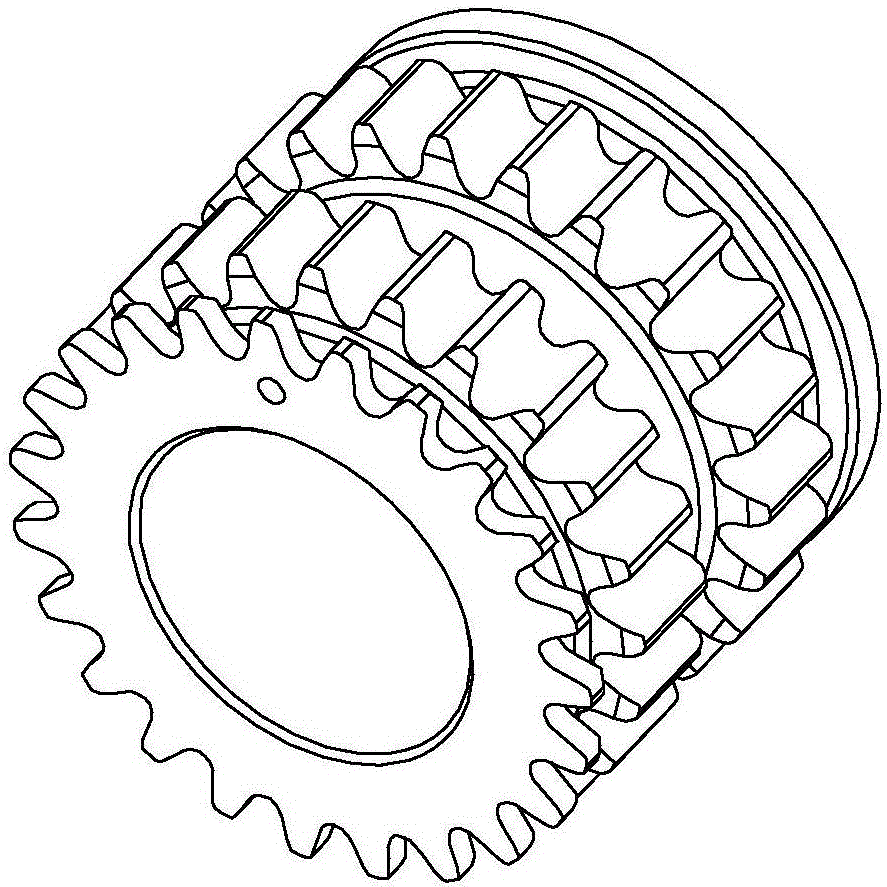

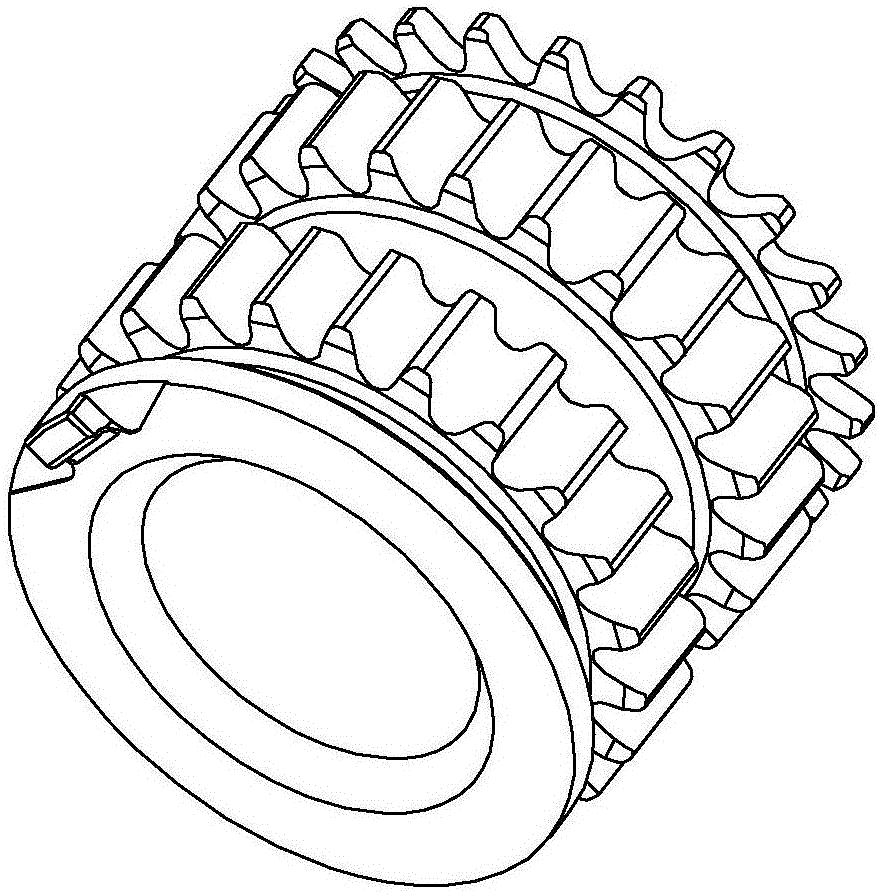

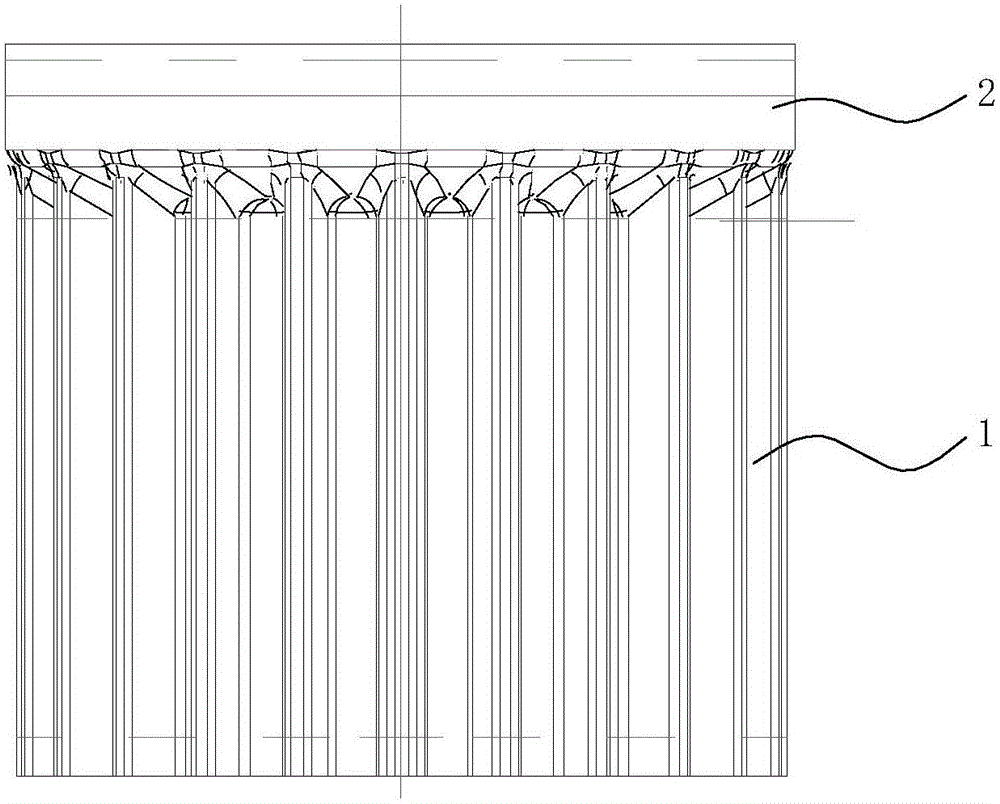

Preparing method for automobile chain wheel

A technology for sprockets and automobiles, which is applied in the field of preparation of automobile sprockets, can solve the problems of too simple structure, cannot be prepared, and have large structural differences, and achieve the effects of improving hardness, avoiding wear, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of automobile sprocket in the present embodiment comprises the following steps:

[0059] (1) Blanking: Cut the 20CrMo round steel of φ45 into a billet of required length with a high-speed circular sawing machine, leaving margins on both sides of the billet;

[0060] (2) Annealing and shot blasting: First, the billet is subjected to stepwise annealing treatment, and the specific process of the annealing treatment process is as follows:

[0061] First raise the temperature to 200°C with the furnace, and keep it warm for 2.2 hours;

[0062] Then heat up to 600°C with the furnace and keep warm for 1.2 hours;

[0063] Then heat up to 780°C with the furnace and keep warm for 8.2 hours;

[0064] Cool down to 680°C with the furnace and keep warm for 8.2 hours;

[0065] Then lower the temperature to 450°C and below, and take it out of the furnace; in the cooling process, first cool down with the furnace, and when the temperature drops to 550°C, turn on ...

Embodiment 2

[0099] The preparation method of automobile sprocket in the present embodiment comprises the following steps:

[0100] (1) Blanking: Cut the 20CrMo round steel of φ46 into the billet of required length with a high-speed circular sawing machine, leaving margin on both sides of the billet;

[0101] (2) Annealing and shot blasting: First, the billet is subjected to stepwise annealing treatment, and the specific process of the annealing treatment process is as follows:

[0102] First raise the temperature to 210°C with the furnace, and keep it warm for 1.8 hours;

[0103] Then heat up to 610°C with the furnace and keep warm for 0.8 hours;

[0104] Then heat up to 790°C with the furnace and keep warm for 7.8 hours;

[0105] Cool down to 690°C with the furnace and keep warm for 7.8 hours;

[0106] Then lower the temperature to 450°C and below, and take it out of the furnace; in the cooling process, first cool down with the furnace, and when the temperature drops to 550°C, turn on...

Embodiment 3

[0141] The preparation method of automobile sprocket in the present embodiment comprises the following steps:

[0142] (1) Blanking: Cut the 20CrMo round steel of φ40 into a billet of required length with a high-speed circular sawing machine, leaving margins on both sides of the billet;

[0143] (2) Annealing and shot blasting: First, the billet is subjected to stepwise annealing treatment, and the specific process of the annealing treatment process is as follows:

[0144] First raise the temperature to 200°C with the furnace, and keep it warm for 2 hours;

[0145] Then heat up to 600°C with the furnace and keep warm for 1 hour;

[0146] Then heat up to 780°C with the furnace and keep warm for 8 hours;

[0147] Cool down to 680°C with the furnace and keep warm for 8 hours;

[0148] Then lower the temperature to 450°C and below, and take it out of the furnace; in the cooling process, first cool down with the furnace, and when the temperature drops to 550°C, turn on the blowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com