Laminated material laminating glue and preparation method thereof

A technology of splicing glue and laminated material, applied in the direction of adhesive, monocarboxylate copolymer adhesive, adhesive type, etc., can solve the problem of insufficient strength, avoid cracking, enhance water resistance, improve The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

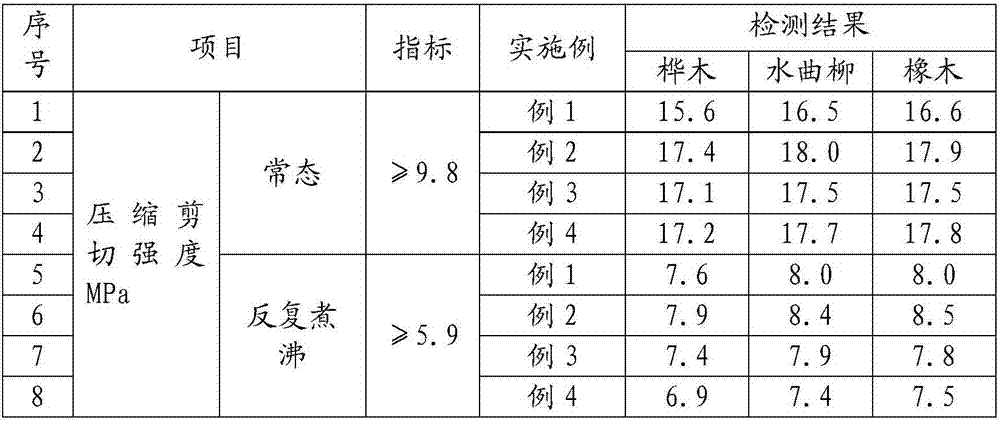

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned glulam glue, the specific steps are as follows:

[0029] S1 Add 15% to 25% deionized water and polyvinyl alcohol in proportion to the reaction kettle and heat up to completely dissolve, then add a chelating agent to react for 1.5 hours and cool to obtain a modified polyvinyl alcohol solution for later use;

[0030] S2 Add the water-based emulsion, plasticizer, dispersant, and defoamer to the dispersing kettle in sequence, slowly add calcium carbonate, and disperse to a uniform mucilage, then add the modified polyvinyl alcohol solution prepared in step S1, bactericide, 0.4 %~2.7% deionized water is added to the dispersing tank and stirred evenly to obtain the finished product;

[0031] S3 Mix components A and B evenly.

[0032] It should be noted that component A and component B are uniformly mixed at a mass ratio of 100:15.

Embodiment 1

[0034] 1. Preparation of component A

[0035] Put 15.0g of deionized water into the reaction flask, put in 2.0g of polyvinyl alcohol 2088 and raise the temperature to 85°C for 1 hour, add 0.1g of titanate coupling agent, react for 1.5h and cool down to obtain a modified polyvinyl alcohol solution. stand-by;

[0036] Then 42.0g ethylene-vinyl acetate copolymer emulsion (VAE emulsion), 21.0g ethylene-vinyl acetate-vinyl chloride copolymer emulsion (chlorine vinegar emulsion), 1.0g carboxylated styrene-butadiene latex, 0.1g dispersant, 0.05g defoamer Add to the dispersing tank, slowly add 16.0g of calcium carbonate under stirring, stir for 1 hour to disperse to a uniform slurry, then slowly add the prefabricated modified polyvinyl alcohol solution, 0.05g of bactericide, and 2.7g of deionized water into the dispersing tank in sequence Stir well to get A component.

[0037] 2. Mix components A and B with a mass ratio of 100:15.

Embodiment 2

[0039] 1. Preparation of component A

[0040] Put 20.0 g of deionized water into the reaction flask, put in 3.0 g of polyvinyl alcohol 2088 and raise the temperature to 85° C. for 1 hour. Add 0.15g titanate coupling agent, react for 1.5h and cool down for later use;

[0041] Then 34.0g ethylene-vinyl acetate copolymer emulsion (VAE emulsion), 17.0g ethylene-vinyl acetate-vinyl chloride copolymer emulsion (chlorine vinegar emulsion), 2.5g carboxylated styrene-butadiene latex, 0.15g dispersant, 0.05g defoamer Add to the dispersing tank, slowly add 21.0g of calcium carbonate under stirring, stir for 1 hour to disperse to a uniform slurry, then slowly add the prefabricated modified polyvinyl alcohol solution, 0.05g of bactericide, and 2.1g of deionized water into the dispersing tank in sequence Stir evenly to obtain component A.

[0042] 2. Mix components A and B with a mass ratio of 100:15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com