Quick pressure-relief gas discharge method for exposing super-thick and soft outburst coal seam in vertical wellbore

A technology for outburst coal seam and wellbore, which is applied in the field of rapid pressure relief and gas discharge, can solve the problems of downhole being easily affected by water seal, small control range of single hole, well wall cracking, etc., so as to achieve rapid pressure relief gas discharge, The effect of increasing single-hole discharge and accelerating gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings.

[0029] A method for quickly releasing pressure and releasing gas through nine strokes and nine injections for piercing through an extra-thick soft outburst coal seam by shaft shaft of the present invention comprises the following steps:

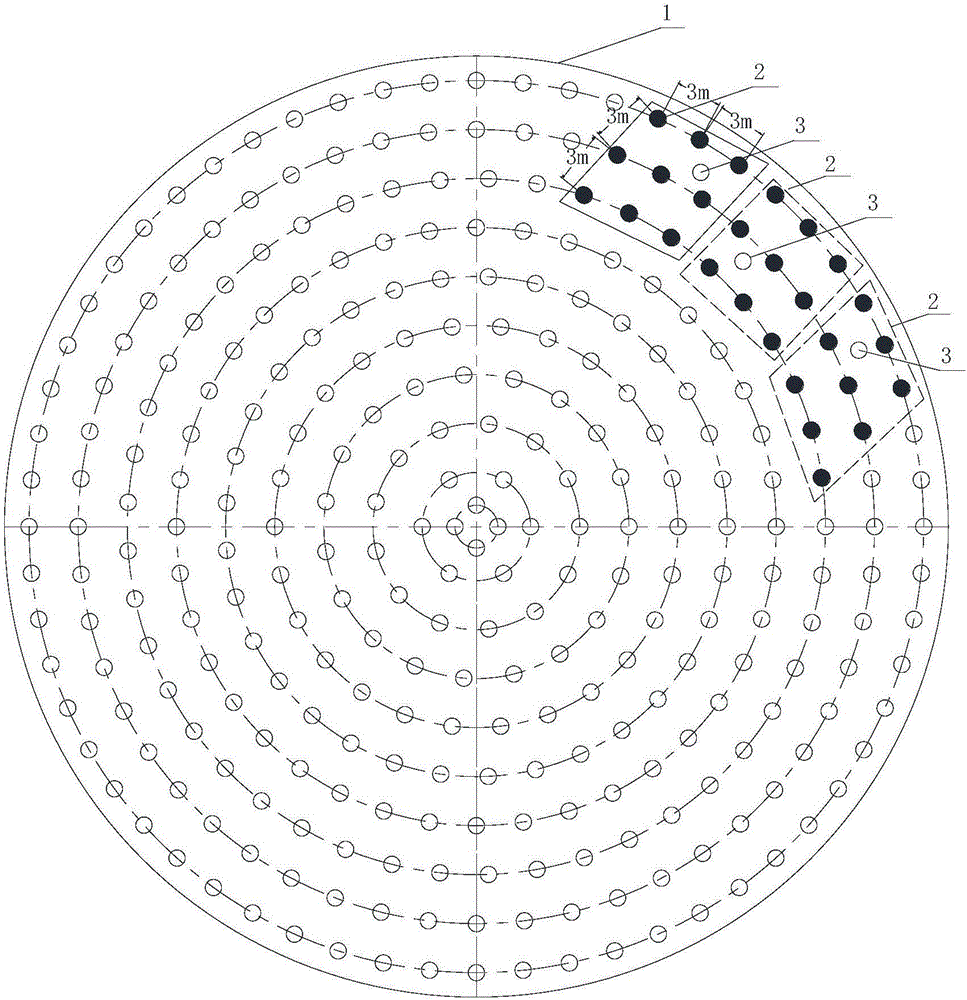

[0030] The first step is to excavate the wellbore to a position 7m away from the coal seam, and design multiple circles of discharge drilling holes from the outside to the inside along the contour line of the working face of the shaft excavation, and the distance between the bottom of the discharge drilling holes is 3m;

[0031] The second step, as shown in the figure, divides the designed discharge borehole into multiple nine-punch and nine-injection units according to the spacing of 6m×6m. Each nine-punch and nine-injection unit contains 9 boreholes, and calculates the single hole Minimum amount of coal flushing;

[0032] The third...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com