Semi-closed tubular aluminium profile heat treatment device

A heat treatment device and technology for aluminum profiles, which are used in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of asymmetric internal structure of aluminum profiles, uneven internal structure of aluminum profiles, and poor heat treatment effect. Achieve the effect of improving physical performance and internal structure stability, good power saving effect, and improved processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

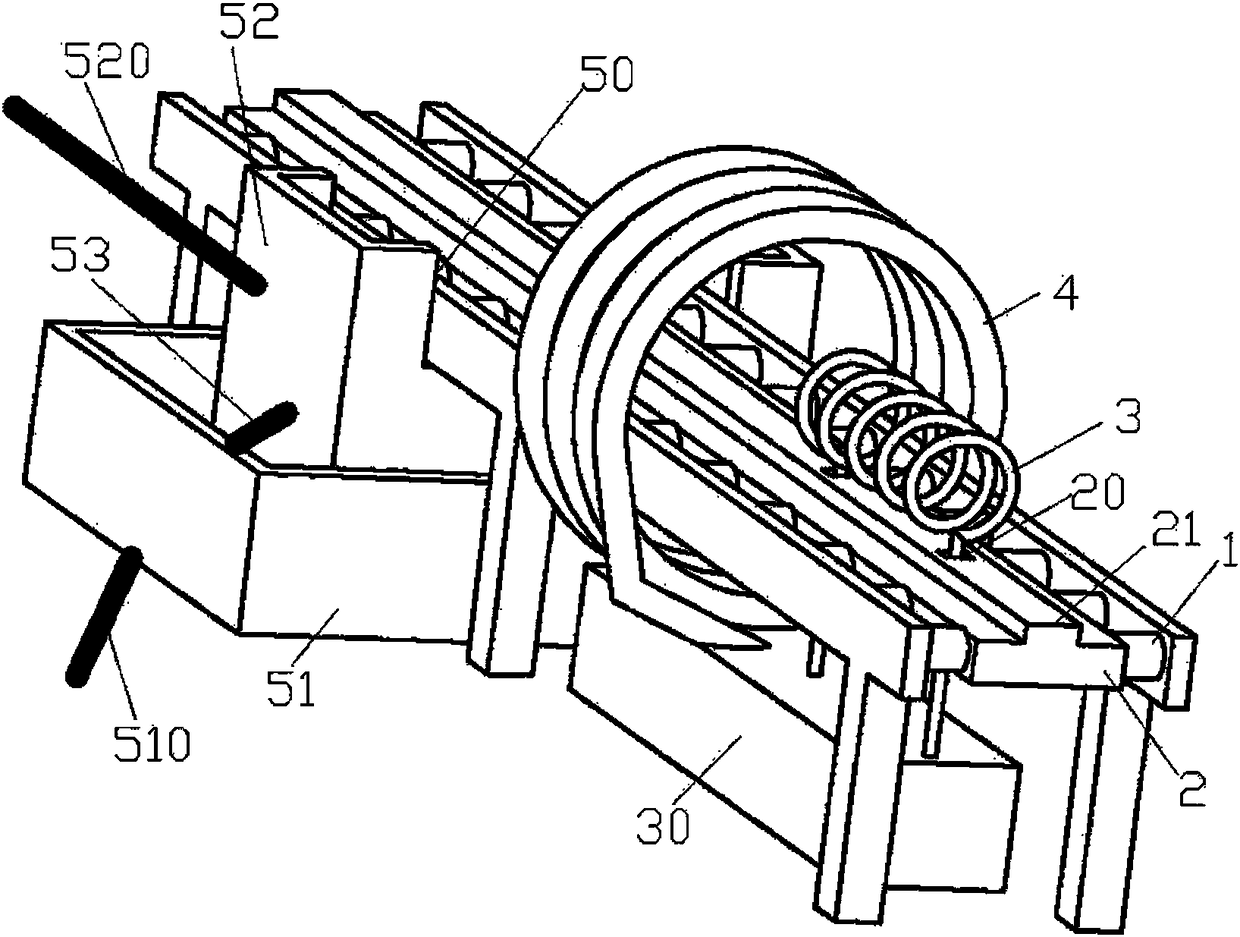

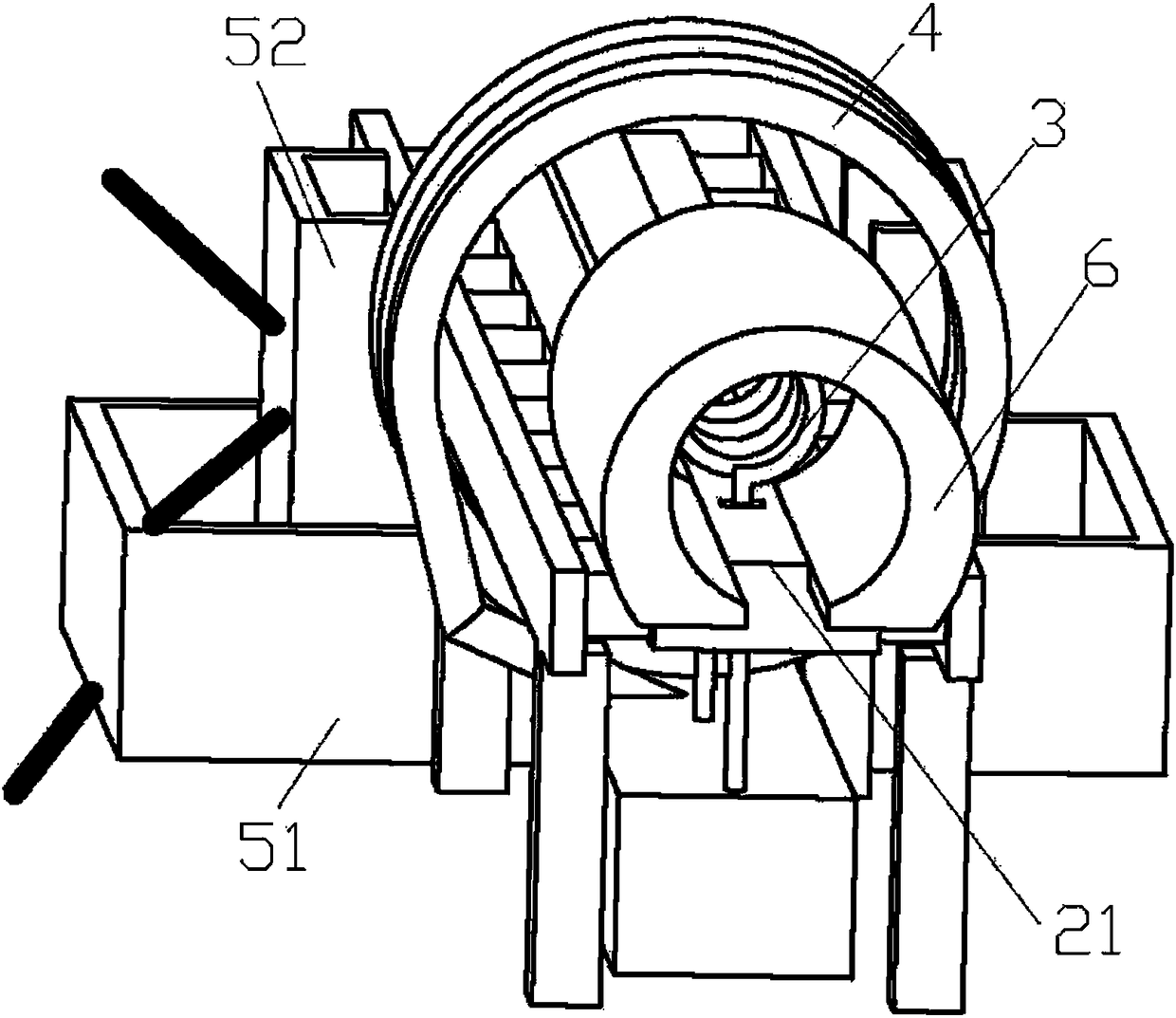

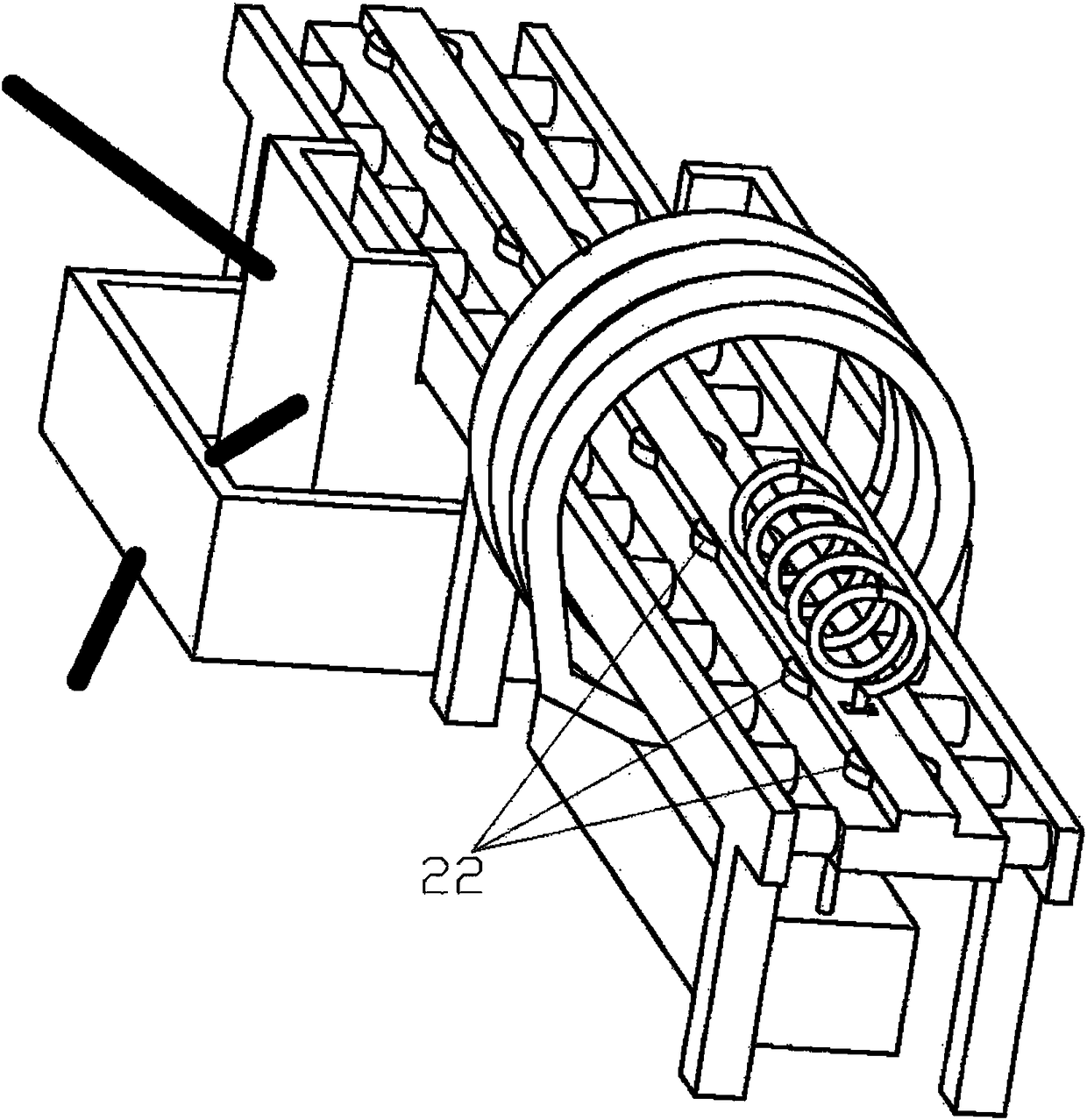

[0021] Example 1, such as figure 1 , figure 2 As shown, a semi-enclosed tubular aluminum profile heat treatment device includes an aluminum profile conveying path 1, and the aluminum profile conveying path 1 is fixed with a positioning track 2 parallel to the conveying direction and in the middle of the conveying direction. The side is equipped with an inner heating device for aluminum profiles, an outer heating device for aluminum profiles, and a cooling device. The aluminum profile internal heating device includes an internal heating coil 3 and an electromagnetic induction device 30 connected to the internal heating coil 3. The aluminum profile external heating device includes an external heating coil 4. The external heating coil 4 is also connected to the electromagnetic induction device 30. The internal heating coil 3 Both the outer heating coil 4 and the outer heating coil 4 have a heating section extending helically along the conveying direction of the aluminum profile...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com