Groove connected PE wound corrugated pipe

A corrugated pipe and groove type technology, applied in the field of groove type connection PE winding corrugated pipe, can solve the problems of poor compression resistance, damage, short pipe life, etc. compressive capacity, the effect of improving the resistance to cracking and fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

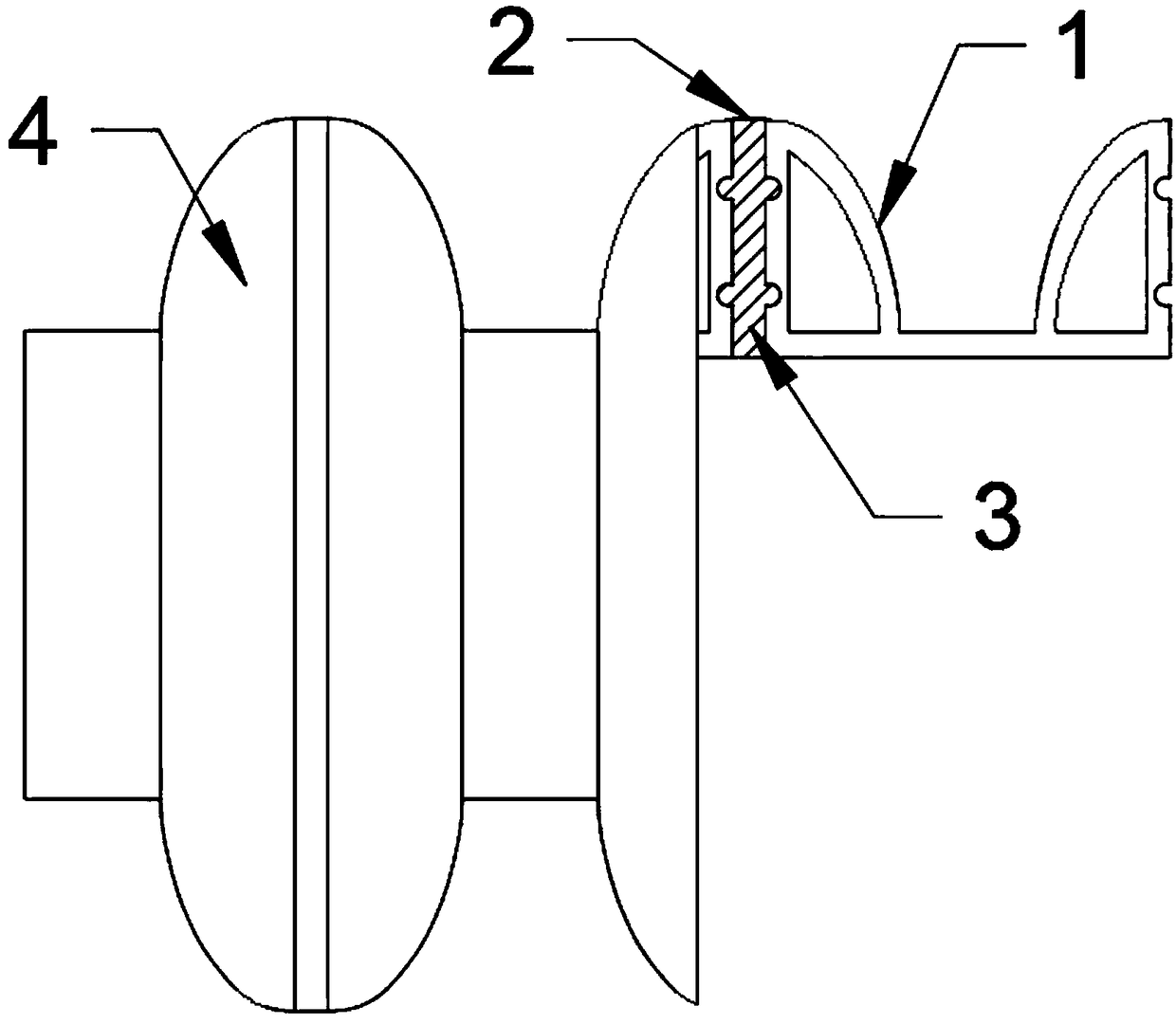

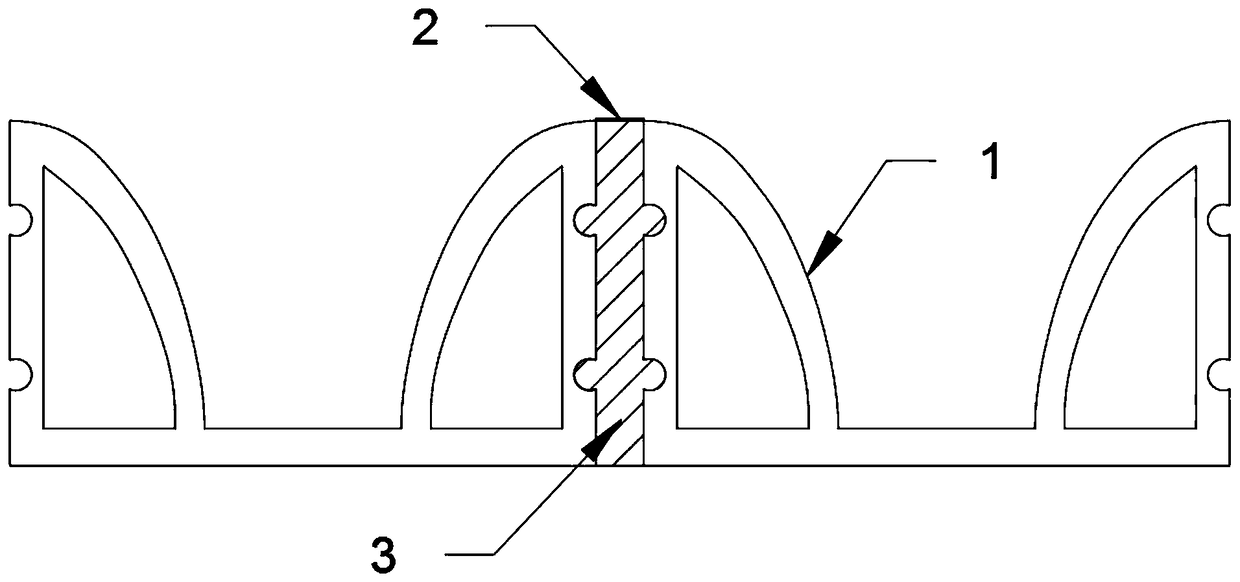

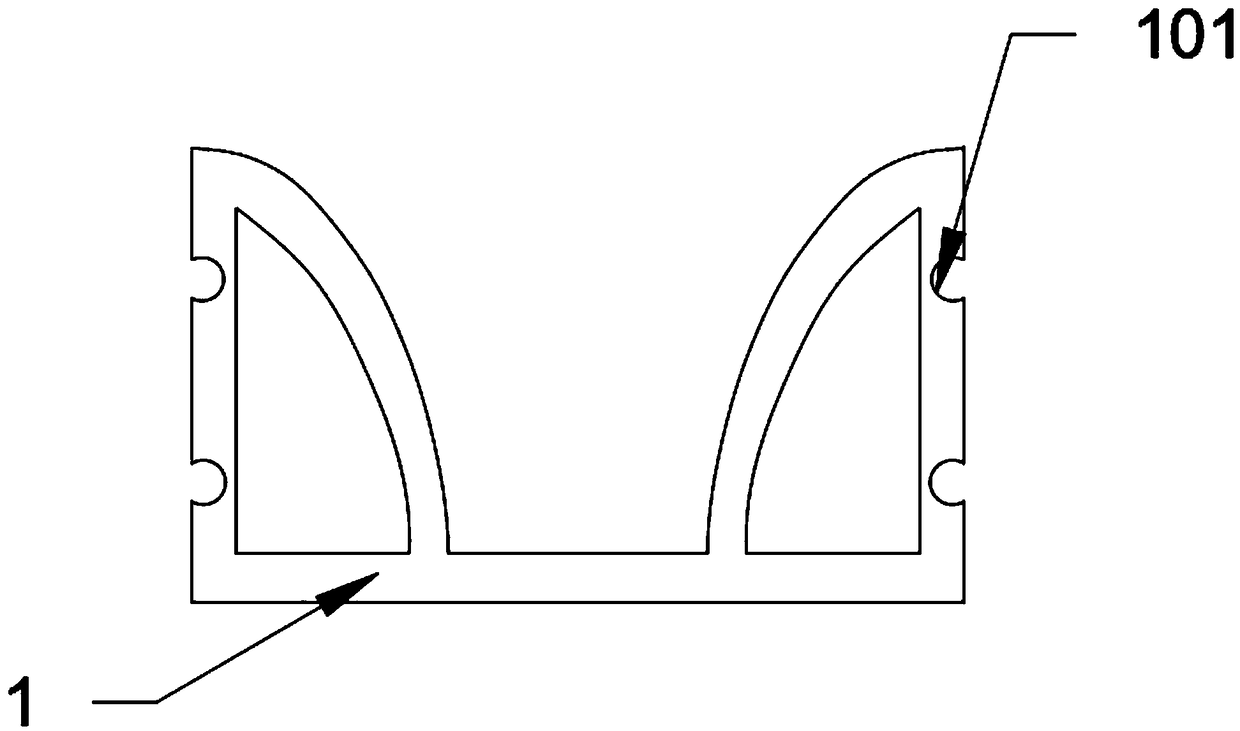

[0021] as attached figure 1 to attach image 3 Shown:

[0022] The present invention provides a groove-type connected PE winding corrugated pipe, which includes a plastic forming belt 1, a connecting groove 101, an adhesive injection surface 2, an annular locking plug 3 and a corrugated pipe 4; the left and right sides of the plastic forming belt 1 Two connection grooves 101 are respectively opened on the end faces, and the bellows 4 is set on the outside of the plastic forming belt 1, and both ends of the plastic forming belt 1 are hollow structures; the adhesive injection surface 2 is located on the inner wall of the bellows 4, and The adhesive injection surface 2 is connected with the ring-shaped locking plug 3, and the ring-shaped locking plug 3 is located inside the bellows 4, and the groove-type connection PE winding bellows can open one or more ring-shaped grooves.

[0023] Wherein, the outer end surface of the annular locking plug 3 is provided with a layer of adhesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com