Segregation-enhanced type deforming high-temperature alloy and preparation process thereof

A technology for deforming high-temperature alloys and precipitation strengthening, which is applied in the field of high-temperature alloys, can solve problems such as alloy processing performance hazards, and achieve the effects of improving alloy structure stability, good structure stability, and improving thermal processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

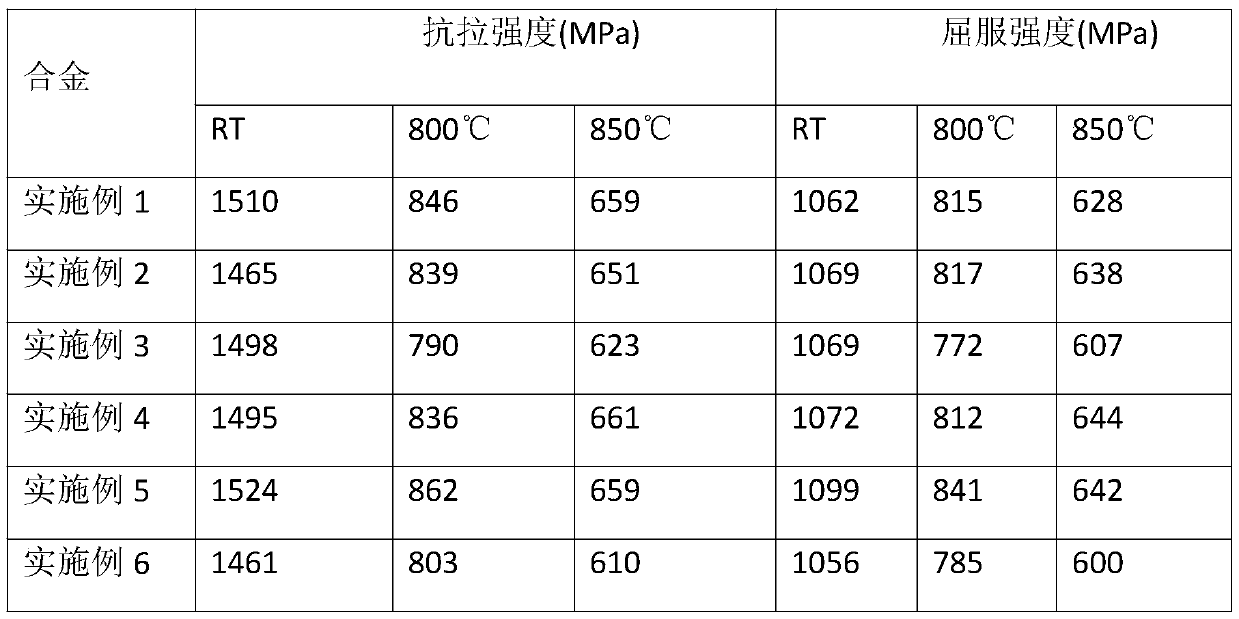

Embodiment 1

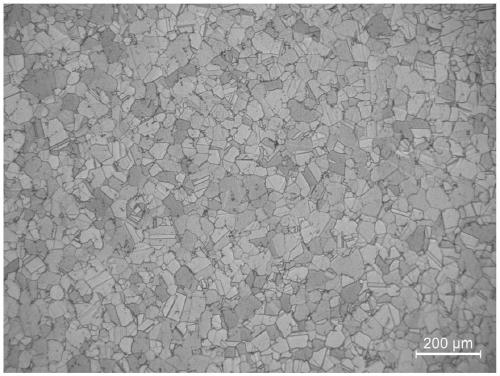

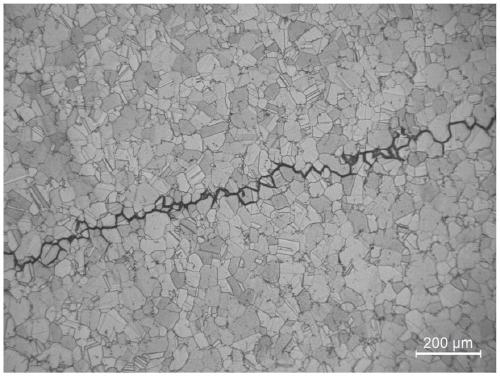

[0037] By adjusting the content and proportion of strengthening elements added, and controlling the content of C element, a high-temperature alloy with good performance, structural stability and processing performance can be obtained. The alloy is smelted in a vacuum induction furnace, and the obtained alloy includes: C: 0.07%, Cr: 12.5%, Co: 15%, Mn: 0.3%, Si: 0.2%, Nb: 1.5%, Mo: 2.5%, W: 3.0%, Ti: 3.0%, Al: 4.0%, B: 0.002%, Zr: 0.02%, and the balance is Ni.

[0038]The alloy was homogenized at 1200°C for 24 hours, followed by high-temperature rolling at 150°C above the γ' melting temperature, with a total deformation of 50%. In order to avoid the influence of excessive temperature drop before rolling, which promotes the precipitation of a large amount of γ' phase, and the excessive internal stress of the ingot caused by too fast cooling rate, which will affect the subsequent deformation processing of the alloy, the alloy is subjected to homogenization treatment and the heati...

Embodiment 2

[0042] By adjusting the content and proportion of strengthening elements added, and controlling the content of C element, a high-temperature alloy with good performance, structural stability and processing performance can be obtained. The alloy is smelted in a vacuum induction furnace, and the obtained alloy includes: C: 0.07%, Cr: 12.1%, Co: 15%, Mn: 0.3%, Si: 0.2%, Nb: 1.5%, Mo: 3.0%, W: 3.0%, Ti: 2.5%, Al: 4.0%, B: 0.002%, Zr: 0.02%, and the balance is Ni.

[0043] The alloy was homogenized at 1200°C for 24 hours, followed by high-temperature rolling at 150°C above the γ' melting temperature, with a total deformation of 50%. In order to avoid the influence of excessive temperature drop before rolling, which promotes the precipitation of a large amount of γ' phase, and the excessive internal stress of the ingot caused by too fast cooling rate, which will affect the subsequent deformation processing of the alloy, the alloy is subjected to homogenization treatment and the heat...

Embodiment 3

[0046] By adjusting the content and proportion of strengthening elements added, and controlling the content of C element, a high-temperature alloy with good performance, structural stability and processing performance can be obtained. The alloy is smelted in a vacuum induction furnace, and the obtained alloy includes: C: 0.07%, Cr: 11.8%, Co: 15%, Mn: 0.3%, Si: 0.2%, Nb: 1.5%, Mo: 3.5%, W: 3.0%, Ti: 2.0%, Al: 4.0%, B: 0.002%, Zr: 0.02%, and the balance is Ni.

[0047] The alloy was homogenized at 1200°C for 24 hours, followed by high-temperature rolling at 150°C above the γ' melting temperature, with a total deformation of 50%. In order to avoid the influence of excessive temperature drop before rolling, which promotes the precipitation of a large amount of γ' phase, and the excessive internal stress of the ingot caused by too fast cooling rate, which will affect the subsequent deformation processing of the alloy, the alloy is subjected to homogenization treatment and the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com