Multi-dimension polypropylene fiber concrete

A technology of polypropylene fiber and concrete, which is applied in the field of concrete to achieve the effects of improving fracture performance, frost resistance, compression resistance and splitting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1. Compressive and split tensile strength test of concrete

[0042] This test uses a 100mm×100mm×100mm cube non-standard specimen. The measured uniaxial compressive strength values should be multiplied by a size conversion factor of 0.95, and the split tensile strength value should be multiplied by a size conversion factor of 0.85.

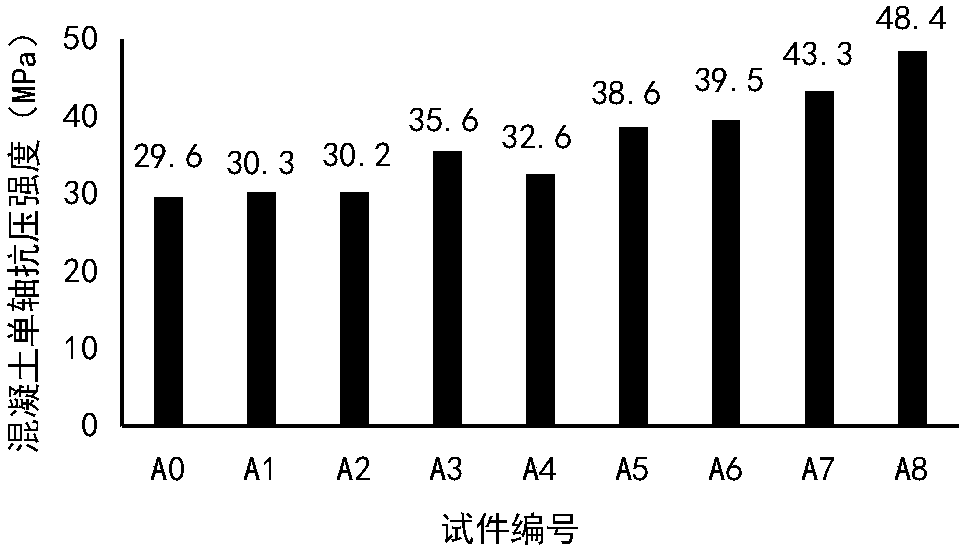

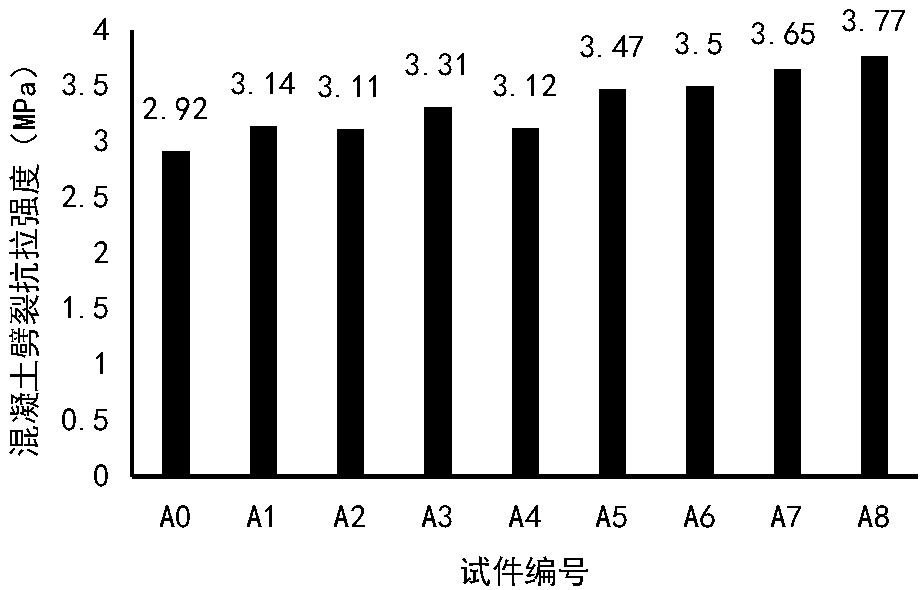

[0043] The uniaxial compressive strength of concrete is shown in Table 3 and figure 1 As shown, the splitting tensile strength is shown in Table 4 and figure 2 Shown:

[0044] Table 3 Record table of determination of uniaxial compressive strength of concrete

[0045]

[0046]

[0047] Table 4 Record table of concrete splitting tensile strength measurement

[0048]

[0049] From Table 3, Table 4, figure 1 with figure 2 It can be seen that: Compared with plain concrete, the compressive and splitting tensile strength of concrete mixed with fiber are improved, the compressive strength is increased by 2% to 63.5%, the tensile strength is incre...

Embodiment 2

[0053] Example 2: Concrete freeze-thaw cycle test

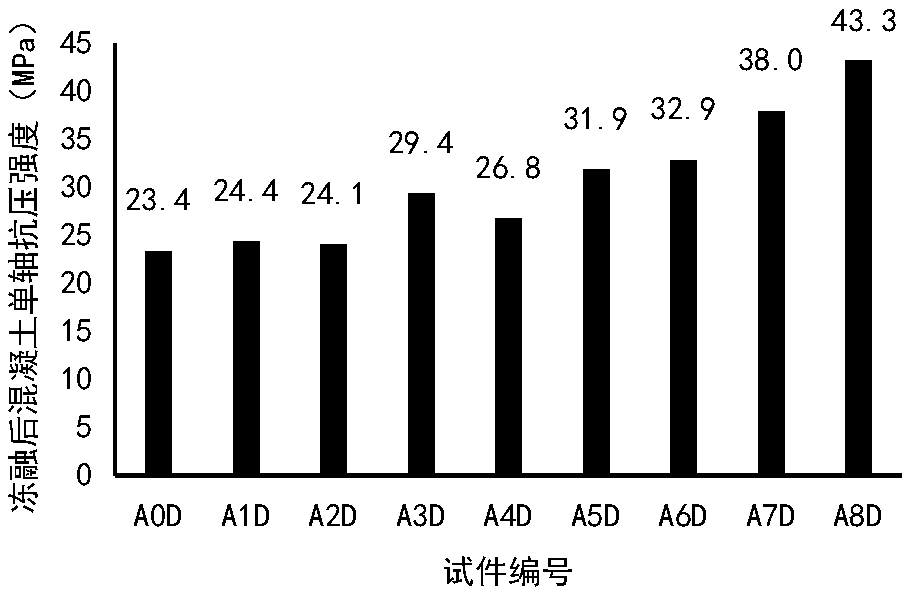

[0054] The uniaxial compressive strength of concrete after 200 freeze-thaw cycles is shown in Table 5 and image 3 As shown, the splitting tensile strength is shown in Table 6 and Figure 4 Shown:

[0055] Table 5 Record table of determination of uniaxial compressive strength of concrete after freezing and thawing

[0056]

[0057] Table 6 Record table of determination of split tensile strength of concrete after freezing and thawing

[0058]

[0059] From Table 5, Table 6, image 3 with Figure 4 It can be seen that the addition of fiber improves the compressive and split tensile strength of concrete after freezing and thawing, and the compressive strength is increased by 3.0% to 85.0%, and the tensile strength is increased by 8.2% to 42.0%; and A0 D In comparison, the addition of polypropylene fine fiber alone improves the compression and splitting tensile strength of concrete after freezing and thawing, while the single addition of ...

Embodiment 3

[0072] Example 3 Three-point bending load test of concrete notched beam

[0073] The concrete fracture energy obtained by the three-point bending load test of the concrete notched beam is shown in Table 9 and Picture 9 Shown:

[0074] Table 9 Test results of concrete fracture energy

[0075]

[0076] From Table 9 and Picture 9 It can be seen that the incorporation of fibers can greatly increase the fracture energy of concrete. Compared with plain concrete, the fracture energy is increased by 46.8% to 237.6%. Among them, the A1 sample with polypropylene fine fiber has the least increase, which is 46.8%. , And multi-size polypropylene fiber concrete A8 specimens increased the most, 237.6%; multi-size polypropylene fiber concrete A7, A8 specimens, from the results can be seen, under the same total content of the same conditions, the proportion of fine fiber The fracture energy of the A8 specimen was 48.3% higher than that of the A7 specimen. Among the concrete specimens A1 to A8 mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com