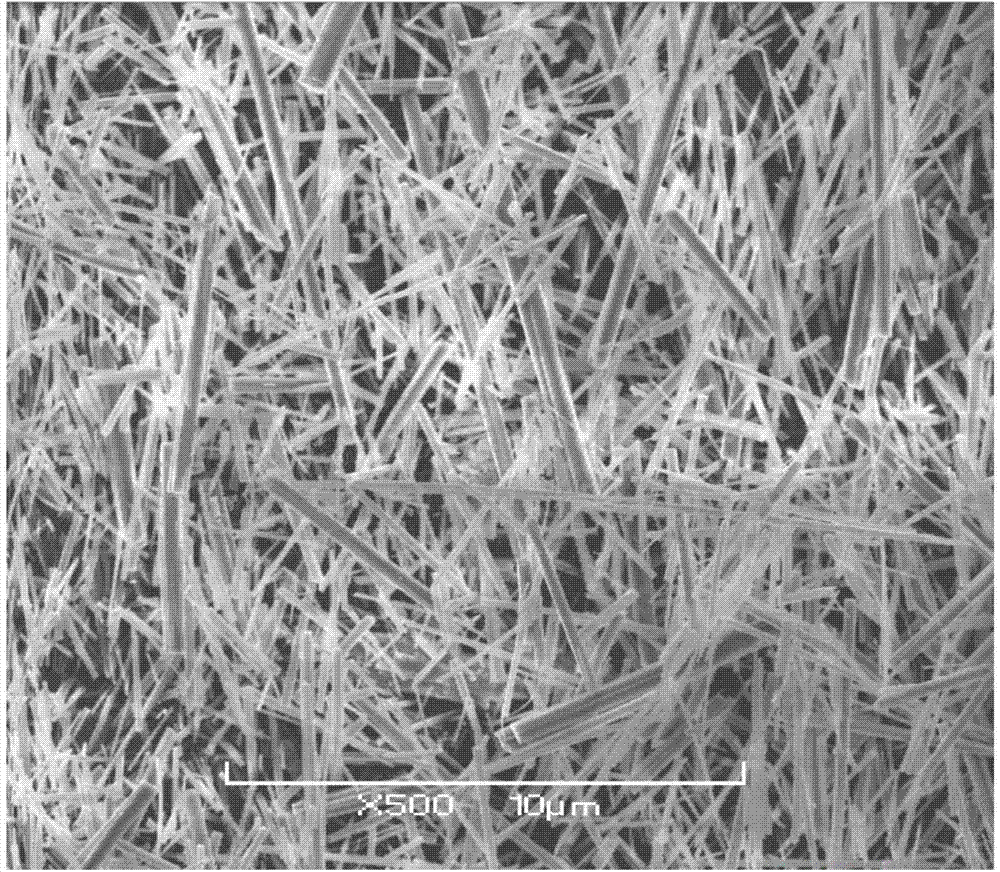

In-situ synthesis mullite whisker-toughened ceramic heat accumulator and preparation method thereof

A technology for mullite whiskers and toughened ceramics is applied in the field of in-situ synthesis of mullite whiskers toughened ceramic regenerators and their preparation, which can solve problems such as poor toughness, brittleness and brittleness, and achieve cost-effectiveness. Low, improved fracture performance, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In the present embodiment, by weight percentage, the main component of the selected coal series kaolin is:

[0037] SiO 2 : 45.08%; Al 2 o 3 : 37.89%; caustic soda: 15.95%; TiO 2 : 0.43%;

[0038] Fe 2 o 3 : 0.2%; MgO: 0.079%; CaO: 0.095%.

[0039] The preparation method comprises the following steps:

[0040] (1) Weigh 280kg of coal-series kaolin and 220kg of alumina micropowder, wherein the mesh number of alumina micropowder is 1000 mesh, the purity is 99%, and the mesh number of coal-series kaolin is 250 mesh.

[0041] (2) Pour the above raw materials into a ball mill, mix and grind for 3 hours, add 500kg of mullite powder that has passed through an 80-mesh sieve, and mix and grind for 3 hours.

[0042] (3) Take 100kg of the mixture obtained in step (2), pour it into a kneader, add 3kg of carboxymethylcellulose, 3kg of water-based acrylic emulsion and 16kg of water, and knead evenly.

[0043] (4) Put the mud material obtained in step (3) into the mud refinin...

Embodiment 2

[0052] In the present embodiment, by weight percentage, the main component of the selected coal series kaolin is:

[0053] SiO 2 : 45.08%; Al 2 o 3 : 37.89%; caustic soda: 15.95%; TiO 2 : 0.43%;

[0054] Fe 2 o 3 : 0.2%; MgO: 0.079%; CaO: 0.095%.

[0055] The preparation method comprises the following steps:

[0056] (1) Weigh 280kg of coal-series kaolin and 230kg of alumina micropowder, of which the mesh number of alumina micropowder is 1000 mesh, the purity is 99%, and the mesh number of coal-series kaolin is 250 mesh.

[0057] (2) Pour the above raw materials into a ball mill, mix and grind for 3 hours, add 500kg of mullite powder that has passed through an 80-mesh sieve, and mix and grind for 3 hours.

[0058] (3) Take 100kg of the mixture obtained in step (2), pour it into a kneader, add 3kg of carboxymethylcellulose, 3kg of water-based acrylic emulsion and 16kg of water, and knead evenly.

[0059] (4) Put the mud material obtained in step (3) into the mud refini...

Embodiment 3

[0068] In the present embodiment, by weight percentage, the main component of the selected coal series kaolin is:

[0069] SiO 2 : 43.28%; Al 2 o 3 : 37.27%; caustic soda: 15.85%; TiO 2 : 0.48%;

[0070] Fe 2 o 3 : 0.2%; MgO: 0.079%; CaO: 0.095%.

[0071] (1) Feed according to the weight ratio of coal series kaolin and alumina micropowder as 100:74, wherein the mesh number of alumina micropowder is 1200 mesh, the purity is 99%, and the particle size of coal series kaolin is 325 mesh.

[0072] (2) Pour the above raw materials into a ball mill, mix and grind for 4 hours, add mullite powder of equal weight that has been pre-passed through a 80-mesh sieve, and mix and grind for 3 hours.

[0073] (3) Take 100kg of the mixture obtained in step (2), pour it into a kneader, add 3kg of carboxymethylcellulose, 4kg of water-based acrylic emulsion and 15kg of water, and knead evenly.

[0074] (4) Add the mud material to the mud refining machine for initial training 3 times, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com