Hot working process of GH4738 nickel-based superalloy

A nickel-based superalloy, thermal processing technology, used in metal processing equipment, transportation and packaging, wheels, etc., can solve the problems of cracking, low corrosion wear rate, prone to mixed crystal and coarse-grained specimens, etc., to reduce production. Cost, good high temperature erosion performance, and the effect of avoiding cracking of the specimen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0136] 1. A thermal working process of GH4738 nickel-based superalloy

[0137] The hot working process of GH4738 nickel-based superalloy includes the following steps:

[0138] Step A: Using GH4738 nickel-based superalloy as a raw material, it is smelted by vacuum induction melting VIM and vacuum consumable remelting VAR processes in sequence to obtain vacuum consumable ingots.

[0139] Step B: Homogenize the vacuum consumable ingot and forge to obtain a GH4738 alloy bar; the homogenization temperature is 1180°C, and the homogenization time is 12 hours; the initial forging temperature of the blank forging is It is 1160°C.

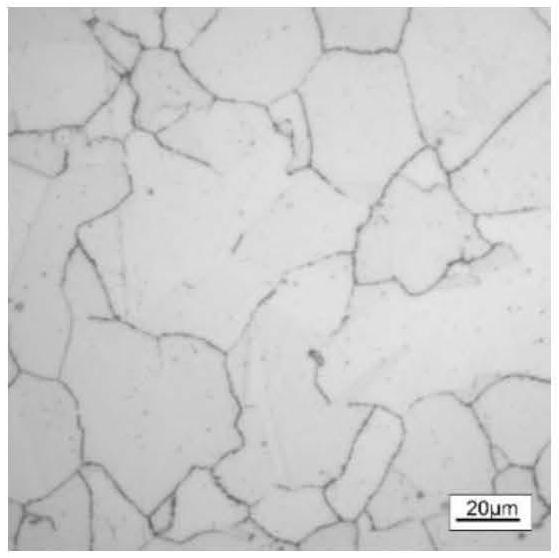

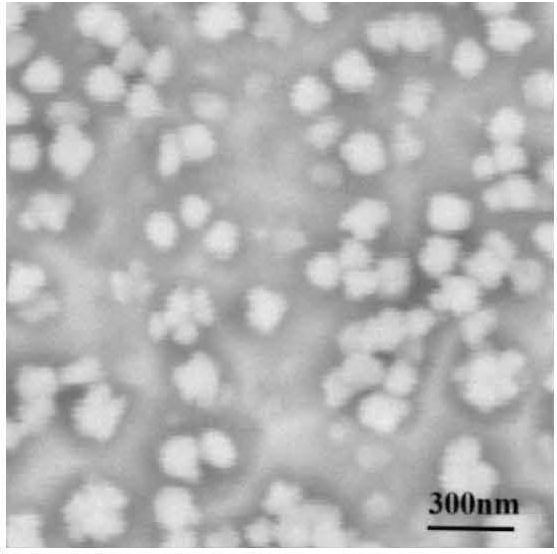

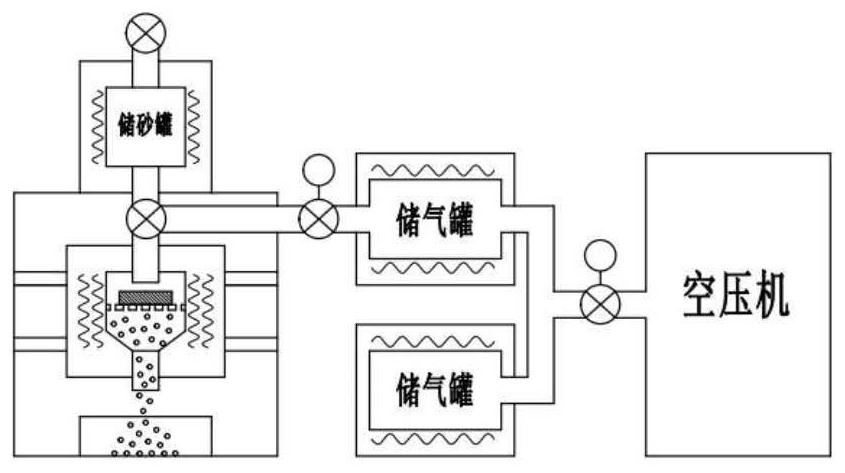

[0140] Step C: put the GH4738 alloy bar blank into a gas furnace and raise the temperature to 1140°C with the furnace. After holding the heat for 15 minutes, use a forging hammer to perform flat anvil upsetting to obtain a GH4738 alloy disc forging. The deformation of the GH4738 alloy disc forging is controlled at 80%; when heating up, the method of stepwi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com