Rotary digital valve and injection system of 3D (Three Dimensional) printing equipment

A digital valve and rotary technology, applied in the field of digital valves, can solve problems such as adverse effects on product printing accuracy, impact on product quality, and high cost, to suppress secondary droplets and other unnecessary jets, achieve high-frequency response, and enhance fracture effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

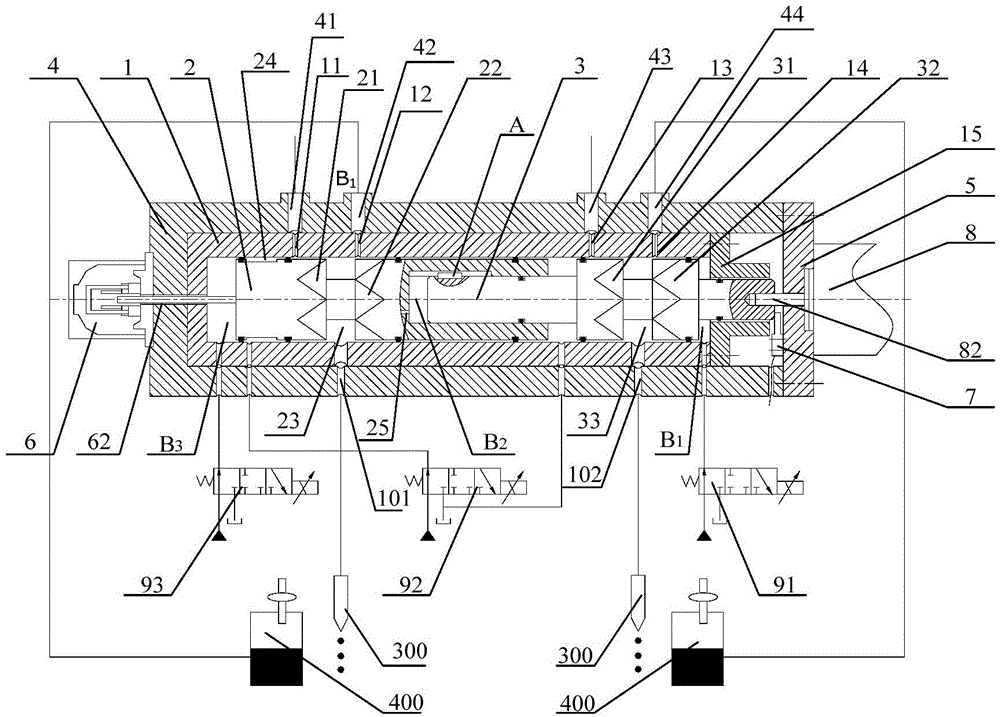

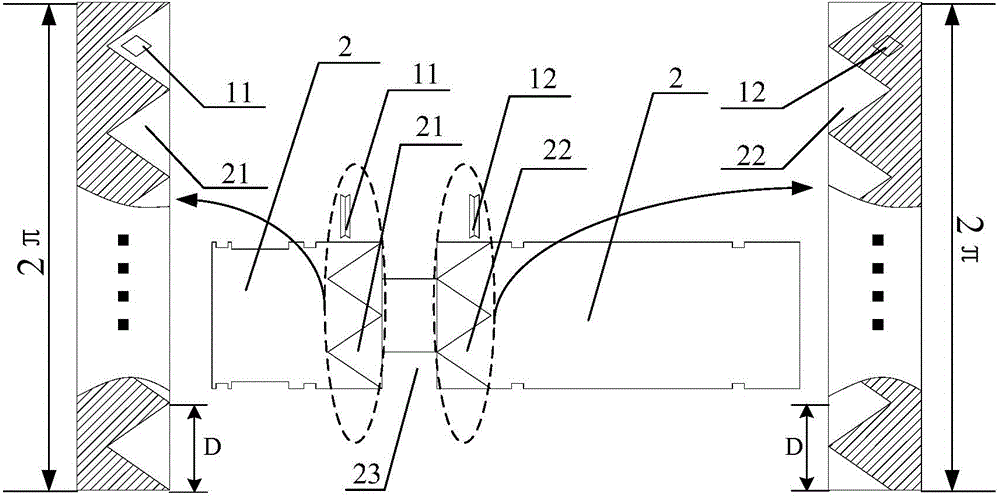

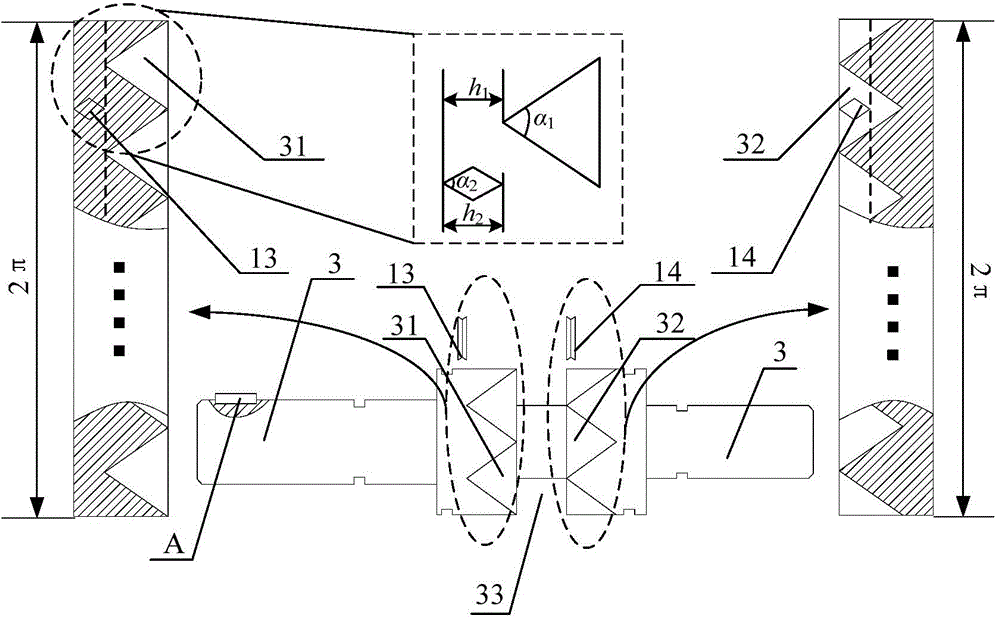

[0038] Such as figure 1 As shown in FIG. 6, a preferred embodiment of the rotary digital valve 100 of the present invention includes a valve sleeve 1, a left valve core 2 and a right valve core 3, and also includes a valve body 4, a valve cover 5, a displacement sensor 6 and a limiter. Position switch 7; the left spool 2 and the right spool 3 can move left and right and are installed inside the valve sleeve 1 in a synchronous rotation; wherein, the left end of the right spool 3 is inserted in the right end of the left spool 2, And the right spool 3 and the left spool 2 are connected by a key and driven by the motor 8 through the motor shaft 82 to realize synchronous rotation. The valve cover 5 is arranged on the right end of the valve body 4, and the valve sleeve 1 is arranged in the valve body 4, and the valve sleeve 1 is provided with a left feed hole 11, a left back suction hole in sequence from left to right in the axial direction. Hole 12, right feeding hole 13 and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com