Special micro-nano composite powder for laser repair for micro-cracks on stainless steel surface

A composite powder, micro-crack technology, applied in the field of laser repair, to achieve the effect of improving the density and fracture performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: by weight percent, comprising 5% nanometer WC (50-80nm), 1% nanometer Al 2 o 3 (30-50nm), the balance is micron-sized stainless steel powder (30-50μm). The stainless steel powder contains 0.08% C, 0.5% Si, 1.46% Mn, 0.03% P, 0.005% S, 19% Cr, 9.5% Ni, 0.5% Mo, and the balance is Fe . Using the above formula, various powders are thoroughly mixed through mechanical ball milling, then blended with absolute ethanol and further mixed evenly.

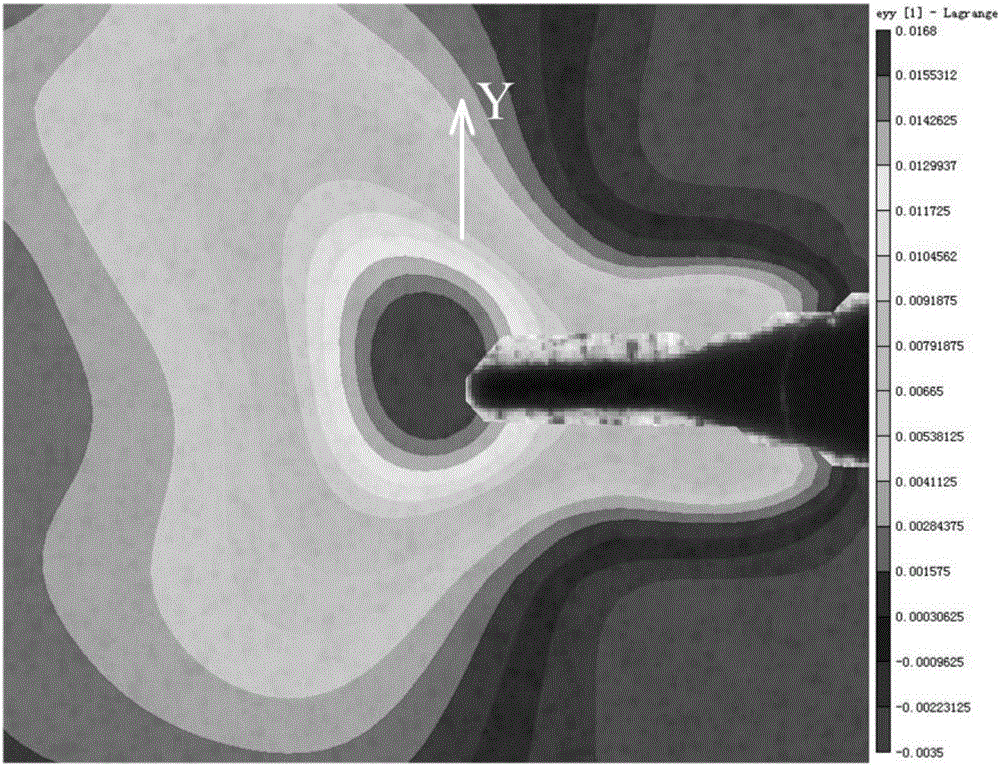

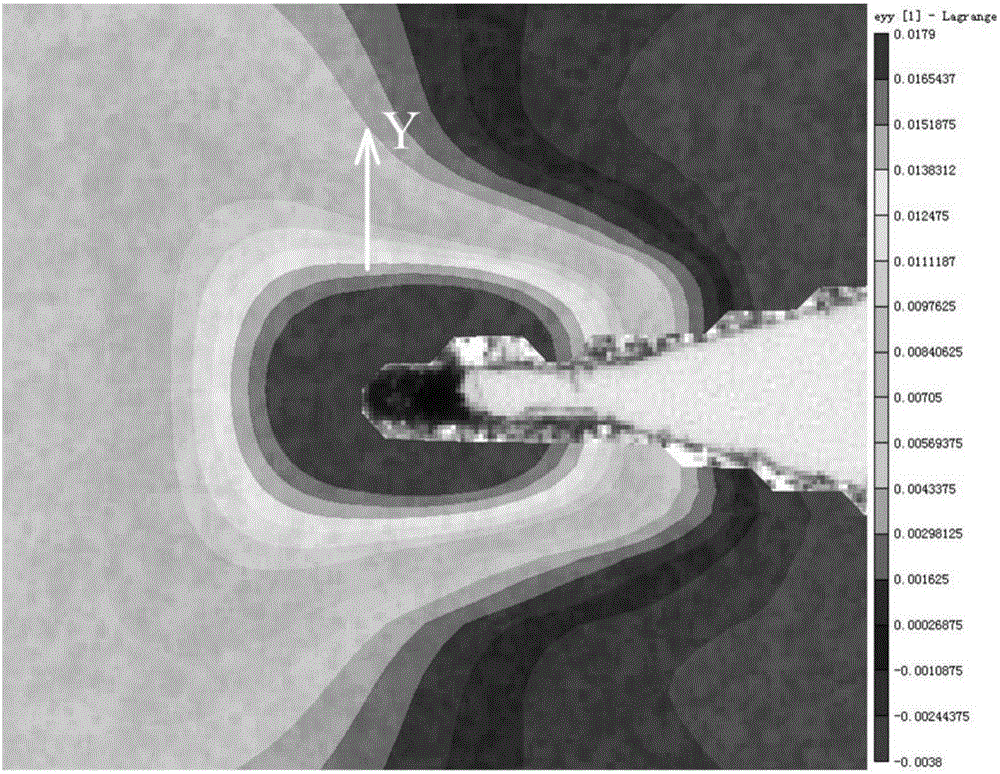

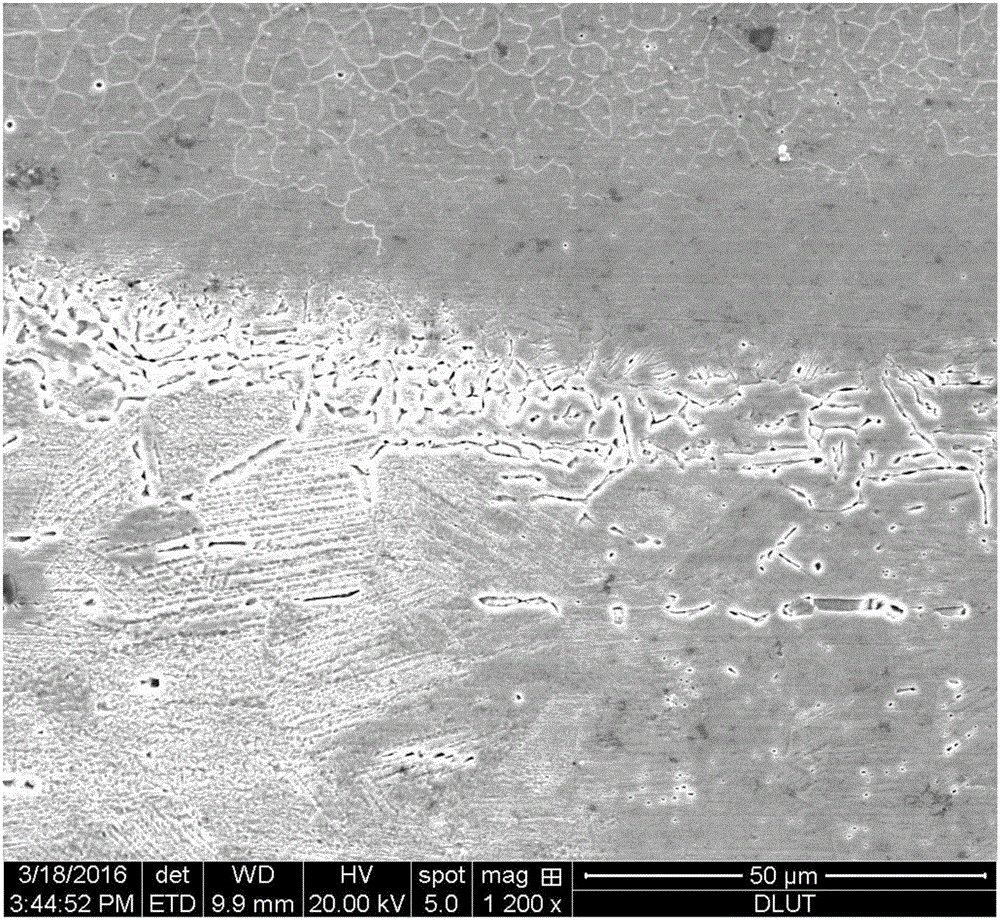

[0020] Before the laser repair process, dry the composite powder at a temperature of 150°C for 2 hours; use 400-2000 sandpaper to polish the area to be repaired in turn, then clean it with absolute ethanol, and then dry it; The composite powder is uniformly pre-placed on the micro-cracks on the surface of the stainless steel substrate to be repaired, and the pre-set thickness is controlled at 0.8-1.2mm to ensure a smooth surface and low porosity; laser technology is used to repair micro-cracks on the surface of the sta...

Embodiment 2

[0022] Embodiment 2: by weight percentage, comprising 3% nanometer WC (50-80nm), 2% nanometer Al 2 o 3 (30-50nm), the balance is micron-sized stainless steel powder (30-50μm). The stainless steel powder contains 0.08% C, 0.5% Si, 1.46% Mn, 0.03% P, 0.005% S, 19% Cr, 9.5% Ni, 0.5% Mo, and the balance is Fe . Using the above formula, various powders are thoroughly mixed through mechanical ball milling, then blended with absolute ethanol and further mixed evenly. The method of repairing cracks by laser is the same as in Example 1. The repaired interface presents metallurgical bonding; the grains in the repaired layer are refined, and the compactness of the structure is improved; under the load of 20kN, the fracture parameter COD of the specimen is reduced by 19.3%, and the fracture performance is improved.

Embodiment 3

[0023] Embodiment 3: by weight percentage, comprising 7% nanometer WC (50-80nm), 0.5% nanometer Al 2 o 3 (30-50nm), the balance is micron-sized stainless steel powder (30-50μm). The stainless steel powder contains 0.08% C, 0.5% Si, 1.46% Mn, 0.03% P, 0.005% S, 19% Cr, 9.5% Ni, 0.5% Mo, and the balance is Fe . Using the above formula, various powders are thoroughly mixed through mechanical ball milling, then blended with absolute ethanol and further mixed evenly. The method of repairing cracks by laser is the same as in Example 1. The repaired interface presents metallurgical bonding; the grains in the repaired layer are refined, and the compactness of the structure is improved; under the load of 20kN, the fracture parameter COD of the specimen is reduced by 18.6%, and the fracture performance is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com