A shield tunnel segment structure and its connection structure

A shield tunnel segment and connection structure technology, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of increasing section space, corrosion of steel bars, and difficult repairs, etc., to improve tensile and compressive strength, and strengthen tensile strength Compression strength, effect of reducing segment thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

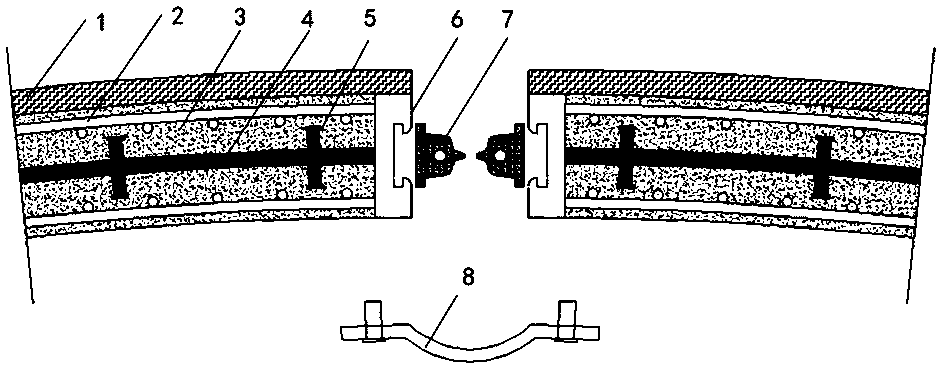

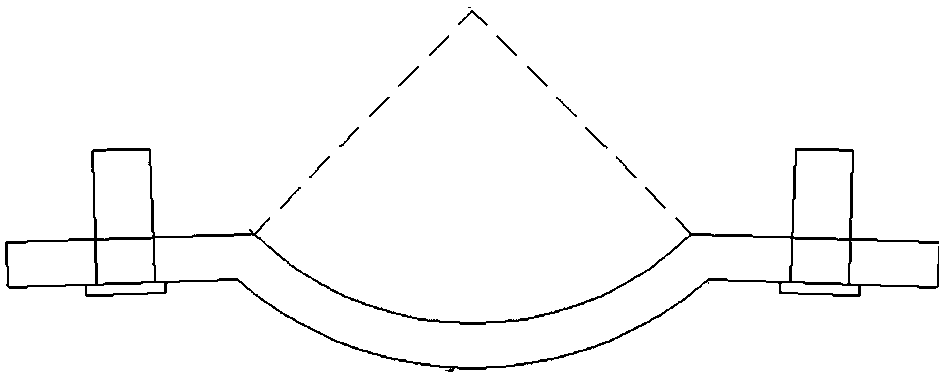

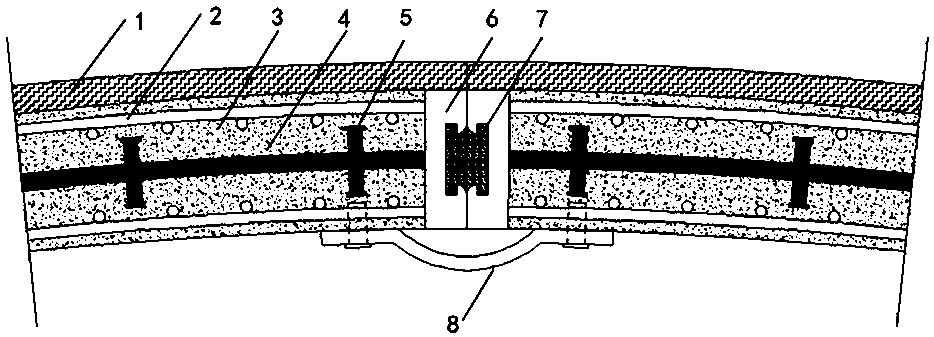

[0034] Example: see Figure 1 to Figure 3 As shown, a new shield tunnel segment mainly includes 20mm thick polyurea layer 1; @10cm×10cmφ8mm steel mesh 2; 10cm thick reactive powder concrete layer 3 (RPC200); 12mm thick steel plate layer 4; @20cm×20cmφ13mm steel nail 5 on both sides of the steel plate; steel joint 6 on the side edge of the segment; Ω-shaped GINA waterstop 7; Ω-shaped connecting steel plate 8.

[0035] Such as figure 1 As shown, the main material of the segment is reactive powder concrete (RPC200), with a thickness of 10cm. The 20mm thick polyurea material is coated on the outside of the segmental concrete, which can isolate the direct contact between the concrete and the groundwater environment, avoid the formation of corrosion micro-cracks, and reduce the corrosion probability of steel bars. The polyurea waterproof and anticorrosion layer is consistent with the structure size of the segment, but does not participate in the stress of the joint and avoids dama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com