Cement-free desulfurized gypsum plastering mortar and preparation method thereof

A technology of desulfurized gypsum and plastering mortar, which is applied in the field of building materials, can solve the problems of large amount of performance improver, inconvenient production and construction, and failure to achieve, so as to achieve smooth and smooth wall surface, reduce energy consumption and pollution, and reduce raw materials cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

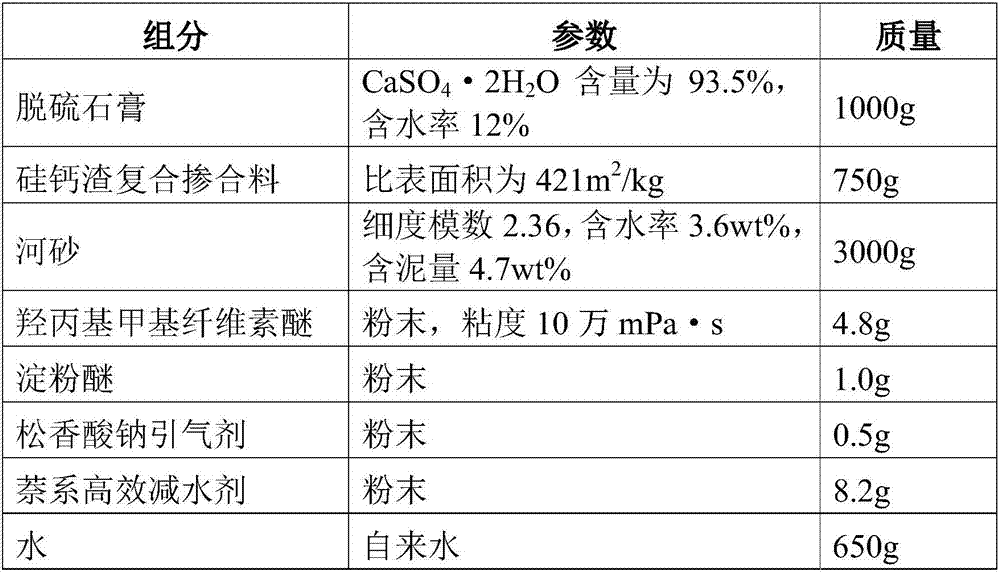

[0035] This example provides a cement-free desulfurized gypsum plastering mortar, the dosage and parameters of each component are shown in Table 1.

[0036] Components of cementless desulfurized gypsum plastering mortar in Table 1 Example 1

[0037]

[0038] The above-mentioned calcium silicate slag composite admixture is composed of 50 parts by weight of calcium silicate slag, 30 parts by weight of fly ash, 15 parts by weight of granulated blast furnace slag, 5 parts by weight of desulfurized gypsum, and 0.06 parts by weight of grinding aid. Proportionally weighed and mixed, and then processed into a specific surface area of 421m using grinding equipment 2 / kg of fine powder. Among them, silicon-calcium slag is produced by Datang International Renewable Resources Development Co., Ltd., which is a by-product after extracting alumina from fly ash by pre-desilication-soda lime sintering method; fly ash and desulfurized gypsum are produced by Datang International Tuoketo P...

Embodiment 2

[0049] This example provides a cement-free desulfurized gypsum plastering mortar, the dosage and parameters of each component are shown in Table 3.

[0050] Components of cementless desulfurized gypsum plastering mortar in Table 3 Example 2

[0051]

[0052] The above-mentioned calcium silicate slag composite admixture is composed of 45 parts by weight of calcium silicate slag, 35 parts by weight of fly ash, 15 parts by weight of granulated blast furnace slag, 5 parts by weight of desulfurized gypsum, and 0.08 parts by weight of grinding aid. Proportionally weighed and mixed, and then processed into a specific surface area of 433m using grinding equipment 2 / kg of fine powder. Among them, silicon-calcium slag is produced by Datang International Renewable Resources Development Co., Ltd., which is a by-product after extracting alumina from fly ash by pre-desilication-soda lime sintering method; fly ash and desulfurized gypsum are produced by Datang International Tuoketo P...

Embodiment 3

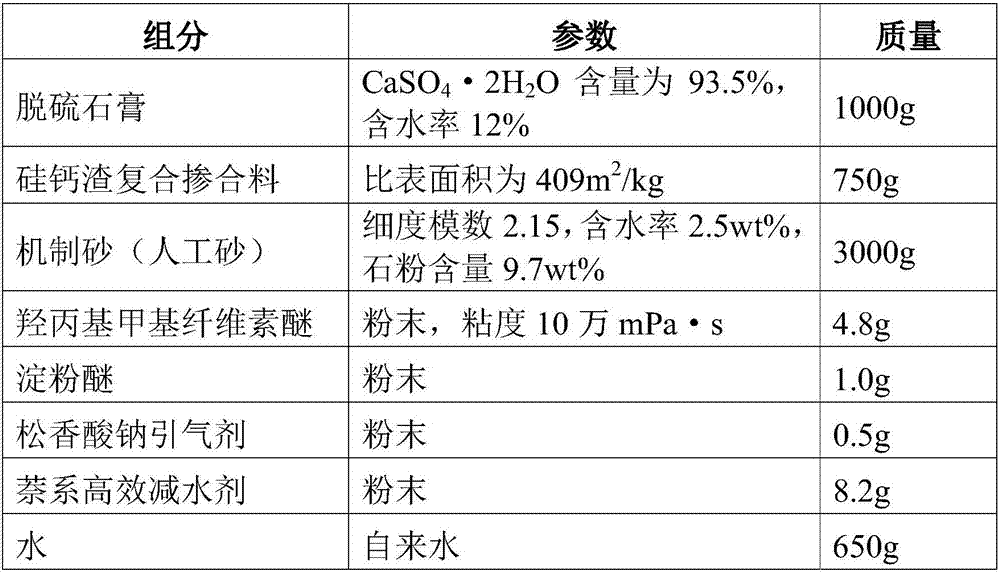

[0063] This example provides a cement-free desulfurized gypsum plastering mortar, the dosage and parameters of each component are shown in Table 5.

[0064] Components of cementless desulfurized gypsum plastering mortar in Table 5 Example 3

[0065]

[0066] The above-mentioned calcium silicate slag composite admixture is composed of 45 parts by weight of calcium silicate slag, 30 parts by weight of fly ash, 22 parts by weight of granulated blast furnace slag, 3 parts by weight of desulfurized gypsum, and 0.06 parts by weight of grinding aid. The ratio is weighed and mixed, and then processed into a specific surface area of 409m using a grinding equipment 2 / kg of fine powder. Among them, silicon-calcium slag is produced by Datang International Renewable Resources Development Co., Ltd., which is a by-product after extracting alumina from fly ash by pre-desilication-soda lime sintering method; fly ash and desulfurized gypsum are produced by Datang International Tuoketo P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com