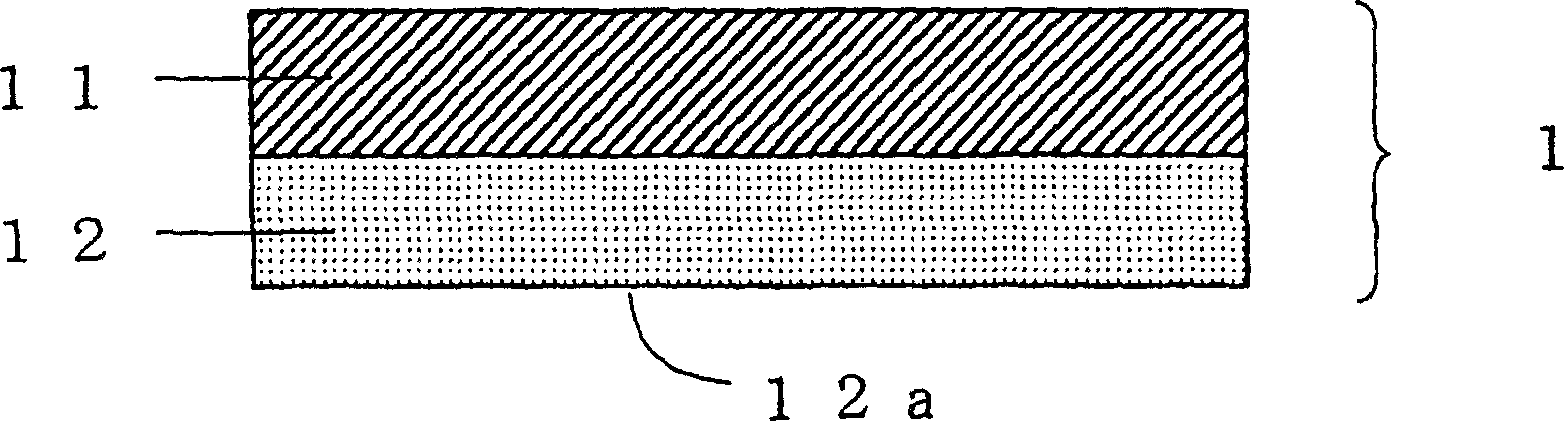

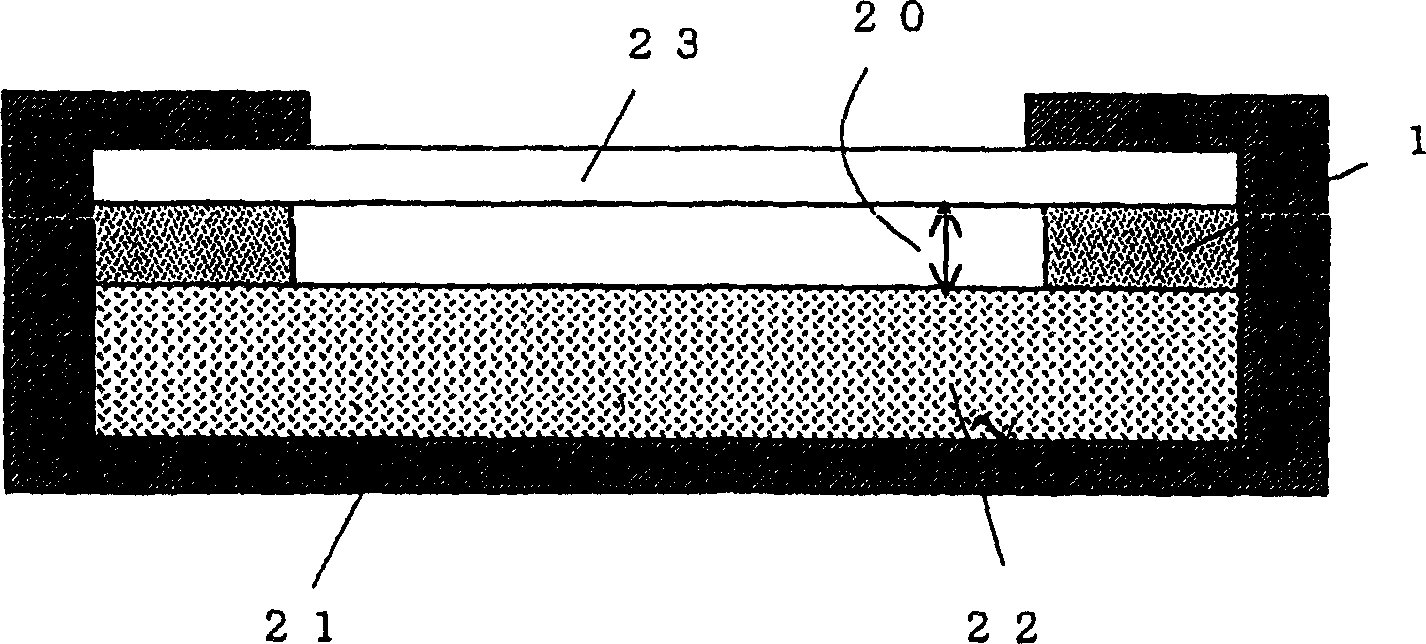

Impact-absorbing sheet

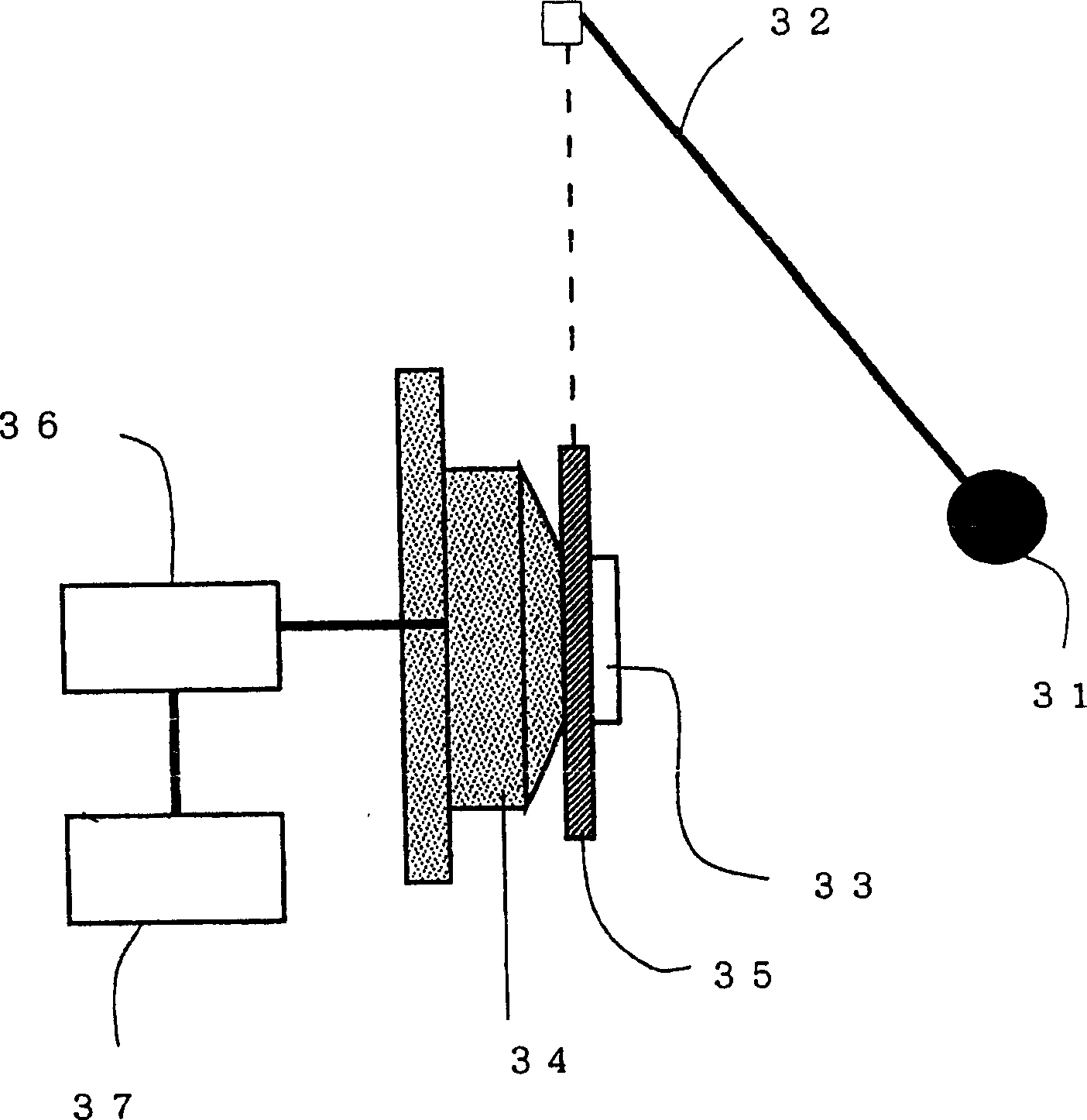

A shock-absorbing, rubberized technology, applied in the field of image display equipment, which can solve problems such as defective appearance, low shock-absorbing performance, deformation of the casing or image display panel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] Therefore, in the present invention, as a method of producing rubber foam, a production method using a high-pressure inert fluid as a foaming agent is preferable, and a method of forming a foam by the steps of using High-pressure inert fluid The step of reducing pressure after impregnation of a rubber-elastic polymer, such as a thermoplastic elastomer. Incidentally, when the impregnation with the inert fluid is performed, an unfoamed molded article previously molded into a sheet may be impregnated with the inert fluid, or a molten polymer may be impregnated with the inert fluid under pressure.

[0065] The above inert fluid is not particularly limited as long as it is inert to the polymer to be used and the polymer can be impregnated with the inert fluid, and examples thereof include rare gases such as helium and argon and inorganic gases such as nitrogen and carbon dioxide. gas etc. Among these, carbon dioxide has a relatively high affinity for polymer materials, has ...

Embodiment 1

[0118] (preparation of rubber foam)

[0119] At 200° C., 45 parts by weight of polypropylene (MFR: 0.35 g / 10 mm), 45 parts by weight of polyolefin elastomer (MFR: 6 g / 10 mm, JISA hardness : 79°), 10 parts by weight of magnesium hydroxide and 10 parts by weight of carbon, extruded in a strand form, cooled with water, and shaped into pellets. The pellets were fed into a short-screw extruder manufactured by JSW, and carbon dioxide gas was injected at 220° C. and 13 MPa. Carbon dioxide gas was injected at a ratio of 5% by weight to the total amount of polymer. After injecting carbon dioxide gas, the pressure was set to 12 MPa. After being fully saturated with carbon dioxide gas, the pellets were cooled to a temperature suitable for molding and extruded from a die to form a sheet with a thickness of 1.0 mm, thereby obtaining a density of 0.04 g / cm 3 and a foam with open cells having an average cell size of 60 μm.

[0120] (preparation of adhesive layer)

[0121] The following ...

Embodiment 2

[0126] A shock absorbing sheet was prepared in the same manner as in Example 1 except that the thickness of the adhesive layer was set to 0.6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com