structures. A connecting steel plate is composed of a middle arc-shaped section and flat sections on two sides. The shield tunnel segment structure and the connecting structure thereof have the characteristics that thickness is small, strength is high and the connectors are not prone to damage; and the connector deformation control effect is good, the seam waterproof effect is good, durability is high, and repairing is convenient.

Owner:SUZHOU UNIV

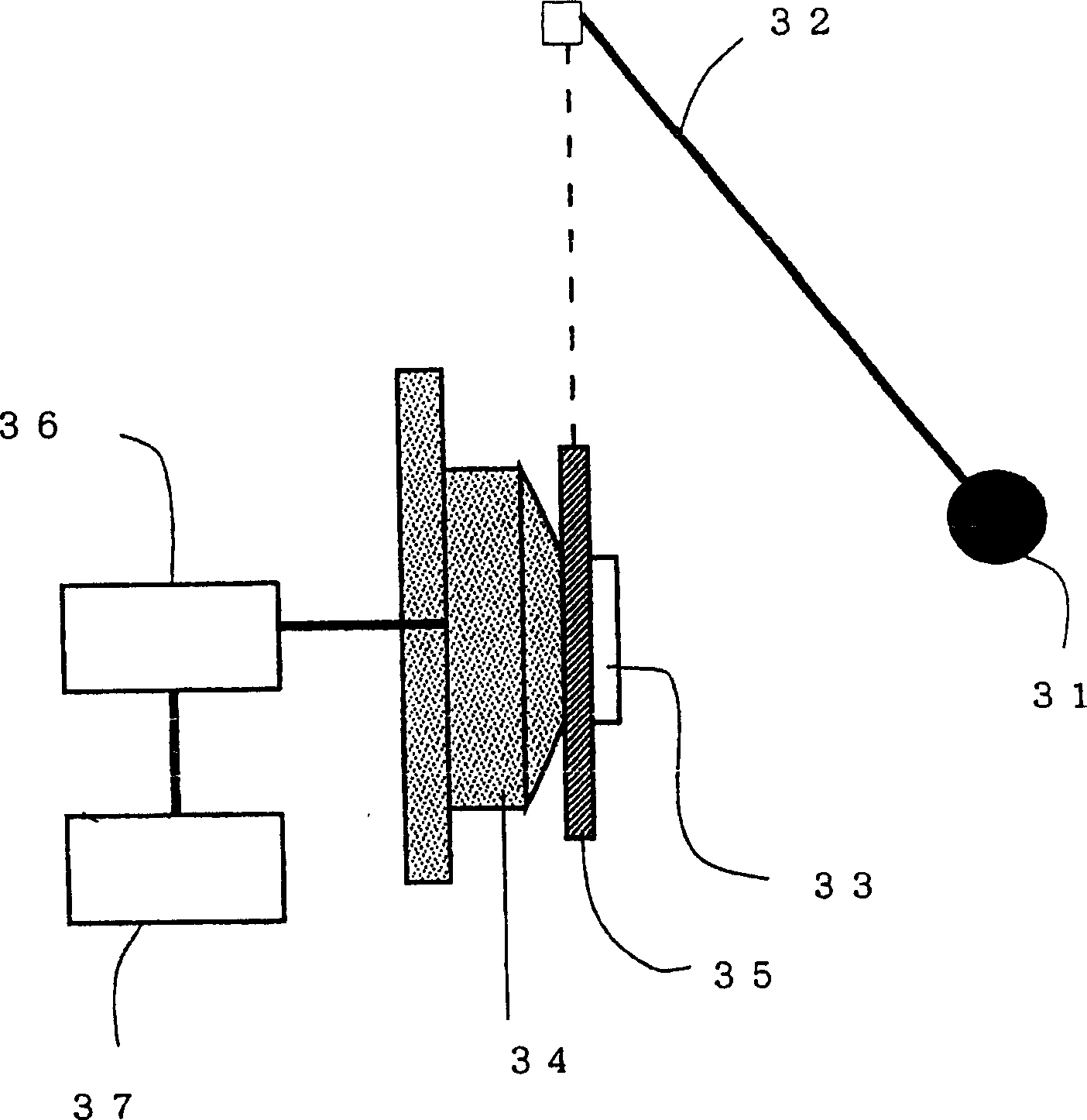

Thermal edge finishing

InactiveCN101646524AImprove impact resistanceImprove fracture performanceLaser beam welding apparatusGlass productionThermal treatmentIn plane

A thermal edge finishing process includes preheating at least one cut edge of a glass sheet, laser finishing the edge to a single full continuous radius from a position orthogonal to the edge and in-plane with the glass sheet while continuing to heat the glass, and localized annealing of the edge to reduce residual stress from the laser / thermal treatment of the edge. By the present process, edgestress is reduced considerably, such as to less than 3000 psi, and more preferably to less than 2500 psi, and to as low as 1000 psi in the first 1 mm along the treated edge.

Owner:CORNING INC

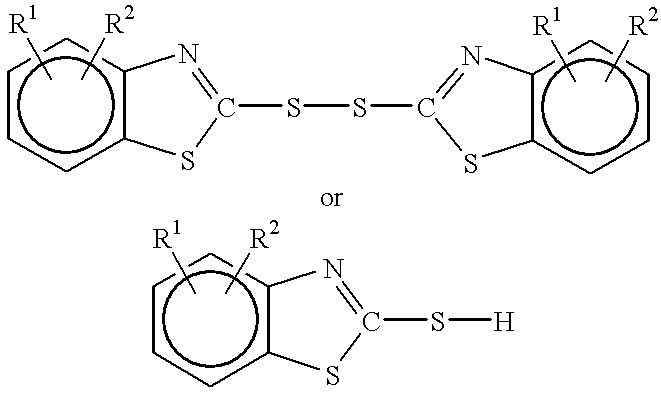

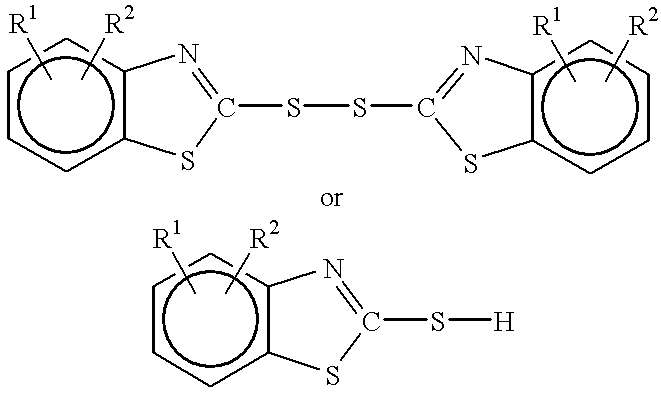

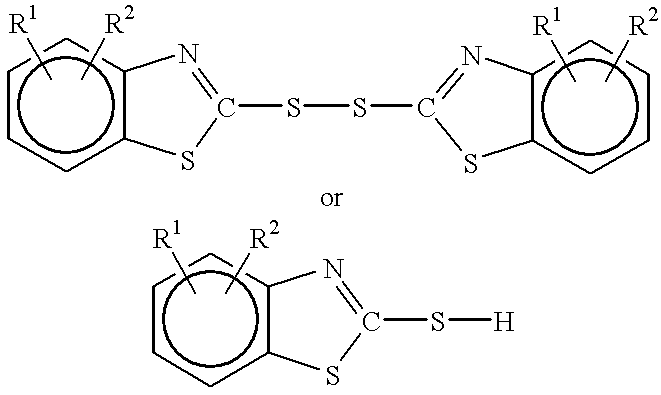

Pneumatic tire containing a vulcanization accelerator

InactiveUS6330897B1Reduce rolling resistanceEasy to separateSpecial tyresPneumatic tyre reinforcementsArylVulcanization

A pneumatic tire formed by using a rubber composition comprising a vulcanization accelerator represented by the following general formula: ##STR1## wherein R.sup.1 represents a hydrogen atom, an alkyl group, or an aryl group, and R.sup.2 represents an alkyl group or an aryl group when R.sup.1 represents a hydrogen atom, and represents a hydrogen atom, an alkyl group, or an aryl group when R.sup.1 represents an alkyl group or an aryl group, in an amount of 0.2 to 8.0 parts by weight per 100 parts by weight of a rubber component. A pneumatic tire which maintains low rolling resistance and is improved to prevent resistance to ply-end separation throughout the entire term of tire use, a pneumatic tire which shows excellent controllability and durability in the last stage of tire use, and a pneumatic tire which prevents heat aging of belt layers and a decrease in the adhesion of steel cord with a rubber composition and shows excellent durability are provided.

Owner:BRIDGESTONE CORP

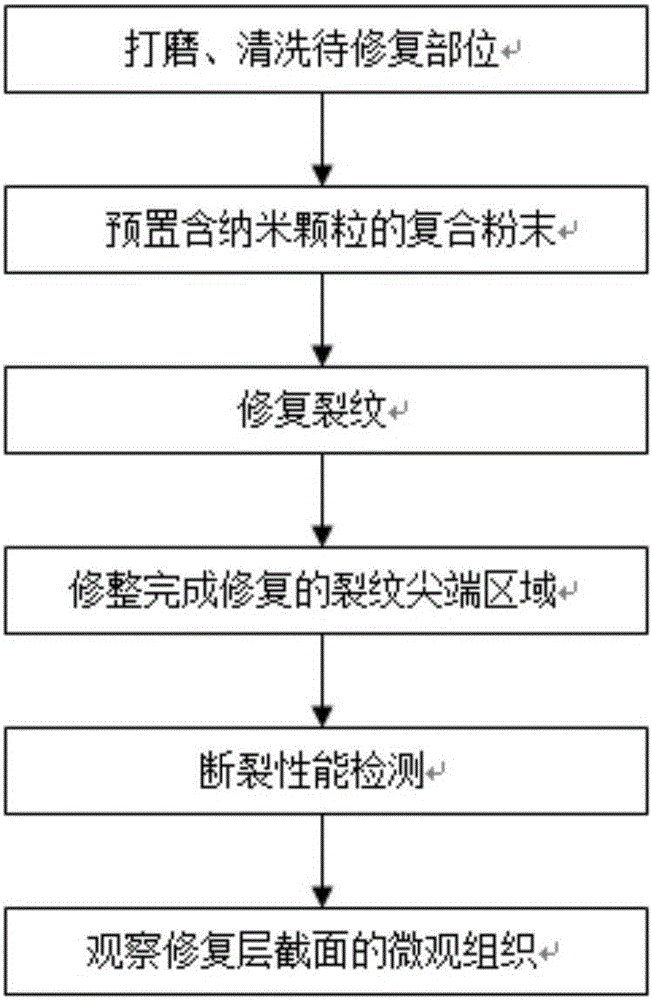

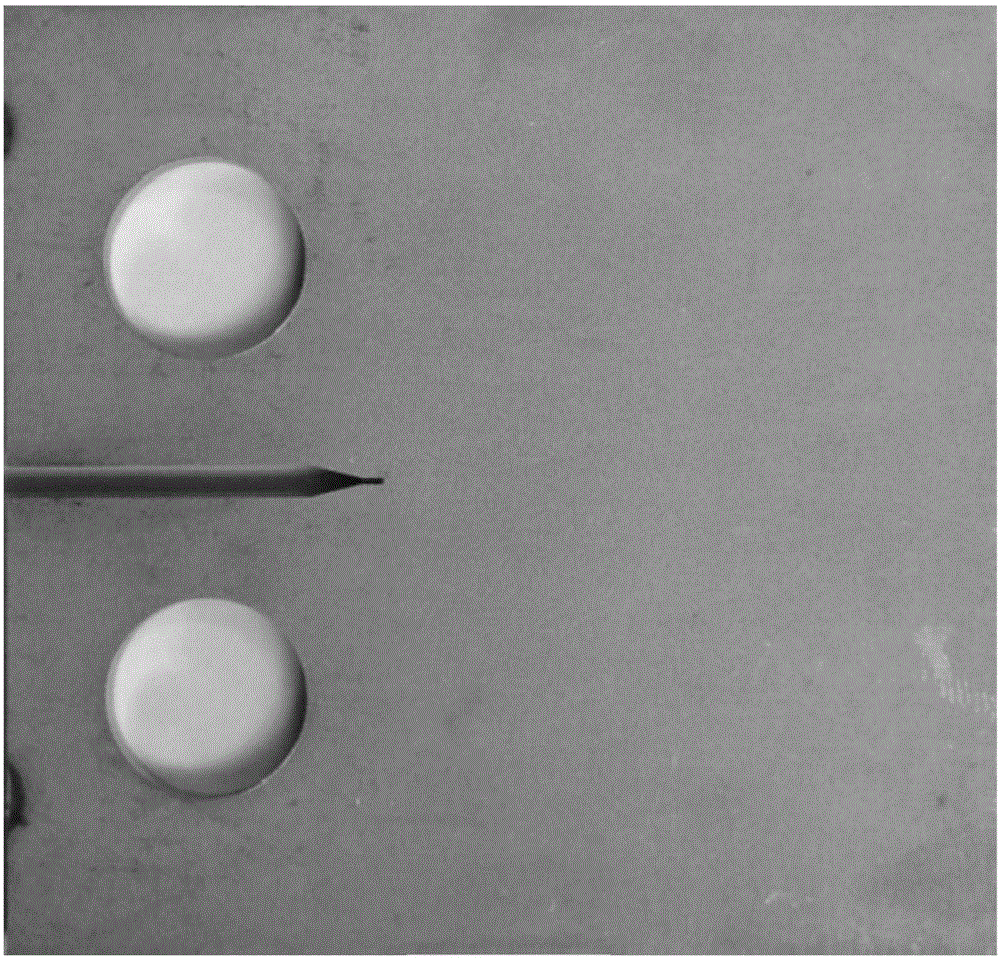

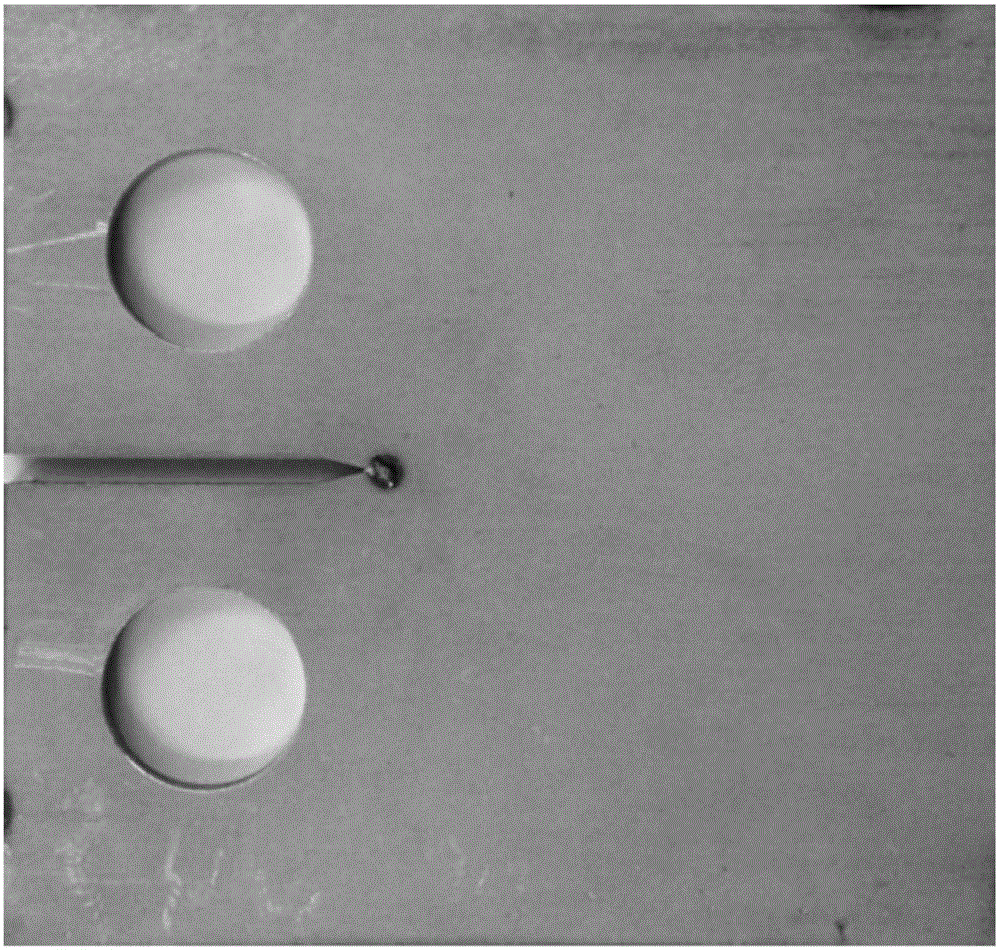

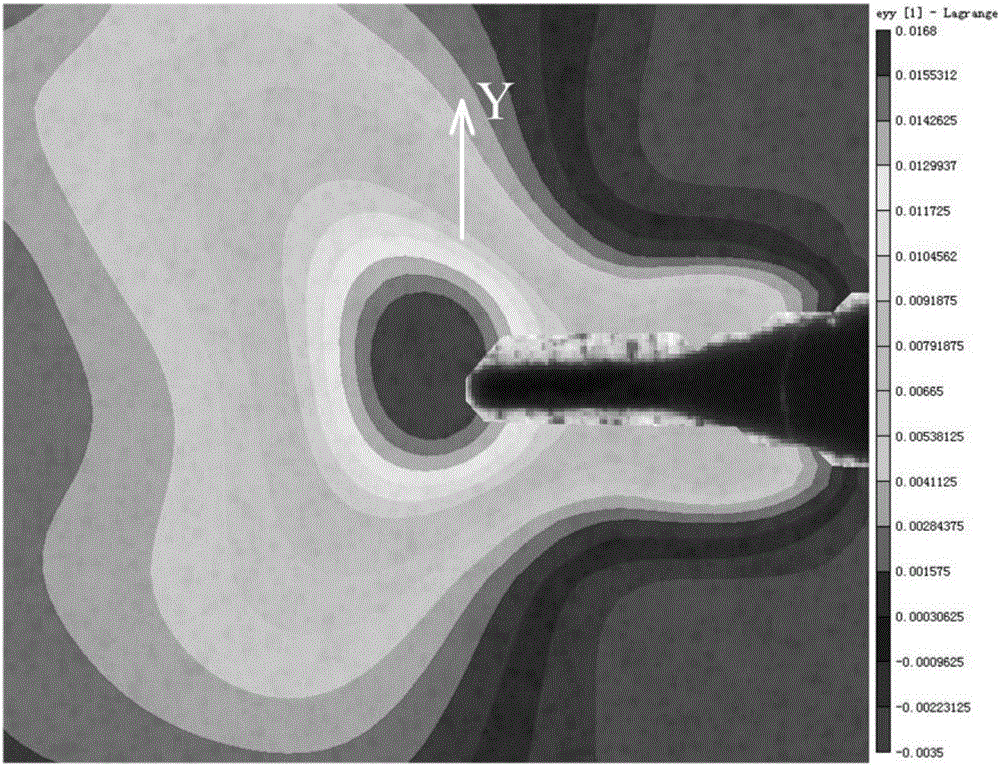

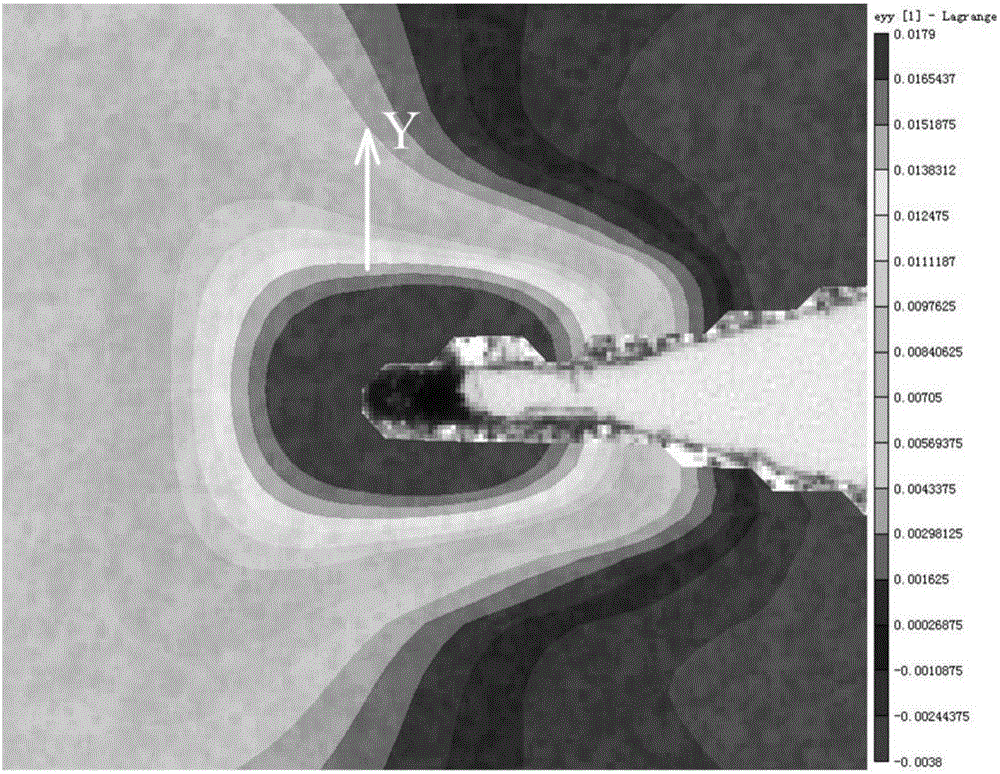

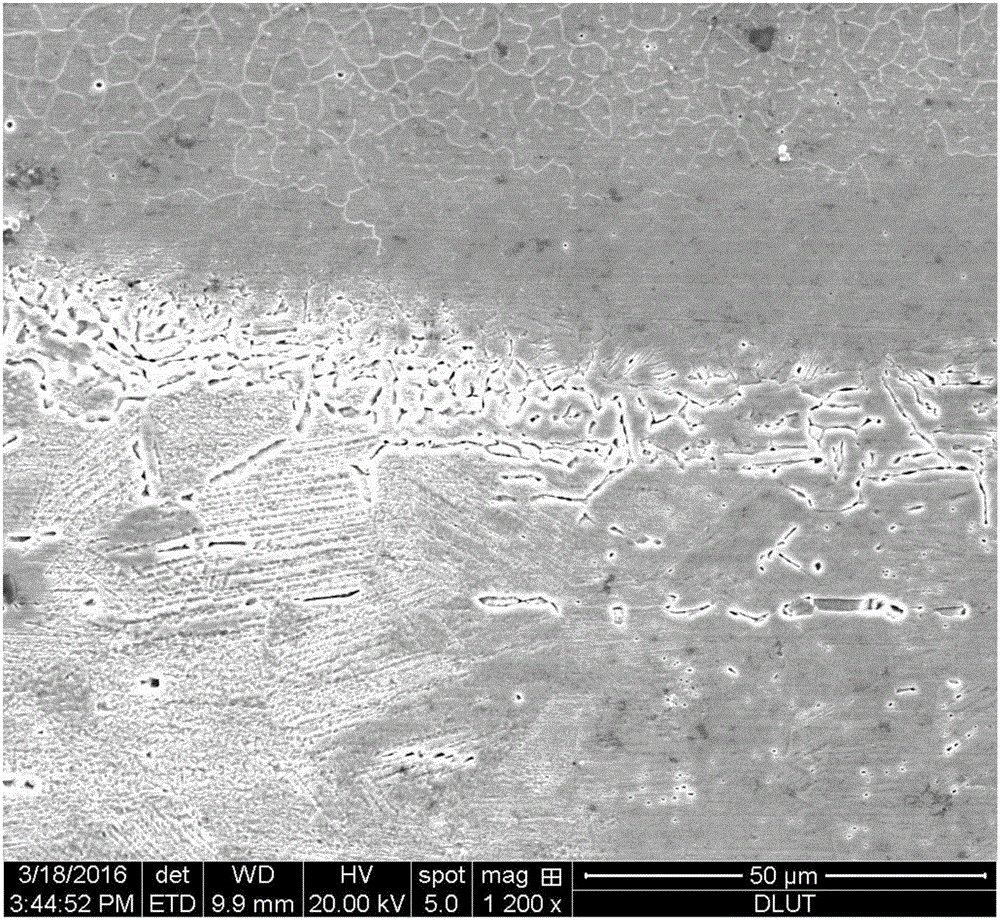

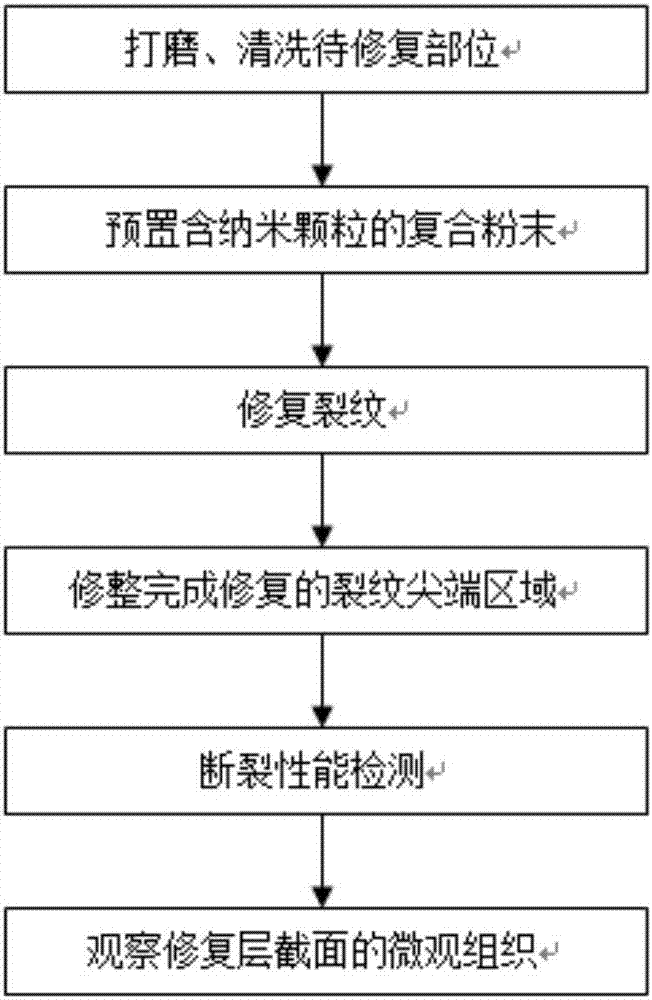

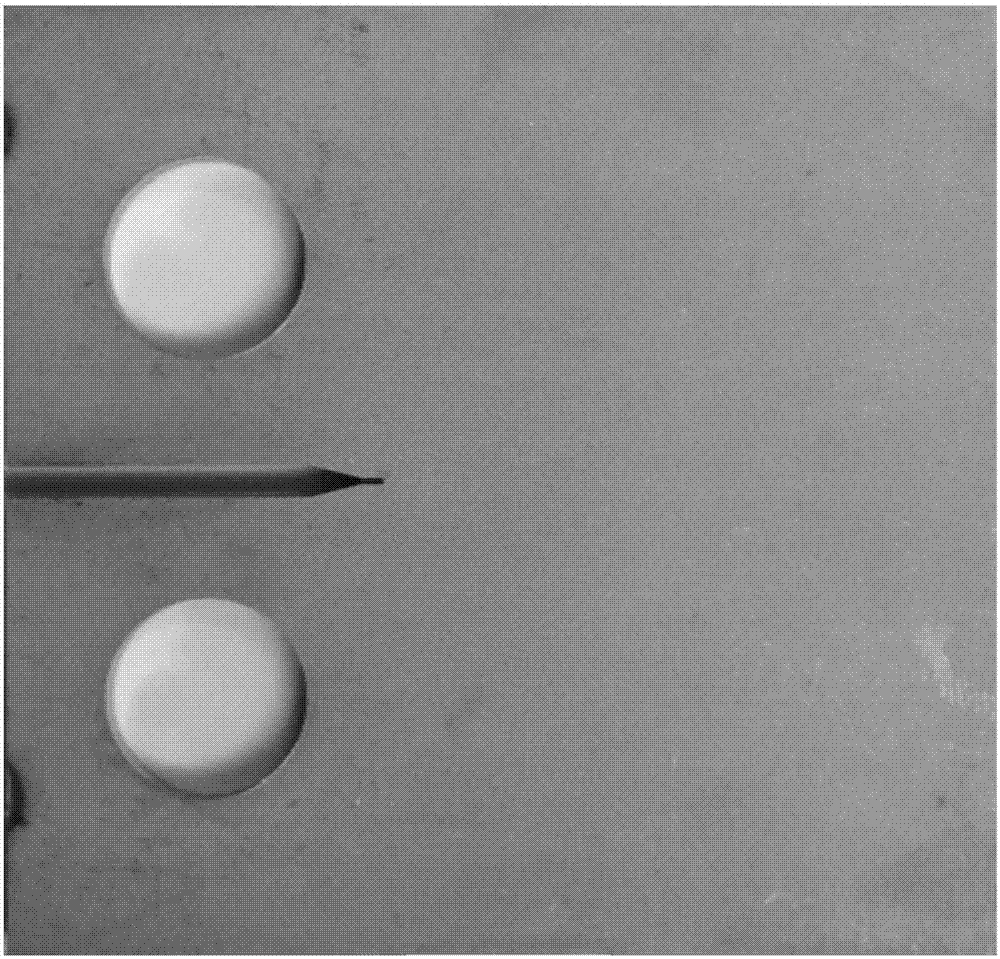

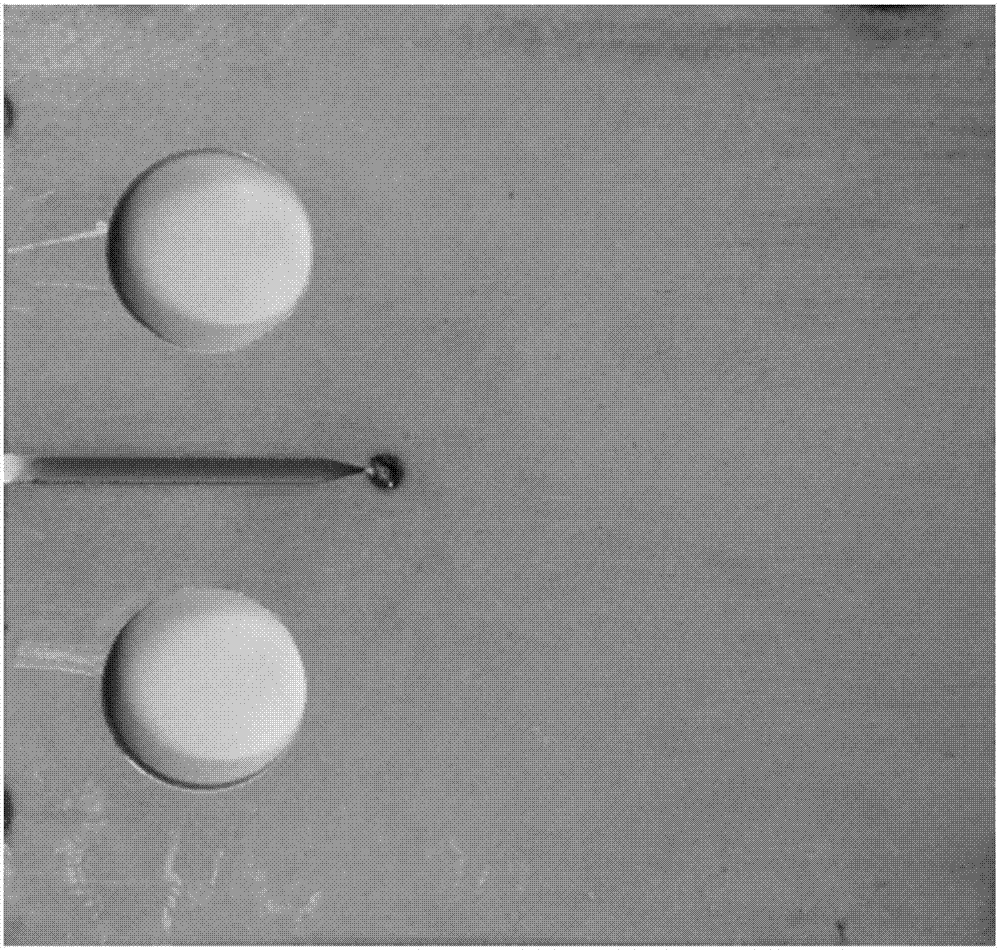

Method for repairing microcrack tip on stainless steel surface by means of nano-particles

ActiveCN105714286AImprove densification performanceExtended service lifeMetallic material coating processesHeat-affected zoneNanoparticle

The invention provides a method for repairing a microcrack tip on a stainless steel surface by means of nano-particles. The method is suitable for stainless steel with microcracks on the surface. The method comprises the steps that the to-be-repaired microcrack tip on the stainless steel surface is treated; composite powder containing the nano-particles is arranged on the microcrack tip in advance; the composite powder and a part of a matrix are fused by means of lasers; the repaired microcrack tip region is finished; and the fracture property of the stainless steel matrix obtained after repairing is detected, and the microstructure of the section of a repair layer is observed. The repairing method is high in flexibility, and repairing can be carried out many times; and meanwhile, the problems of large deformation, a large heat affected zone and the like in a conventional method are avoided in the repairing method. According to the repairing method, the microcrack tip is closed again, the matrix and the composite powder arranged on the microcrack tip in advance are in metallurgical bonding, and the defects of cracks, pores and the like do not exist in the bonding region; grains of the repair layer of the microcrack tip are refined, and the structural compactness is improved; and in addition, the fracture property generated after repairing is remarkably improved.

Owner:DALIAN UNIV OF TECH

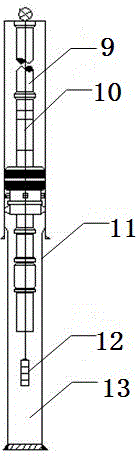

Clustered perforating and staged fracturing combined process

ActiveCN104879110AMeet the needs of layered fracturingEfficient developmentFluid removalFiberWell logging

The invention discloses a clustered perforating and staged fracturing combined process which comprises the following processes: a, determining the perforated interval clustering according to the requirements of well logging interpretation results and staged fracturing or volume fracturing processes; b, lowering a completion pipe string, lowering a completion tool, and sealing a packer according to the design requirements, and filling with a completion fluid; c, completing the first-stage perforating operation by adopting an under-pressure cable conveying oil passing pipe clustered perforating technology; d, performing fracturing construction; e, after the first-stage fracturing is completed, throwing degradable fiber temporary plugging balls to plug perforating holes, repeating the second-stage clustered perforating and fracturing till the perforating and fracturing construction operation of a whole well is completed. The requirement of ultrahigh-temperature ultrahigh-pressure ultra-deep well one-trip pipe string separated layer fracturing can be met, the high-efficient development of the well is realized, the ultrahigh-temperature ultrahigh-pressure perforating and fracturing completion practice is simplified, the operation ageing is improved greatly, the fracturing operation effect is improved, and the oil and gas production layer protection is beneficial to be improved, and the single well productivity is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

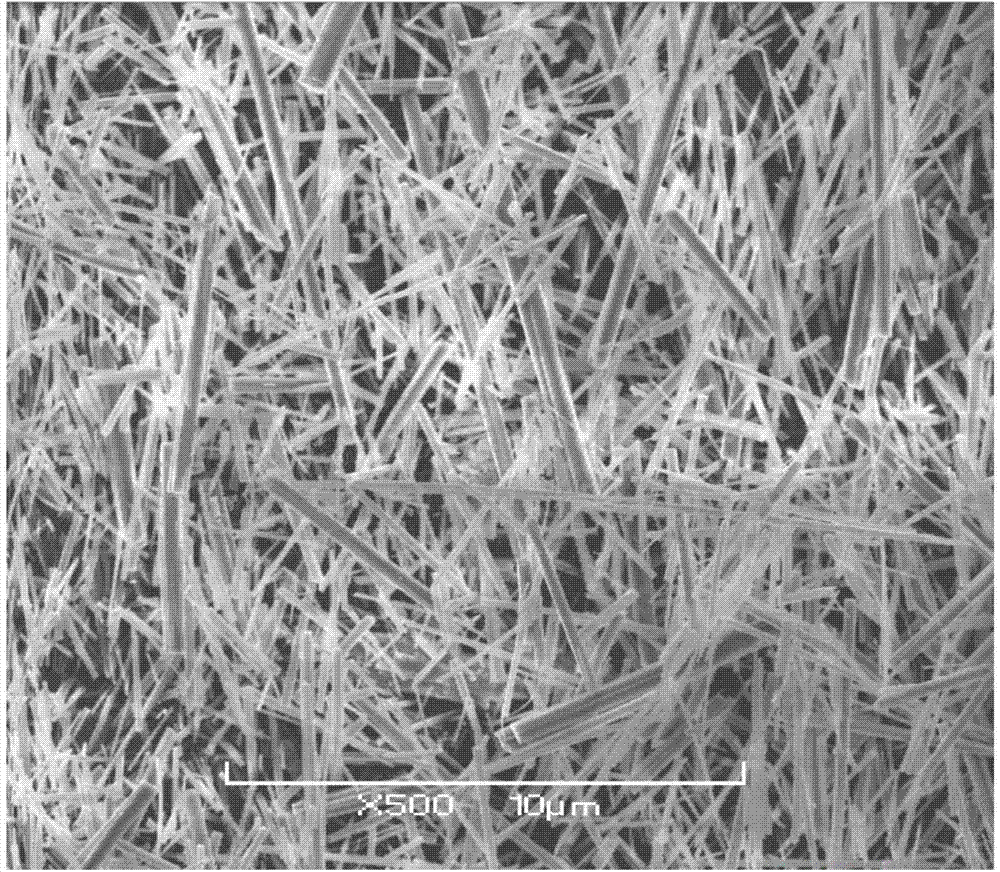

In-situ synthesis mullite whisker-toughened ceramic heat accumulator and preparation method thereof

The invention provides an in-situ synthesis mullite whisker-toughened ceramic heat accumulator and a preparation method thereof. The in-situ synthesis mullite whisker-toughened ceramic heat accumulator is prepared from coal-based kaolin, alumina micro powder, mullite powder, a binding agent, a water solubility plasticizer and water by the steps of mixing materials, kneading mud, pugging, microwave sizing, baking and firing. The heat accumulator prepared by adopting the technical scheme is a composite material formed by high-strength and high-modulus mullite ceramic whisker and mullite matrix. Even mullite whisker is generated between matrix tissues of a microstructure. In addition, the method is simple in preparation technology, low in cost and easy for realization of industrial production.

Owner:TIANJIN KANGBAO ZHENTE INORGANIC NONMETAL SCI& TECH

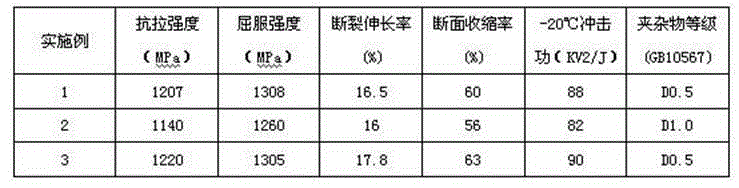

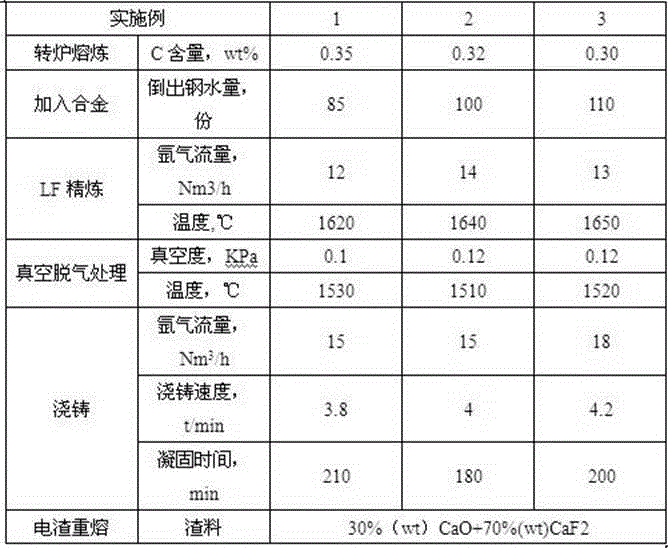

Manufacturing method of steel ingot for gas cylinder

ActiveCN103555881AGuaranteed purityReduce contentProcess efficiency improvementWorking pressureGas cylinder

The invention belongs to the technical field of manufacturing of steel ingots and discloses a manufacturing method of a steel ingot for a gas cylinder. The manufacturing method of the steel ingot for the gas cylinder comprises the following steps of: raw material purporting, converter smelting, alloy addition, LF (Low Frequency) steel ladle refining, vacuum degreasing treatment, casting as well as electroslag re-melting, wherein the raw material contains not less than 4wt% of C, not more than 0.015wt% of P and blast furnace molten iron with a temperature being not lower than 1200 DEG C; in a converter smelting stage, content of P is lowered by P-removing pretreatment; the LF steel ladle refining adopts an aluminum-free deoxidation process; after the electroslag re-melting and the secondary refining are carried out onto the steel ingot obtained by primary refining and casting so that S and impurities in the steel are lowered. According to the manufacturing method disclosed by the invention, the quantity of harmful elements and impurities in the steel ingot are controlled by twice refining, so that a purpose of controlling components and structure of the steel ingot is reached, the steel ingot for the gas cylinder with excellent strength and toughness is finally obtained, and therefore, working pressure and safety of the steel ingot for the gas cylinder are improved.

Owner:中船双瑞(洛阳)特种装备股份有限公司

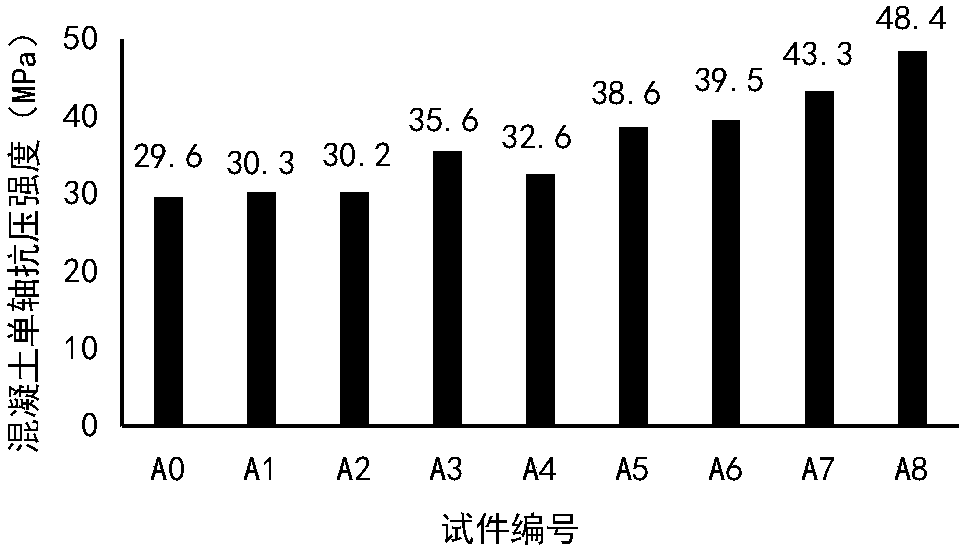

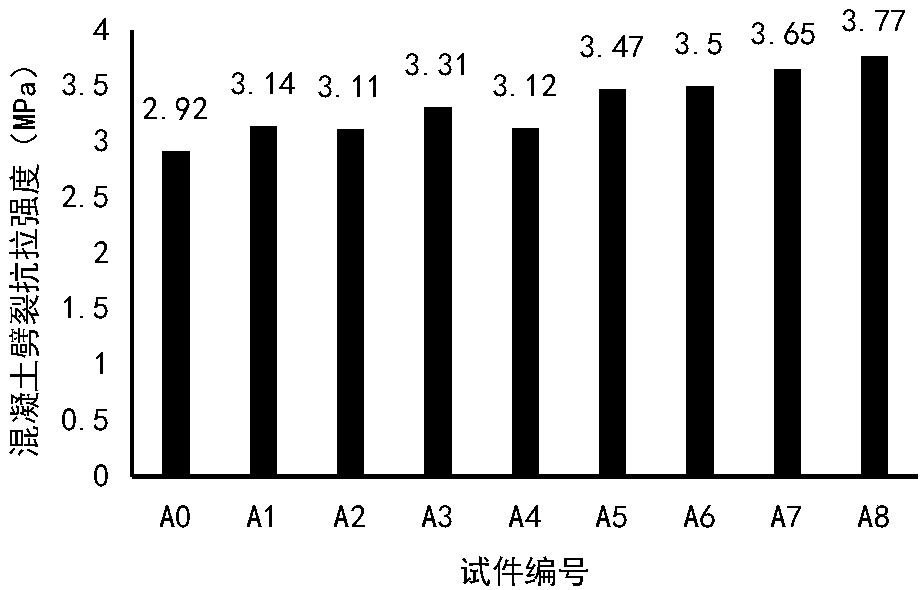

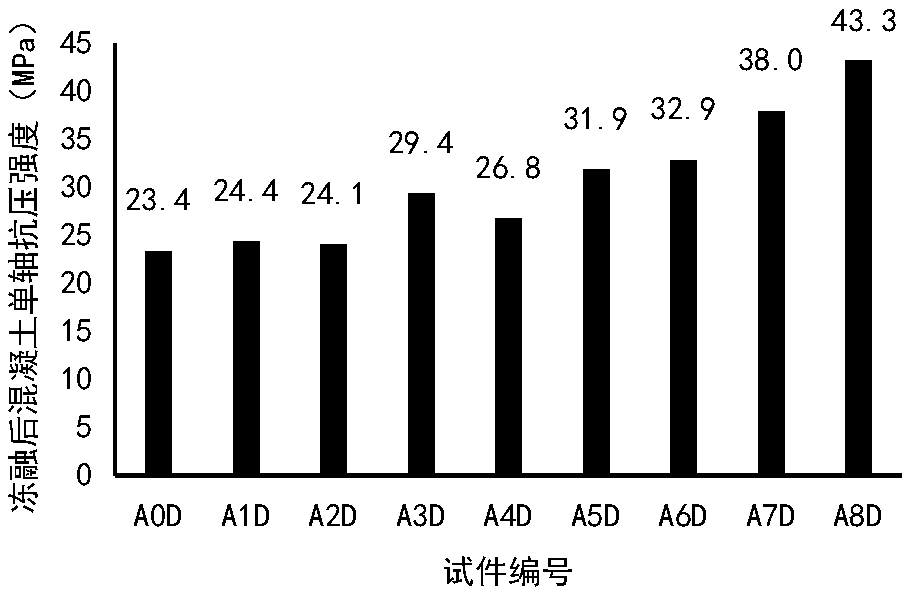

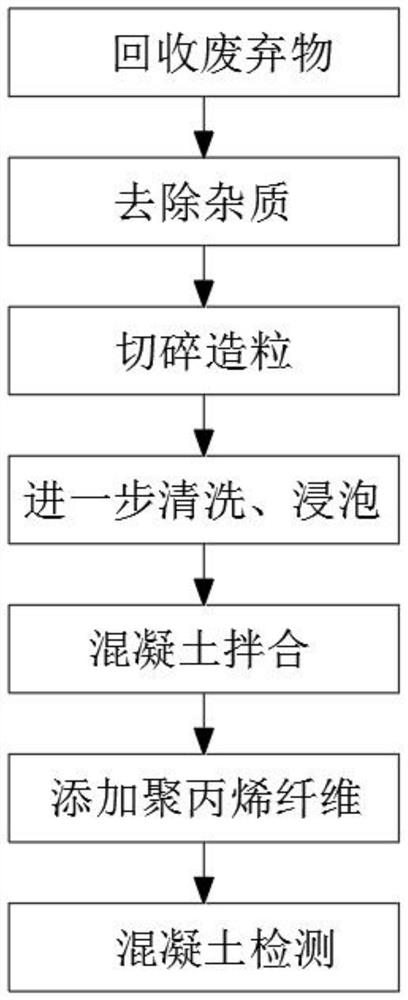

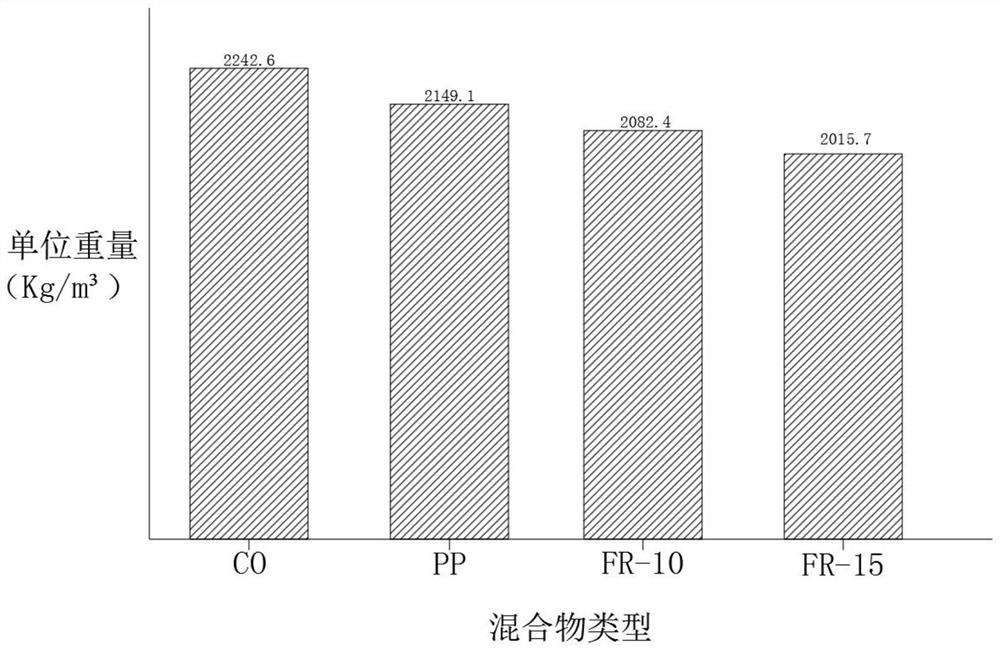

Multi-dimension polypropylene fiber concrete

ActiveCN106699070AImprove stress resistanceImprove splitting performanceUniaxial compressionPolymer science

The invention relates to multi-dimension polypropylene fiber concrete, which is formed by a polypropylene fiber, a concrete and a water reducing agent, wherein the polypropylene fiber is a fascicular monofilament polypropylene fiber formed by FF1, FF2 and CF1; the FF1 and the FF2 are polypropylene fine fibers with the diameters being 0.026mm and 0.10mm respectively and the lengths being 19mm; the CF1 is a polypropylene coarse fiber with the diameter being 0.8mm and the length being 50mm; the mixing amount of the FF1 ranges from 0.50 to 0.65kg / m<3>, the mixing amount of the FF2 ranges from 0.50 to 0.65kg / m<3>, and the mixing amount of the CF1 ranges from 4.0 to 5.0kg / m<3>. The multi-dimension polypropylene fiber is added into a cement base according to the mixing amount so as to obtain the multi-dimension polypropylene fiber concrete, and compared with the prior art, the uniaxial compression and the splitting tensile strength of the concrete can be remarkably improved, the freezing-thawing durability of the concrete can be effectively improved, and the fracture property of the concrete can be greatly improved.

Owner:CHONGQING UNIV

Aluminum alloy material for door and window

The invention discloses an aluminum alloy material for door and window. The material consists of the following components by weight percentage: 0.15-0.5% of iron, 0.85-1.5% of magnesium, 5-6% of zinc, 0.05-0.15% of chromium, 0.05-0.15% of titanium, 0.1-0.2% of cerium, 0.1-0.2% of yttrium, 0.1-0.2% of silicon, and 0.1-0.2% of manganese, with the balance being aluminum. The chromium, titanium, cerium, yttrium and other elements in the alloy material improve the resistance to corrosion of the alloy. The cerium, yttrium and other elements improve normal and low temperature toughness and breakability of the alloy. The material improves the ability of heating and the soundness of the weld assembly.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Electrode for secondary battery, and lithium secondary battery comprising same

ActiveCN108352504AInhibit migrationIncrease capacityNegative electrodesPositive electrodesTensile strainElectrical battery

The invention discloses an electrode for a secondary battery, and a method for manufacturing the electrode. According to the present invention, a secondary battery having ensured stability by allowingan excellent evaluation to be received in a nail penetration test while having a high capacity can be manufactured. To this end, disclosed is an electrode for a secondary battery, comprising: a current collector; a first electrode active material layer formed on the current collector; and a second electrode active material layer formed on the first electrode active material layer, wherein the tensile strain of the layer comprising the current collector and the first electrode active material layer is 1.2% or less.

Owner:LG ENERGY SOLUTION LTD

Novel environment-friendly wood plastic material and preparation method thereof

The invention discloses a novel environment-friendly wood plastic material and a preparation method thereof and relates to the field of novel environment-friendly materials. The novel environment-friendly wood plastic material is prepared from the following raw materials in parts by weight: 22-26 parts of polyvinyl chloride resin, 12-18 parts of modified coffee shell powder, 24-32 parts of straw powder, 5-10 parts of nano titanium dioxide, 8-15 parts of nano calcium carbonate, 1-3 parts of polyvinyl alcohol, 0.8-1.8 parts of dicumyl peroxide, 2-5 parts of methacrylic resin, 2-4 parts of beta-damascone, 2-5 parts of a flame retardant and 1.4-2.2 parts of a foamer. The wood plastic material has excellent corrosion resistance, ultraviolet resistance and mechanical impact resistance by takingthe coffee shell powder as the raw material matched with other raw materials, is wide in nutritional range, wide in source of raw materials, reduces the production cost of the wood plastic material and meanwhile, solves the problem of reutilization of the coffee shells, and is green and environmentally friendly.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

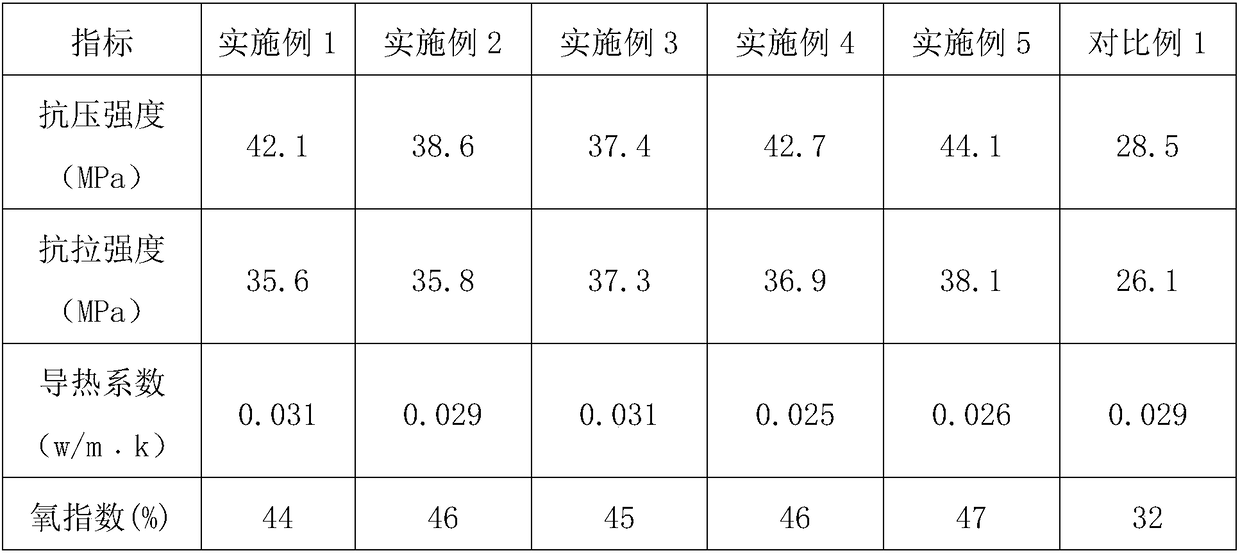

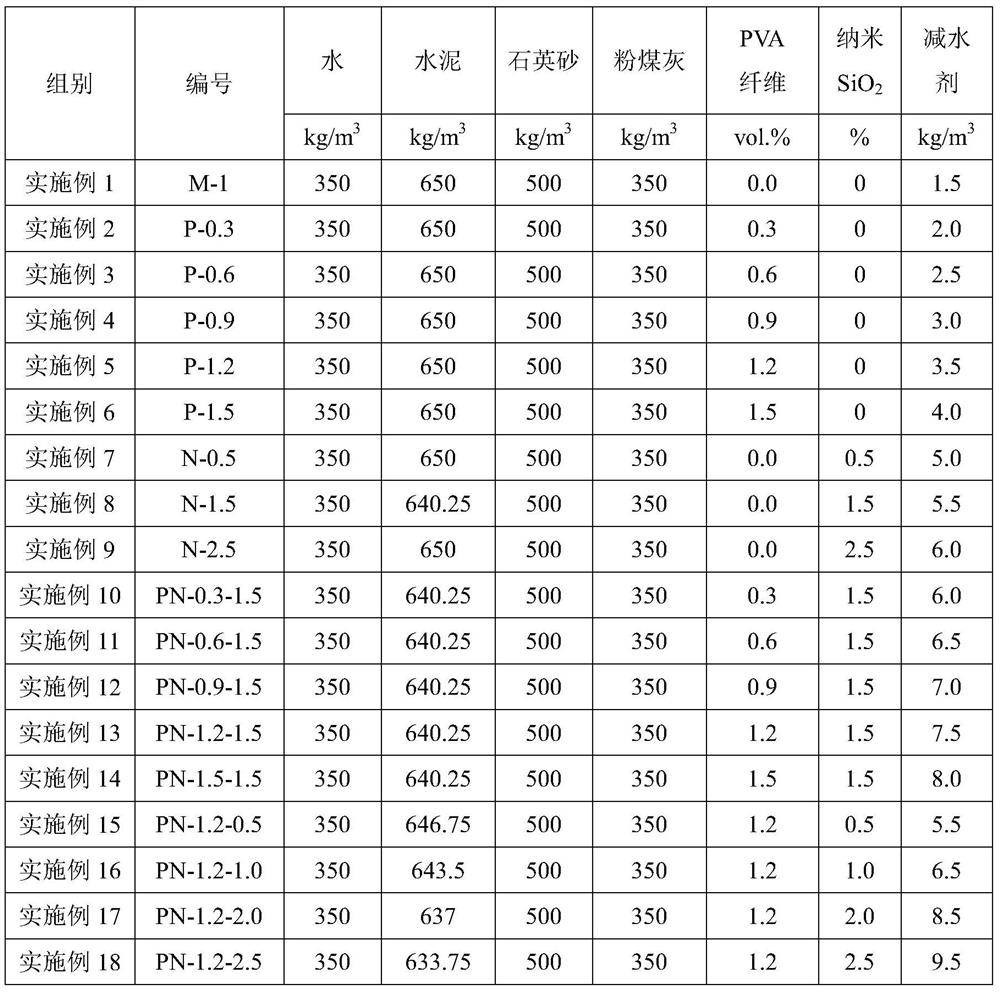

High-performance cement-based composite material and preparation method thereof

The invention discloses a high-performance cement-based composite material and a preparation method thereof, and belongs to the technical field of building materials, the composite material comprises the following raw materials: water, quartz sand, fly ash, a water reducing agent, nano SiO2, cement and polyvinyl alcohol fiber; the preparation method comprises the following steps: mixing cement, fly ash and quartz sand to obtain mortar; mixing nano SiO2 with a water reducing agent, adding part of water, stirring, adding the obtained dispersion liquid into the mortar, stirring, adding the rest water, stirring, and adding polyvinyl alcohol fiber to obtain the cement-based composite material. According to the cement-based composite material disclosed by the invention, the nano SiO2 and the polyvinyl alcohol fiber in a certain proportion are simultaneously doped into the cement-based composite material, so that the performance of the cement-based composite material under the coupling action of damp and hot salts is remarkably enhanced, and the application of the cement-based composite material in hydraulic structures and ocean engineering is more facilitated.

Owner:ZHENGZHOU UNIV

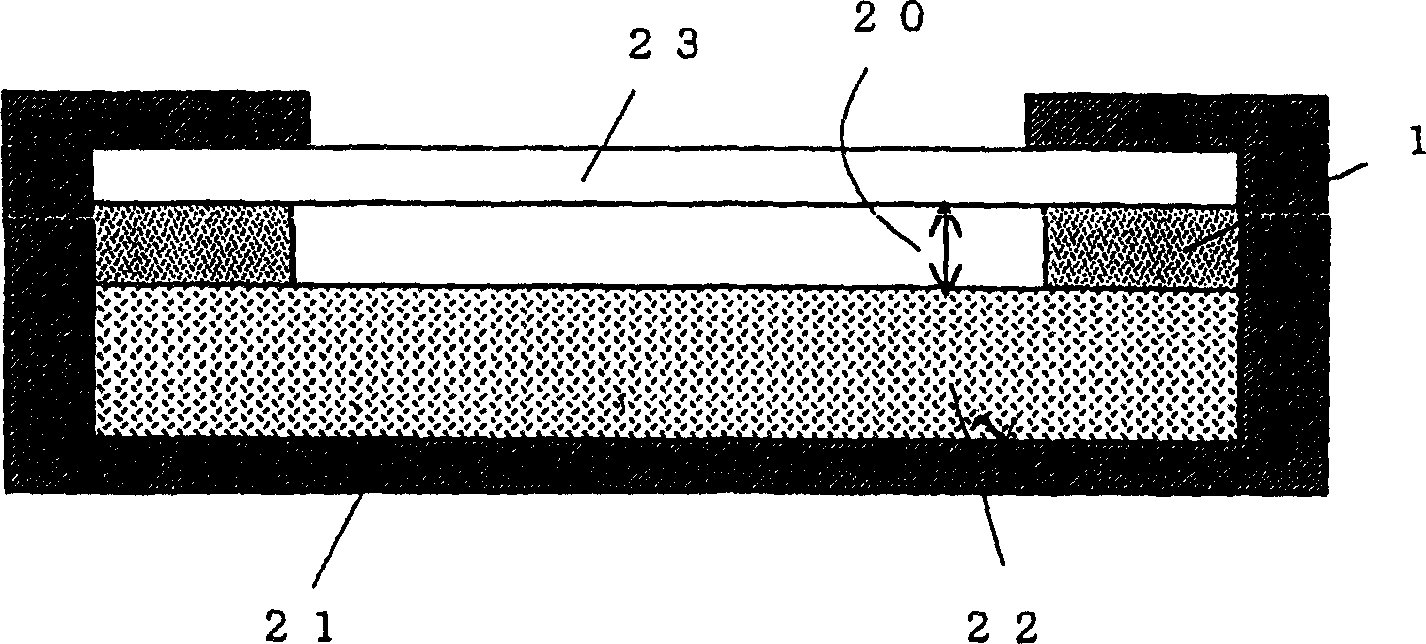

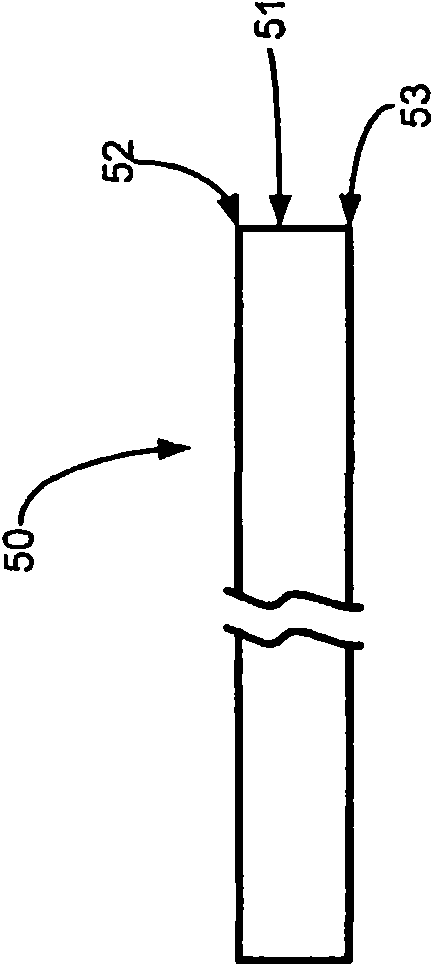

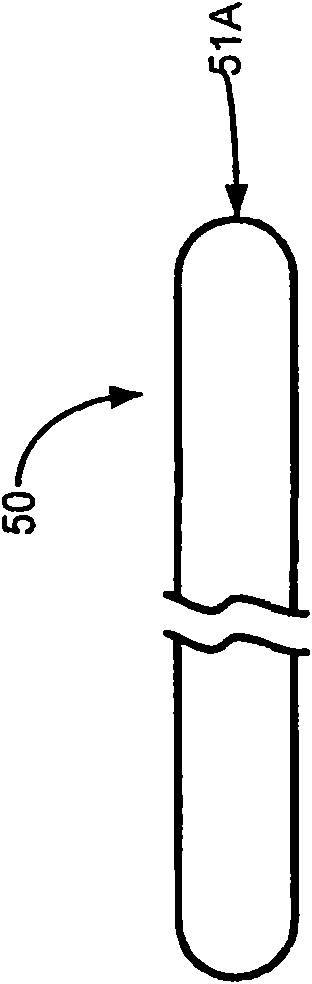

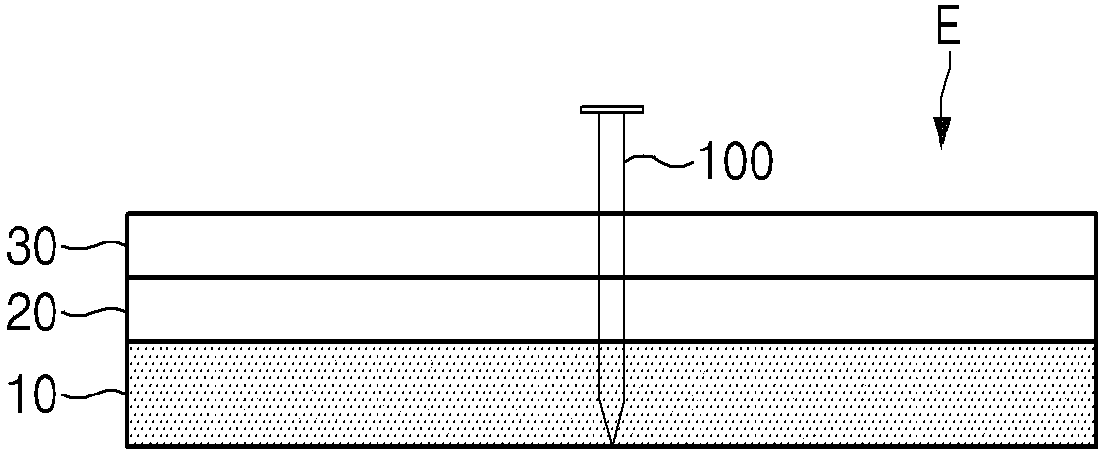

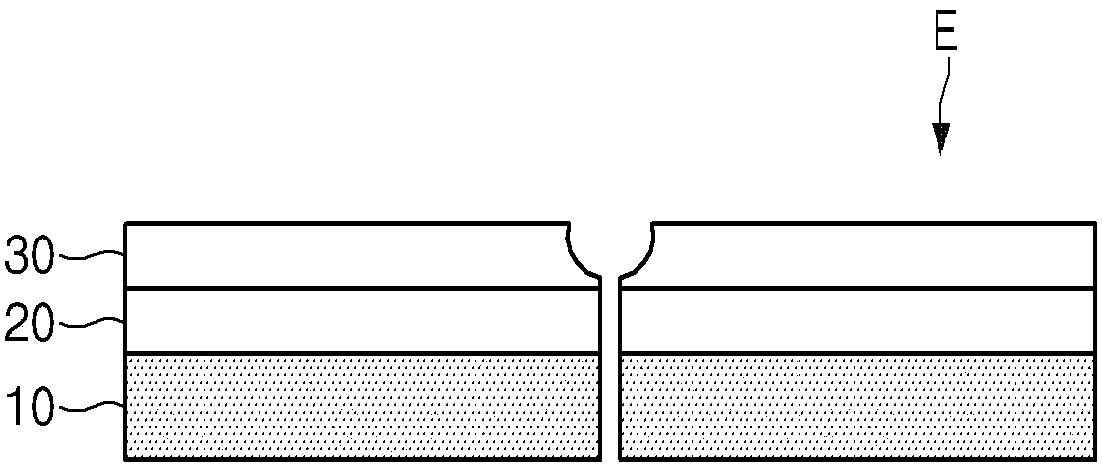

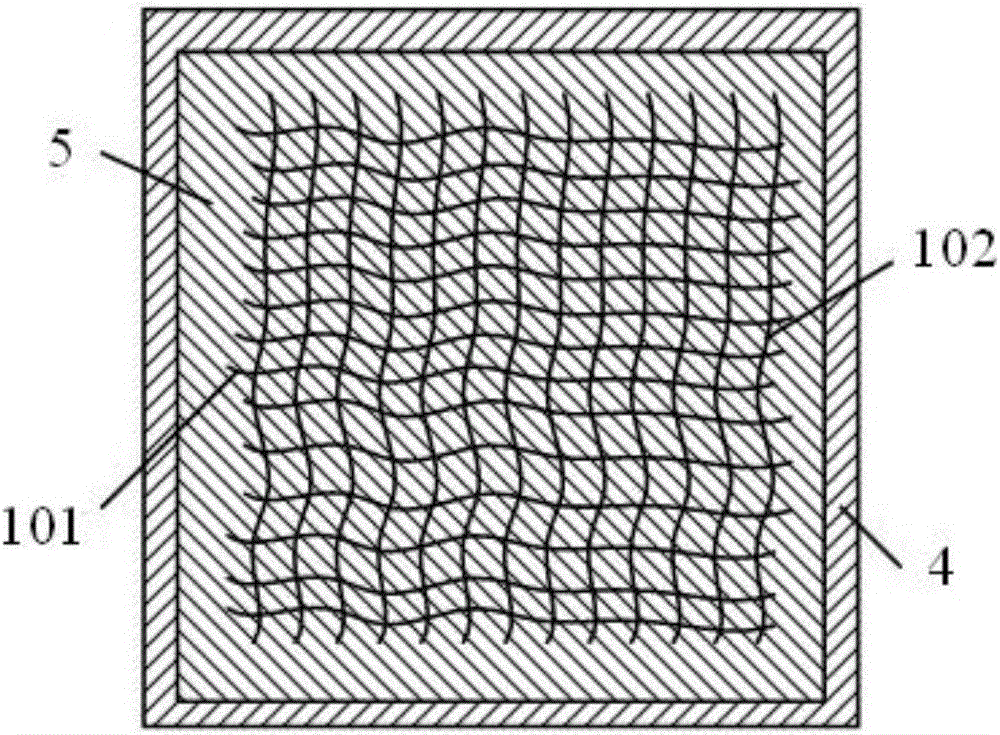

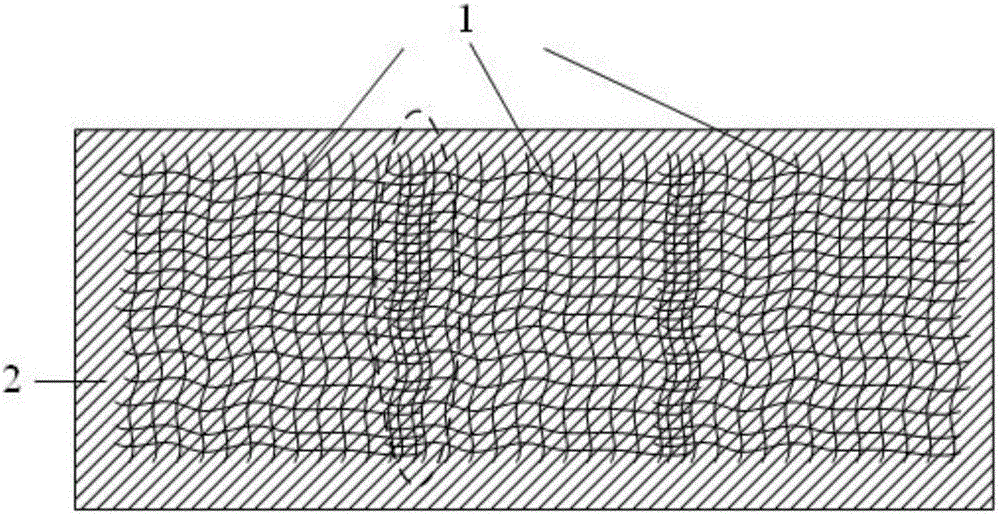

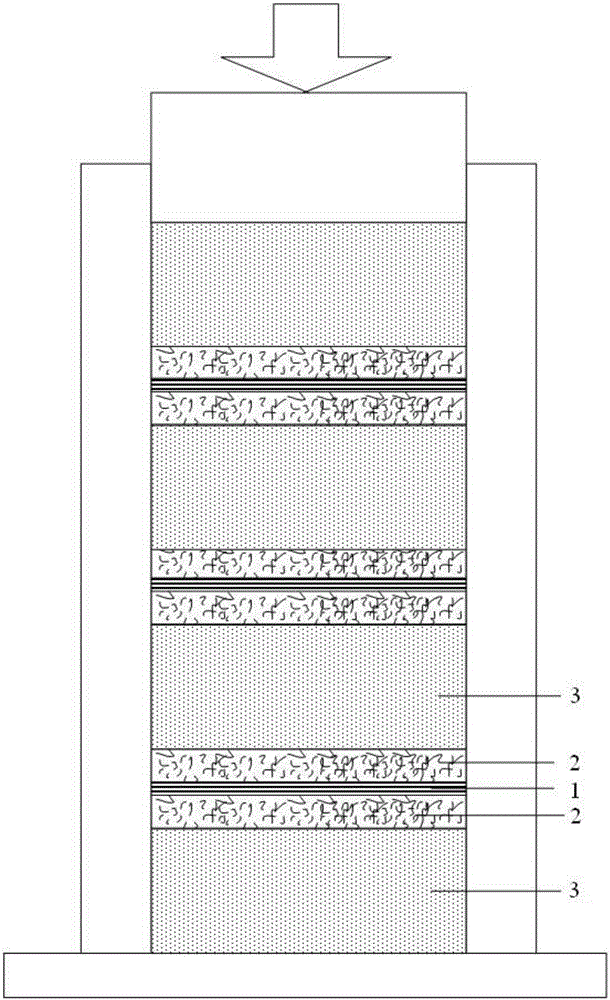

Functionally graded piezoelectric material preparation method for improving anti-fracture performance

InactiveCN106003849AImprove structural strengthImprove fracture performanceNon-macromolecular adhesive additivesLaminationAdhesiveHigh pressure

The invention relates to a functionally graded piezoelectric material preparation method for improving anti-fracture performance and belongs to a preparation method of a functionally graded piezoelectric material. Long fiber glass filaments are woven and arranged through longitudinal and transverse warp-weft grids to form grid sheets, an adhesive is prepared, and the functionally graded piezoelectric material is prepared through hot pressing, a static high-pressure high-temperature large-cavity synthesis method is adopted, the temperature is 1000-3000 DEG C, the pressure is 30-60 Mpa, and the time is 20-40 minutes. The preparation method has the advantages that the functionally graded piezoelectric material having the anti-fracture performance can be produced in a scale mode, so that the functionally graded piezoelectric material has a good using value and a wide application field.

Owner:JILIN UNIV

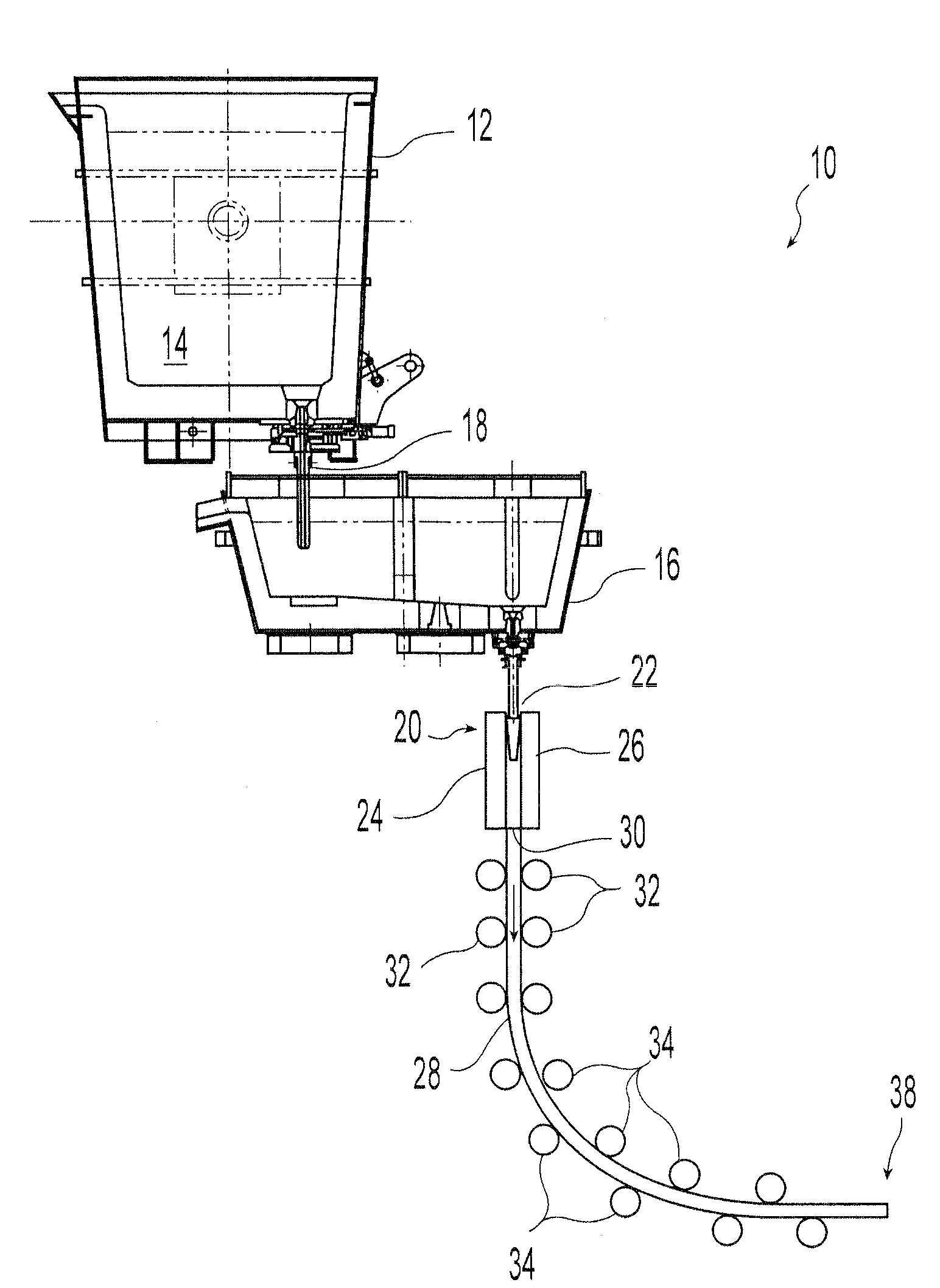

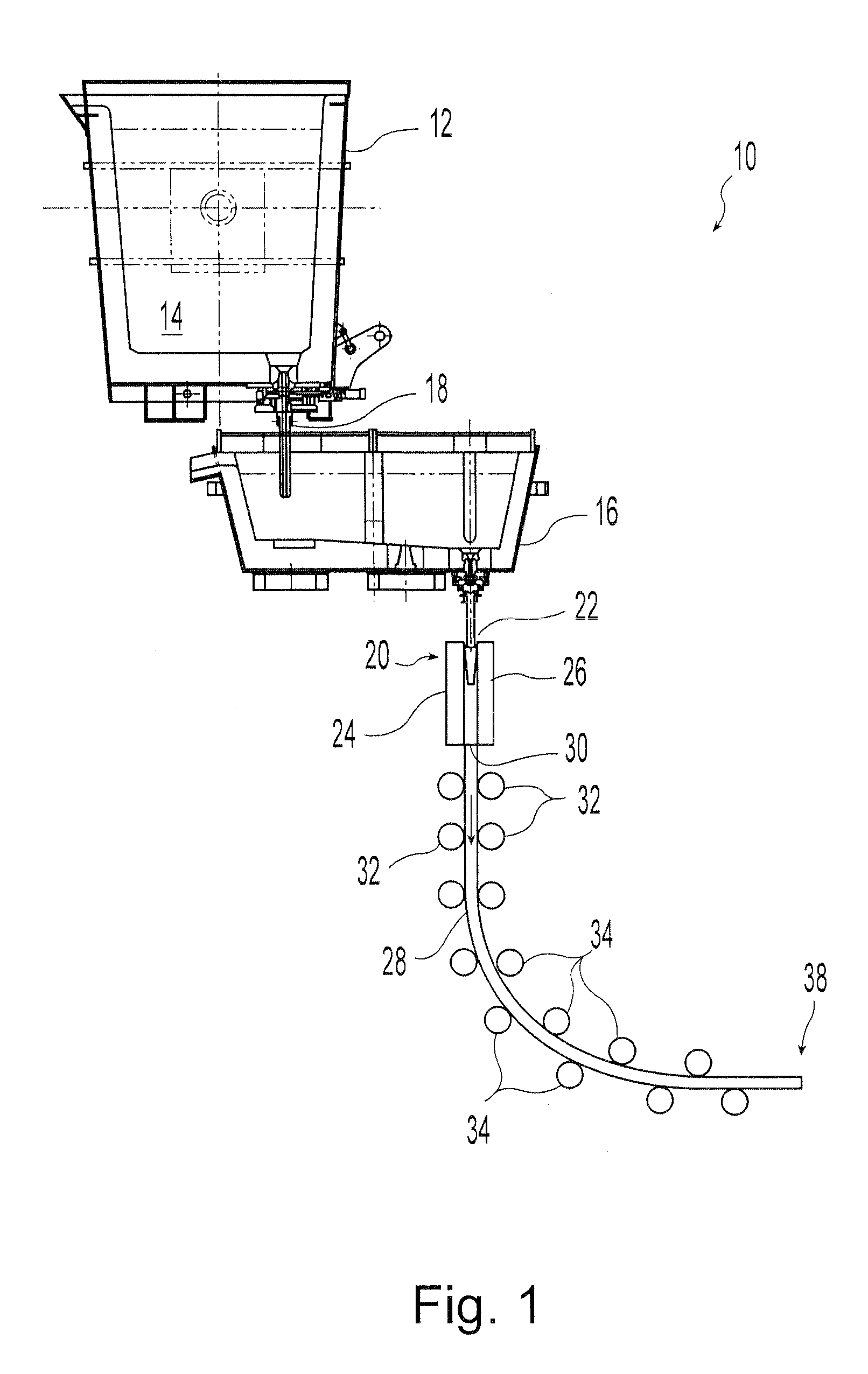

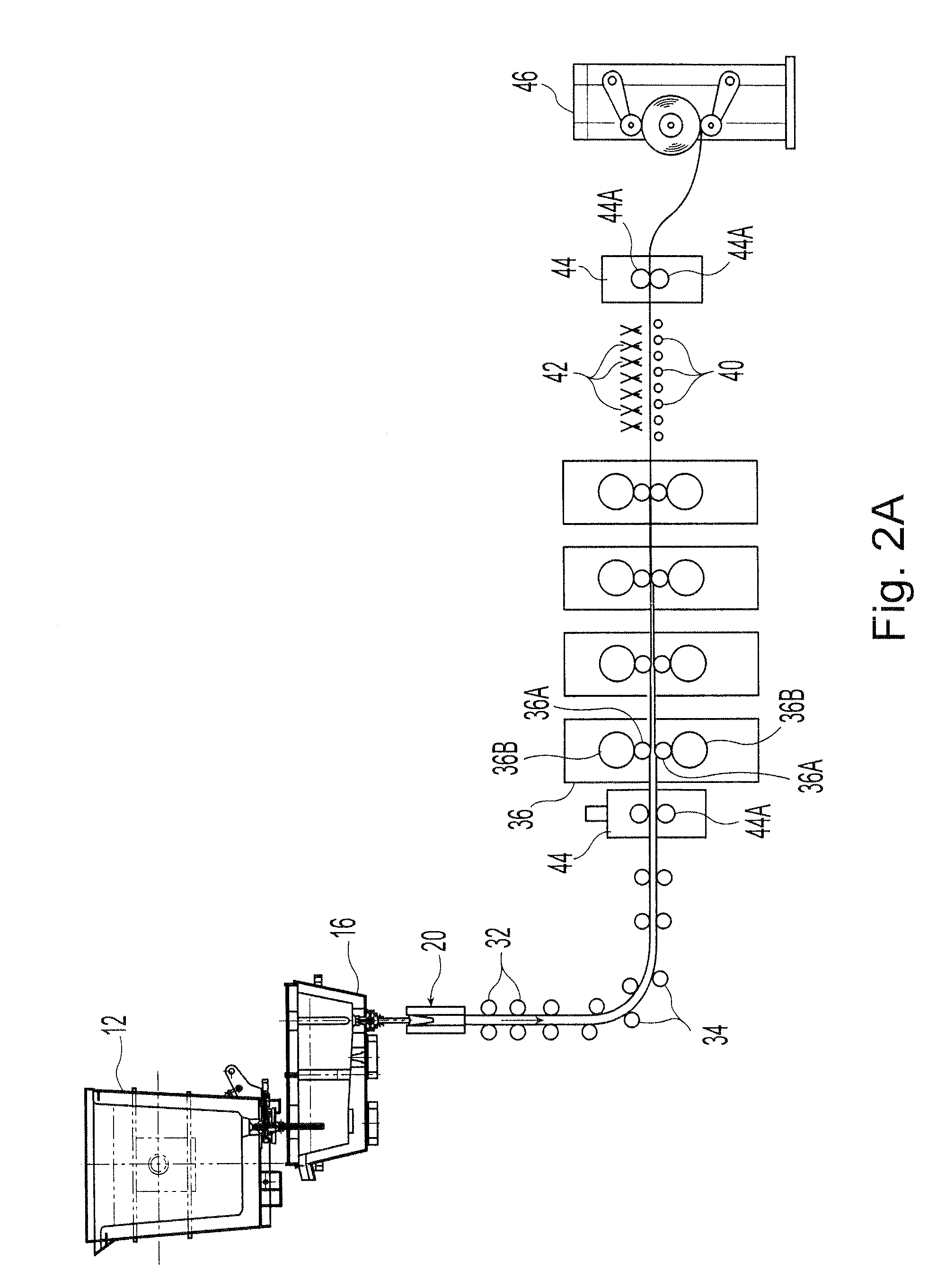

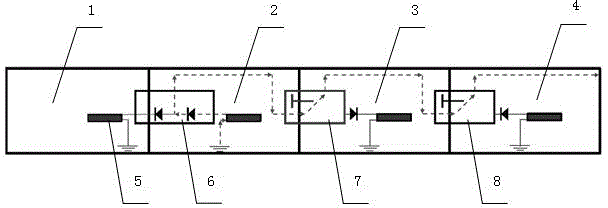

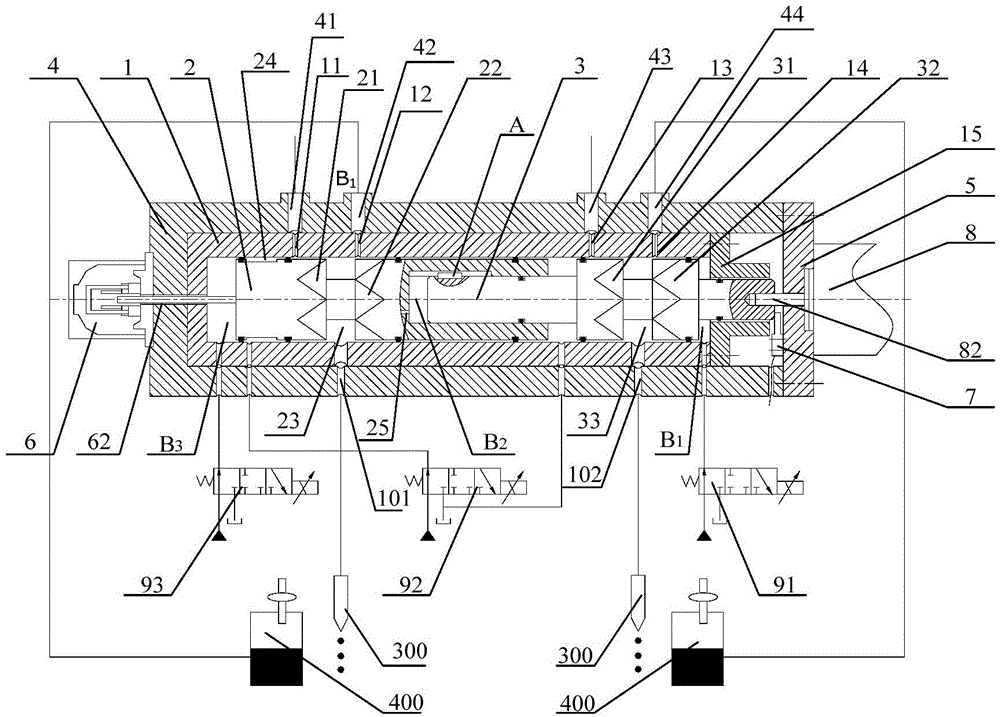

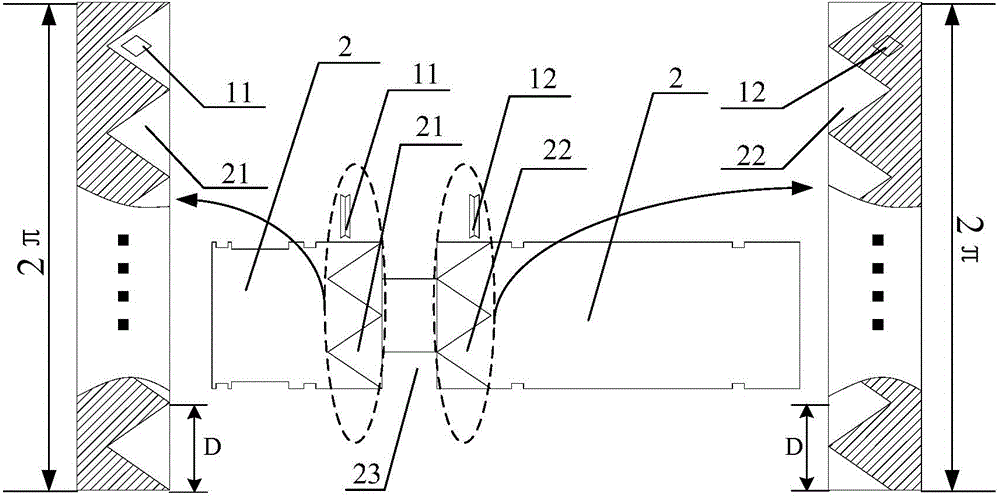

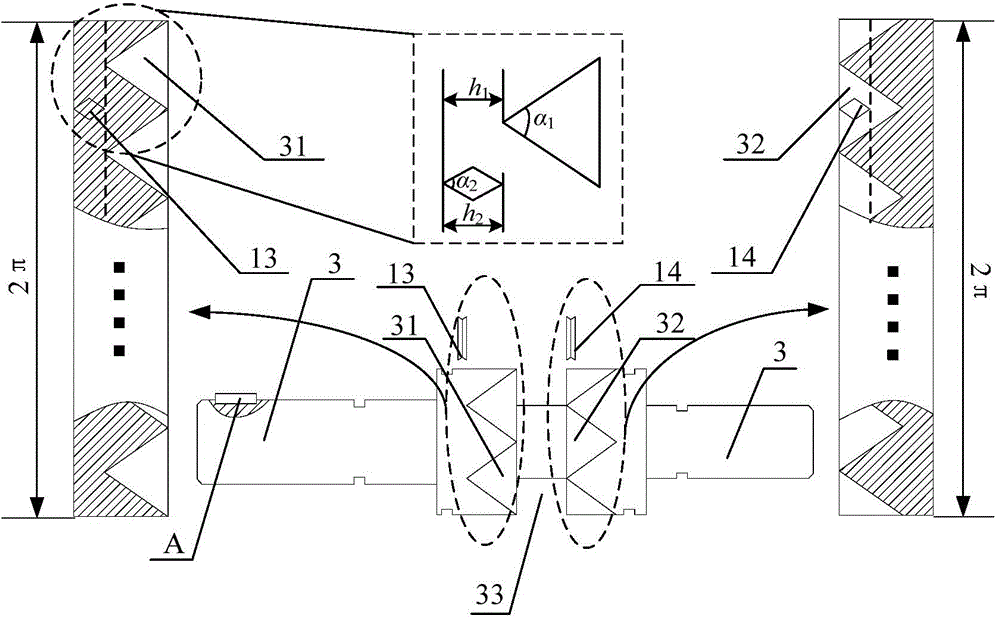

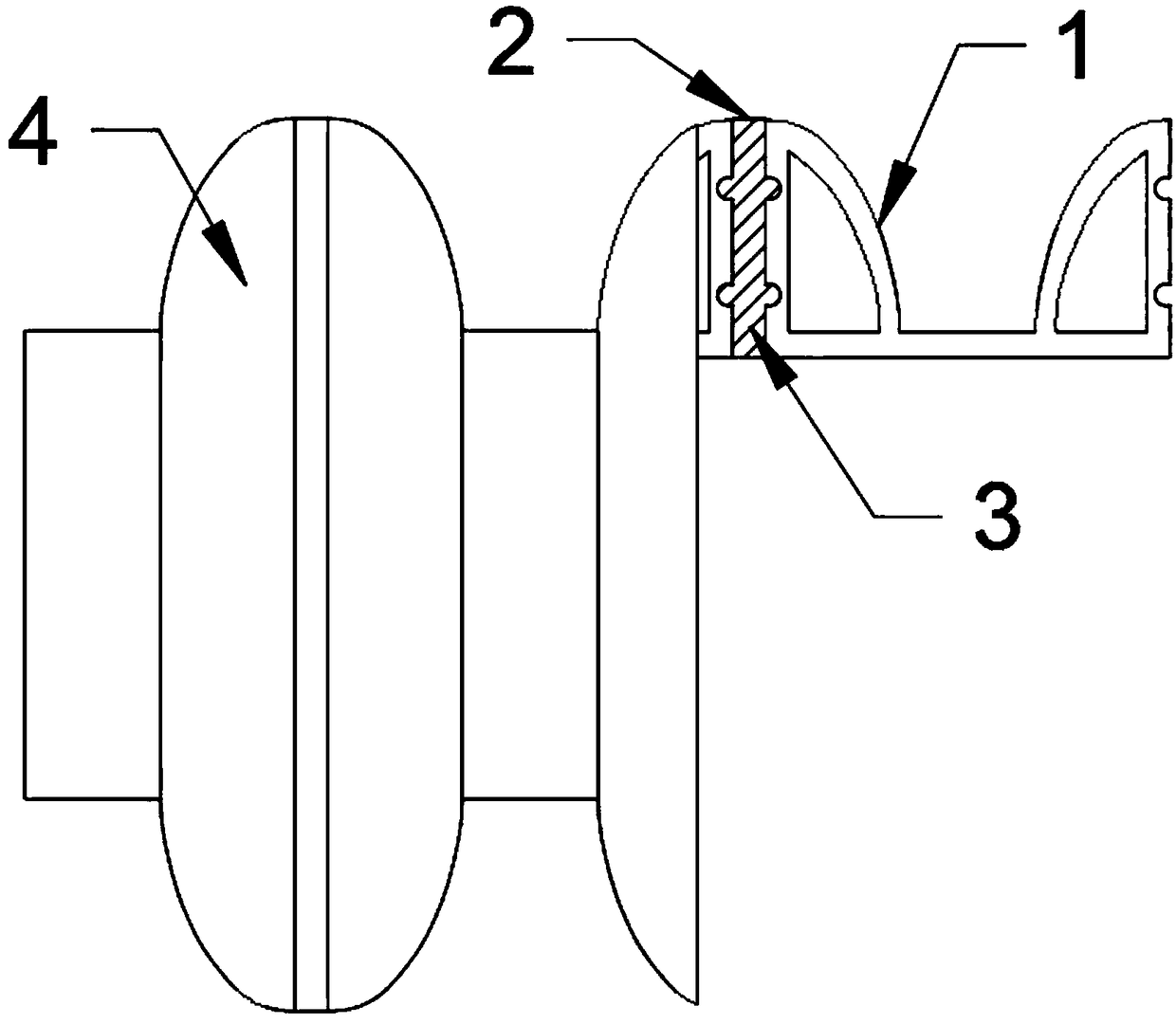

Rotary digital valve and injection system of 3D (Three Dimensional) printing equipment

ActiveCN104389832AHigh outputImprove printing efficiencyAdditive manufacturing apparatusOperating means/releasing devices for valvesRotary valveEngineering

The invention provides a rotary digital valve. The rotary digital valve comprises a valve sleeve, a left valve core and a right valve core, wherein the left valve core and the right valve core can move axially left and right and are arranged in the valve sleeve in a synchronous rotating manner; the valve sleeve is provided with a left feed hole and a right feed hole; the circumferential surface of the left valve core is provided with a periodically distributed left receiving groove array, and the left receiving groove array is communicated with a left feeding passage; the circumferential surface of the left valve core is provided with a periodically distributed right receiving groove array, and the right receiving groove array is communicated with a right feeding passage; the proportional output quantity of the left feeding and the right feeding depends on the mechanical duty ratio formed by axial movement displacement of the left valve core and the right valve core; the opening and closing frequency of the rotary digital valve is equal to the product of the rotation speed of the synchronous rotation of the left valve core and the right valve core and the number of grooves in the left receiving groove array or the right receiving groove array. According to the rotary digital valve, high frequency response and accurate feeding can be realized through quick switching of the rotary valve core and proportional output of the double valve cores; the rotary digital valve can be applied to 3D (Three Dimensional) printing equipment.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

Groove connected PE wound corrugated pipe

InactiveCN108930842AStable supportImprove stress resistanceRigid pipesPipe connection arrangementsAdhesive glueEngineering

The invention provides a groove connected PE wound corrugated pipe. The groove connected PE wound corrugated pipe comprises a plastic forming strip, connecting grooves, an adhesive glue injecting face, an annular locking plunger and a corrugated pipe. Two connecting grooves are separately formed in the end surfaces of left and right sides of the plastic forming strip and the corrugated pipe is mounted out of the plastic forming strip in a sleeving mode, and two ends of the plastic forming strip are of hollow structures; the adhesive glue injecting face is located on the inner wall of the corrugated pipe and is connected to the annular locking plunger, and the annular locking plunger is located in the corrugated pipe. The inner wall of the wound corrugated pipe is supported favorably, the internal anti-pressure ability of the wound corrugated pipe is enhanced, and the condition that circulation in the corrugated pipe is affected as the wound corrugated pipe is flattened and deformed because the corrugated pipe is extruded by an external force is avoided. By using the connecting grooves and the annular locking plunger, the plastic forming strip mounted in the wound corrugated pipe can be connected together to improve the tensile coefficient and the anti-break coefficient of the wound corrugated pipe, so that the wound corrugated pipe is steadier and more reliable.

Owner:HUBEI FEIGE TECH

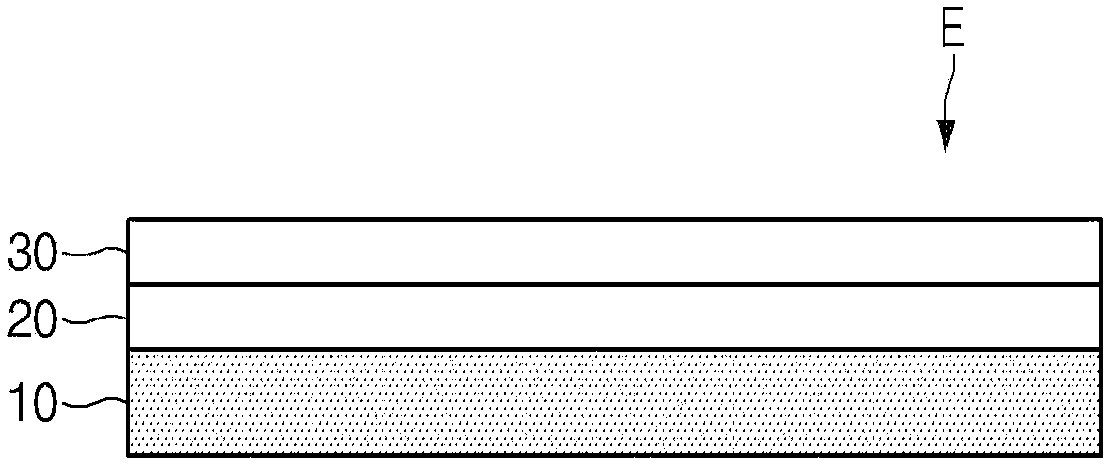

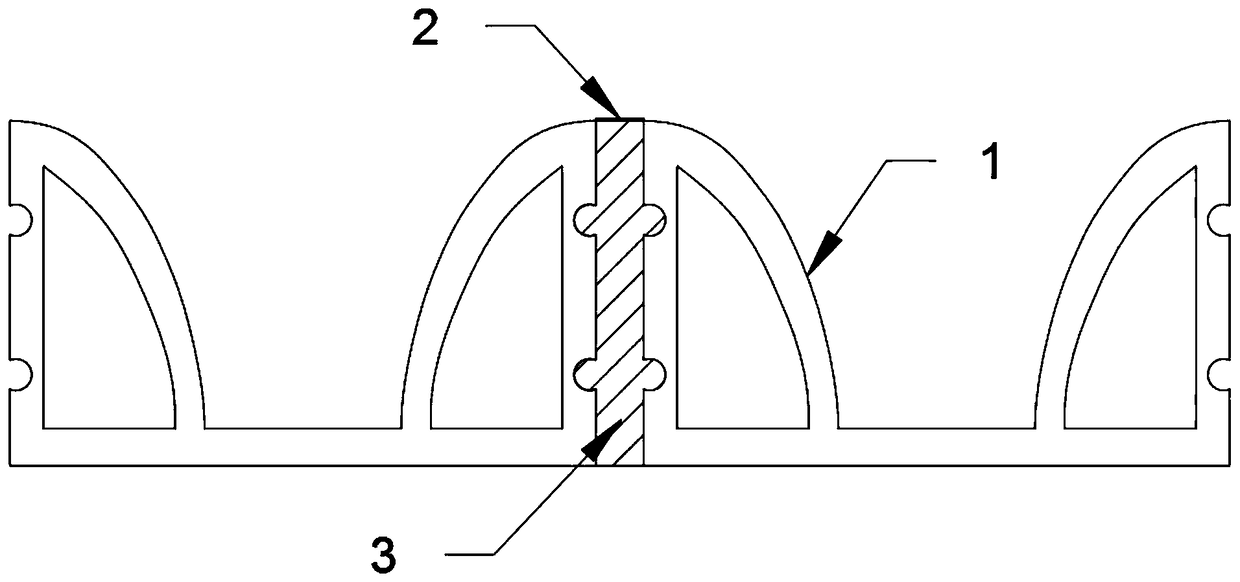

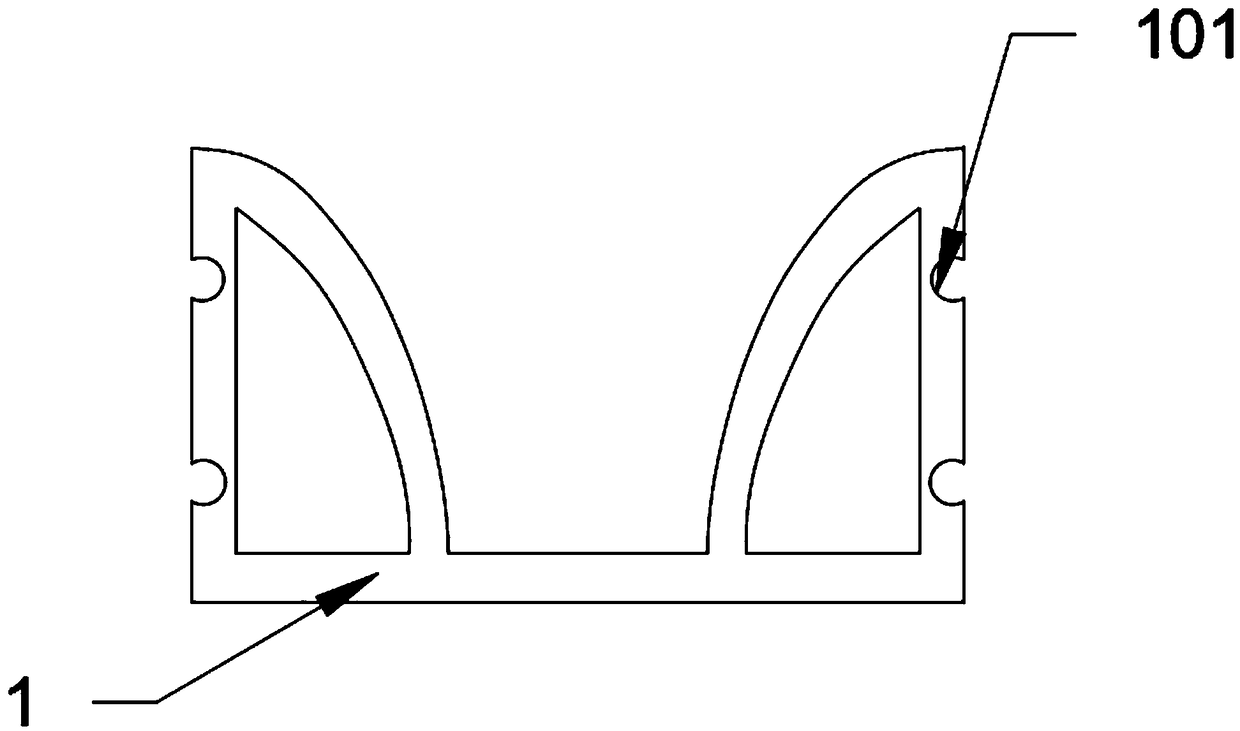

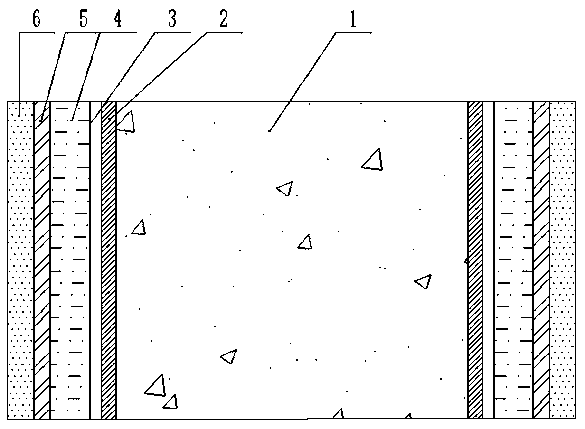

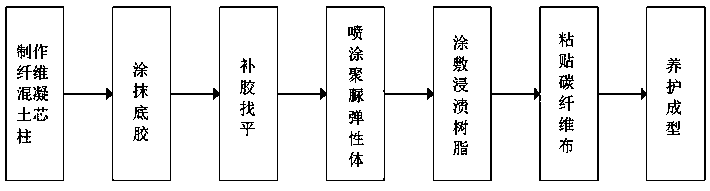

Bionic trunk fiber reinforced concrete beam and column structure

InactiveCN110359724APerfect mechanical propertiesVariety DurabilityBuilding repairsTrunk structureCarbon fibers

The invention relates to concrete beams and columns and discloses a carbon fiber-polyurea double-constraint fiber reinforced concrete beam and column structure based on a trunk structure bionic designconcept. The beam and column structure comprises a fiber reinforced concrete core, a bonding layer, a polyurea middle layer, an impregnating resin layer and a carbon fiber outer layer from inside tooutside in sequence. The carbon fiber outer layer and the polyurea middle layer constrain the inside fiber reinforced concrete core structure, thereby jointly forming a beam and column strengthened structure. The fiber reinforced concrete core and the polyurea middle layer are integrated through the bonding layer, and the carbon fiber outer layer is bonded to the outside of the polyurea middle layer through the impregnating resin layer. According to the structure, a bionic trunk structure is adopted for strengthening and optimizing the concrete structure, compared with a traditional steel-concrete combined structure, a C-P-C combined component designed based on the characteristics of wooden substrate, forming layer and active phloem of the trunk structure can derive diversified mechanicalperformance and durability.

Owner:TAIYUAN UNIV OF TECH

Special micro-nano composite powder for laser repair for micro-cracks on stainless steel surface

ActiveCN106636892AImprove compactnessImprove fracture performanceTransportation and packagingMetal-working apparatusMicro nanoCrystallite

The invention discloses a special micro-nano composite powder for laser repair for micro-cracks on a stainless steel surface. The special micro-nano composite powder comprises, in percentage by weight, 3-7% of nano-WC, 0.5-2% of nano-Al2O3 and the balance micro-scale stainless steel powder, wherein the micro-nano powders are adequately mixed through mechanical ball milling, then blended by virtue of absolute ethyl alcohol, and then further uniformly mixed; and the stainless steel powder comprises, in percentage by weight, 0.08% of C, 0.5% of Si, 1.46% of Mn, 0.03% of P, 0.005% of S, 19% of Cr, 9.5% of Ni, 0.5% of Mo and the balance Fe. The composite powder provided by the invention is applicable to laser repair with a high-toughness requirement for micro-cracks on the surface of a stainless steel part; and after the laser repair, the composite powder can be adequately fused with a base material, a repair layer is metallurgically bonded with the interface of a base body without cracks and inclusions, and fine crystal grains are contained in the repair layer, thus the compactness and fracture performance of the repair layer are improved.

Owner:DALIAN UNIV OF TECH

A method for repairing micro-crack tips on stainless steel surfaces using nanoparticles

ActiveCN105714286BImprove fracture performanceImprove reliabilityMetallic material coating processesHeat-affected zoneNanoparticle

The invention provides a method for repairing a microcrack tip on a stainless steel surface by means of nano-particles. The method is suitable for stainless steel with microcracks on the surface. The method comprises the steps that the to-be-repaired microcrack tip on the stainless steel surface is treated; composite powder containing the nano-particles is arranged on the microcrack tip in advance; the composite powder and a part of a matrix are fused by means of lasers; the repaired microcrack tip region is finished; and the fracture property of the stainless steel matrix obtained after repairing is detected, and the microstructure of the section of a repair layer is observed. The repairing method is high in flexibility, and repairing can be carried out many times; and meanwhile, the problems of large deformation, a large heat affected zone and the like in a conventional method are avoided in the repairing method. According to the repairing method, the microcrack tip is closed again, the matrix and the composite powder arranged on the microcrack tip in advance are in metallurgical bonding, and the defects of cracks, pores and the like do not exist in the bonding region; grains of the repair layer of the microcrack tip are refined, and the structural compactness is improved; and in addition, the fracture property generated after repairing is remarkably improved.

Owner:DALIAN UNIV OF TECH

Powder capable of being used for improving fracture performance of stainless steel surface micro crack laser repaired piece

InactiveCN106835117AImprove fracture performanceGood workmanshipMetallic material coating processesAlcoholAlloy

The invention belongs to the technical field of alloy materials, and discloses powder capable of being used for improving the fracture performance of a stainless steel surface micro crack laser repaired piece. The composite powder comprises, by weight percent, 1%-10% of nano WC and the balance micron-level stainless steel powder. The above powder is subjected to mechanical ball milling to be sufficiently mixed and then is blended through absolute ethyl alcohol to be further evenly mixed. The stainless steel powder comprises, by weight percent, 0.08% of C, 0.5% of Si, 1.46% of Mn, 0.03% of P, 0.005% of S, 19% of Cr, 9.5% of Ni, 0.5% of Mo and the balance Fe. The provided composite powder is particularly suitable for laser repairing of a stainless steel component surface micro crack with the fracture performance requirement. Under the laser repairing action, the composite powder and the stainless steel surface micro crack are sufficiently and evenly fused, grain of a repairing layer is refined through nano WC powder, the sharp end of the surface micro crack is effectively closed, the problem about the stainless steel surface micro crack is solved, and the fracture performance of a workpiece is greatly improved.

Owner:DALIAN UNIV OF TECH

Method for whitening and decoloring black human hair

The invention discloses a method for whitening and decoloring black human hair. The method is characterized by comprising the following steps: cleaning black human hair through a detergent; adding water for soaking; preprocessing through ultrasonic wave; preprocessing by discharging through plasma under low temperature in a vacuum condition; correspondingly dissolving papain and neutral protease in a phosphate buffering solution; then sequentially adding the preprocessed human hair for correspondingly dipping; washing with clean water; transferring the scale-removed human hair into a catalyzing processing solution in a closed environment; increasing the temperature; taking out; washing with water; transferring into a penetrant solution; heating; adding catalase to a whitening solution; adding the human hair processed by coordination catalysis and penetrating; whitening in constant-temperature water bath; regulating the pH to be neutrality; taking out; washing with water; processing through a fluorescent whitening agent solution; washing with water; and drying through an air blasting drying box.

Owner:ANHUI FORTUNE FASHION CULTURE

Toughness-enhanced carbon fiber reinforced polyformaldehyde composite material and preparation method thereof

The invention discloses a toughness-enhanced carbon fiber reinforced polyformaldehyde composite material and a preparation method thereof. The composite material is characterized by being prepared from the following raw materials in parts by weight: 90-100 parts of polyformaldehyde, 10-30 parts of carbon fibers, 4-7 parts of light calcium carbonate, 2-4 parts of copolyamide, 0.4-0.5 part of fatty acid zinc, 0.3-0.5 part of an antioxidant 1010, 3-5 parts of thermoplastic elastomer G155D, 0.3-0.6 part of a silane coupling agent KH-550, 2-4 parts of oxidized graphene and 2-3 parts of nano silica. According to the invention, the added carbon fibers are dispersed evenly in polyformaldehyde after being preheated, so that the comprehensive properties of the material can be improved; the added thermoplastic elastomer is capable of increasing the elasticity of the polyformaldehyde and improving the fracture property; the added light calcium carbonate is capable of improving the toughness of the polyformaldehyde; as a result, the product competitiveness is greatly improved.

Owner:HEFEI KANGLING HEALTH TECH

High-performance concrete recycled from waste solids and preparation method thereof

InactiveCN113461355AEfficient reuseIncrease productionSolid waste managementCrazingUltimate tensile strength

The invention discloses high-performance concrete recycled from waste solids and a preparation method thereof. The high-performance concrete recycled from waste solids is prepared by the following steps of: reprocessing waste tires and waste plastics as main recycled materials, removing impurities in the materials, performing corresponding surface treatment, and mixing and stirring the materials with concrete. The high-performance concrete is prepared by replacing a part of aggregate with a rubber particle material, optimizing the proportion to a certain extent and adding a recycled polypropylene fiber material. The freezing resistance, the strength and the durability of the high-performance concrete are improved, and cracks of the concrete are reduced. The durability and anti-crack toughness of the concrete are improved. When cracks are generated and the tips of the cracks extend to the rubber particles, the deformation capability of the rubber particles dissipates the stress at the tips of the cracks, and further extension of the cracks is delayed. By adding the recycled polypropylene fibers, the concrete shows more superior residual strength and fracture energy than common concrete.

Owner:NANJING FORESTRY UNIV

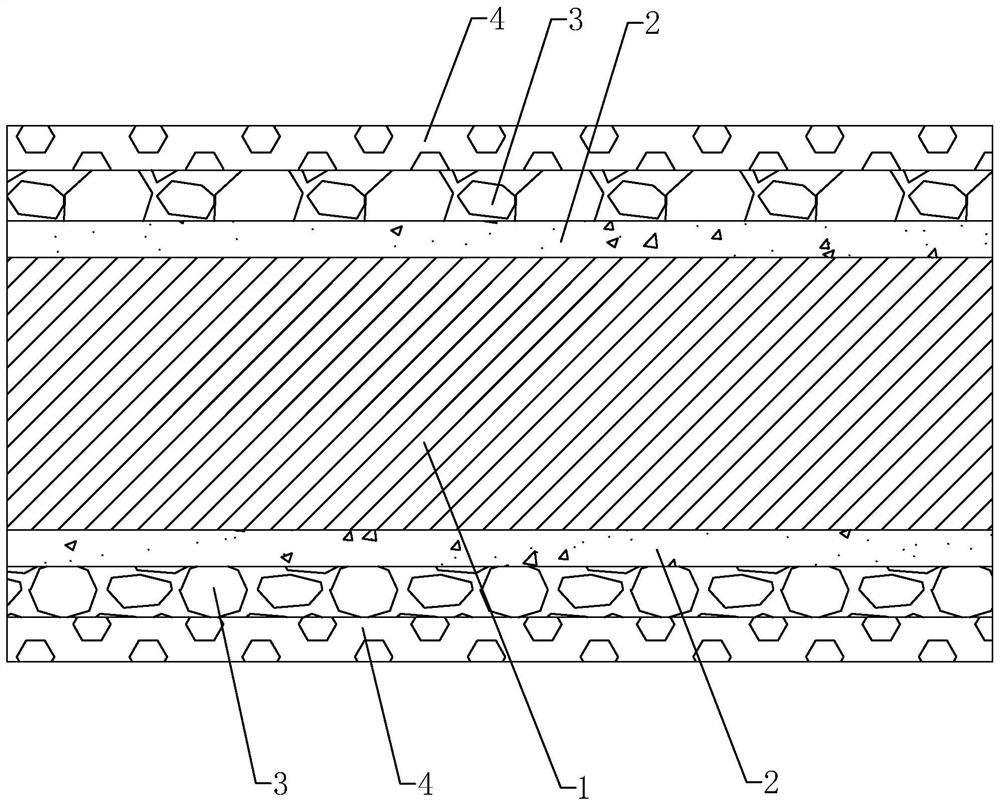

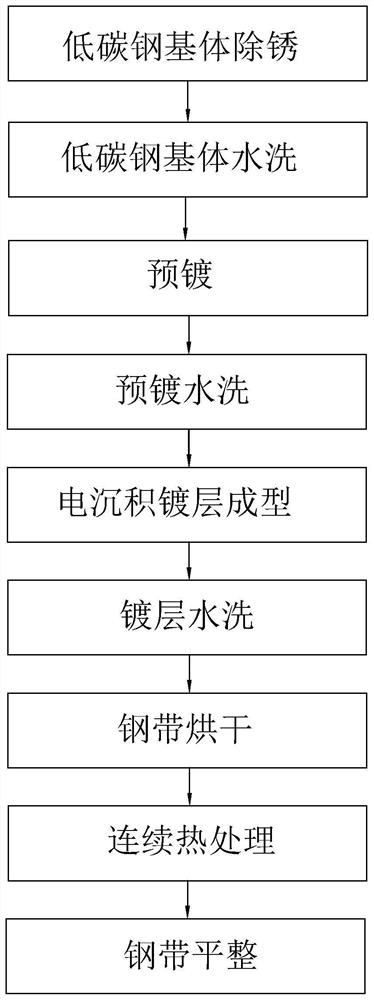

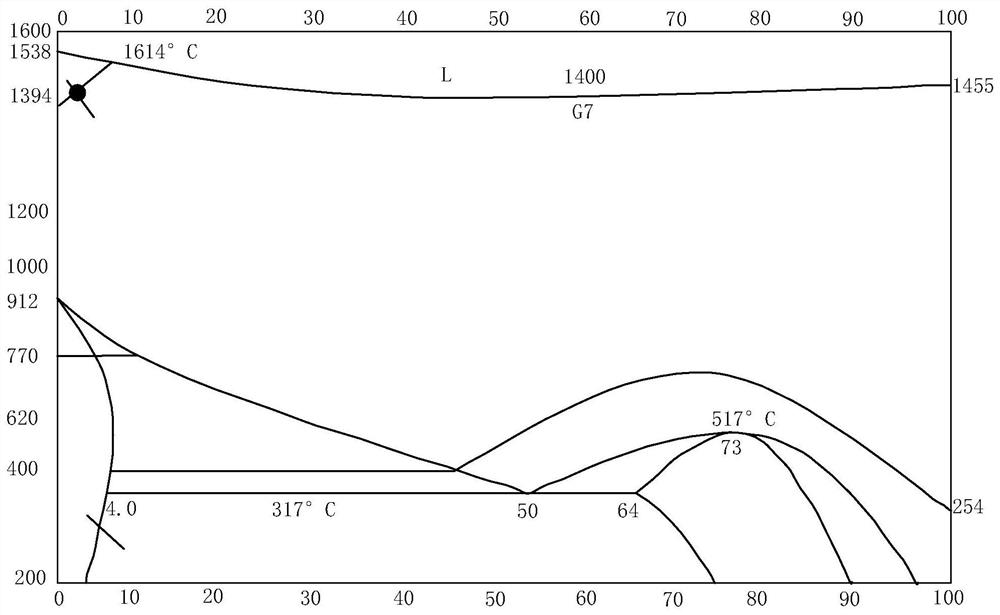

A battery steel strip and its preparation method

The invention discloses a method for preparing battery steel strips, which belongs to the field of steel strip alloys and preparation methods thereof. The key points of the technical solution include: S1: derusting the low-carbon steel substrate; S2: washing the low-carbon steel substrate; S3: pre-washing the low-carbon steel substrate Plating; S4: pre-plating water washing; S5: electrodeposited coating forming; S6: coating washing; S7: steel strip drying; S8: continuous heat treatment; A battery steel strip, comprising a low-carbon steel substrate, both sides of the low-carbon steel substrate are provided with a rice crystal Ni-Cr coating, and the rice crystal Ni-Cr coating is provided with a semi-bright Ni-Co coating, so The semi-bright Ni-Co coating is provided with a full-gloss Ni-Co coating outside, and the crystal phase structure of the steel strip interpenetrates to improve the strength and fracture resistance of the steel strip.

Owner:无锡市程晖电源配件有限公司

A shield tunnel segment structure and its connection structure

The invention discloses a shield tunnel segment structure and its connection structure, comprising a segment body, characterized in that: the segment body is mainly composed of a steel plate layer, a concrete layer wrapping the steel plate layer, respectively located on both sides of the steel plate layer and It is composed of steel mesh embedded in the concrete layer; the side edge of the segment body is fixed with metal joints, and the outer side of the metal joints is provided with a groove for accommodating a waterstop. Waterstop: the outer side of the segment body is provided with an outer protective layer, and the outer protective layer is a polyurea layer compounded on the outer side of the segment body. The connecting structure is composed of two shield tunnel segment structures arranged adjacently and a connector connecting the two shield tunnel segment structures, and the connecting steel plate is composed of an arc section in the middle and straight sections on both sides. The invention has the characteristics of small thickness, high strength, and the joint is not easy to be damaged, and has good joint deformation control effect, good seam waterproof effect, high durability and convenient repair.

Owner:SUZHOU UNIV

Preparation method of low-hydrophilicity polyurethane film

InactiveCN111484593AImprove mechanical propertiesHigh breaking strengthPolymer sciencePolyurethane membrane

The invention discloses a preparation method of a low-hydrophilicity polyurethane film. The preparation method comprises the following steps: (1) preparing an intermediate 1; (2) obtaining a compositesolution; (3) obtaining composite particles; (4) obtaining a dimethyl formamide group reaction mucus; (5) coating the dimethyl formamide reaction mucus on a flat plate, and then drying to constant weight to obtain a polyurethane film. The invention provides the preparation method of the low-hydrophilicity polyurethane film. The water contact angle of the polyurethane film treated by the method disclosed by the invention is reduced to a certain extent; therefore, the water repellency of the polyurethane film is greatly improved; compared with the prior art, the prepared polyurethane film has the advantages that a certain hydrophobic effect is shown, the relatively strong hydrophilicity is reduced, and meanwhile, the breaking property and the tensile property can be improved to a certain extent, so that the mechanical property of the prepared polyurethane film is improved to a certain extent, and the application range of the prepared polyurethane film can be obviously expanded.

Owner:含山县领创新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com