Novel environment-friendly wood plastic material and preparation method thereof

A wood-plastic material and environmental protection technology, applied in the field of new environmental-friendly wood-plastic material and its preparation, can solve problems such as environmental pollution and resource waste, and achieve the effects of reducing production cost, enhancing bonding force and strong interface force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

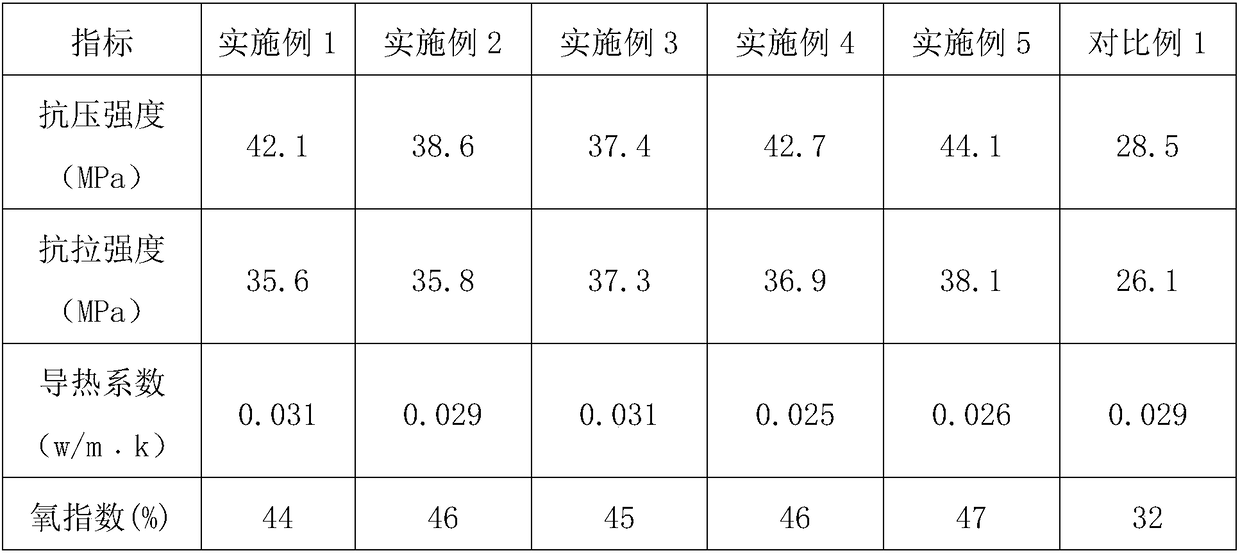

Examples

Embodiment 1

[0033] A novel environmentally friendly wood-plastic material, comprising the following raw materials in parts by weight:

[0034] 22 parts of polyvinyl chloride resin, 12 parts of modified coffee shell powder, 24 parts of straw powder, 5 parts of nano-titanium dioxide, 8 parts of nano-calcium carbonate, 1 part of polyvinyl alcohol, 0.8 parts of dicumyl peroxide, methacrylic resin 2 parts, 2 parts of β-damascone, 2 parts of flame retardant, 1.4 parts of blowing agent.

[0035] The preparation method of modified coffee shell powder is as follows:

[0036] (a) put the coffee husks into a pulverizer to aggregate and pulverize them, and pass through an 80-mesh sieve to obtain coffee husk powder;

[0037] (b) Add the sodium hypochlorite solution with a mass fraction of 1.5% to the coffee shell powder, stir and mix evenly, add an appropriate amount of glacial acetic acid to adjust the pH value to 4, place it in a water bath to control the temperature to 72 degrees Celsius, and stir...

Embodiment 2

[0051] A novel environmentally friendly wood-plastic material, comprising the following raw materials in parts by weight:

[0052] 26 parts of polyvinyl chloride resin, 18 parts of modified coffee shell powder, 32 parts of straw powder, 10 parts of nano-titanium dioxide, 15 parts of nano-calcium carbonate, 3 parts of polyvinyl alcohol, 1.8 parts of dicumyl peroxide, methacrylic resin 5 parts, 4 parts of β-damascone, 5 parts of flame retardant, and 2.2 parts of blowing agent.

[0053] The preparation method of modified coffee shell powder is as follows:

[0054] (a) put the coffee husks into a pulverizer to aggregate and pulverize them, and pass through a 100-mesh sieve to obtain coffee husk powder;

[0055] (b) Add the sodium hypochlorite solution with a mass fraction of 1.5% to the coffee shell powder, stir and mix evenly, add an appropriate amount of glacial acetic acid to adjust the pH value to 4-5, place it in a water bath and control the temperature to 78 degrees Celsius...

Embodiment 3

[0069] A novel environmentally friendly wood-plastic material, comprising the following raw materials in parts by weight:

[0070] 23 parts of polyvinyl chloride resin, 14 parts of modified coffee shell powder, 26 parts of straw powder, 6 parts of nano-titanium dioxide, 10 parts of nano-calcium carbonate, 1.5 parts of polyvinyl alcohol, 1.2 parts of dicumyl peroxide, methacrylic resin 3 parts, 2.5 parts of β-damascone, 3 parts of flame retardant, and 1.6 parts of blowing agent.

[0071] The preparation method of modified coffee shell powder is as follows:

[0072] (a) put the coffee husks into a pulverizer to aggregate and pulverize them, and pass through a 90-mesh sieve to obtain coffee husk powder;

[0073] (b) Add the sodium hypochlorite solution with a mass fraction of 1.5% to the coffee shell powder, stir and mix evenly, add an appropriate amount of glacial acetic acid to adjust the pH value to 4-5, place it in a water bath and control the temperature to 75 degrees Celsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com