A battery steel strip and its preparation method

A technology for steel strips and batteries, applied in the field of battery steel strips and their preparation, can solve problems such as cracking of the coating, exposure of the substrate, and peeling of the coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

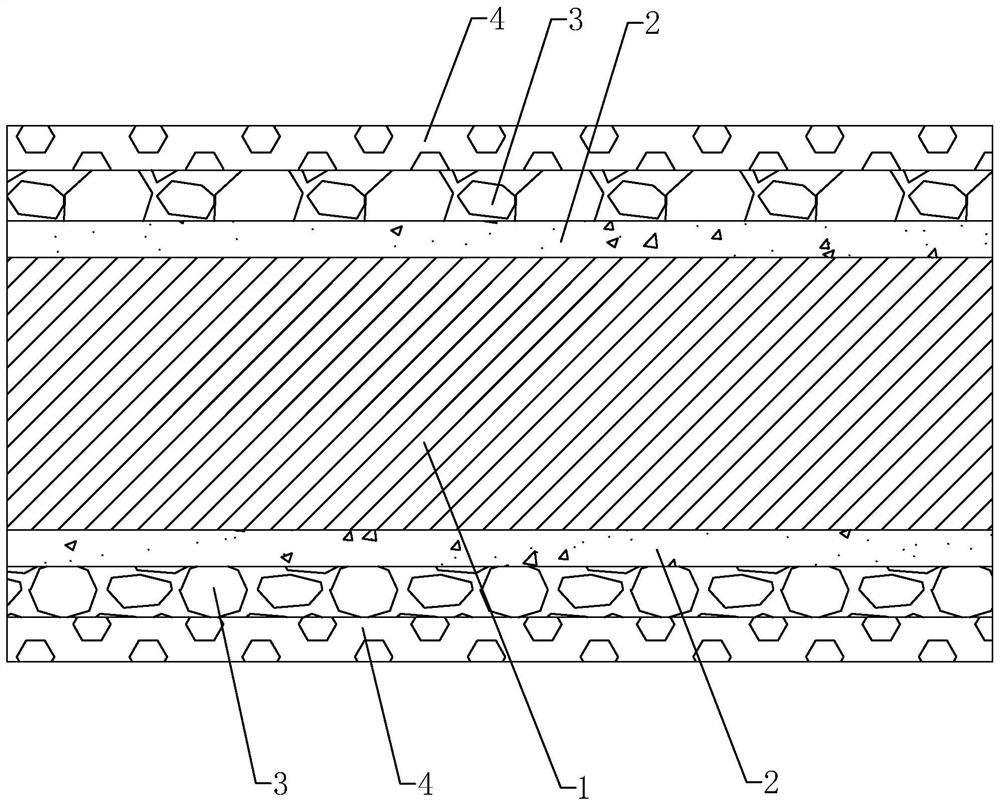

[0047]Embodiment 1: a kind of battery steel belt, such as figure 1 As shown, including the low-carbon steel matrix 1, the low-carbon steel is preferably Q235 steel. Since the manufacturing technology of Q235 steel is mature, it is convenient to purchase in the market and the material cost is low. Both sides of the low-carbon steel substrate 1 are provided with a rice crystal Ni-Cr coating 2, and the rice crystal Ni-Cr coating 2 is provided with a semi-bright Ni-Co coating 3, and the semi-bright Ni-Co coating 3 is provided with a full-gloss Ni -Co plating4. The thickness of the low-carbon steel substrate 1 is 0.2 mm; the thickness of the rice crystal Ni-Cr coating 2 is 0.2 μm; the thickness of the semi-bright Ni-Co coating 3 and the full-gloss Ni-Co coating 4 is 0.6 μm.

Embodiment 2

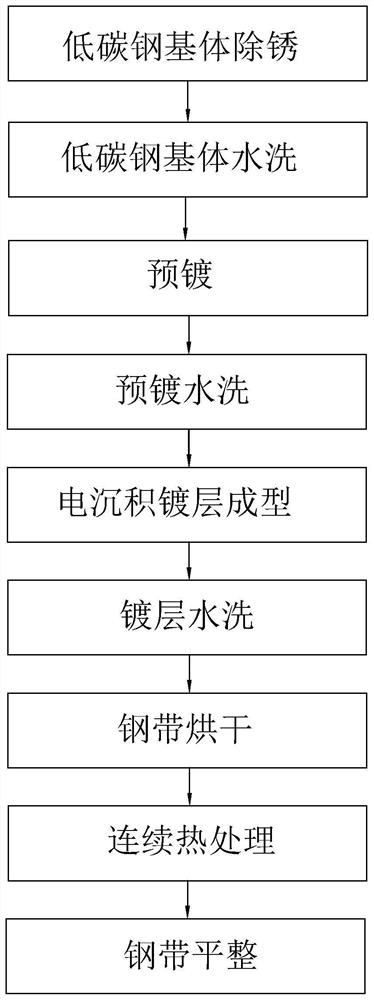

[0048] Embodiment 2: A method for preparing a battery steel strip, which is mainly used for forming the battery steel strip described in Implementation 1, such as figure 2 shown, including:

[0049] S1: Low-carbon steel substrate 1 derusting: Use 9% HCl solution to clean the low-carbon steel substrate 1. Each surface of the low-carbon steel substrate 1 should be cleaned for 1 minute. The cleaning process should be repeated 2-3 times to ensure the removal of rust. Most of the oxidized rust on the carbon steel substrate 1 is provided with a coating layer on the low carbon steel substrate 1 to avoid rust interference.

[0050] S2: washing the low-carbon steel substrate 1 with water: washing the low-carbon steel substrate 1 with distilled water. The staff rinses the low-carbon steel substrate 1 with distilled water for 20 seconds on each surface, and repeats 3 to 4 times to ensure that no HCl solution remains on the low-carbon steel substrate 1 .

[0051] S3: Pre-plating: Put t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com