High-performance cement-based composite material and preparation method thereof

A composite material and cement-based technology, applied in the field of building materials, can solve the problems of reinforced concrete structure strength decline, ecological environment impact, structural component service life and safety threats, etc., to achieve enhanced performance, static compression elastic modulus and the effect of improving the fracture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16

[0023] The preparation of cement-based composite material comprises the following steps:

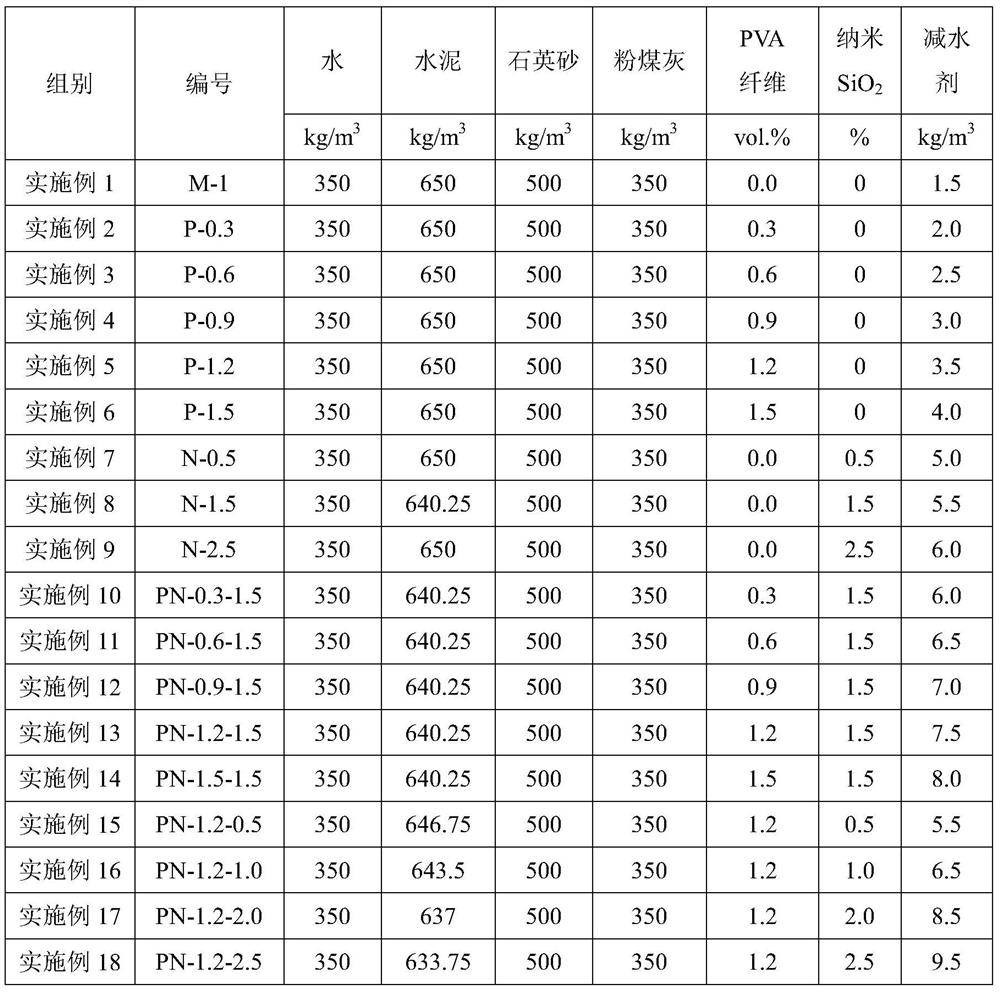

[0024] (1) Take each raw material according to the raw material consumption in Table 1;

[0025] (2) mix cement, fly ash and quartz sand, stir evenly, obtain mortar;

[0026] (3) Nano-SiO 2 After mixing with the water reducer, add part of the water, stir, and after the dispersion is uniform, add to the mortar obtained in step (2), continue to stir for 2 minutes, then add the remaining water, stir for 1 minute, then add the PVA fiber powder four times, each time After stirring for 2 minutes, after the PVA fiber is completely added, stir again evenly to obtain the cement-based composite material.

[0027] Embodiments 1 to 16 all adopt the above steps to prepare cement-based composite materials. The cement-based composite materials adopt a water-binder ratio of 0.35, a lime-sand ratio of 2, and an equivalent amount of fly ash to replace 35% of the quality cement. The ratio of raw materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com