Functionally graded piezoelectric material preparation method for improving anti-fracture performance

A technology of functionally gradient and piezoelectric materials, applied in chemical instruments and methods, lamination, lamination devices, etc., can solve problems such as poor fracture resistance, and achieve the effect of improving fracture performance and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

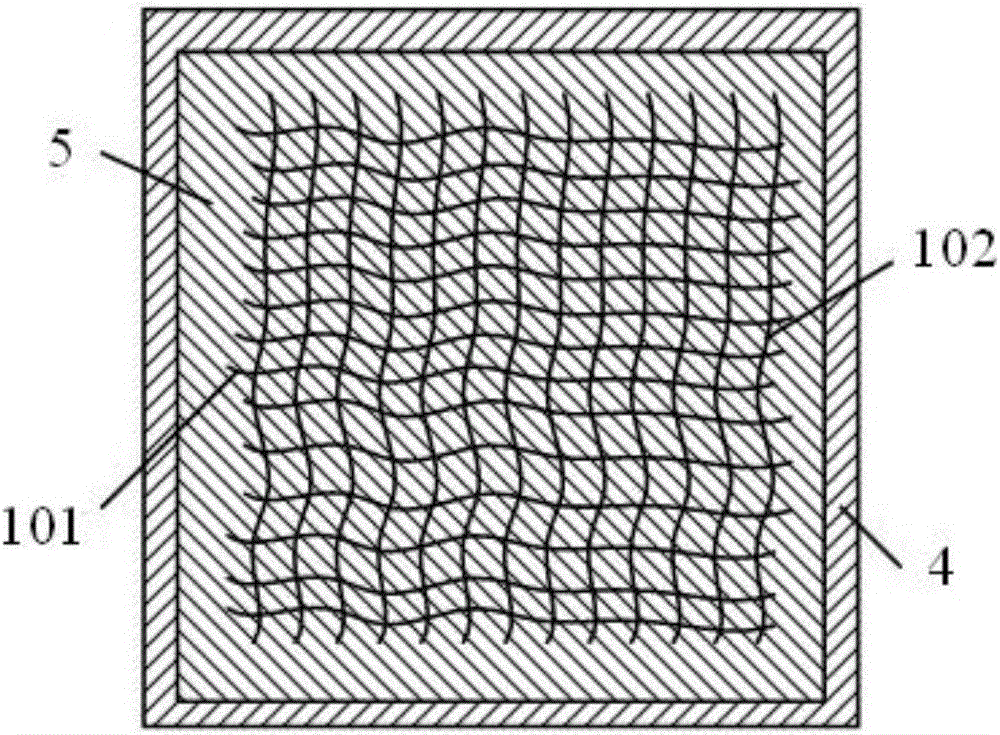

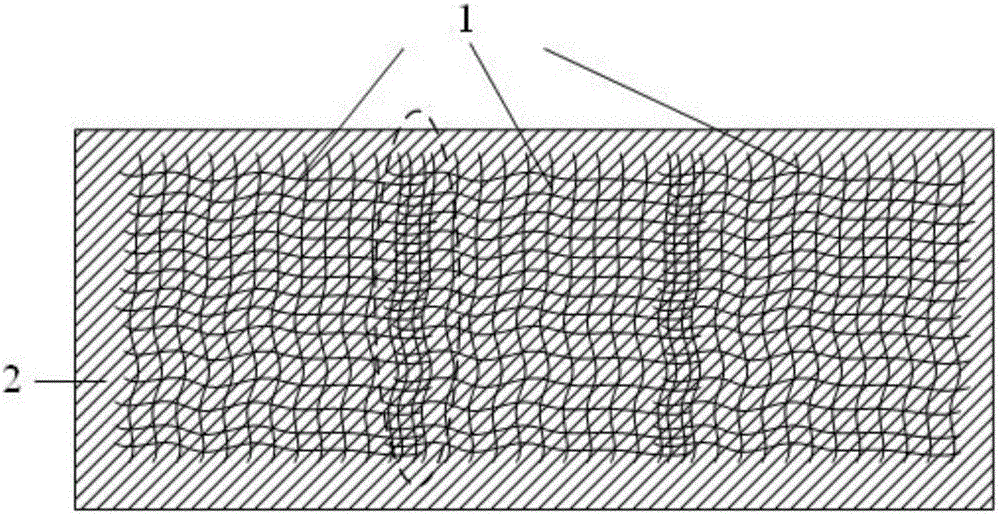

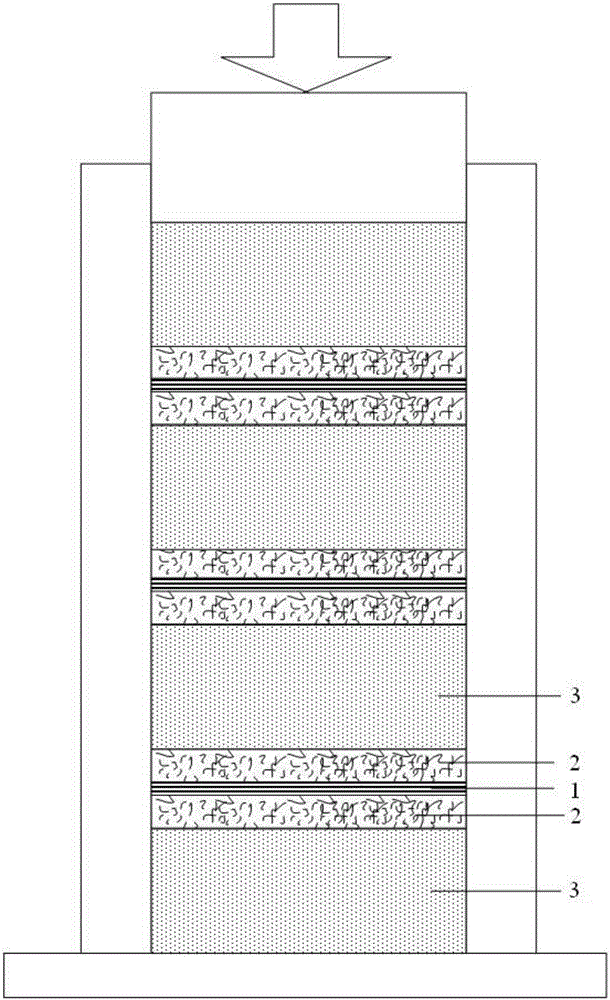

[0026] 1. Arranging the long glass fiber filaments in a horizontal and vertical warp and weft grid to form a grid sheet 1;

[0027] The fiber length of the long glass fiber filaments is 2 mm. Since the fiber filaments are not easy to maintain a single straight line during glass fiber production, and the fiber filaments are easy to break, so when making a horizontal and vertical latitude and longitude grid sheet, first clean the bottom surface of the glass plate 4 Lay the same horizontal long glass fiber filaments 101 flat, keep the distance between each long glass fiber filaments 0.5mm, spray glass glue on them with a sprayer, due to the circular cross-section of the glass fiber filaments, the sprayed glass glue will adhere On the upper arc surface of the fiber filaments, although the glass glue is sprayed onto the smooth glass plate in the gaps between the fiber filaments, the contact surface between the circular cross-section fiber filaments and the glass plate will not be gl...

Embodiment 2

[0035] 1. Arrange the long glass fiber filaments in horizontal and vertical latitude and longitude grids to form a grid sheet 1:

[0036] Take the fiber length 6mm of long glass fiber filaments,

[0037] Because the fiber filaments are not easy to keep a single straight line when the glass fiber is made, and the fiber filaments are easy to break, so when the horizontal and vertical warp and weft grid sheets are made, the same horizontal long glass fiber filaments 101 are first flattened on the bottom smooth glass plate plane 4. Lay the long glass fiber filaments at a distance of 1.0 mm, and spray glass glue on them with a sprayer. Due to the circular cross-section of the glass fiber filaments, the sprayed glass glue will adhere to the upper arc surface of the fiber filaments. Although there will be glass glue sprayed on the smooth glass plate in the gap between the fiber filaments, the contact surface between the circular cross-section fiber filament and the glass plate will n...

Embodiment 3

[0045] 1. Arrange the long glass fiber filaments in horizontal and vertical latitude and longitude grids to form a grid sheet 1:

[0046] Take the fiber length 10mm of long glass fiber filaments,

[0047] Because the fiber filaments are not easy to keep a single straight line when the glass fiber is made, and the fiber filaments are easy to break, so when the horizontal and vertical warp and weft grid sheets are made, the same horizontal long glass fiber filaments 101 are first flattened on the bottom smooth glass plate plane 4. Lay the long glass fiber filaments at a distance of 1.5 mm, and spray glass glue on them with a sprayer. Due to the circular cross-section of the glass fiber filaments, the sprayed glass glue will adhere to the upper arc surface of the fiber filaments. Although there will be glass glue sprayed on the smooth glass plate in the gap between the fiber filaments, the contact surface between the circular cross-section fiber filament and the glass plate will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com