Patents

Literature

151results about How to "Avoid material waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

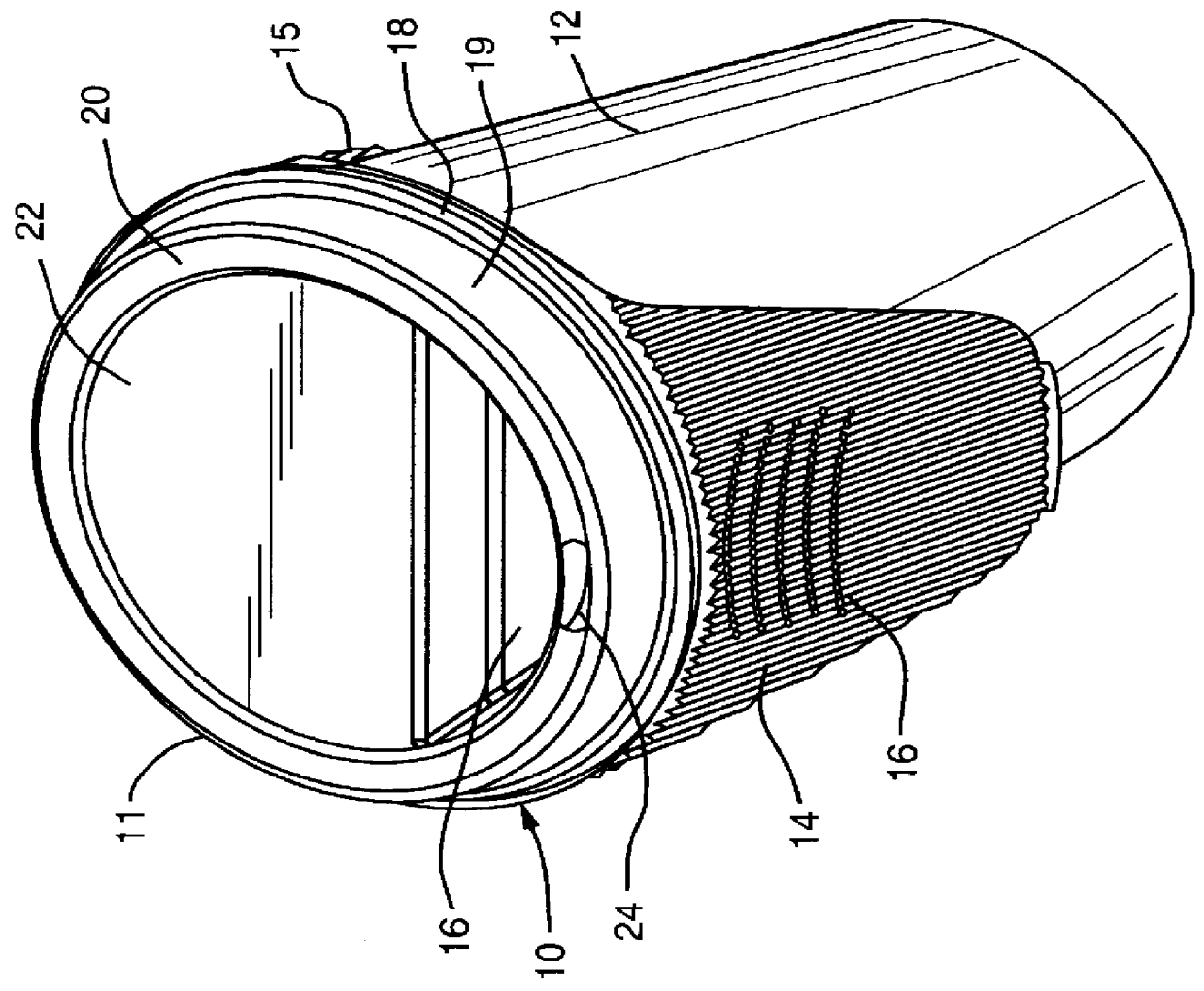

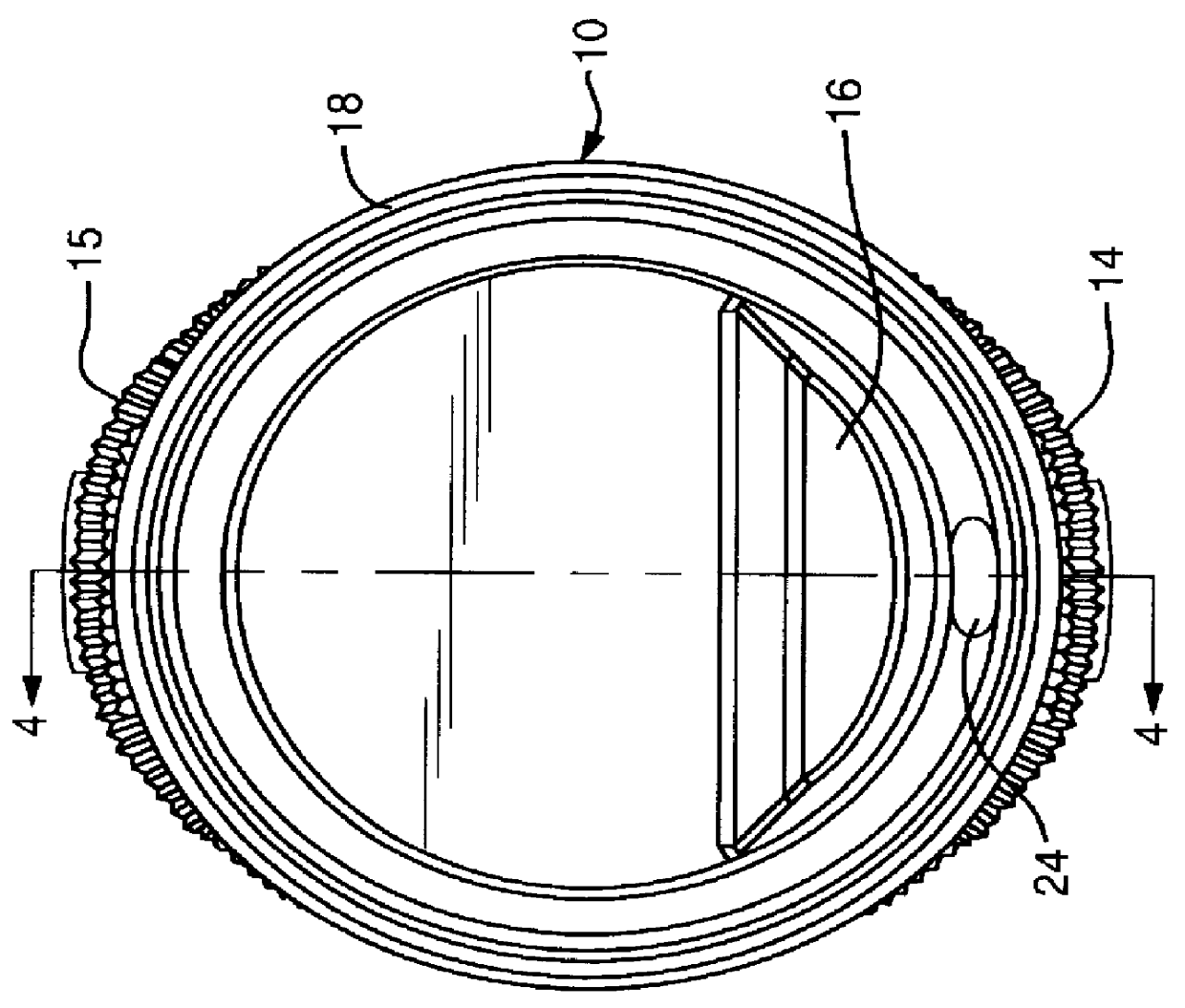

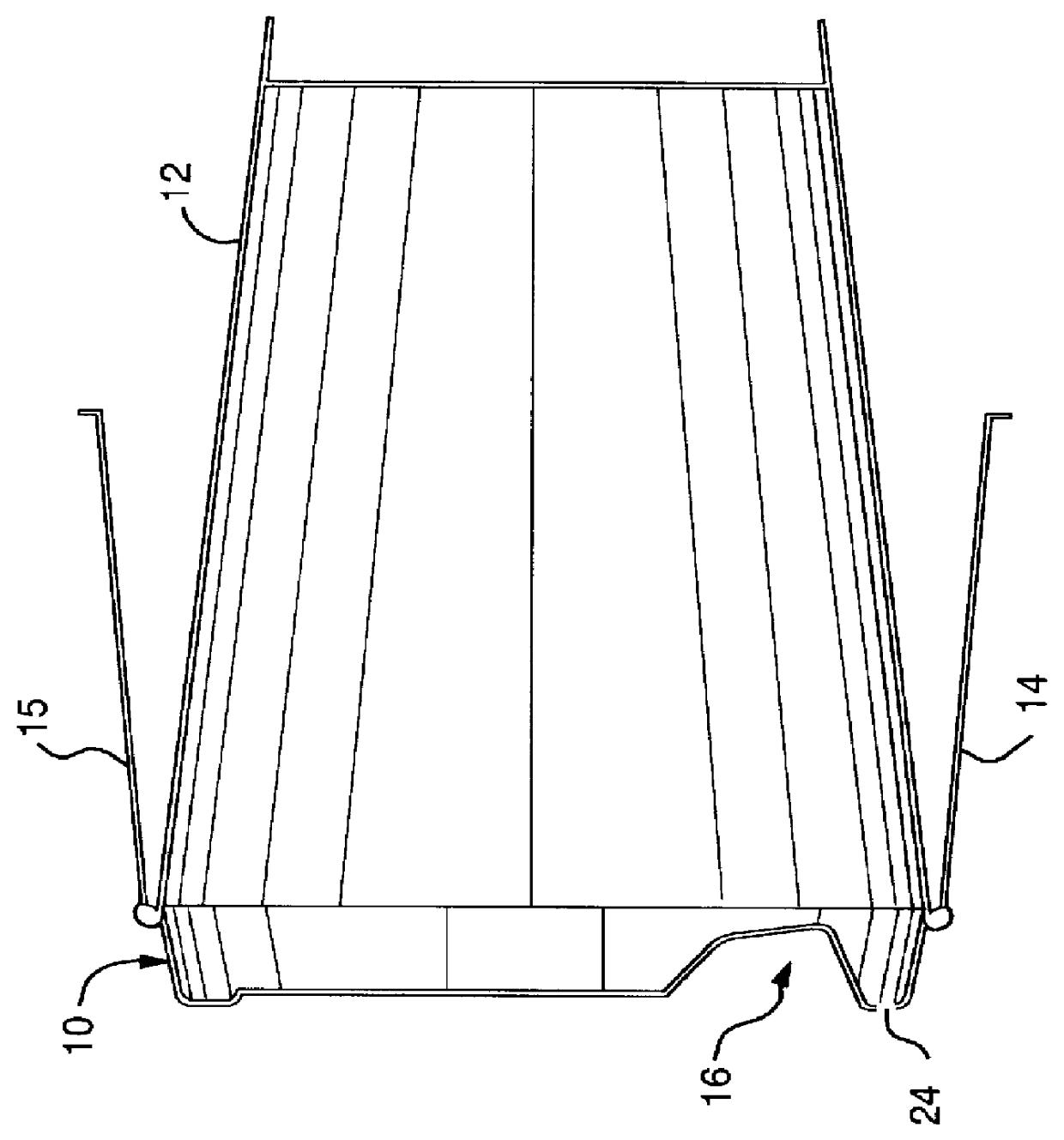

Hot beverage lid with thermal flex-guards

InactiveUS6047852ASufficient protectionAvoid material wasteCapsClosure with auxillary devicesEngineeringMechanical engineering

A hot beverage lid having thermal protective flex-guards or flaps extending from opposite sides of a cover portion of the lid for protecting a consumer's fingers from heat emanating from the side of a cup. A first flap extends a first distance from under a drinking opening having sufficient area for a thumb. A second flap extends a second distance which is greater than the first flap from the opposite side of the lid and has sufficient area for at least two fingers. Each flap is contoured to conform to the curvature or the sidewall of the cup and each flap comprises swirled rib embossing for improved retention against fingers holding the cup. The top of the cover portion is concave with a hole in the center to allow liquid spillage to reenter the cup. Also, a channel surrounding the base of a circular plateau on top of the cover of the lid is provided for collecting fluid spillage.

Owner:WADDINGTON NORTH AMERICA BUSINESS TRUST

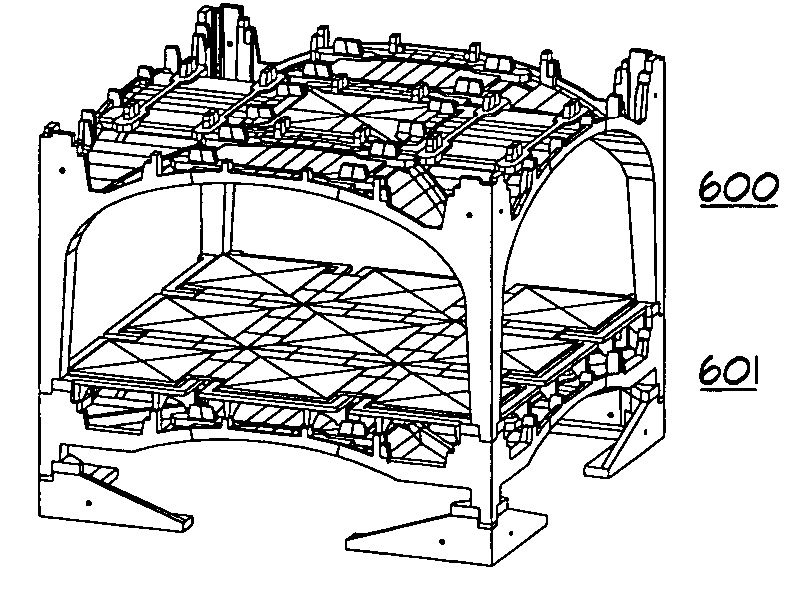

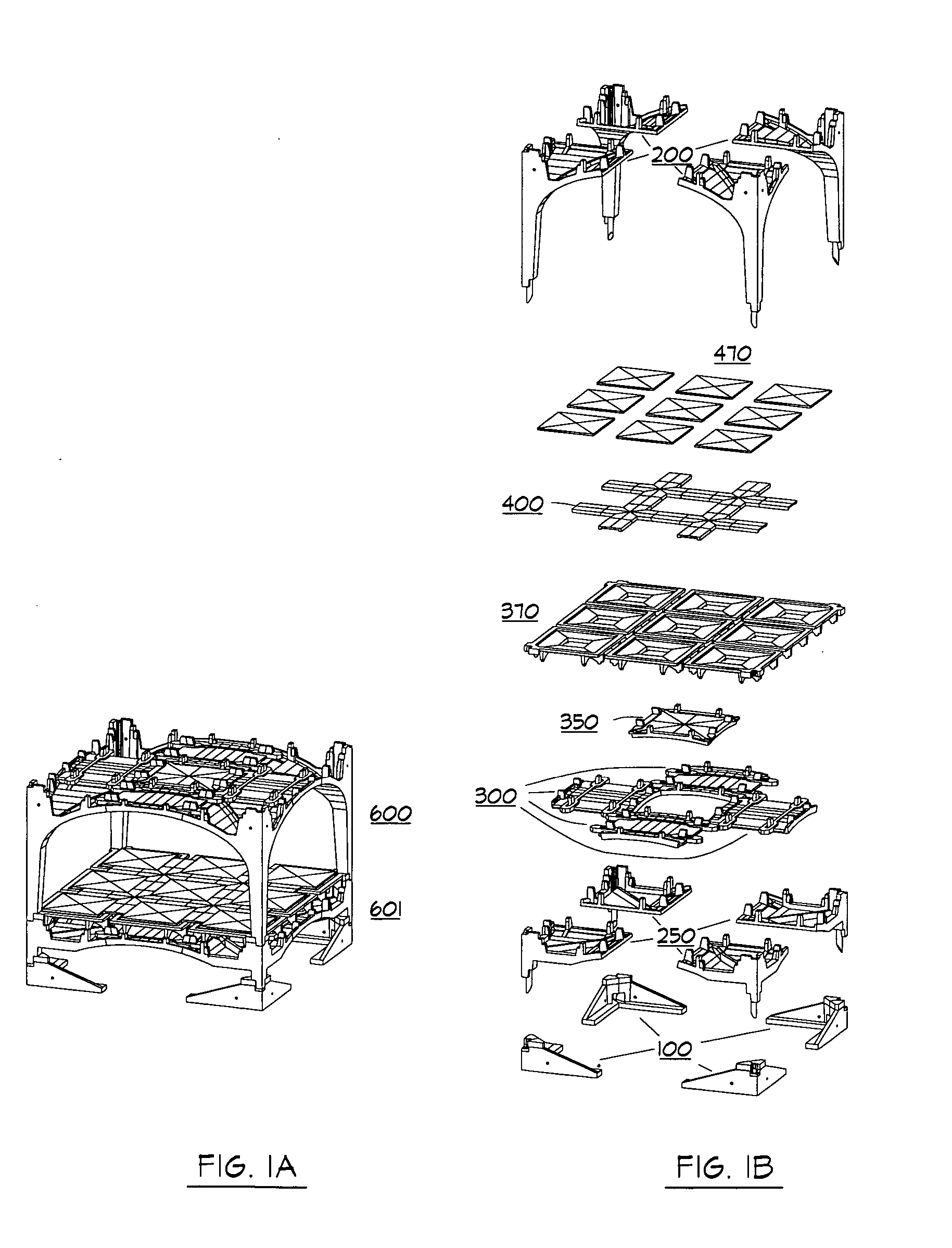

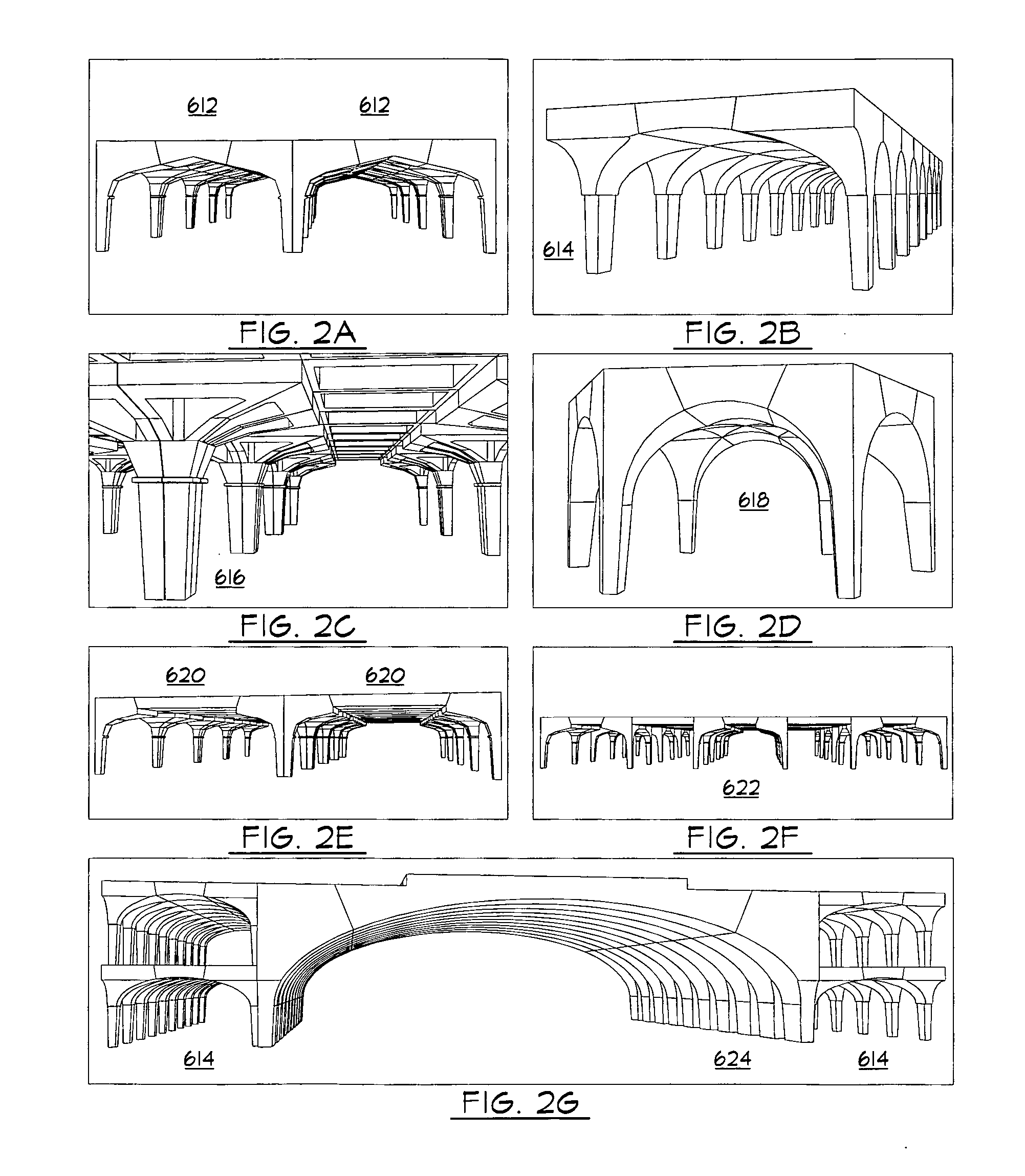

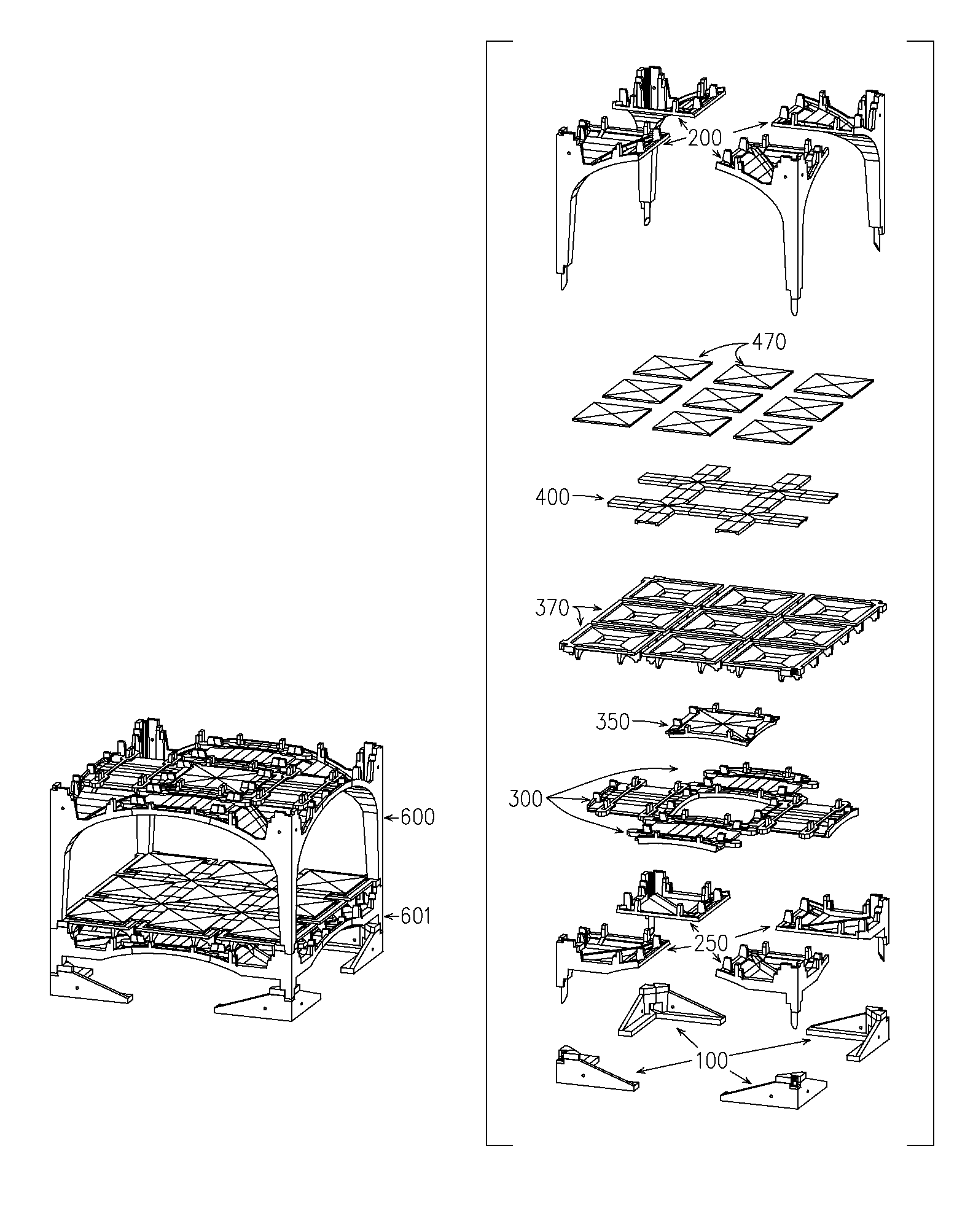

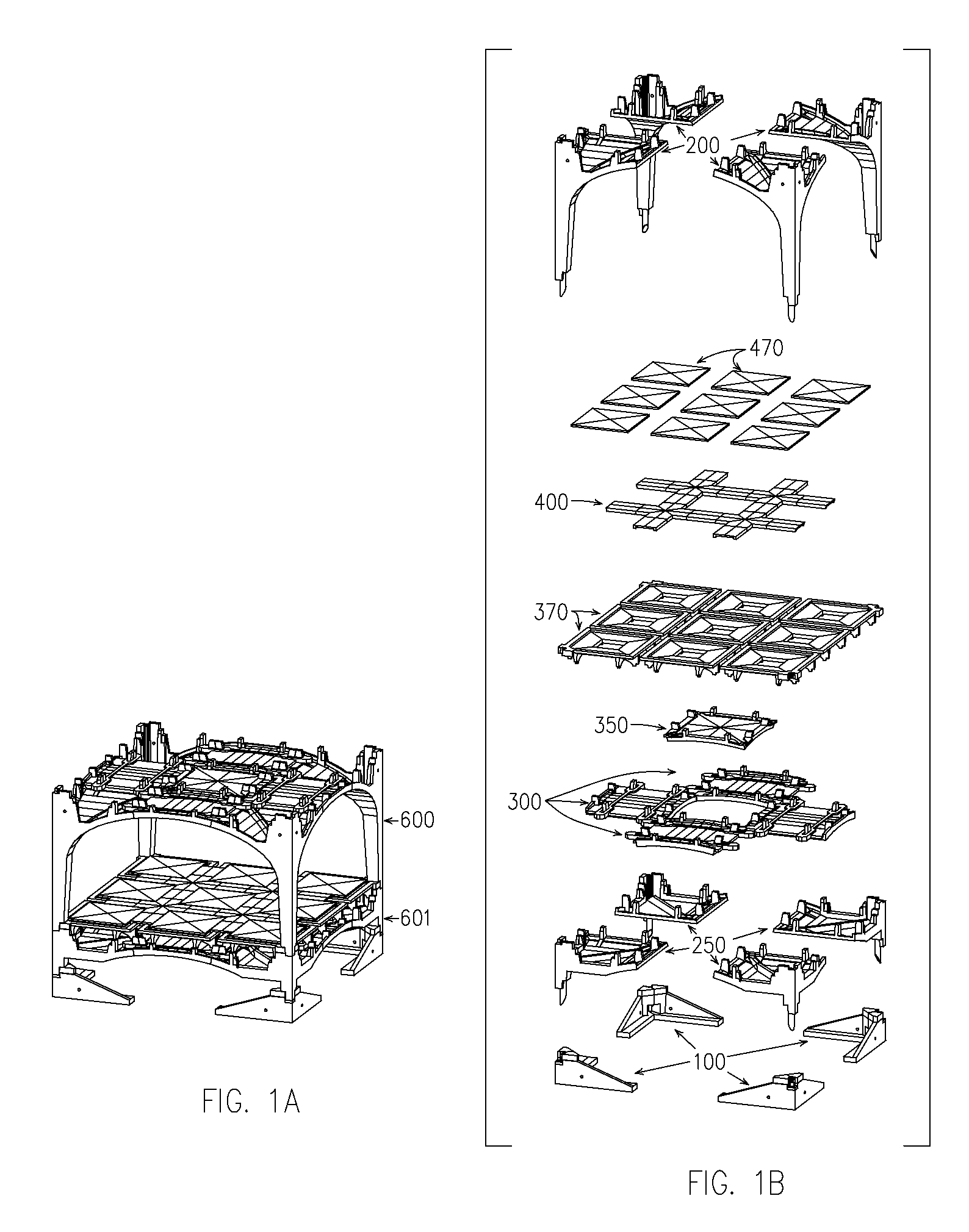

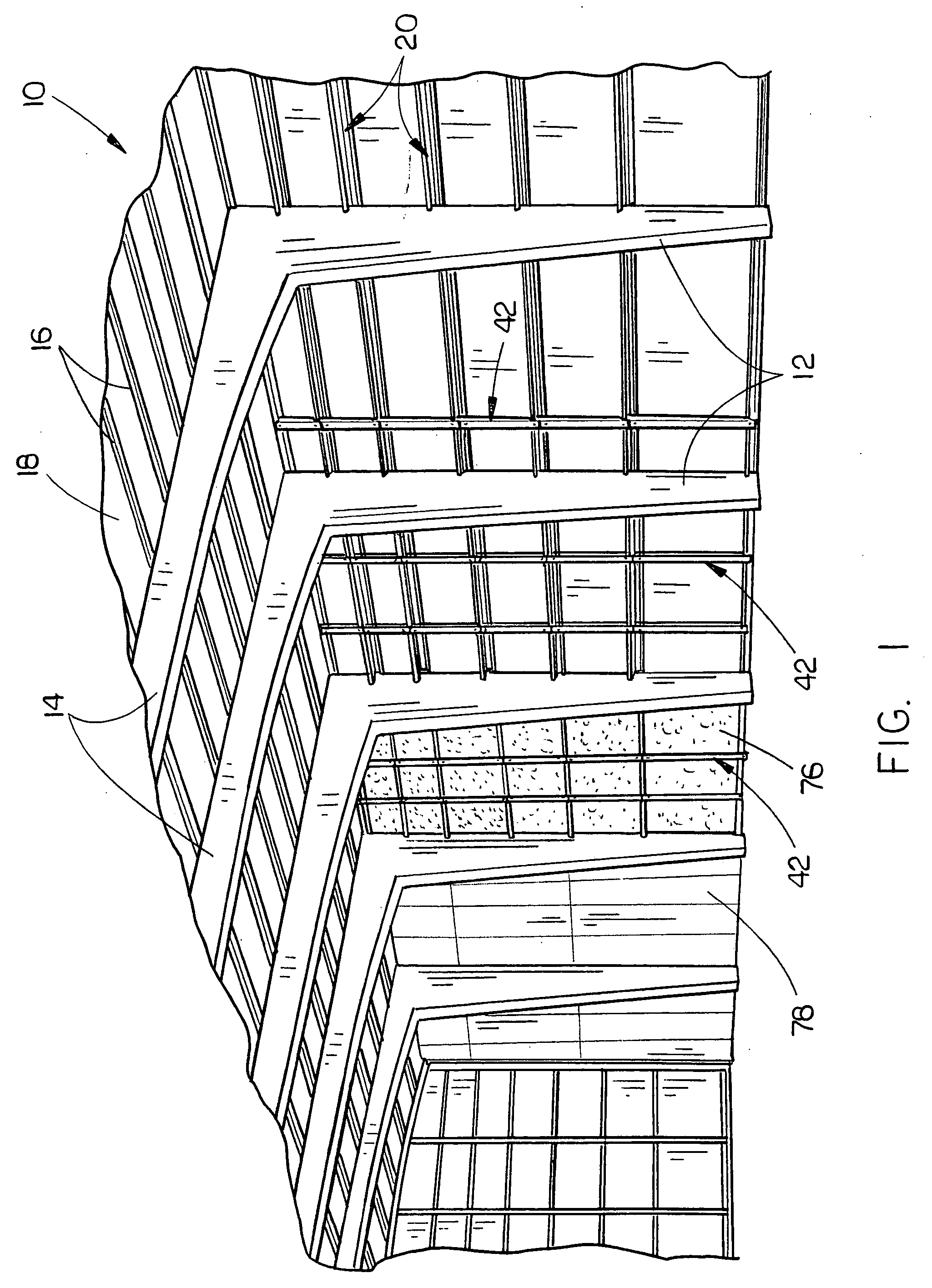

Method and system for prefabricated construction

A structure assembled from a combination of stackable modules, each module assembled from multiple prefabricated, transportable blocks. The blocks are typically reinforced cast concrete formed in reusable molds. Module framing blocks may include arched corner blocks, key blocks that interlock with a pair of corner blocks, and optional center blocks. Other structural elements include roof, floor, and wall components that interlock with the framing modules. Modules may be stacked or nested to form structures including buildings, elevated roadways, and parking garages. Utilities may be provided through optional conduits formed in the corner elements. The framing supports raised floor modules for ease in mechanical system installation and modification. The roof elements support usable terraces and rainwater collection. The blocks are demountable and reusable. The modules are self-supporting during erection, and may be assembled without fasteners.

Owner:POWELL DAVID W

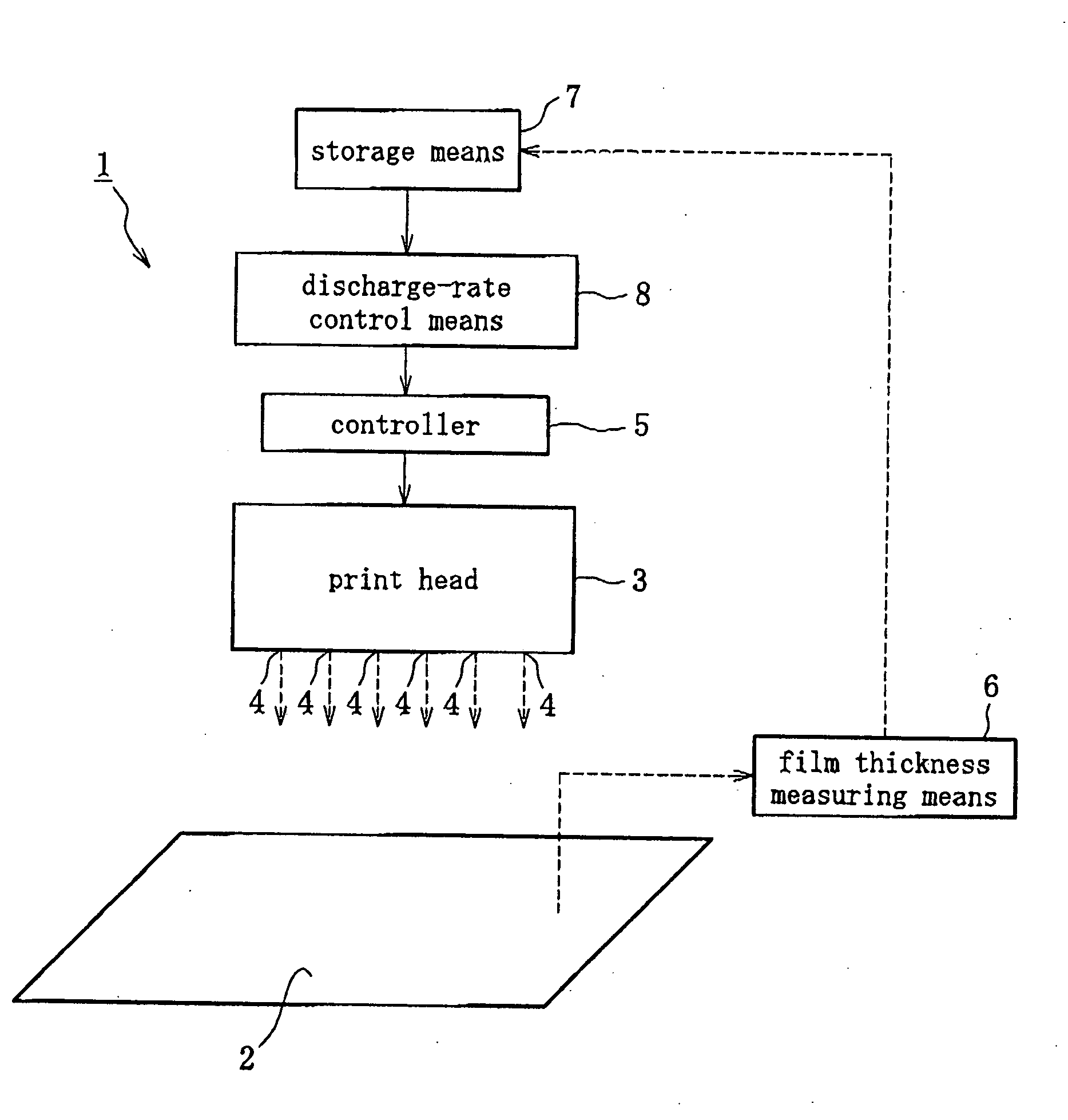

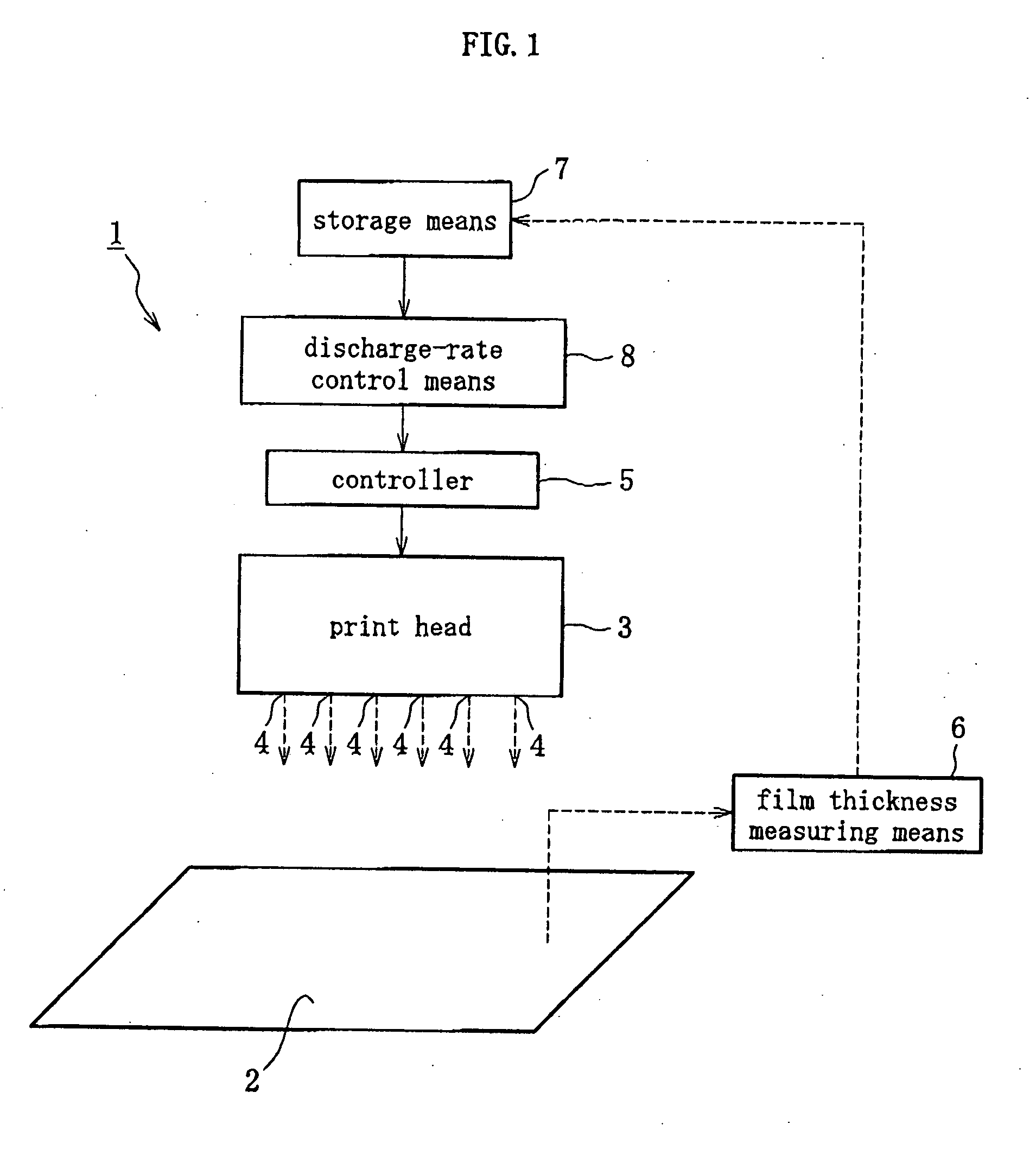

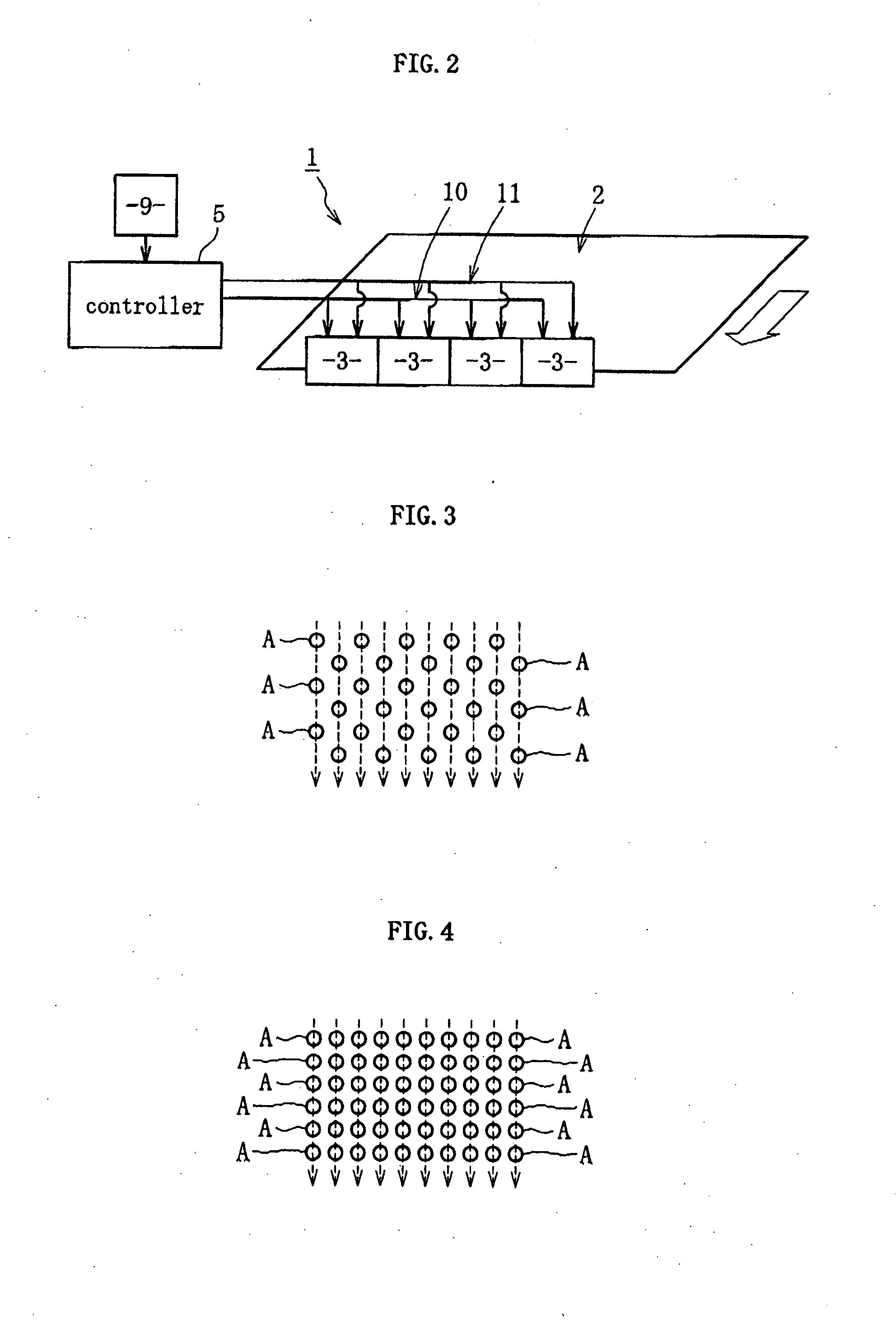

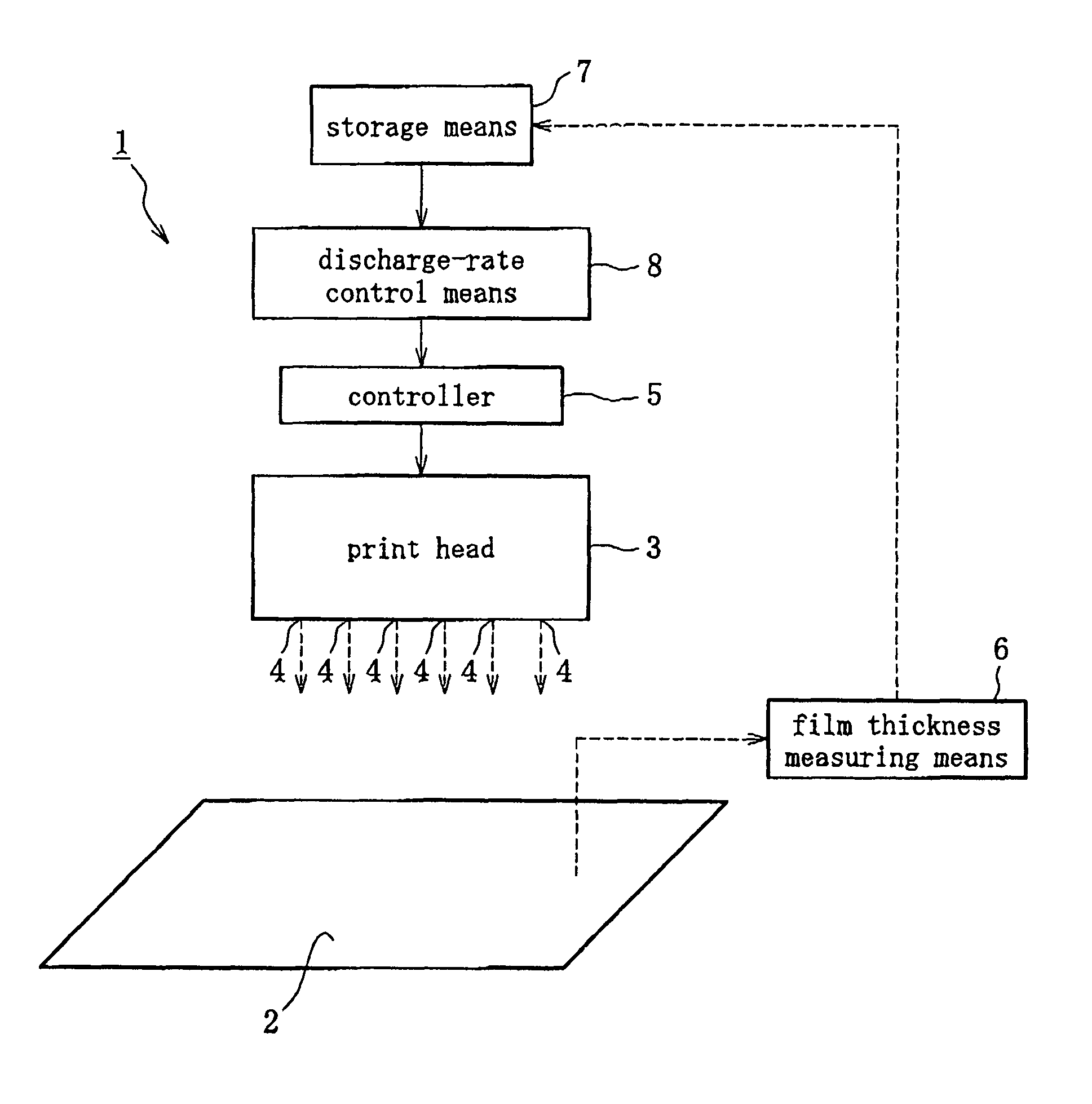

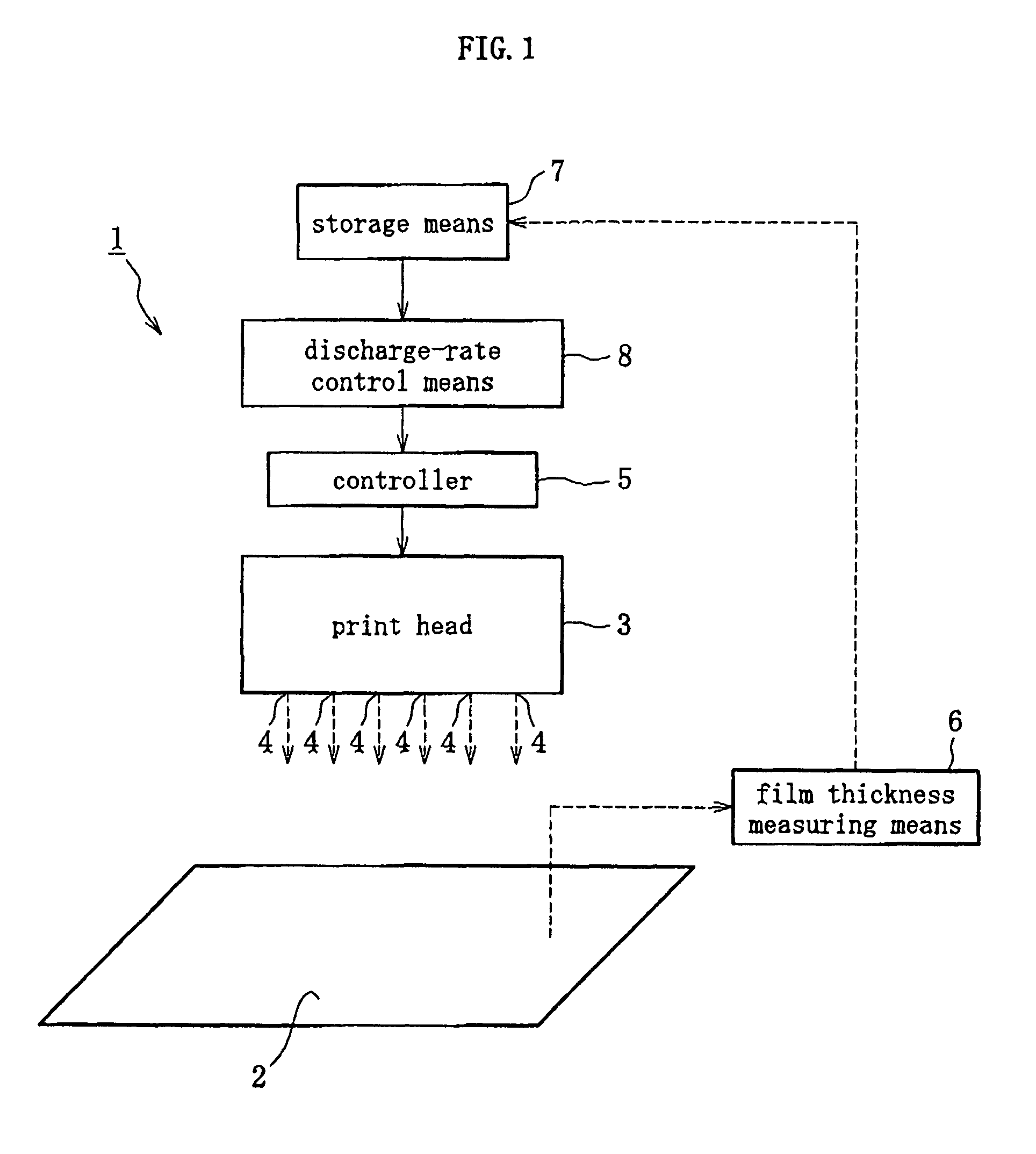

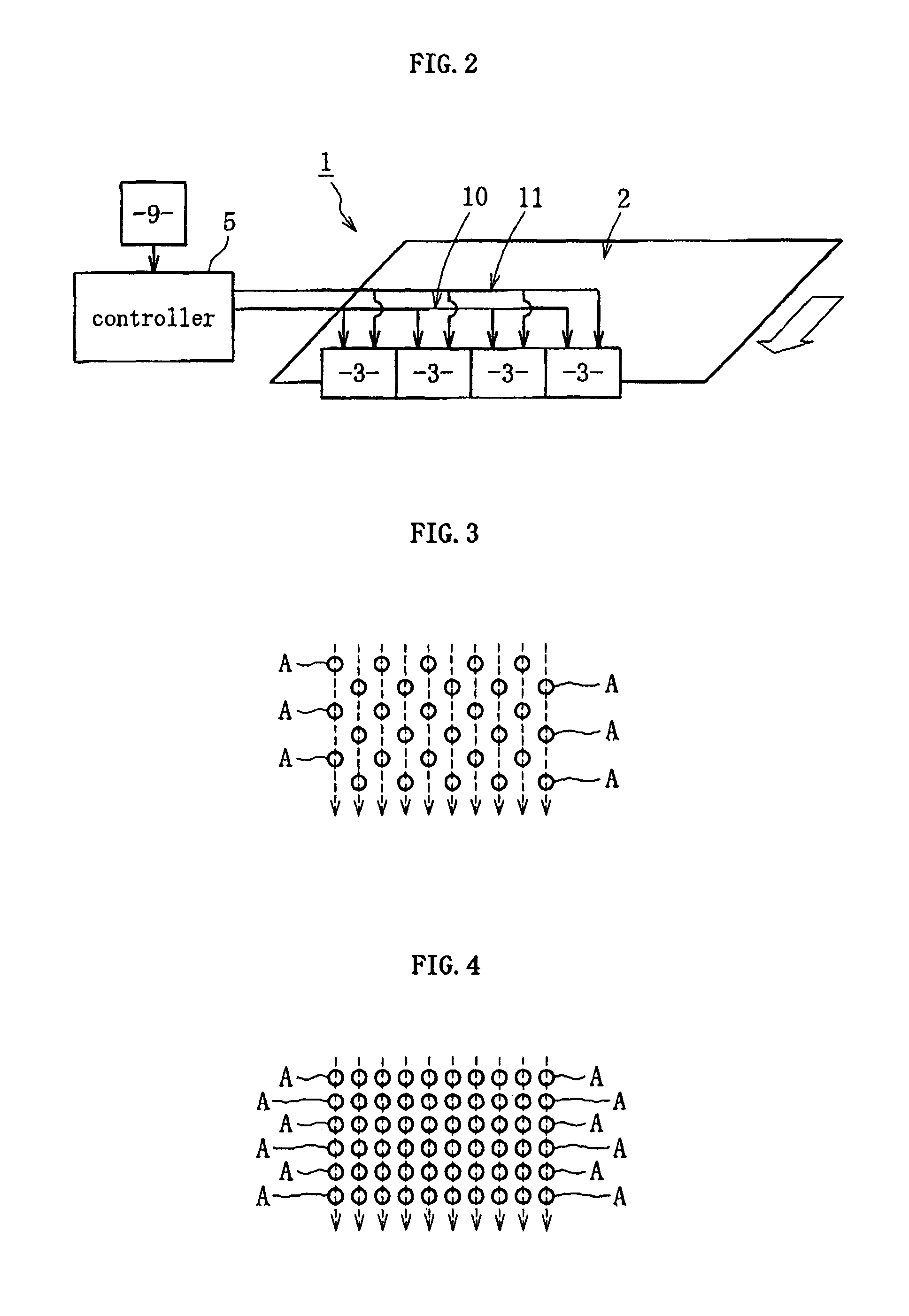

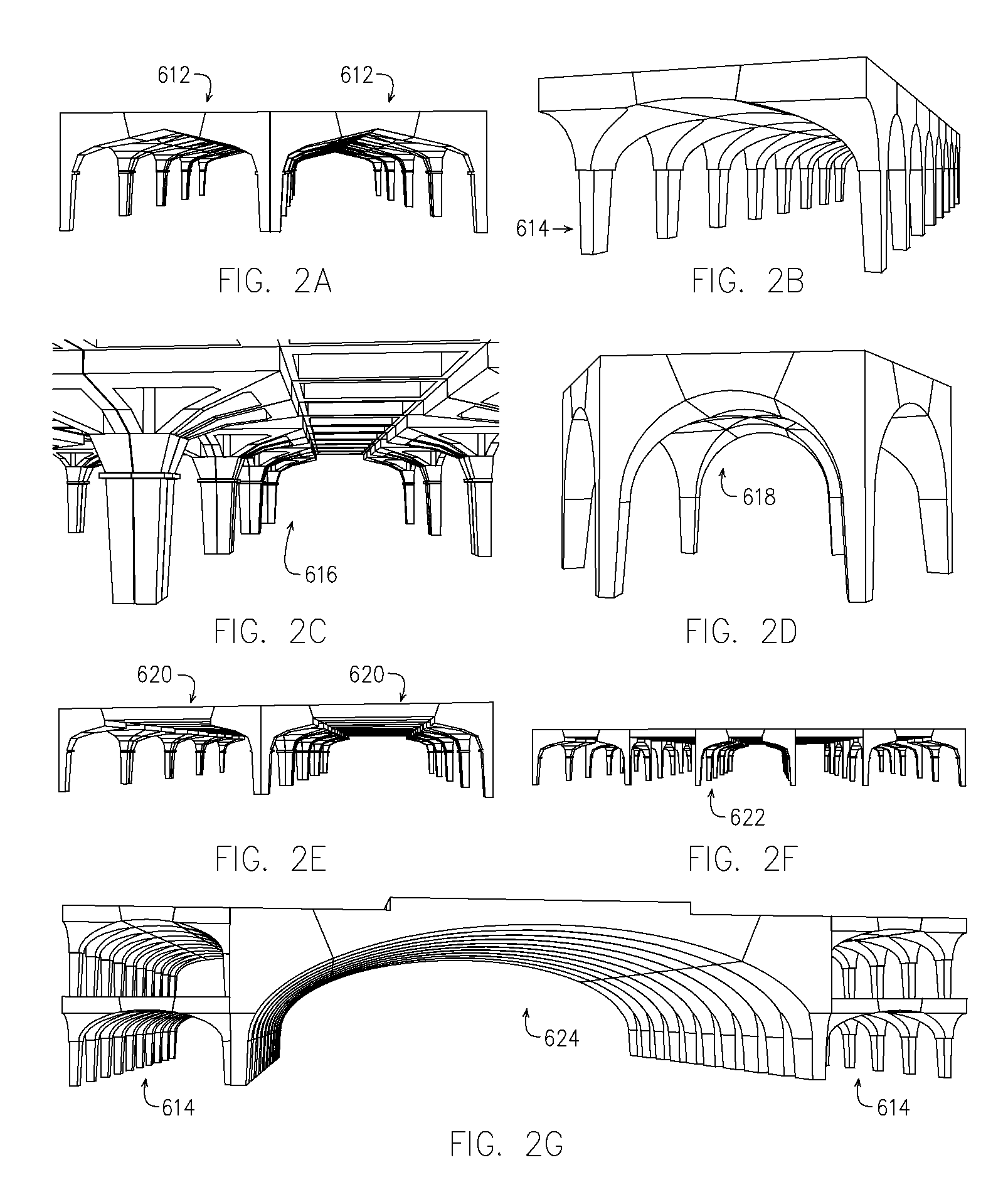

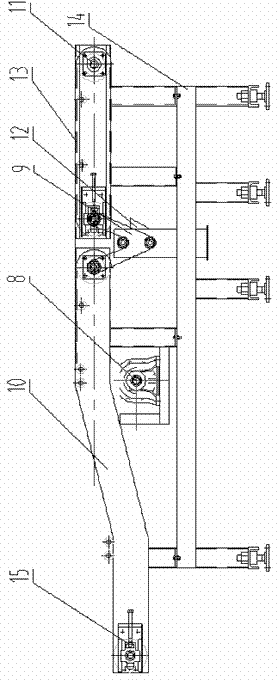

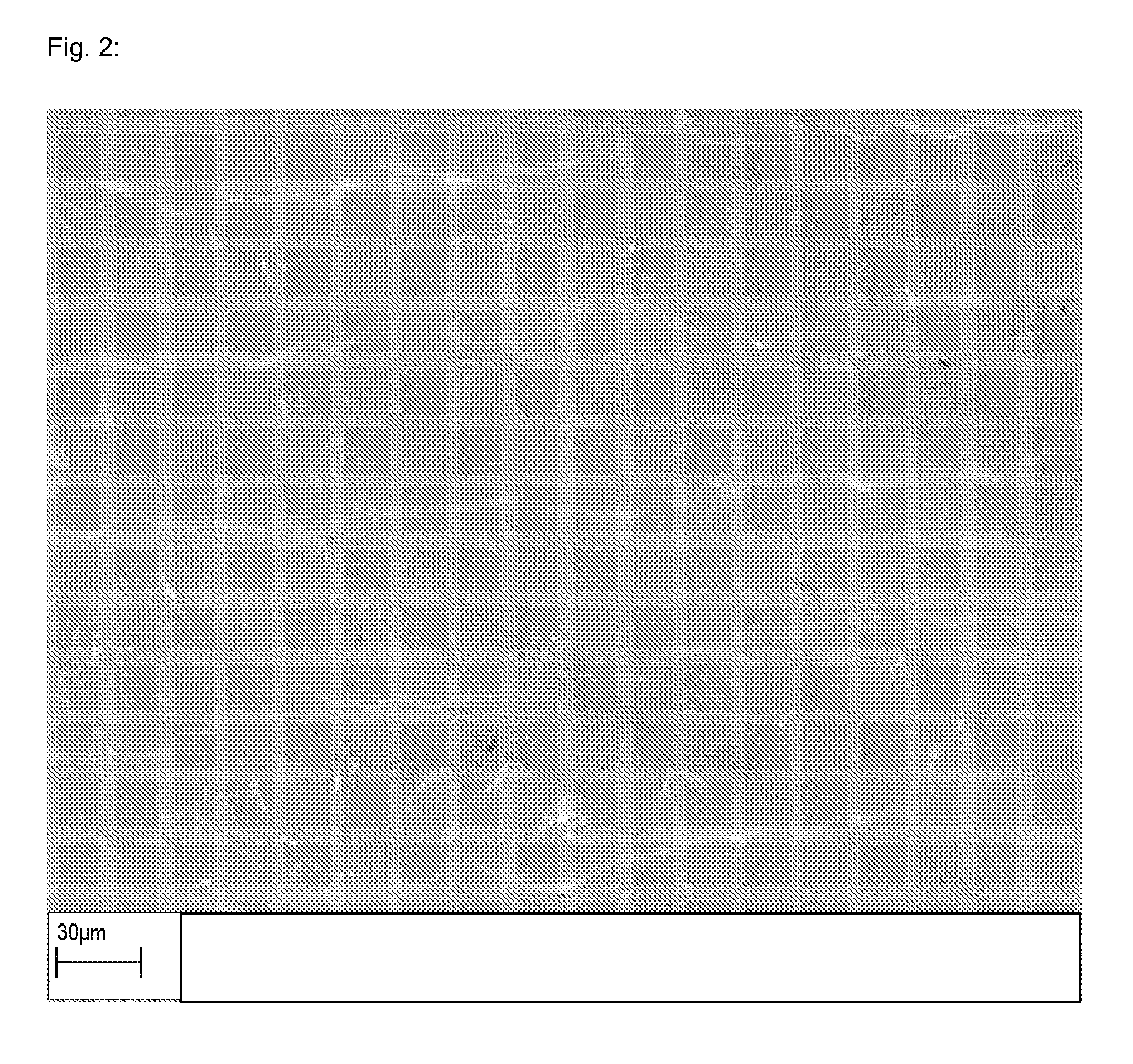

Discharge Rate Control Method for Ink-Jet Printer, Ink Spread Inspecting Method, and Oriented Film Forming Method

ActiveUS20080309698A1Unnecessary forming can be preventedAvoid work environmentLiquid surface applicatorsSpraying apparatusDischarge rateEngineering

Discharge rate control method for ink-jet printer 1 including film forming step forming film B on coating article 2 with non ink-absorbent characteristic by discharging ink on coating article 2 from a plurality of nozzles 4 of print head 3, film thickness measuring step measuring film thickness of film B, corresponding to ink discharge position of each nozzle 4, formed on coating article 2 in film forming step, and discharge rate correcting step correcting discharge rate of ink from each nozzle 4 by increasing or decreasing discharge rate based on difference between target film thickness Ba and film thickness at ink discharge position of each nozzle 4 measured in film thickness measuring step.

Owner:ISHII HYOKI

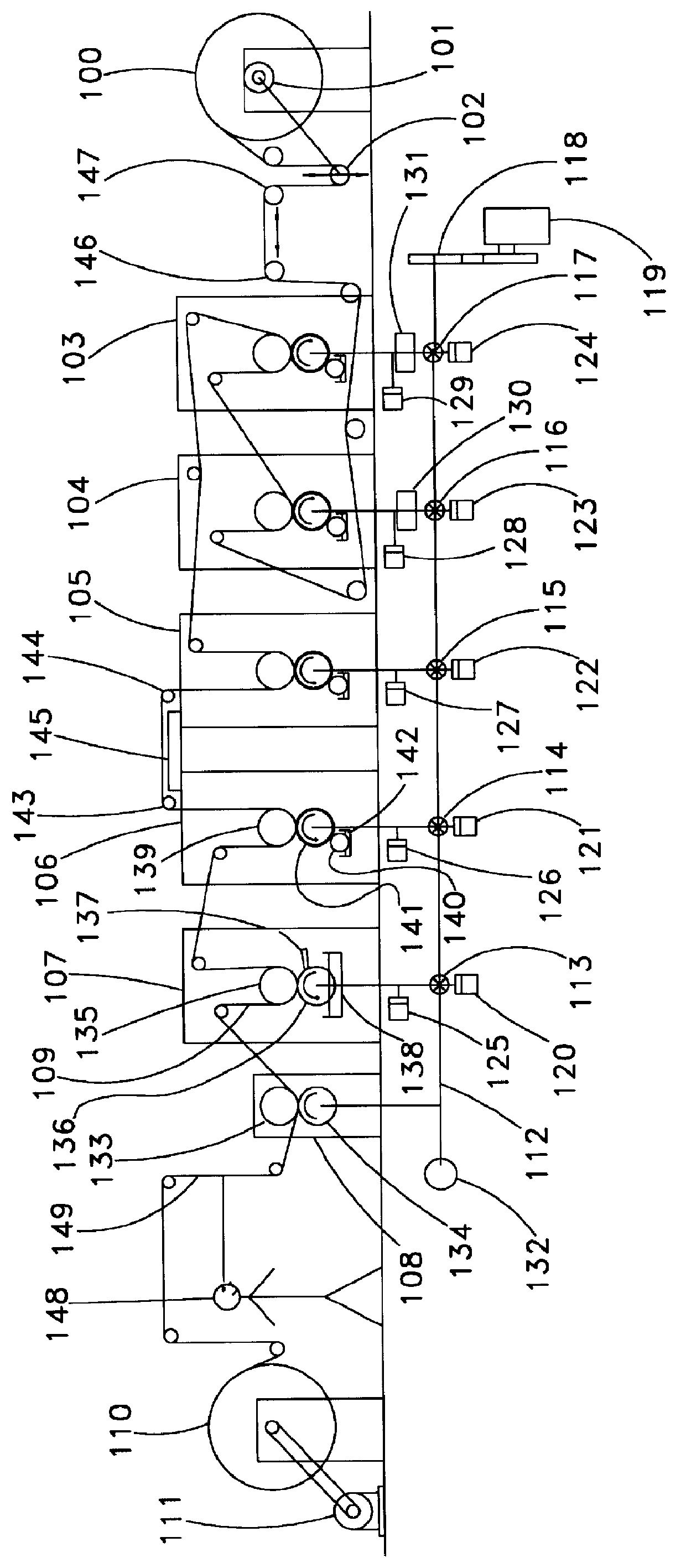

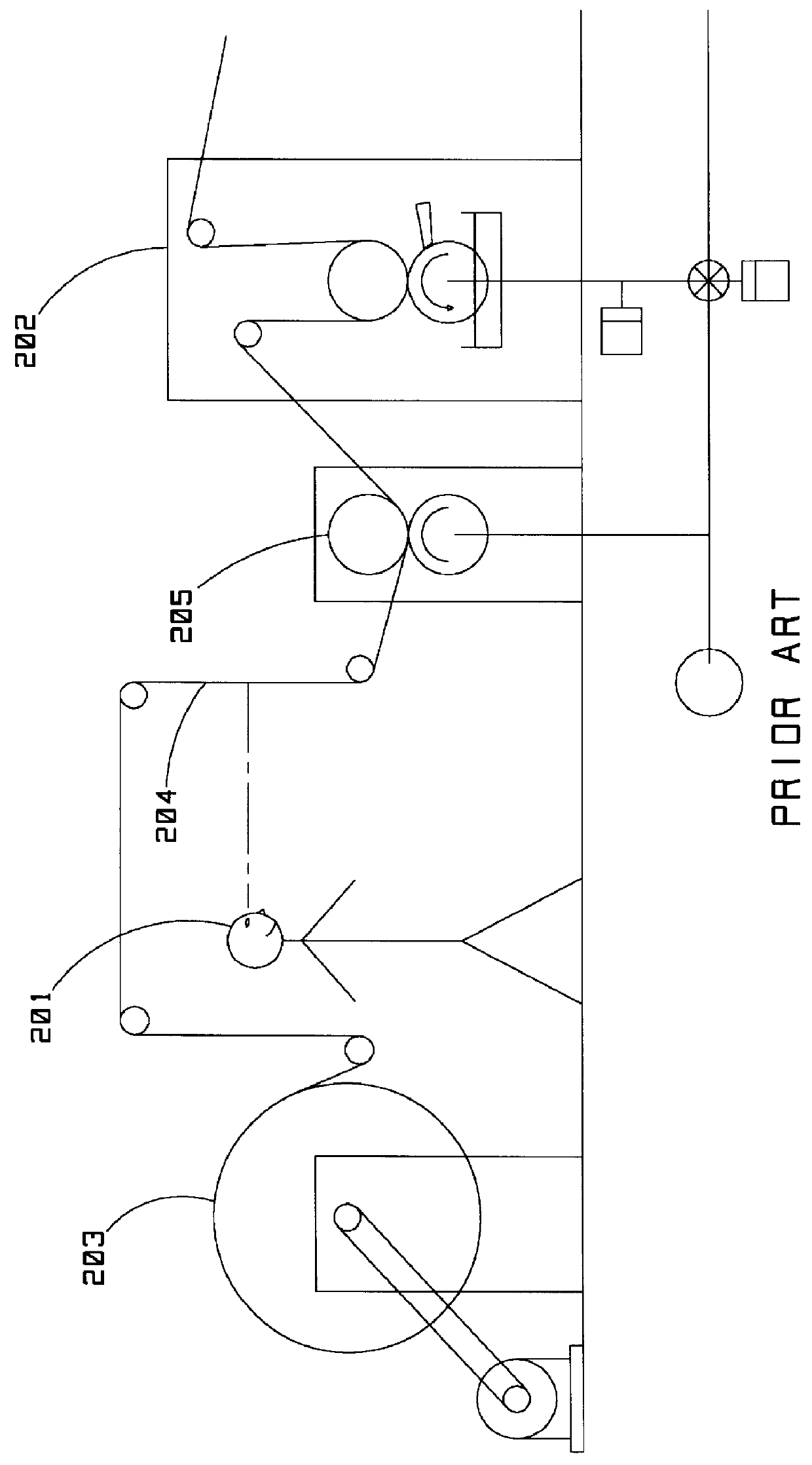

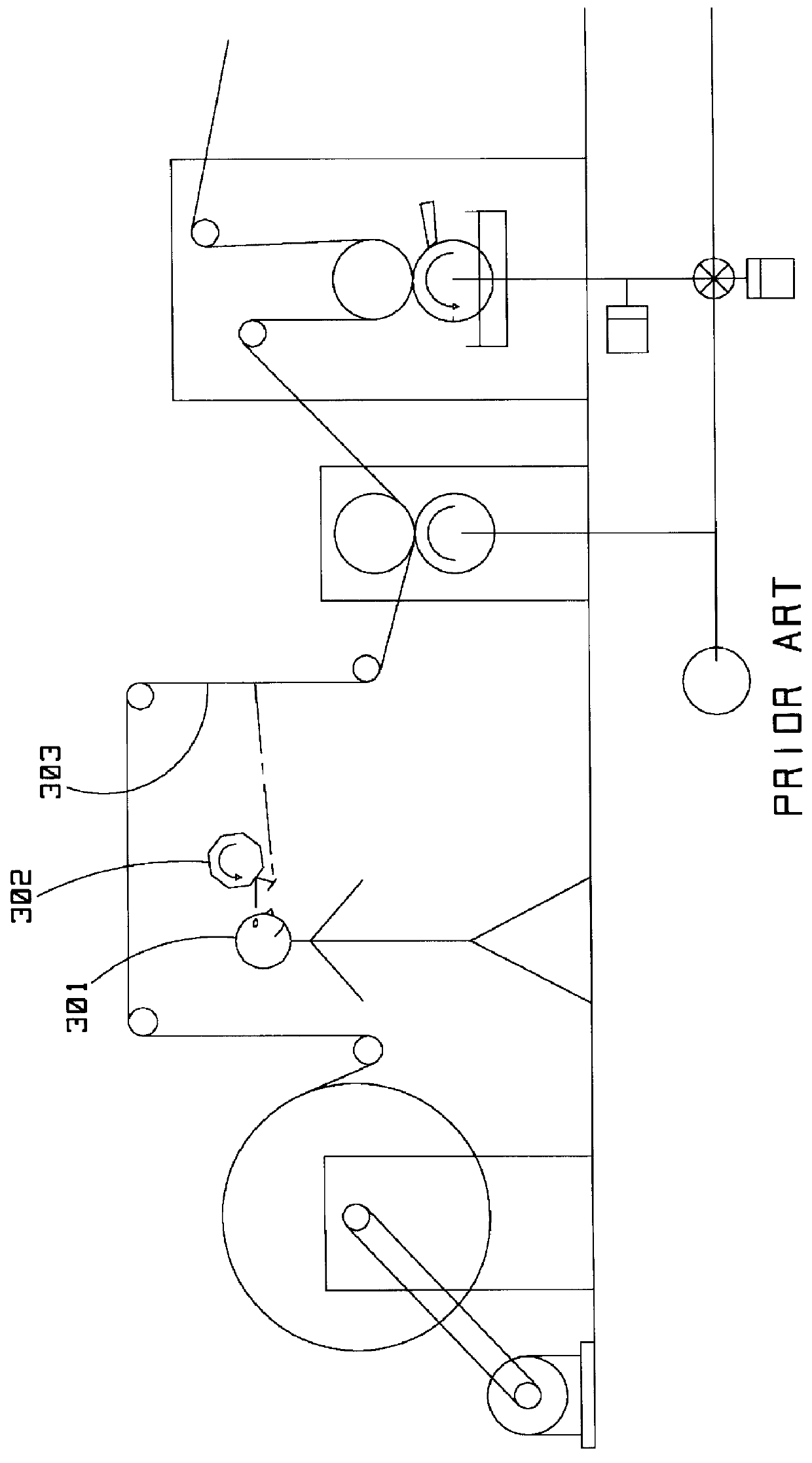

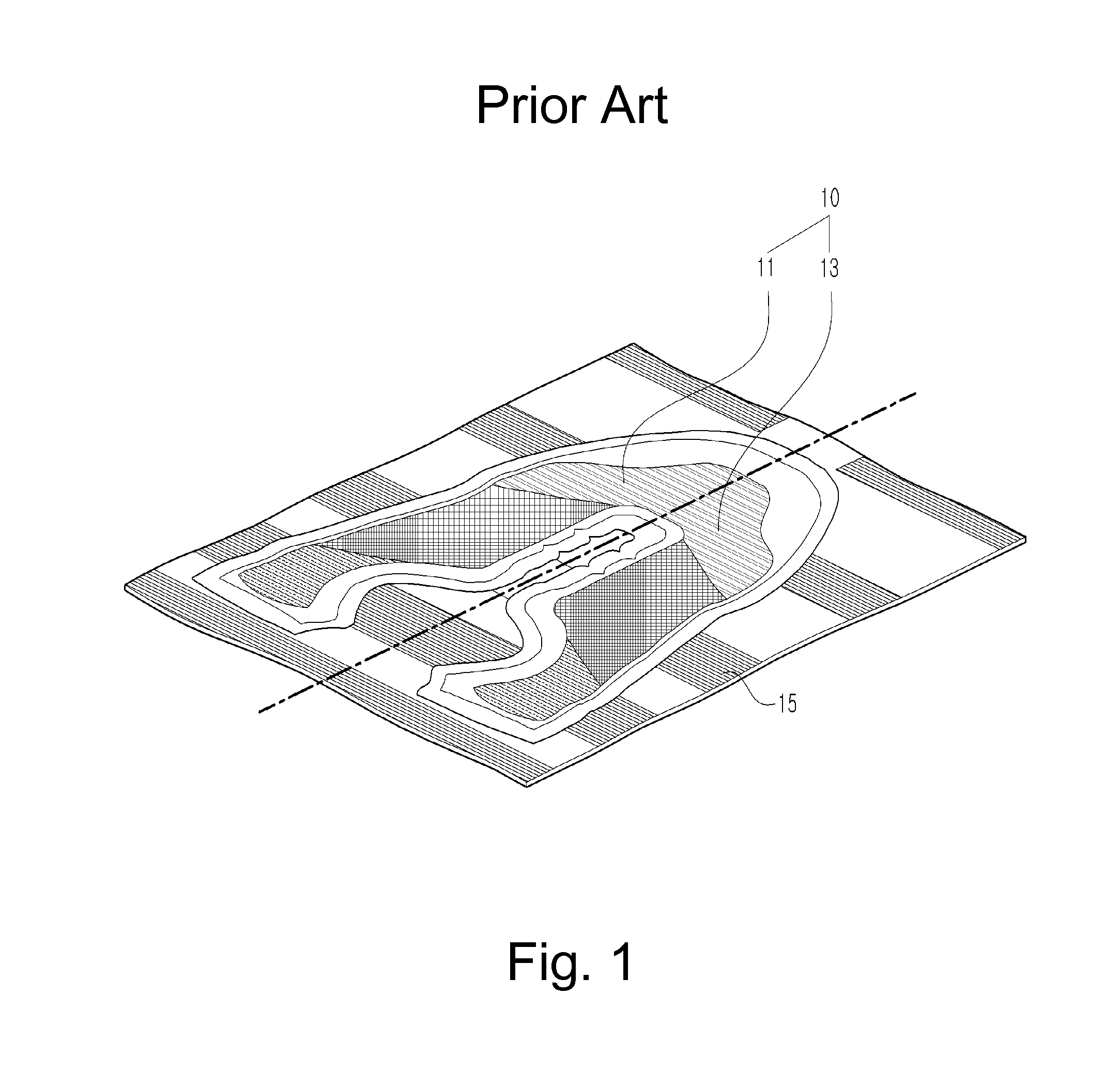

System and method for monitoring and controlling the deposition of pattern and overall material coatings

InactiveUS6166366AAvoid material wasteProgramme controlSolid-state devicesEngineeringOptical sensing

Utilizing optical and signal processing techniques a system permitting the continuous monitoring and quality control of pattern and overall coatings applied to web materials is disclosed. Rather than using manual feedback control means to accomplish a uniform and consistent application of pattern or overall material to roll web material, the disclosed system incorporates optical sensing means along with software methodologies that enable the web material to be sampled and characterized over a number of different points. This characterization of the manufacturing process can be used with the disclosed algorithms to implement a quality control feedback mechanism which in turn can automatically correct for changes in manufacturing conditions in realtime. This permits patterns and coatings to be applied consistently without the use of human intervention and with a great reduction in overall material waste and a corresponding increase in overall coating reliability.

Owner:CC1

Discharge rate control method for ink-jet printer, ink spread inspecting method, and oriented film forming method

ActiveUS8342636B2Accurate UniformityAvoid material wasteLiquid surface applicatorsSpraying apparatusDischarge rateCoating

A discharge rate control method for an ink-jet printer (1) includes forming a film (B) on a coating article (2) having a non ink-absorbent characteristic. Ink is discharged on coating article (2) from a plurality of nozzles (4) of a print head (3). The film thickness of film (B) is measured, corresponding to ink discharge positions of each nozzle (4). The discharge rate of ink is corrected for each nozzle (4) by increasing or decreasing the discharge rate based on differences between a target film thickness (Ba) and a film thickness at an ink discharge position of each nozzle (4).

Owner:ISHII HYOKI

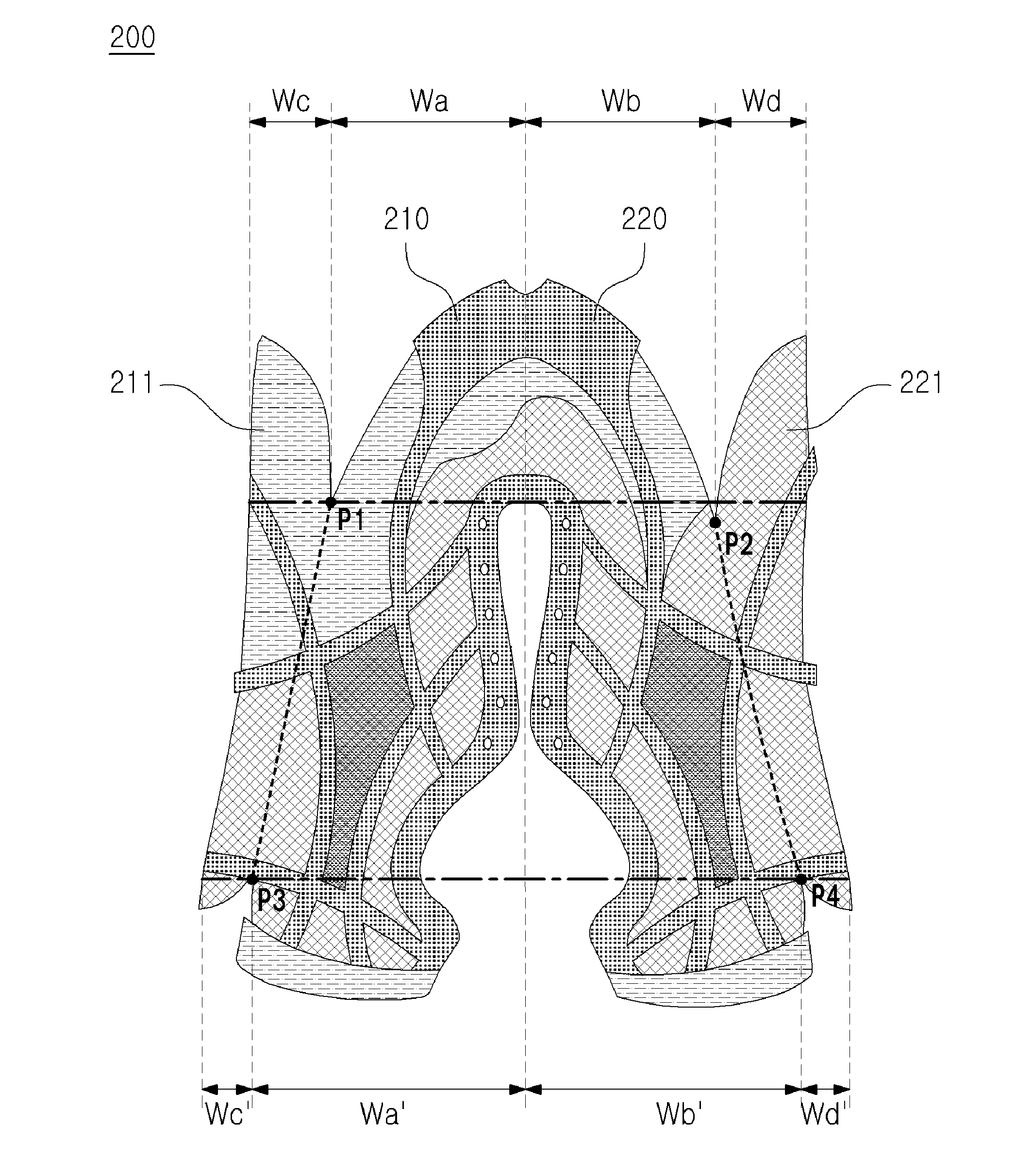

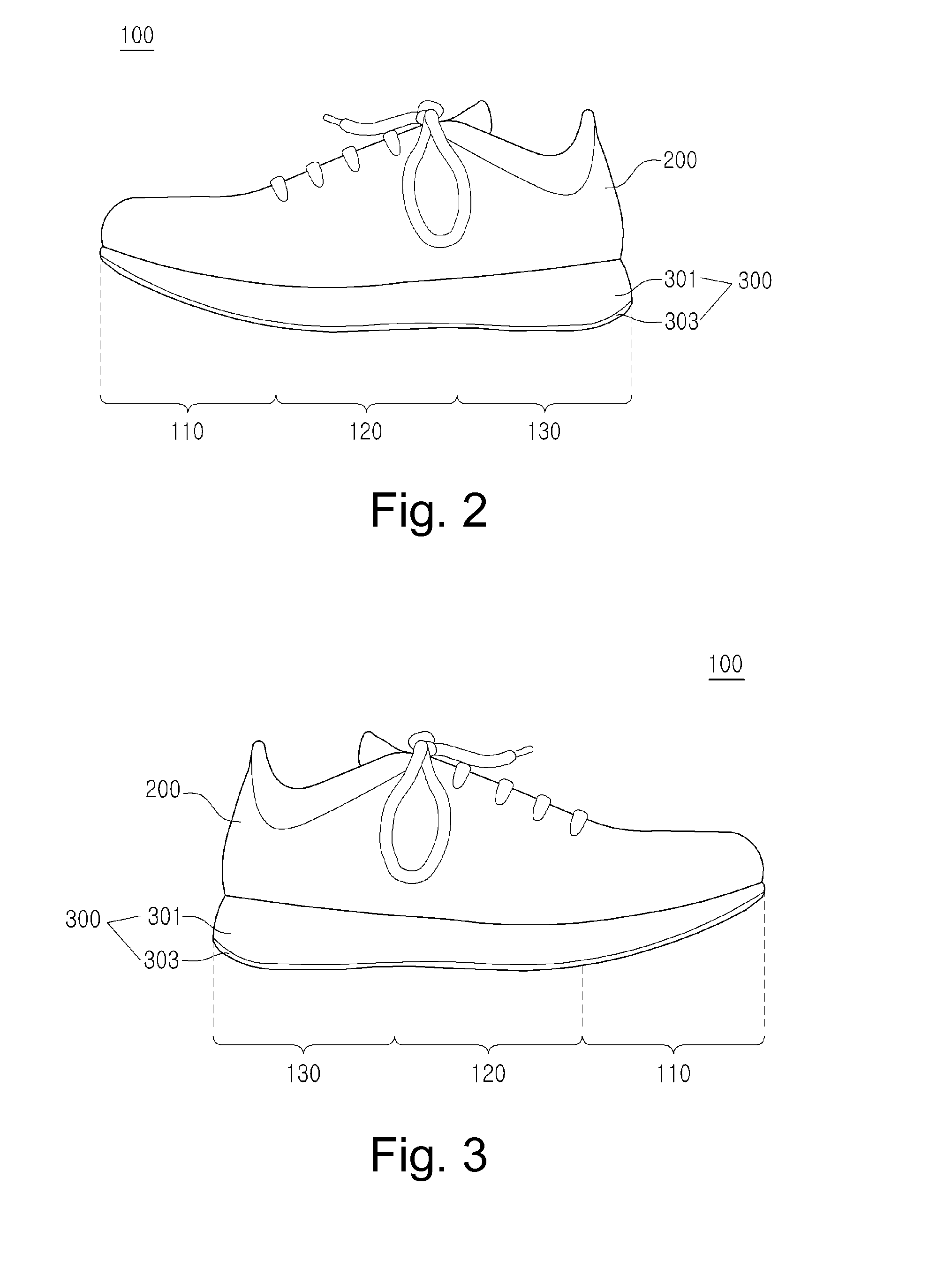

Non-sewing material for a footwear upper, footwear upper and footwear using the same

InactiveUS20150289592A1Avoid lostImprove processing efficiencyDomestic footwearUpperManufacturing efficiencyEngineering

A material for a footwear upper, includes a first side corresponding to an inner foot top and an inner side of a foot, a second side corresponding to an outer foot top and an outer side of the foot and extending outwards from an end of the first side to face the first side, a first wing portion extending outwards from the first side in a wing shape, and a second wing portion extending outwards from the second side in the wing shape. The first side and the second side, the first side and the first wing portion, and the second side and the second wing portion are integrated with each other, respectively so that a loss of the material may be reduced and manufacturing efficiency may be improved.

Owner:SONG SOO BOK

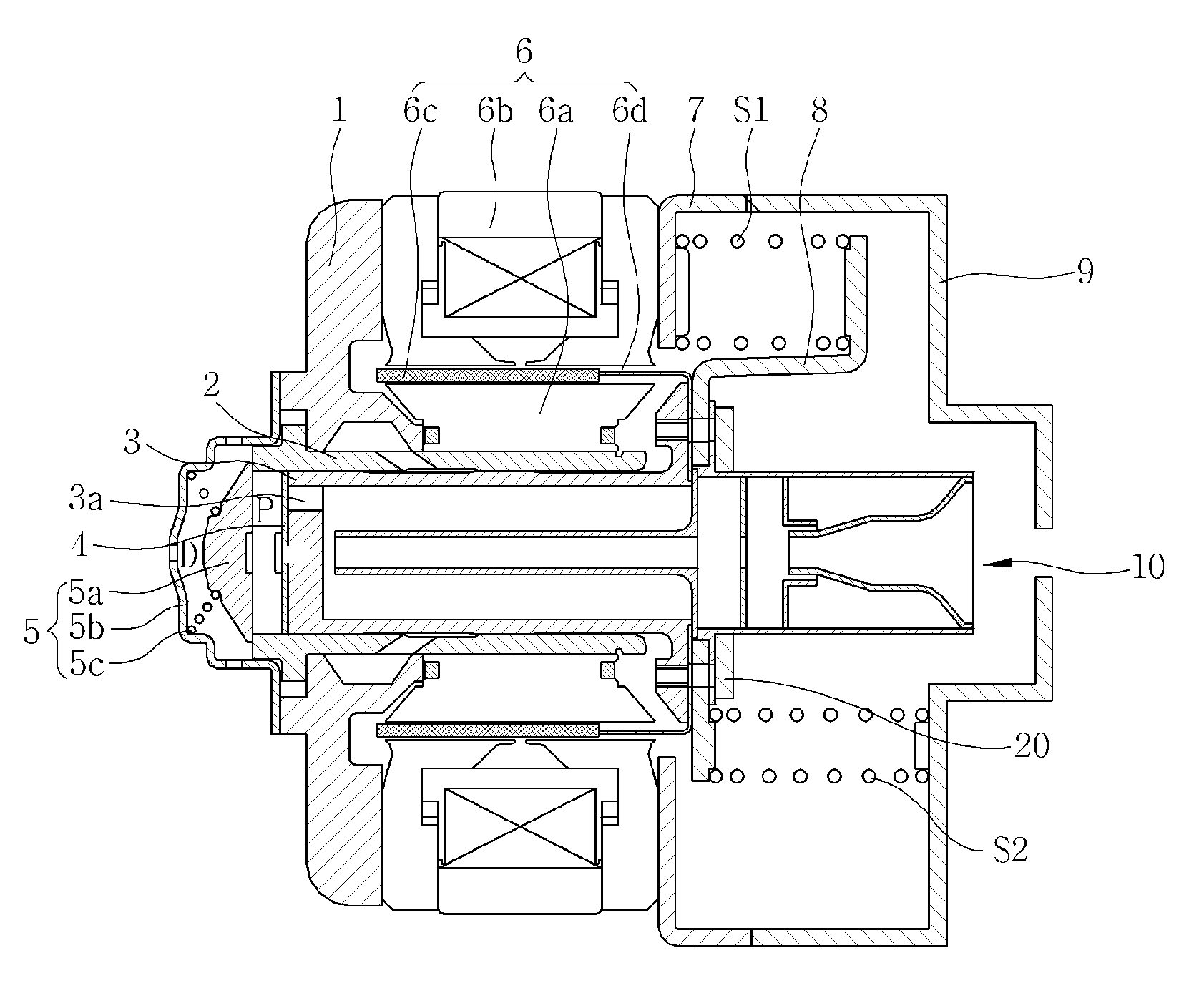

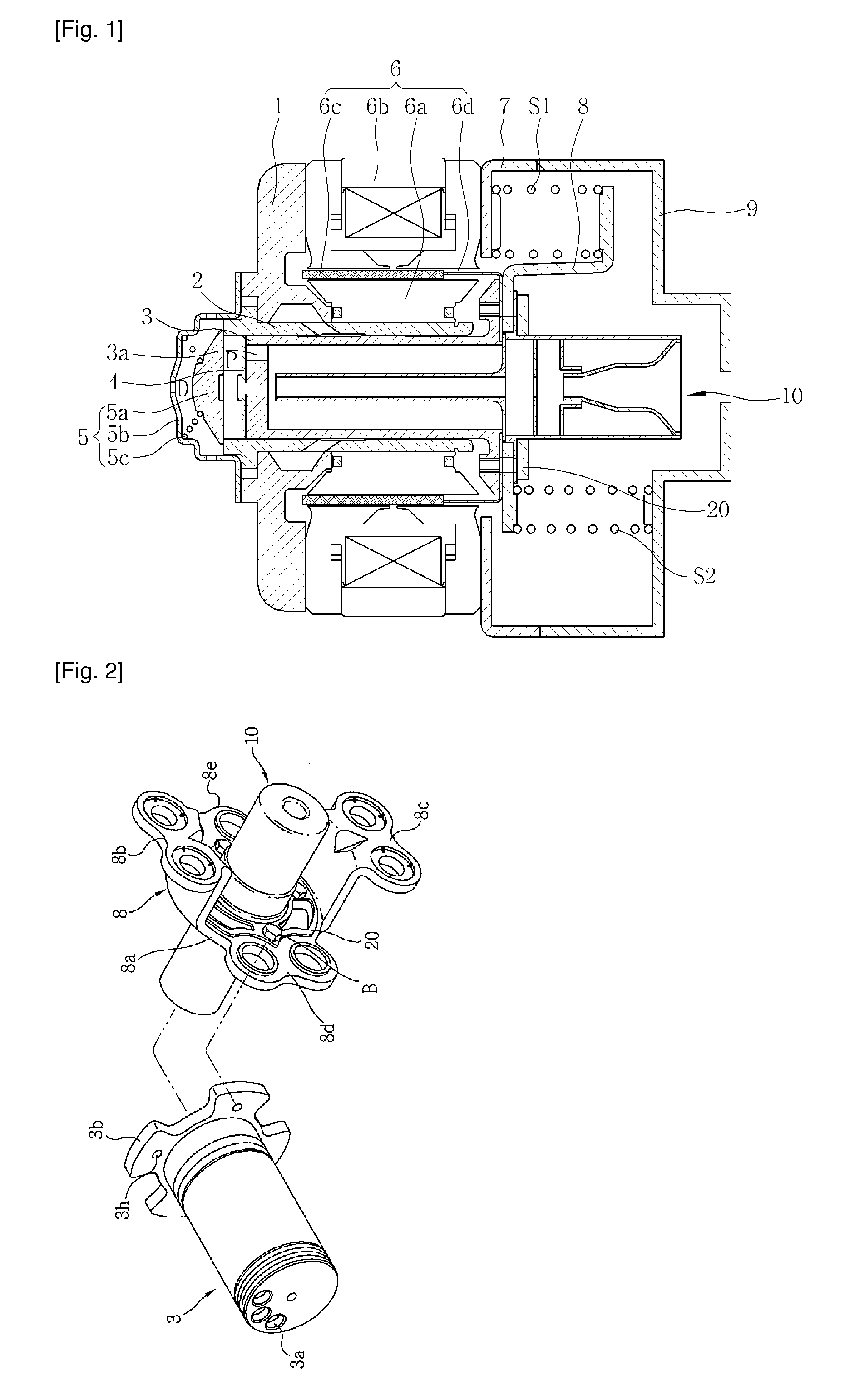

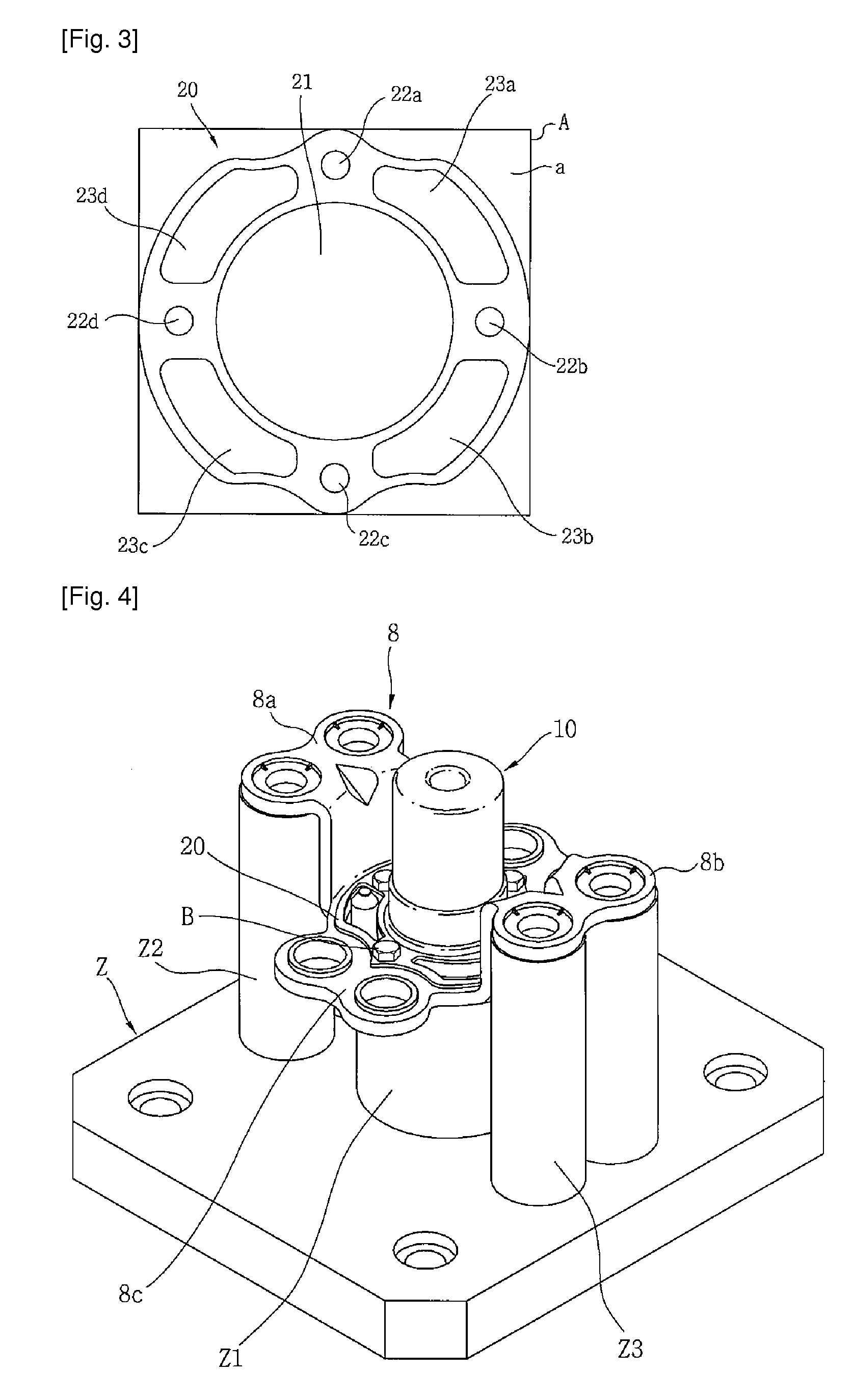

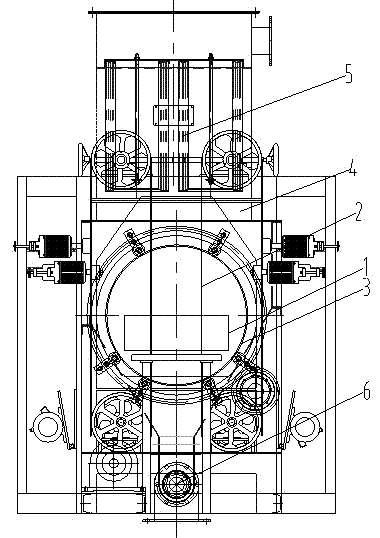

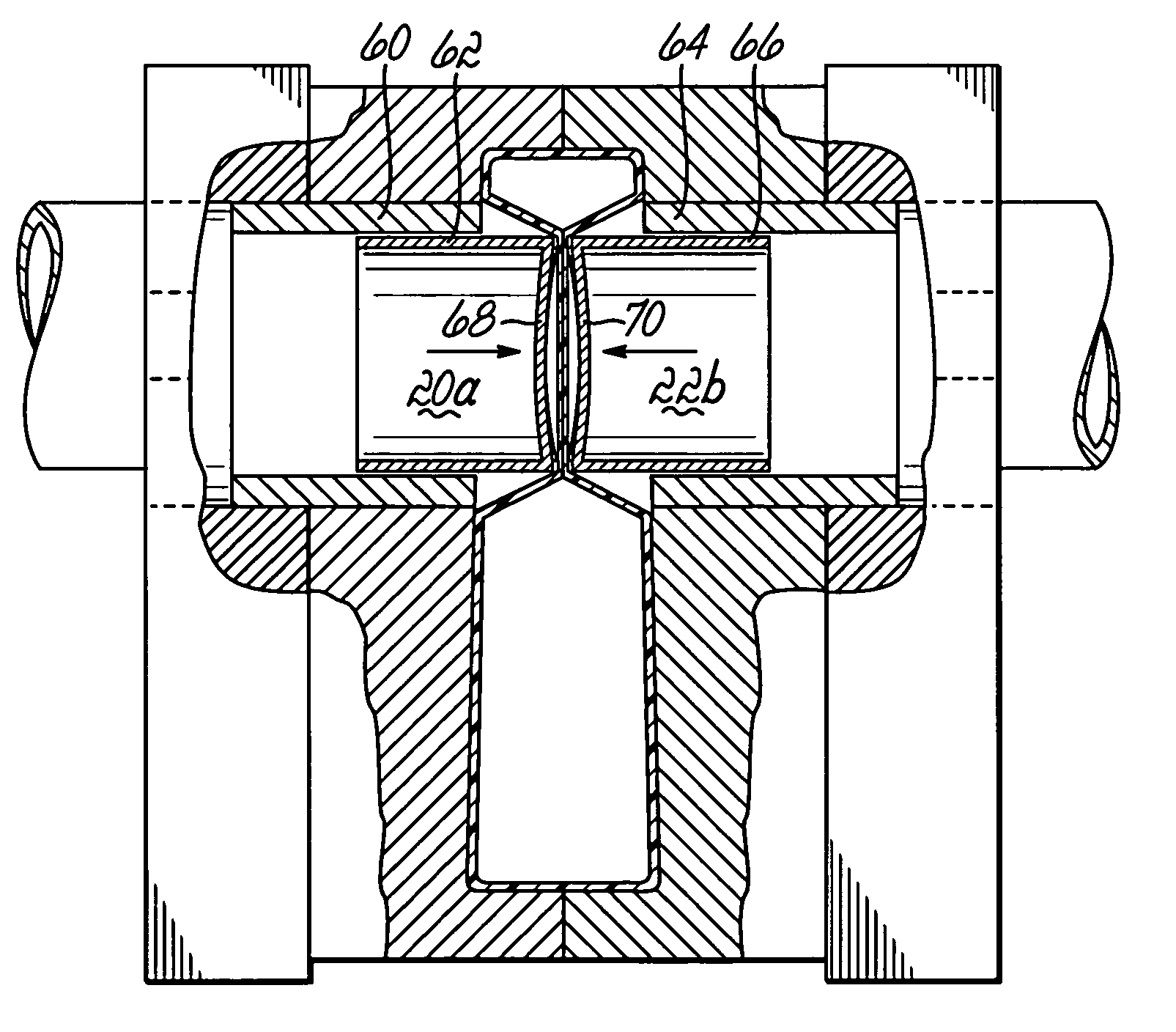

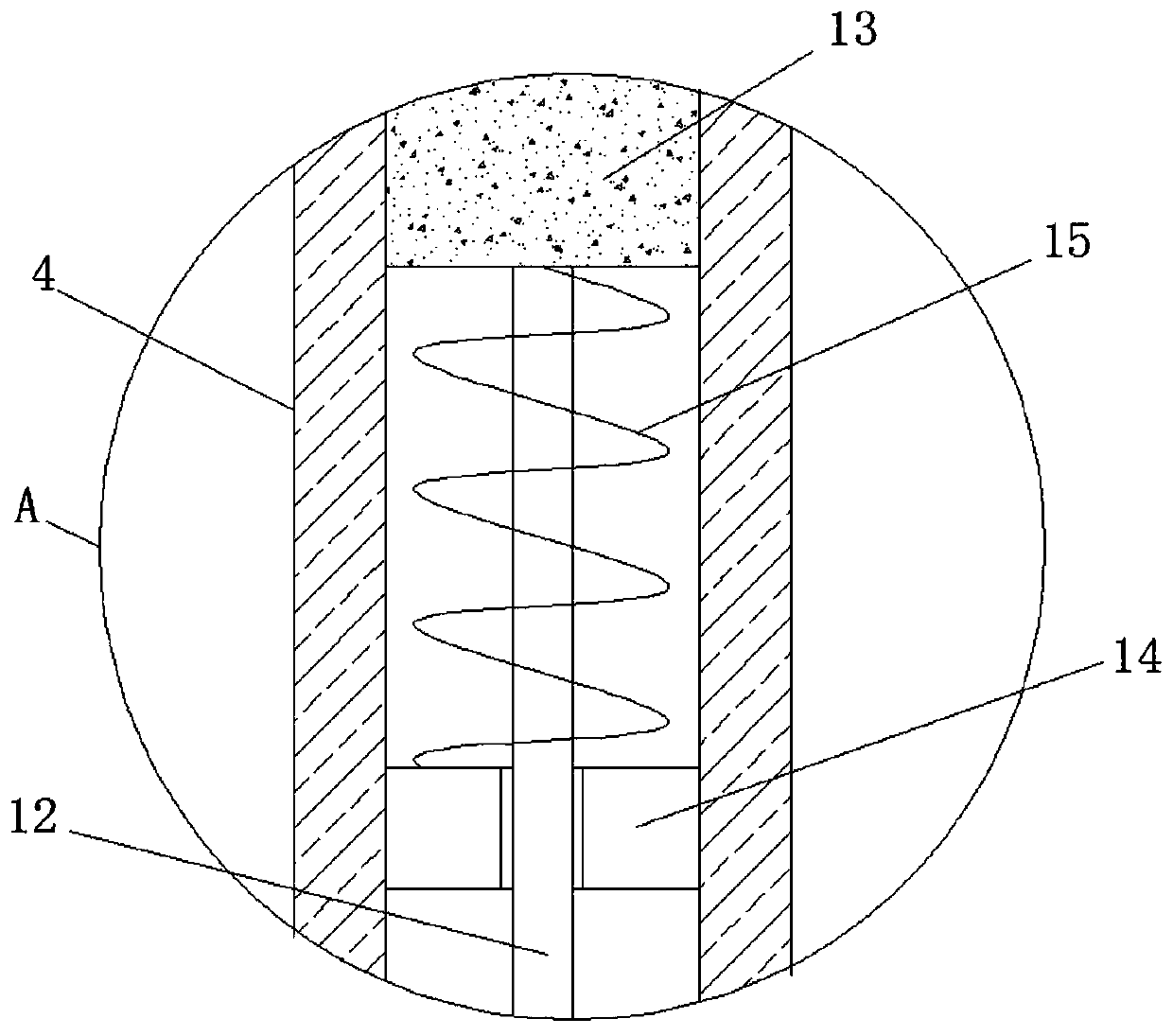

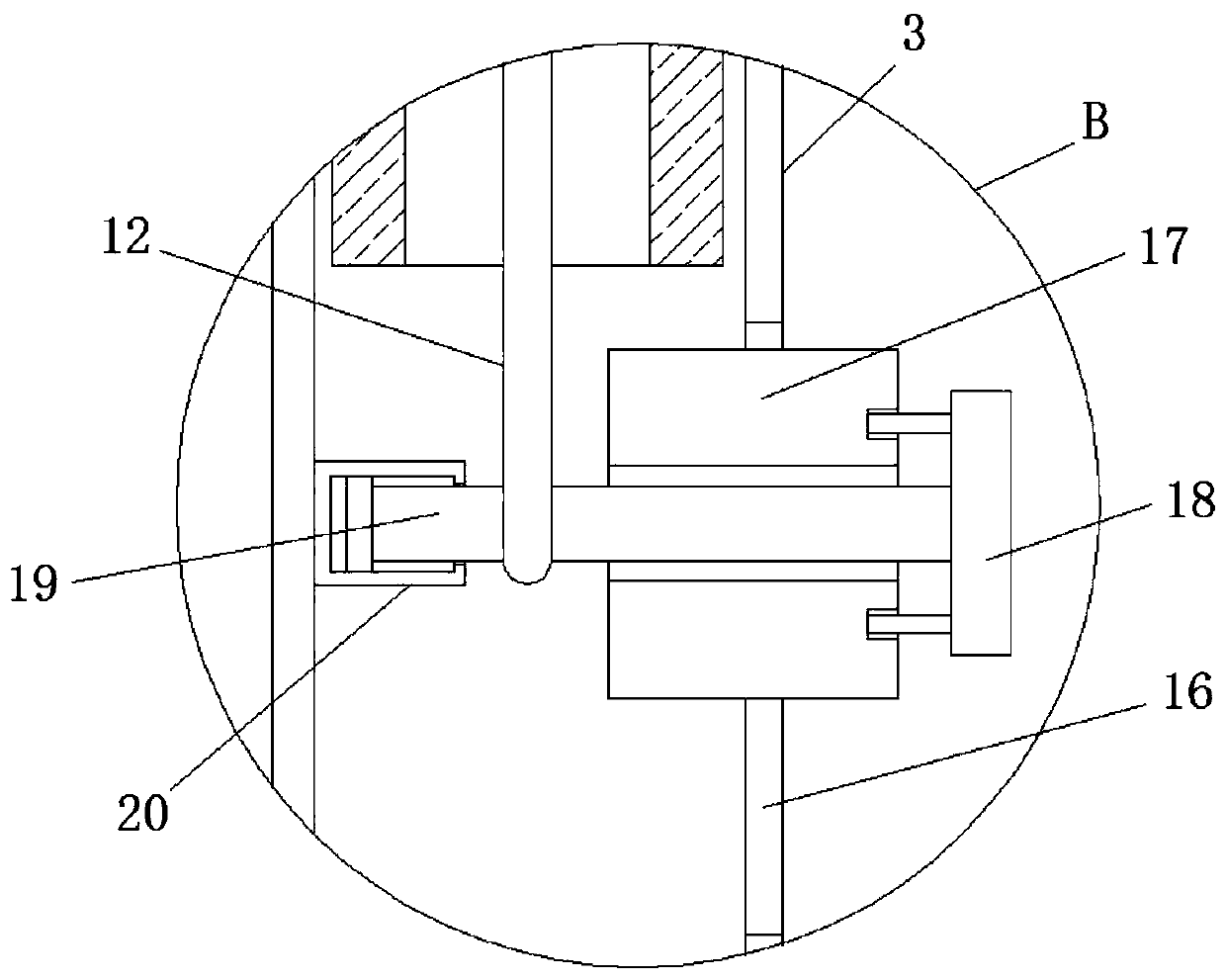

Linear compressor

ActiveUS20100316513A1Sufficient massSecuring operating reliabilityPositive displacement pump componentsPiston pumpsLinear compressorReciprocating motion

A linear compressor comprises: a fixed member including a cylinder for providing a refrigerant compression space; a movable member, which includes a piston for compressing refrigerant inside the cylinder and a supporter composed of a center portion being aligned with a center of the piston and a support portion extended radially of the piston and which makes a linear reciprocating movement about the fixed member; a plurality of mainsprings supported on the support portion of the supporter, for elastically supporting the piston in an axial direction; and a mass member, which includes a center portion to couple with the center portion of the supporter and a plurality of ends extended from the center portion to maintain an air-gap towards the support portion of the supporter and towards the mainsprings. The linear compressor of the present invention can accommodate a maximum mass member in a defined space of a linearly reciprocating movable member, so material loss is prevented and more installation space can be secured.

Owner:LG ELECTRONICS INC

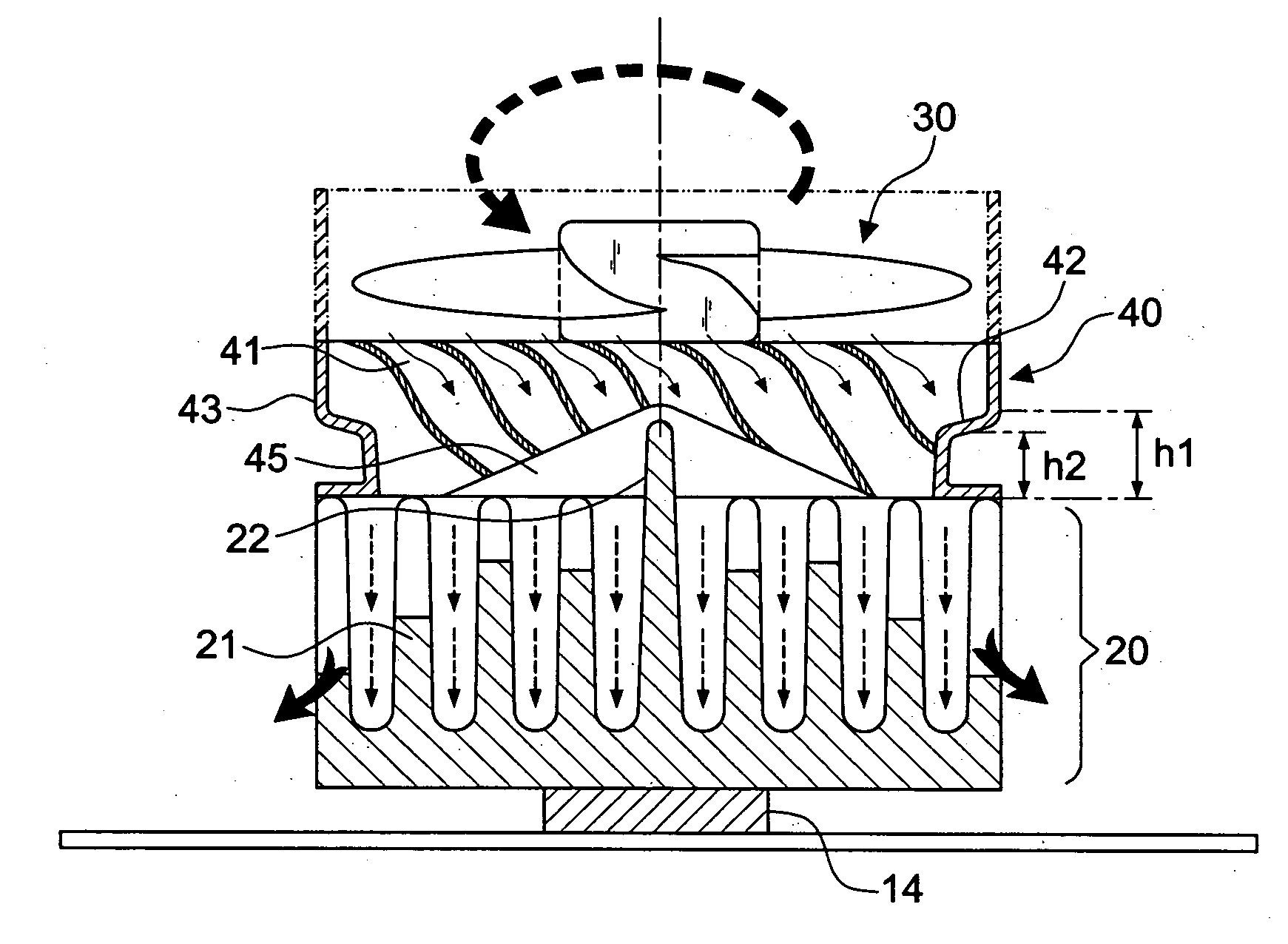

Turbo-guiding type cooling apparatus

InactiveUS20090101315A1Process stabilityImprove heat removal efficiencyPump componentsDigital data processing detailsExit surfaceHeat spreader

A turbo-guiding type cooling apparatus includes a reverse fixed blade unit interposed between the wind exit surface of the fan and the heat sink. The rotation direction of the reverse fixed blade unit is opposite to that of the fan. A receiving chamber is formed under the shaft of the reverse fixed blade unit, and the receiving chamber has at least one-third height of the reverse fixed blade unit. A separation portion extending into the receiving chamber is formed at the center of the top of at least one part of the heat sink. The reverse fixed blade unit includes a reduction cover inward tapered at the periphery of the wind outlet thereof. The height (h1) of the periphery of the reduction cover is the same to or greater than the height (h2) of the periphery of the wind outlet of the reverse fixed blade unit, thereby forming a ring-shaped enclosing type. Therefore, the wind will be smoothly concentrated and the flow direction will be changed. Meanwhile, each of the airflows will be separated by the separation portion and delivered to the heat source of the heat sink.

Owner:CHENG LIANG HO

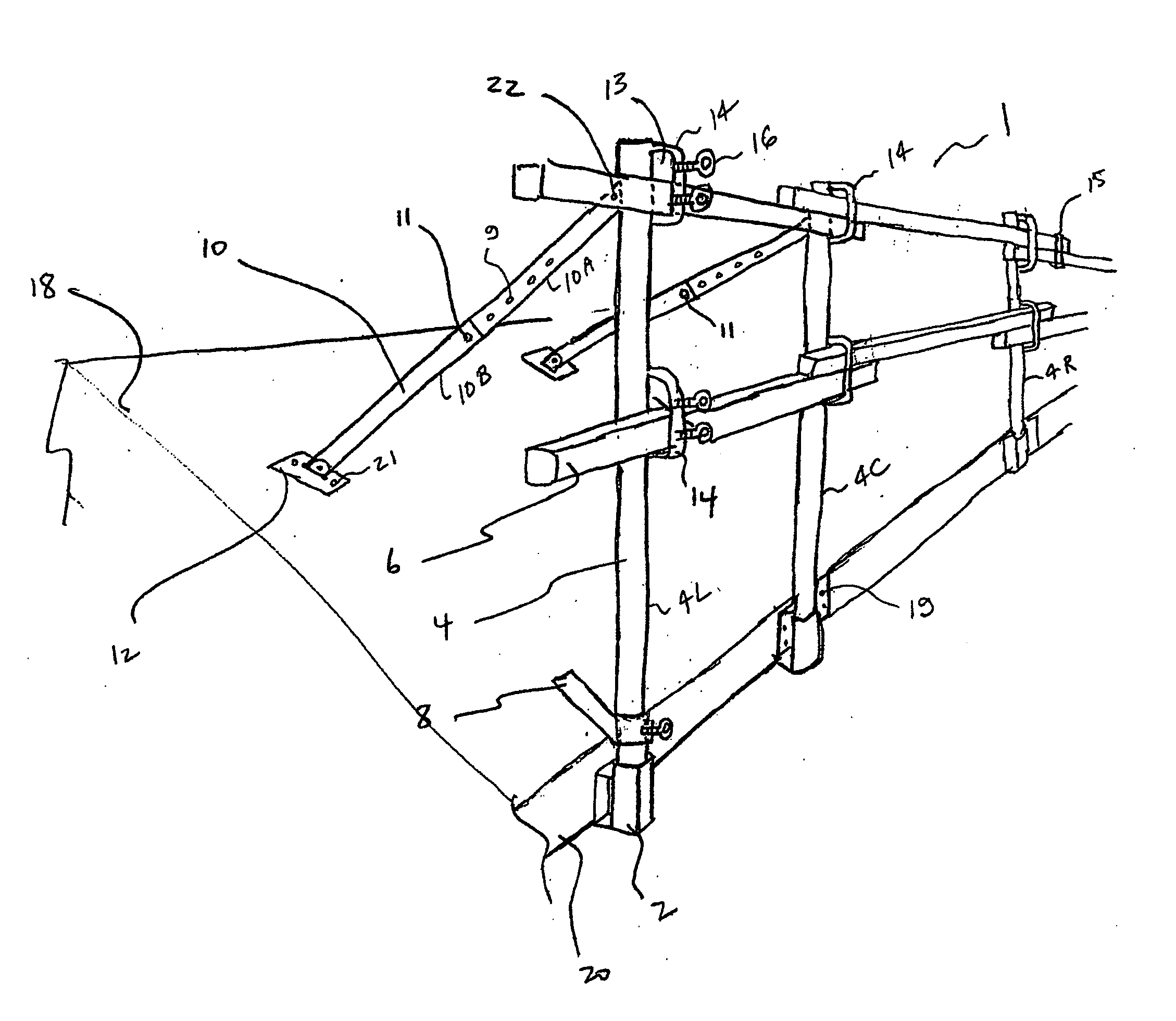

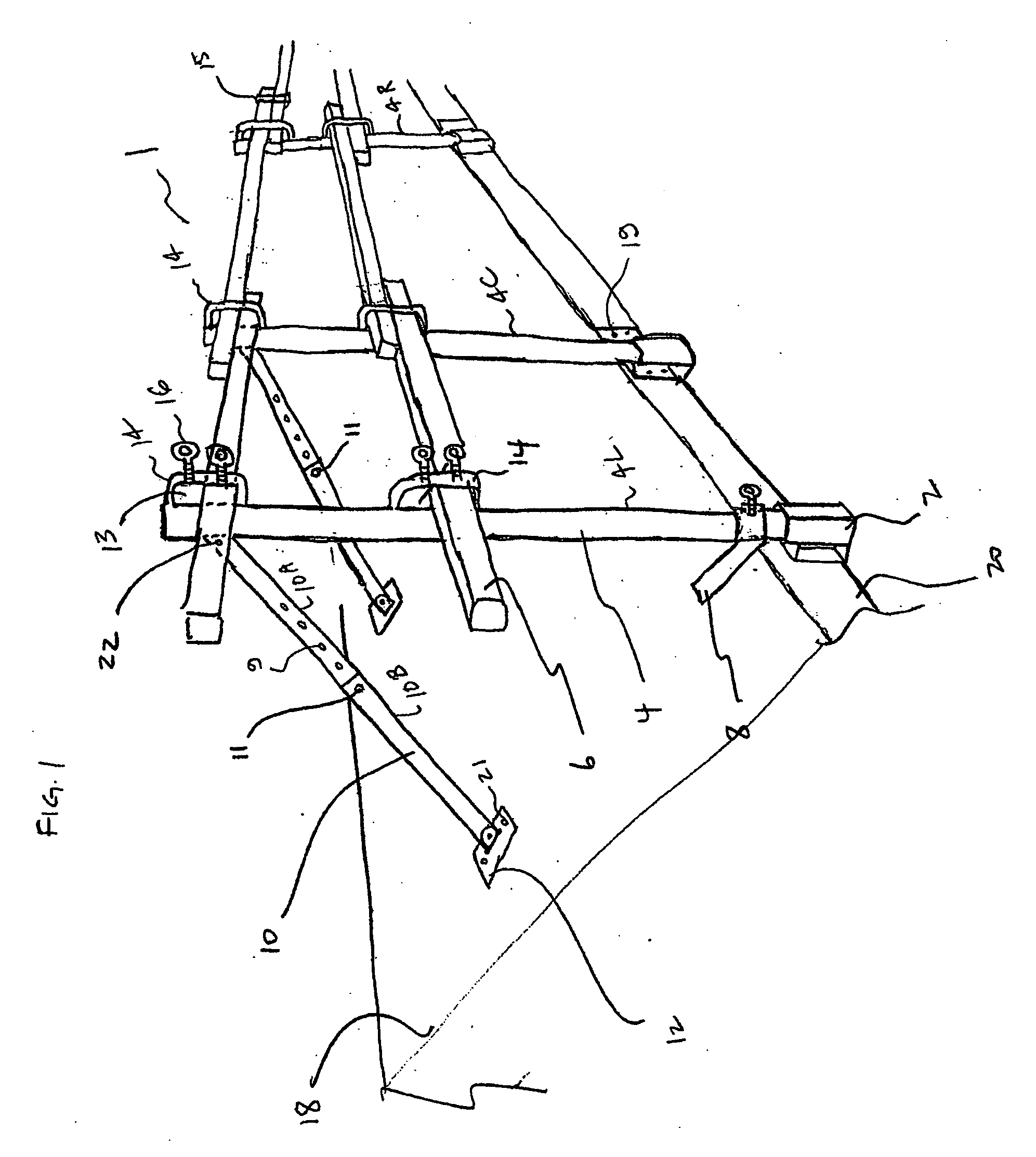

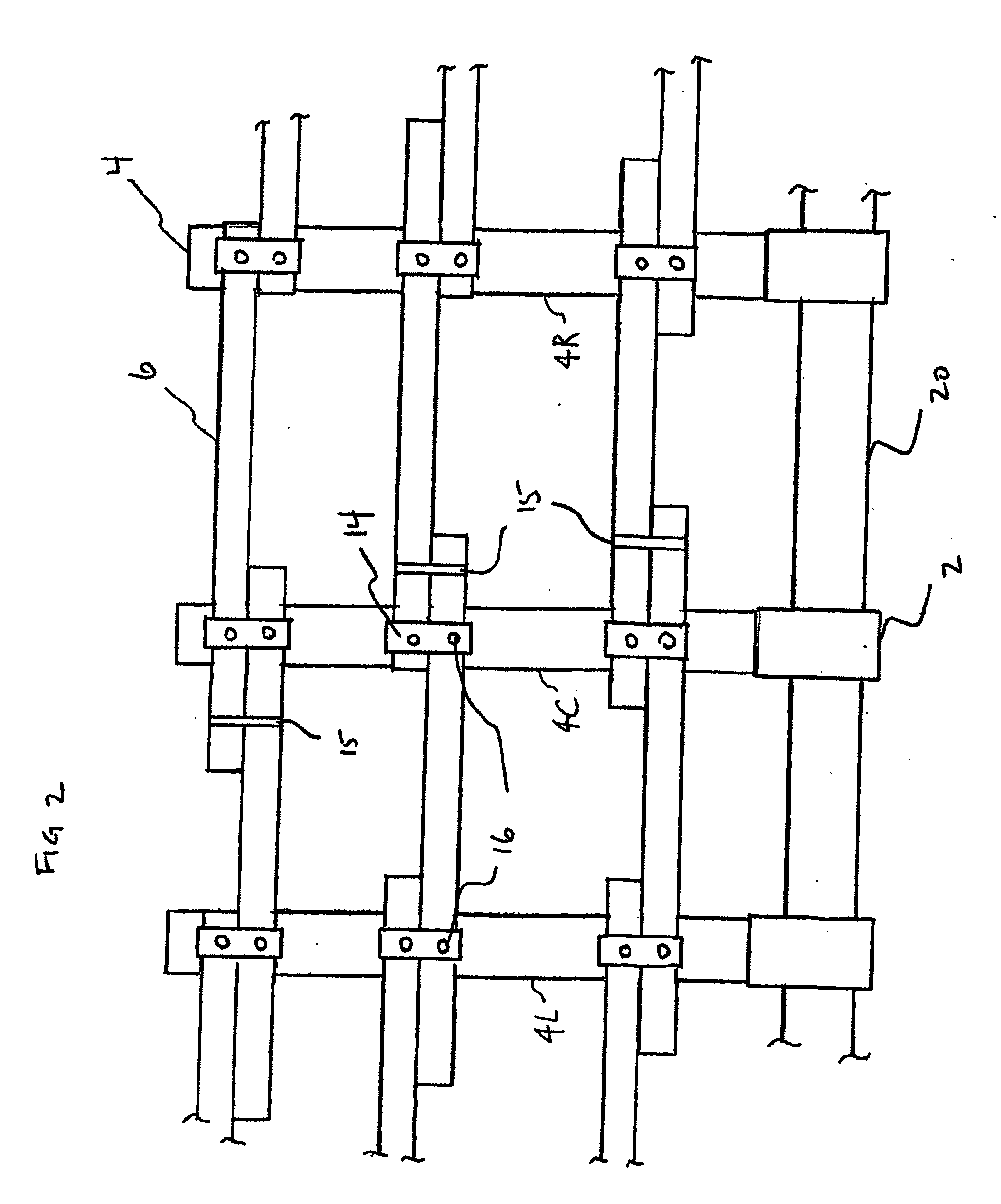

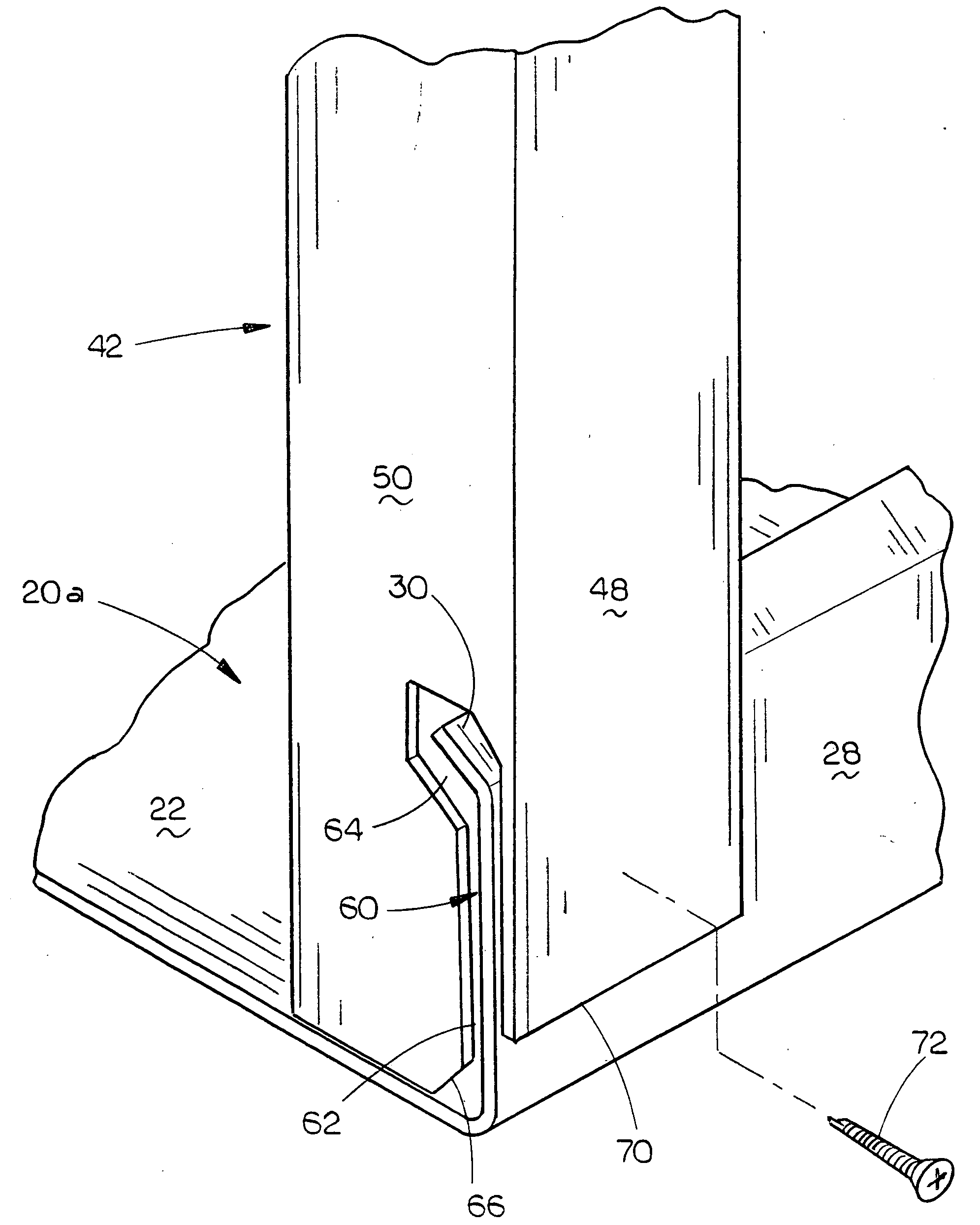

System for construction of a compression structure with corner blocks, key blocks, and corner block supports

A structure assembled from a combination of stackable modules, each module assembled from multiple prefabricated, transportable blocks. The blocks are typically reinforced cast concrete formed in reusable molds. Module framing blocks may include arched corner blocks, key blocks that interlock with a pair of corner blocks, and optional center blocks. Other structural elements include roof, floor, and wall components that interlock with the framing modules. Modules may be stacked or nested to form structures including buildings, elevated roadways, and parking garages. Utilities may be provided through optional conduits formed in the corner elements. The framing supports raised floor modules for ease in mechanical system installation and modification. The roof elements support usable terraces and rainwater collection. The blocks are demountable and reusable. The modules are self-supporting during erection, and may be assembled without fasteners.

Owner:POWELL DAVID W

Foamed type TPU (thermoplastic polyurethane elastomer) material and preparation method thereof

The invention relates to a foamed type TPU (thermoplastic polyurethane elastomer) material and a preparation method thereof. The preparation method comprises the following steps: polymer polyol, diisocyanate and a chain extender are taken and poured into a casting machine to be mixed uniformly, then a mixture I is added to a first reactive extrusion machine for a polymerization reaction, and a TPU polymer melt is obtained; a physical foaming agent is injected into the tail end of a screw of the first reactive extrusion machine, the TPU polymer melt is mixed preliminarily with the physical foaming agent, and a mixture II is obtained; the mixture II is added to a second reactive extrusion machine, and the physical foaming agent and the TPU polymer melt are mixed uniformly to form a homogeneous system; the homogeneous system passes through a neck ring mold of the second reactive extrusion machine and then is subjected to underwater palletizing, and foamed thermoplastic polyurethane particles are obtained; the foamed thermoplastic polyurethane particles are dehydrated and dried, and the foamed type TPU material is obtained. The foamed type TPU material has stable foaming density, the batch-to-batch product quality is stable, central control monitoring is performed at any time, and the yield is increased.

Owner:MIRACLL CHEM

Modular safety railing system

InactiveUS20060054393A1Avoid wasteEasily erectWindow cleanersBuilding material handlingModularityEngineering

A modular safety railing system comprises post brackets adapted for attachment to a building structure. Posts are adapted to engage the post brackets the posts are oriented substantially vertically. Upper and lower rail mounts are located on each post and right and left upper and lower rails are releasably attachable at inner portions thereof to corresponding upper and lower rail mounts of a center post and are releasably attachable at outer portions thereof to upper and lower rail mounts of corresponding right and left posts. An upper brace is attached at an upper end thereof to the post and adapted at a lower end thereof for releasable attachment to the building structure. The upper brace is adjustable such that same can be attached to the building structure at an angle to the center post that is sufficient to support the center post in the substantially vertical orientation.

Owner:EISENKREIN LARRY

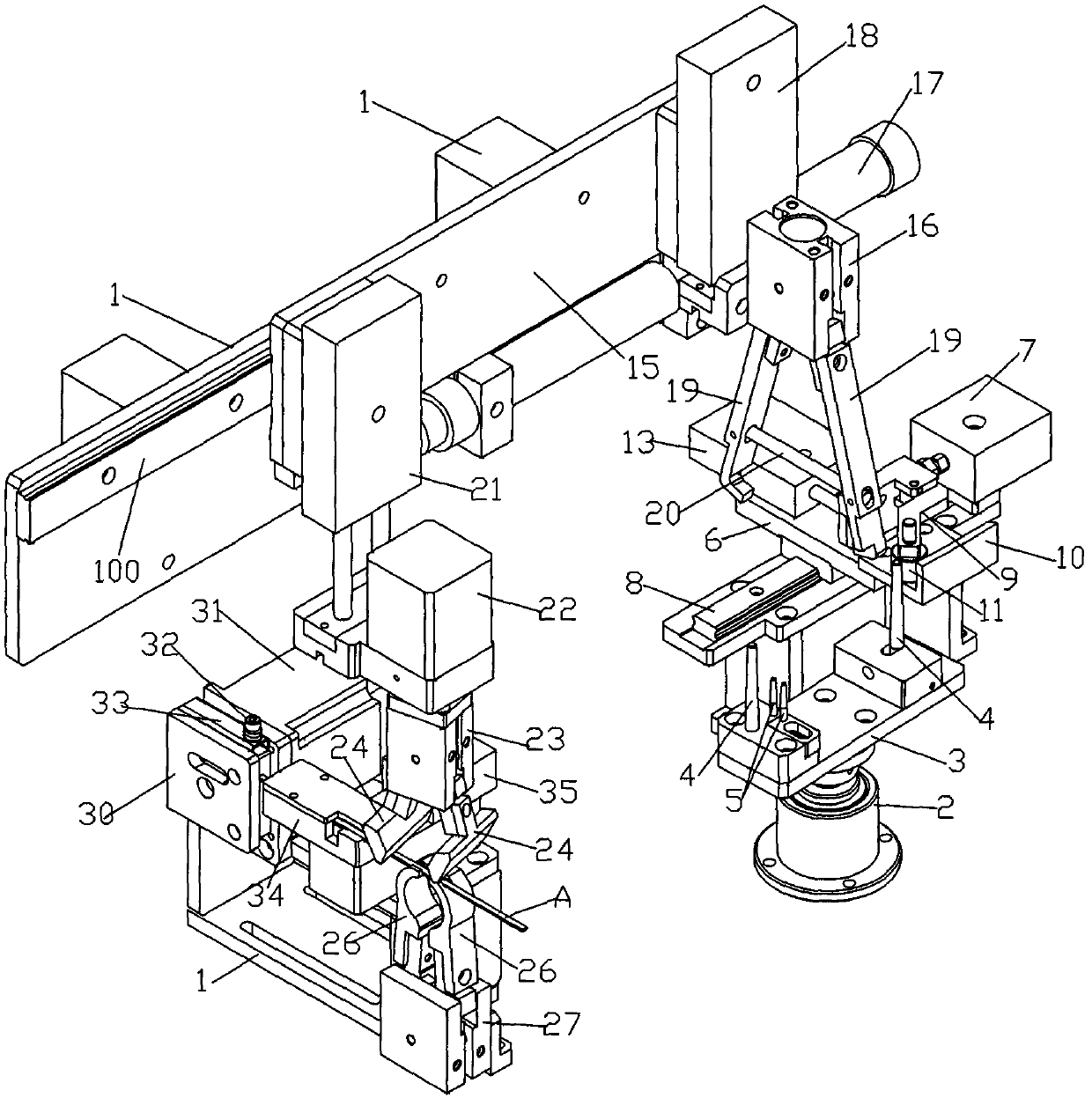

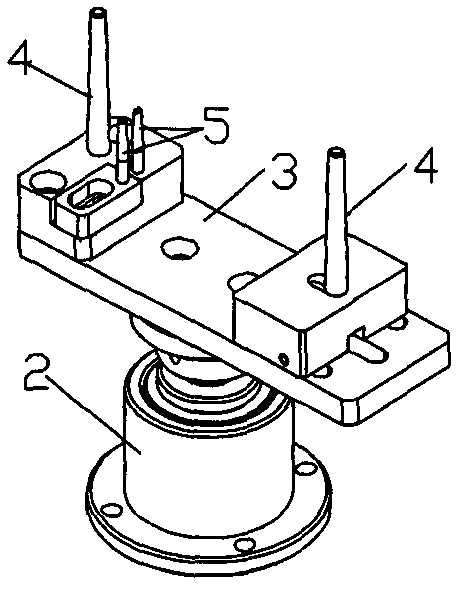

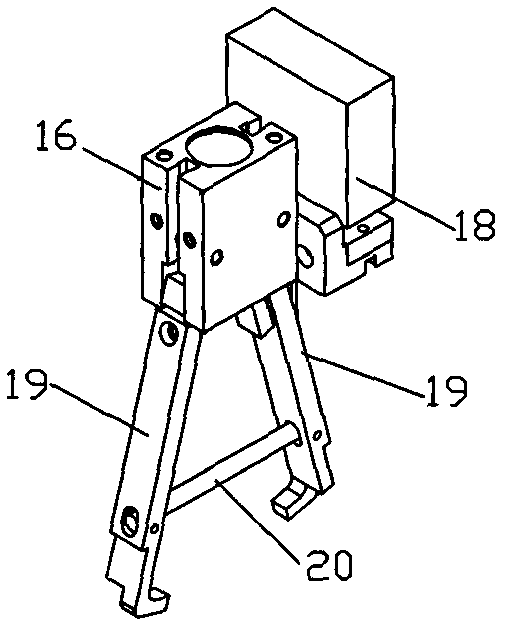

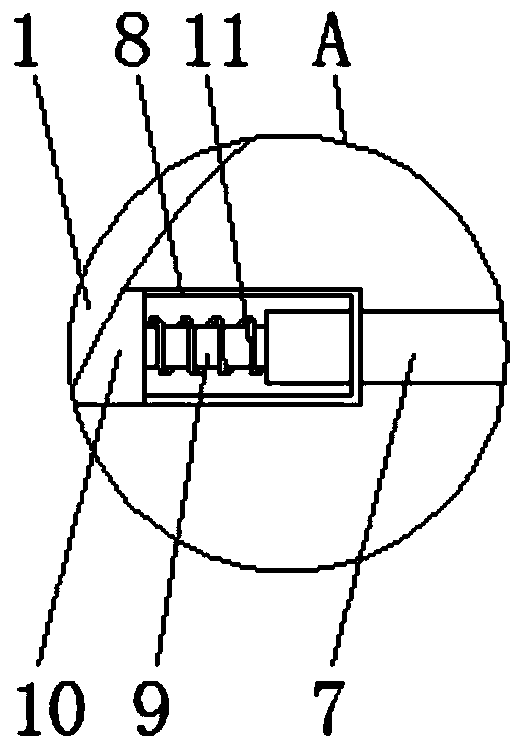

Automatic winding and bundling device for connecting wires

InactiveCN102602555AImprove binding efficiencyAvoid artificialBinding material applicationBundling machine detailsEngineeringConductor Coil

The invention belongs to the technical field which is suitable for winding and bundling connecting wires or guide wires, and discloses an automatic winding and bundling device for connecting wires, which comprises a rack provided with a guide groove, wherein the rack is provided with a winding device, a winding conveying device, a bundling device, a twisting and bundling device, a device for feeding cable ties and cutting cable ties, and a circuit and gas circuit control device for controlling the above devices to operate coordinately, wherein the winding conveying device is connected with the guide groove or a guide rail on the rack through a winding conveying rack; and the winding conveying rack is also connected with the output end of a winding conveying cylinder fixed on the rack. As the connecting wire can be automatically bundled by the bundling device, on one hand, the bundling efficiency of the connecting wire can be improved; on the other hand, the cable ties needs not to be cut to a certain length in advance, thus avoiding the wastes of labors and cable ties caused by cutting in advance.

Owner:刘光辉

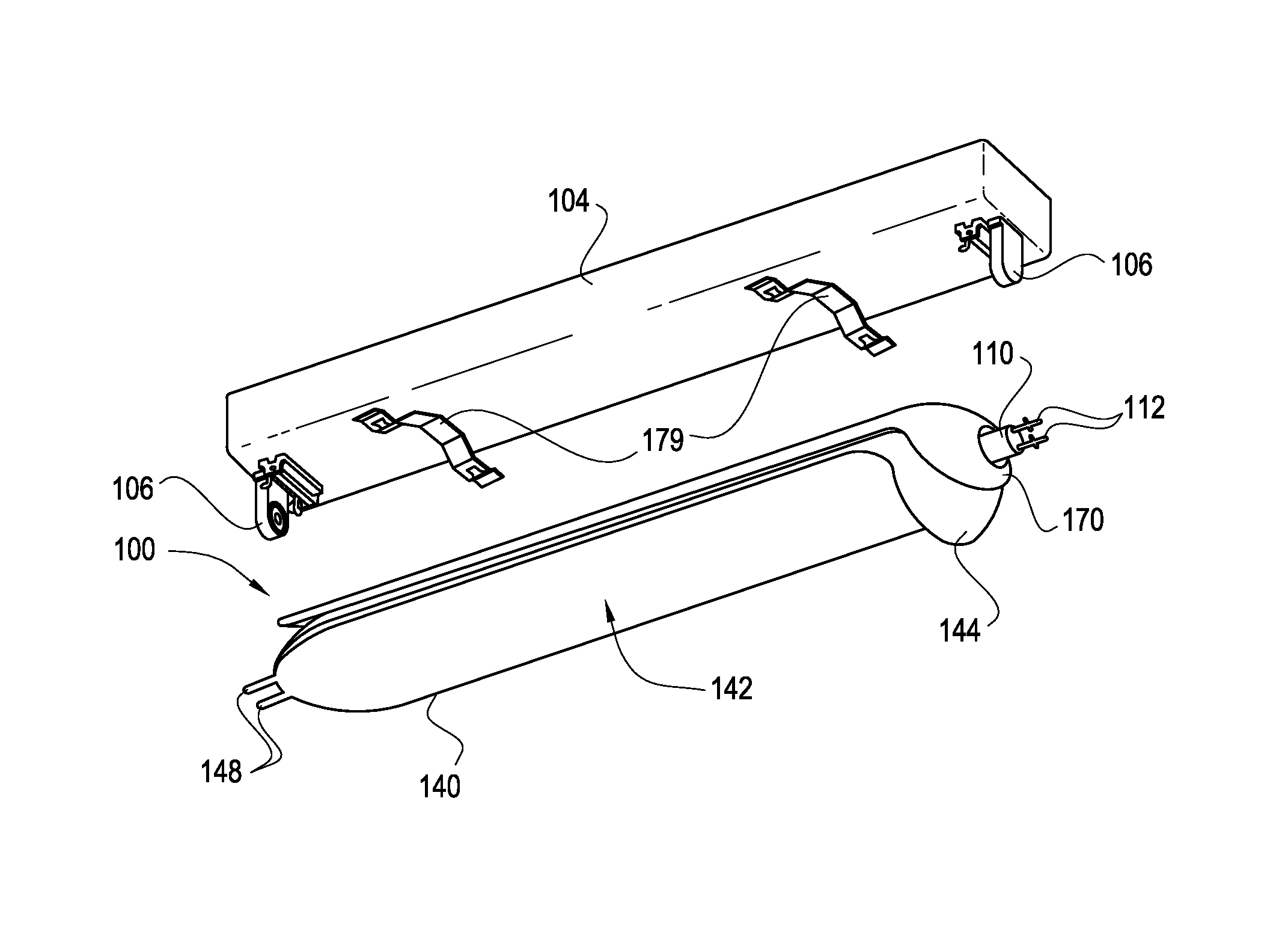

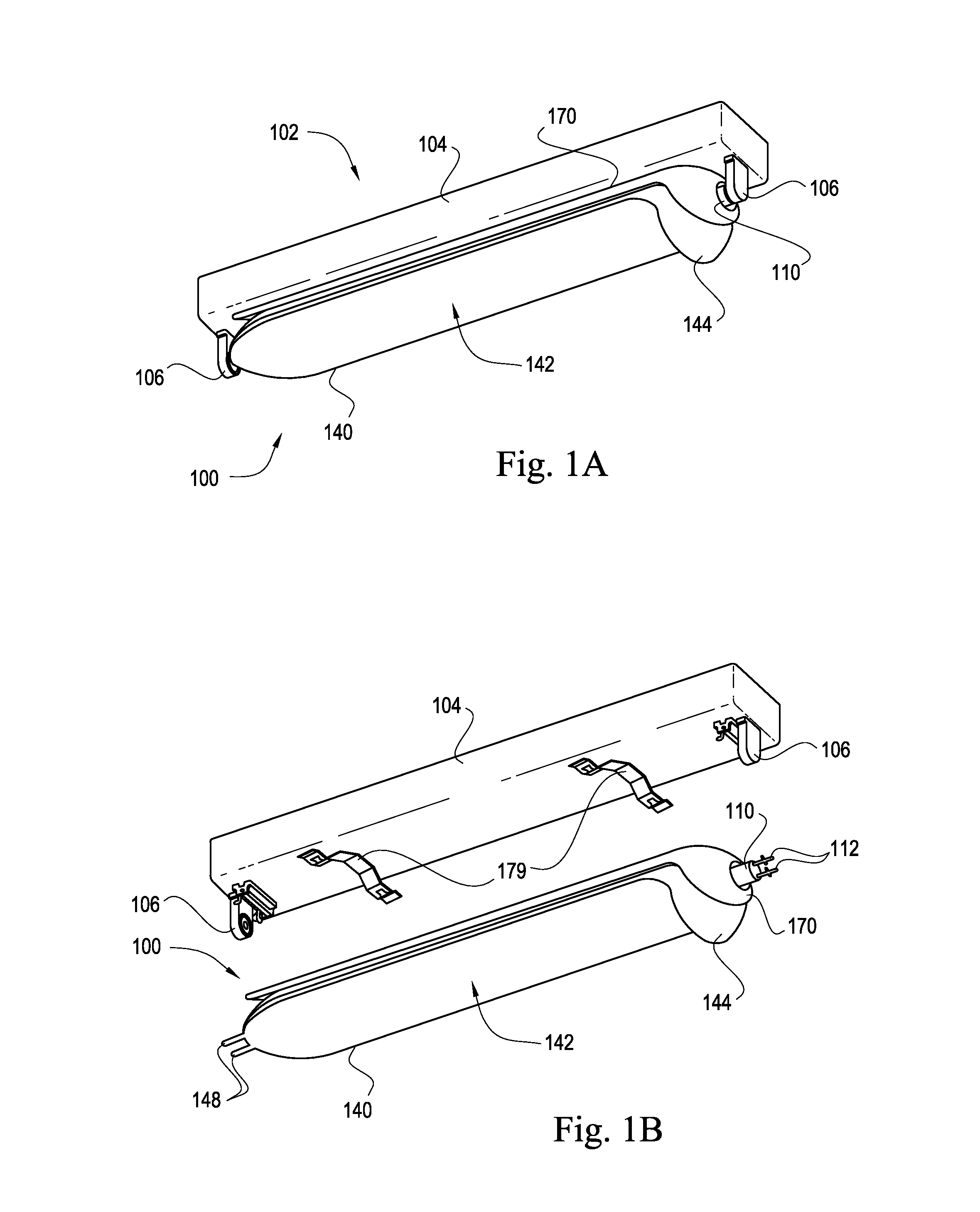

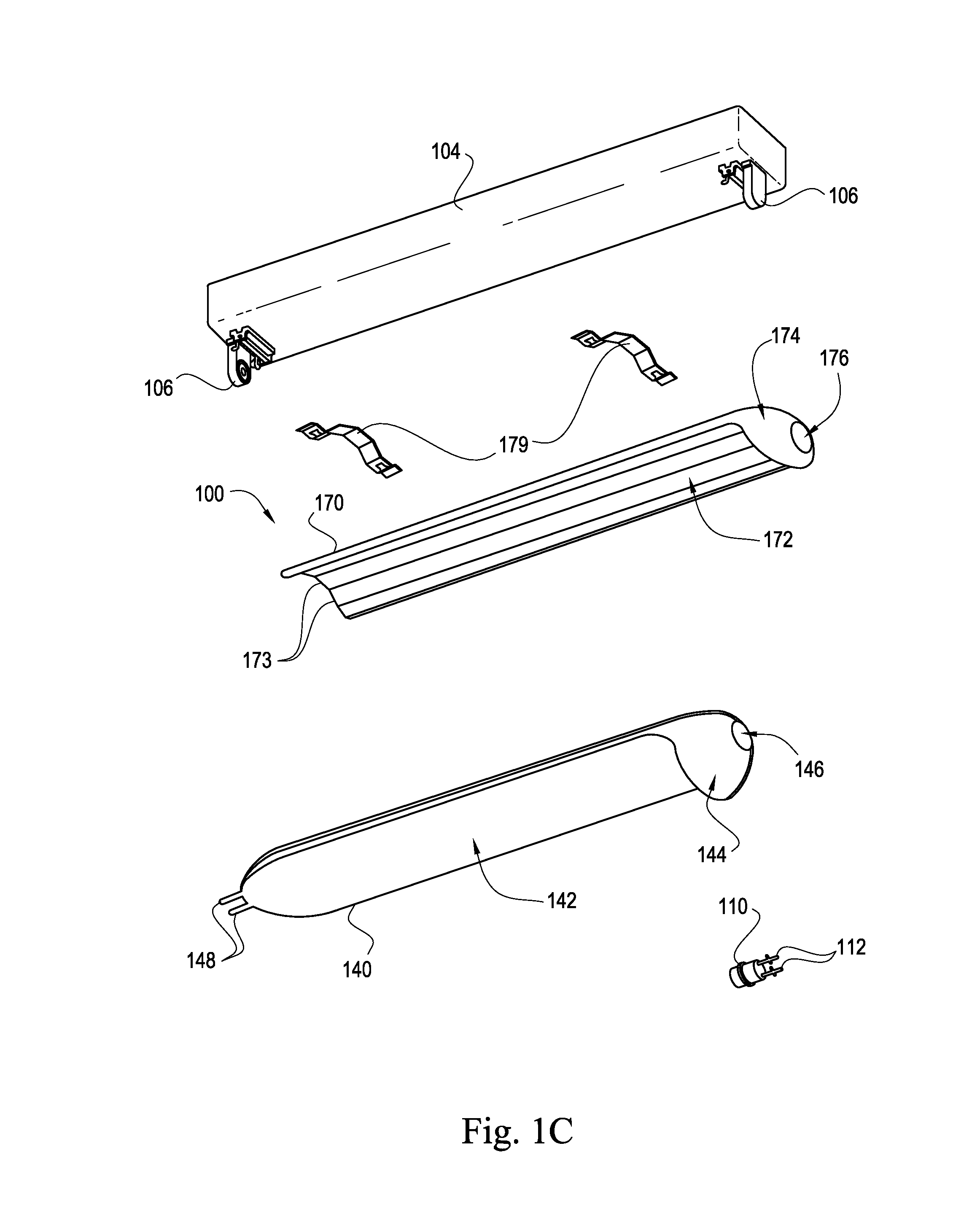

Elongated LED luminaire and associated methods

InactiveUS9127818B2Simple and inexpensive retrofit optionAvoid material wasteMechanical apparatusLighting heating/cooling arrangementsLight guideEngineering

A fluorescent tube retrofit luminaire includes a lamp, a light guide, and a heat dissipating frame. The lamp may include a bi-pin base, middle structure, and outer structure, which may include a light-emitting diode (LED)-based light source in thermal communication with a finned heat sink section of the middle structure. Light emitted from the light source may be distributed generally along the length and / or width of the light guide. A bi-pin connector in the light guide may attach the luminaire to a first fluorescent socket. The bi-pin base may be received by a mounting aperture in the light guide before anchoring the luminaire to a second fluorescent socket using a pin-lock. The heat dissipating frame may be in thermal communication with both the light guide and the heat sink section of the lamp.

Owner:LIGHTING SCI GROUP

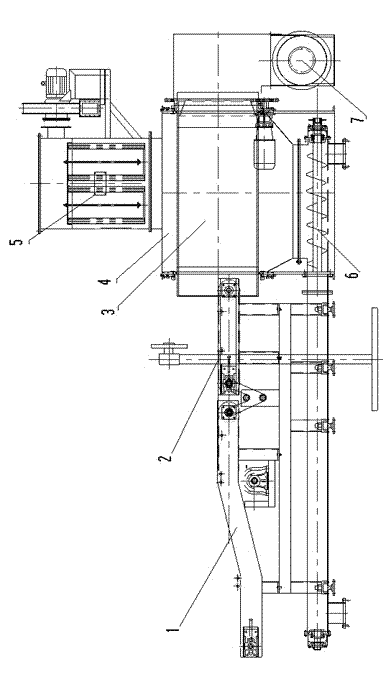

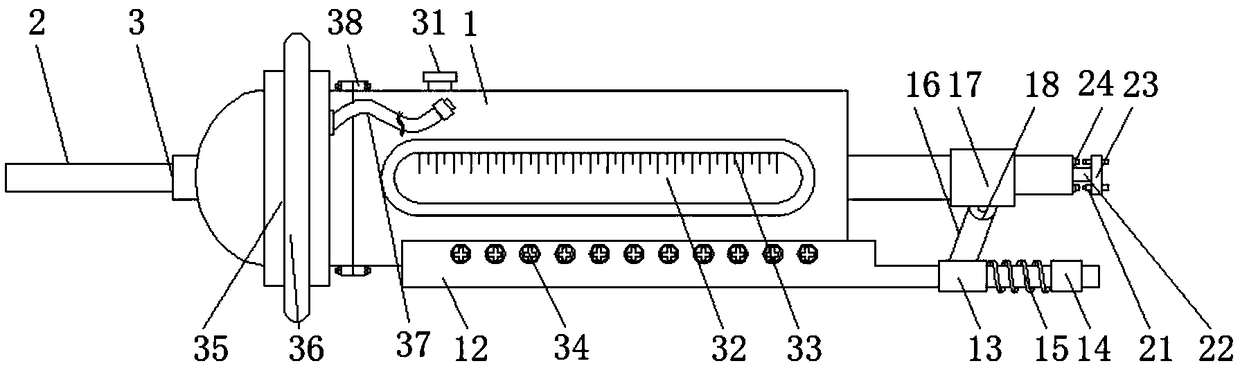

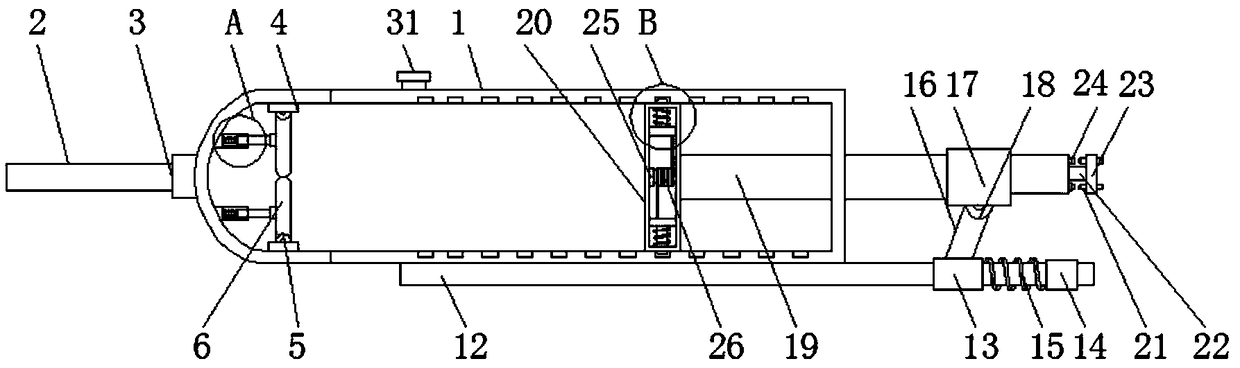

Bag tearing ventilation and dust removing equipment and method

InactiveCN103112630AProtect the environment and workspaceAvoid material wasteDispersed particle filtrationArticle unpackingHazardous substanceUltimate tensile strength

The invention relates to bag tearing ventilation and dust removing equipment and a method. A belt conveyor is arranged on one side of the equipment, a dust remover is arranged at the upper end of a middle support, a rotary screen is arranged at the lower end of the middle support, a spiral conveying device is arranged at the lower end of the rotary screen, a cutting device is arranged on one side of a feed inlet and at the front end of the rotary screen, and a waste bag automatic recycling device is arranged on the rear side of the rotary screen. When material bags are conveyed by the belt conveyor and pass through the cutting device, the material bag are cut, the cut material bags are conveyed to the rotary screen through the belt conveyor after cutting so as to conduct separation of materials and the bags; separated waste bags enter into the waste bag automatic recycling device, the separated materials enter into the spiral conveying device, and generated dust is removed through a ventilation dust remover. No dust is leaked in the process of bag tearing, the waste bags are packaged and recycled automatically, and thus labor intensity of working staff is reduced, dust is removed, waste bags are recycled, environment and working space are effectively protected, and meanwhile damage to the working staff by toxic and harmful substance is avoided.

Owner:山东胜安石油科技有限责任公司

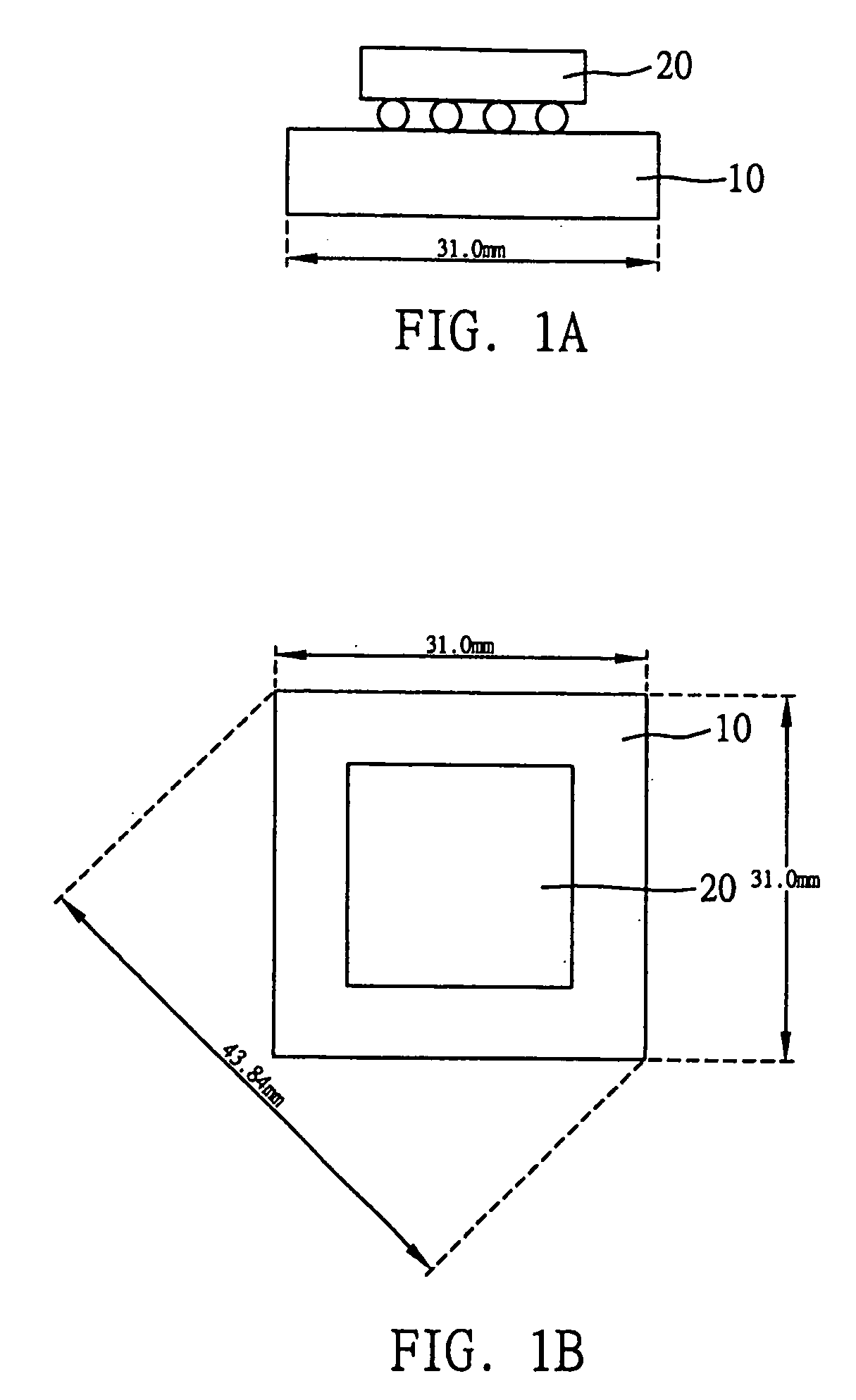

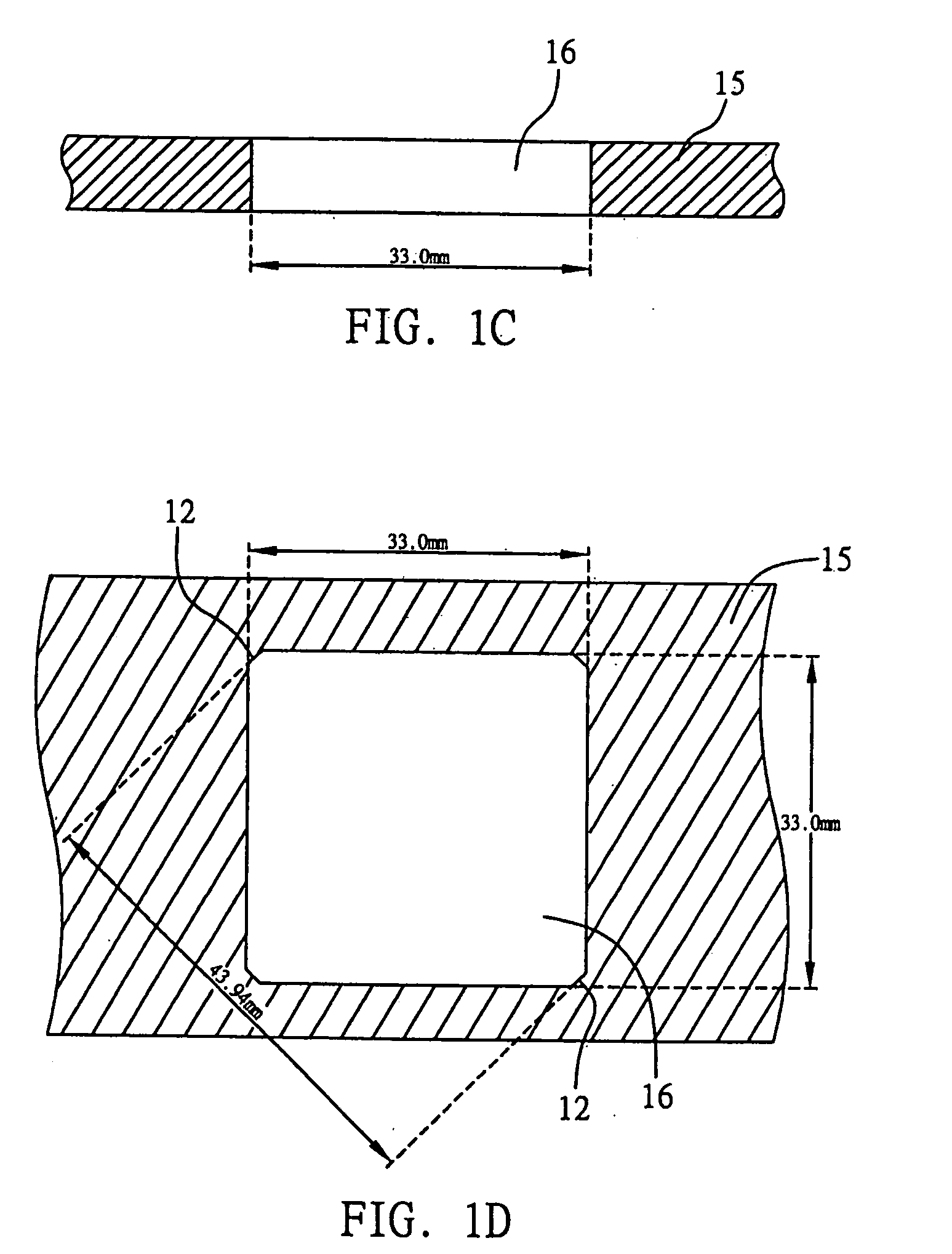

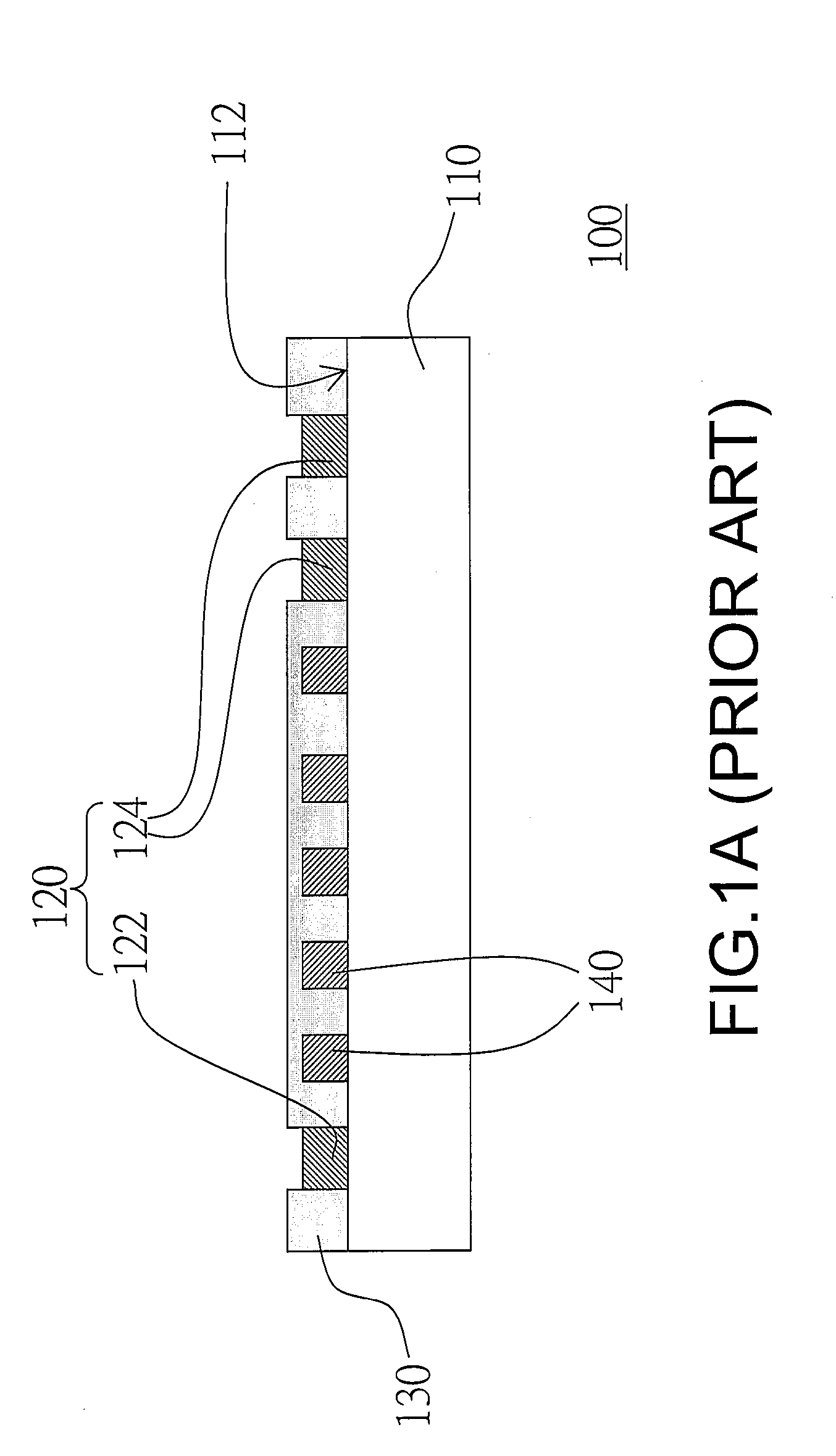

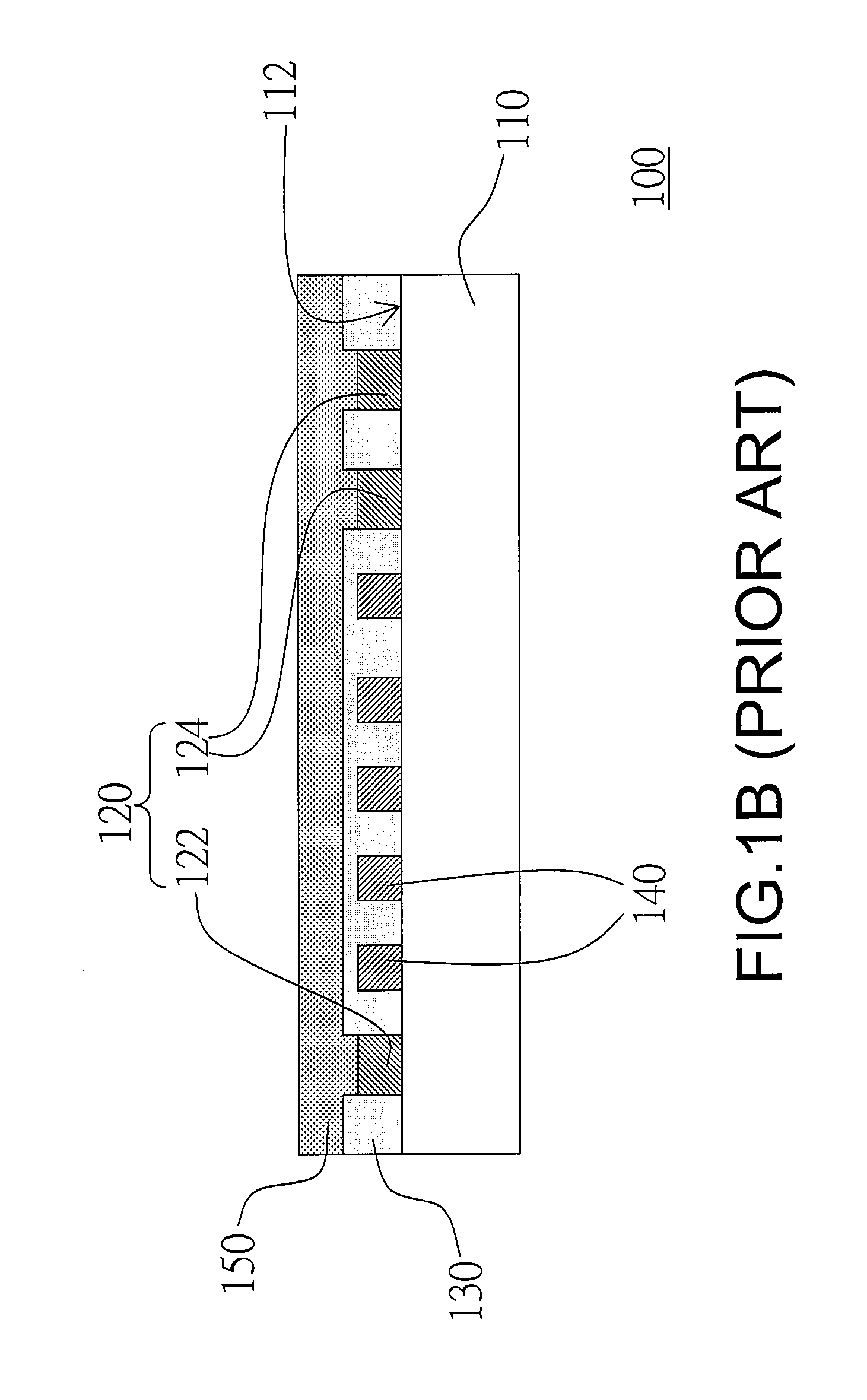

Method for fabricating semiconductor packages

ActiveUS20050287713A1Easy to separatePoor adhesionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageDiagonal

A method for fabricating semiconductor packages is proposed. A plurality of substrates are prepared each having a chip thereon. Length and width of each substrate are equal to predetermined length and width of the semiconductor package. A carrier having a plurality of openings is prepared. A protruded portion is formed at each corner of each opening, wherein a distance between two diagonal protruded portions is slightly larger than that between two diagonal corners of the substrate. The substrates are fixed in the openings of the carrier by means of the protruded portions, and gaps between the substrates and the carrier are sealed. An encapsulant is formed over each opening to encapsulate the corresponding chip by a molding process. An area on the carrier covered by the encapsulant is larger in length and width than the opening. A plurality of the semiconductor packages are formed after performing mold-releasing and singulation processes.

Owner:SILICONWARE PRECISION IND CO LTD

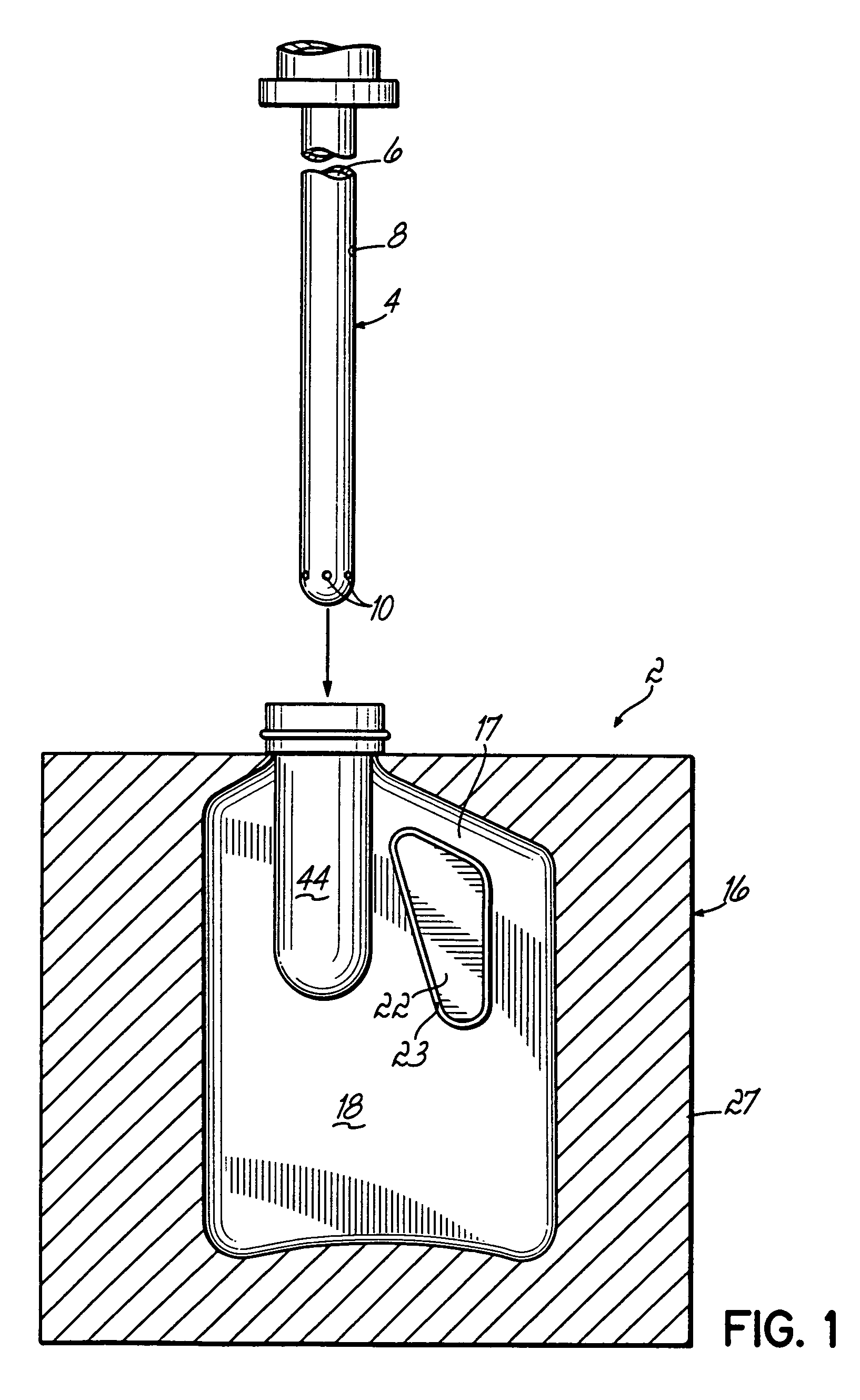

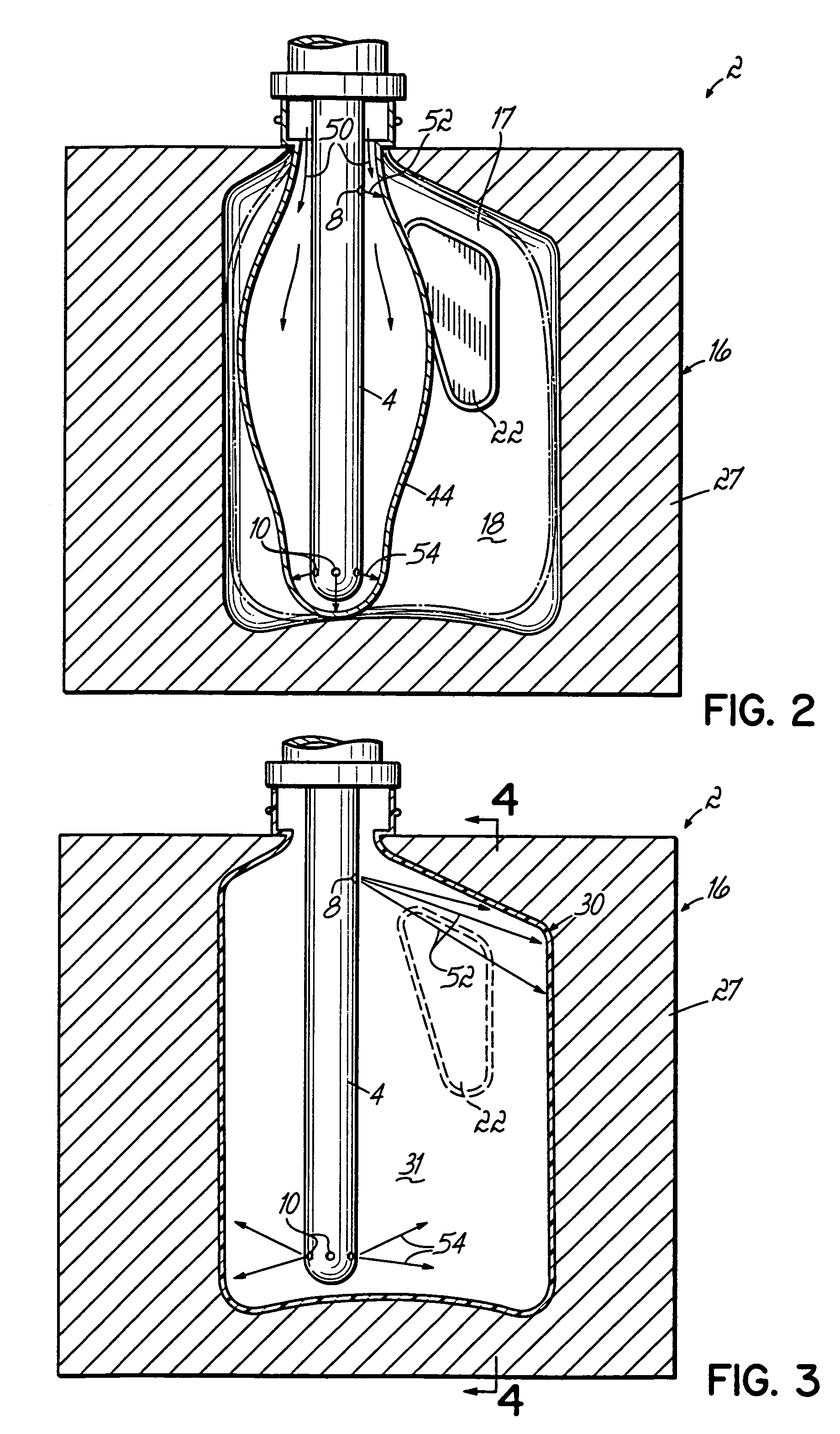

Method of making a stretch/blow molded article (bottle) with an integral projection such as a handle

InactiveUS7153455B2Avoid material wasteDomestic articlesHollow articlesPolyethylene terephthalateBottle

The method involves making a hollow blow molded thermoplastic article having an integral handle. An unblown preform of polyethylene terephthalate (PET) is inserted into a blow mold and thereafter stretched by a stretch rod. Blow gas is then injected into the interior of the preform when the blow mold is closed and the preform is at a stretch temperature. After the preform is blown into the shape of the bottle in the mold, blow gas is discharged from the stretch rod onto an interior wall surface where the handle is to be formed. Heated movable mold segments are then advanced within the blow mold from a first retracted position to a second position thereby compressing an interior wall surface of the article into contact with a facing interior wall surface of the bottle to bond the surfaces at an elevated temperature and form an integral handle extending from the exterior wall of the blow molded article.

Owner:PLASTIPAK PACKAGING

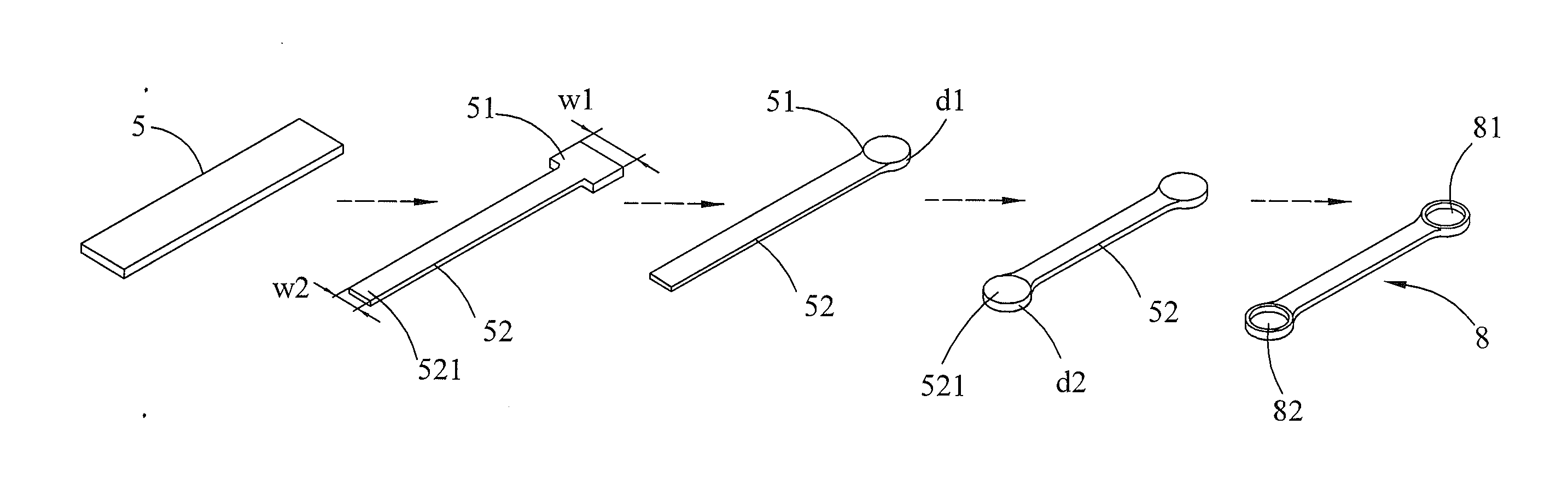

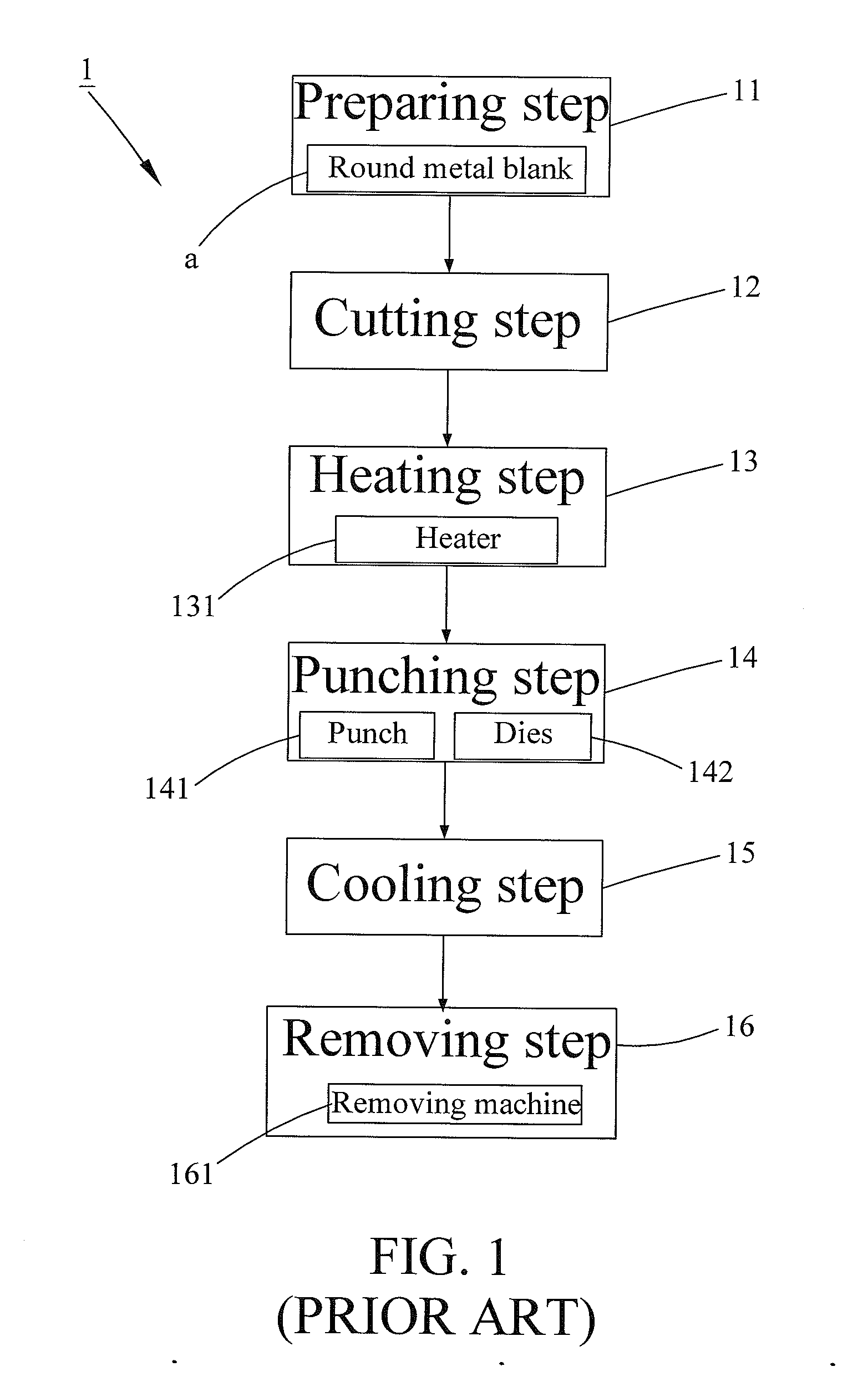

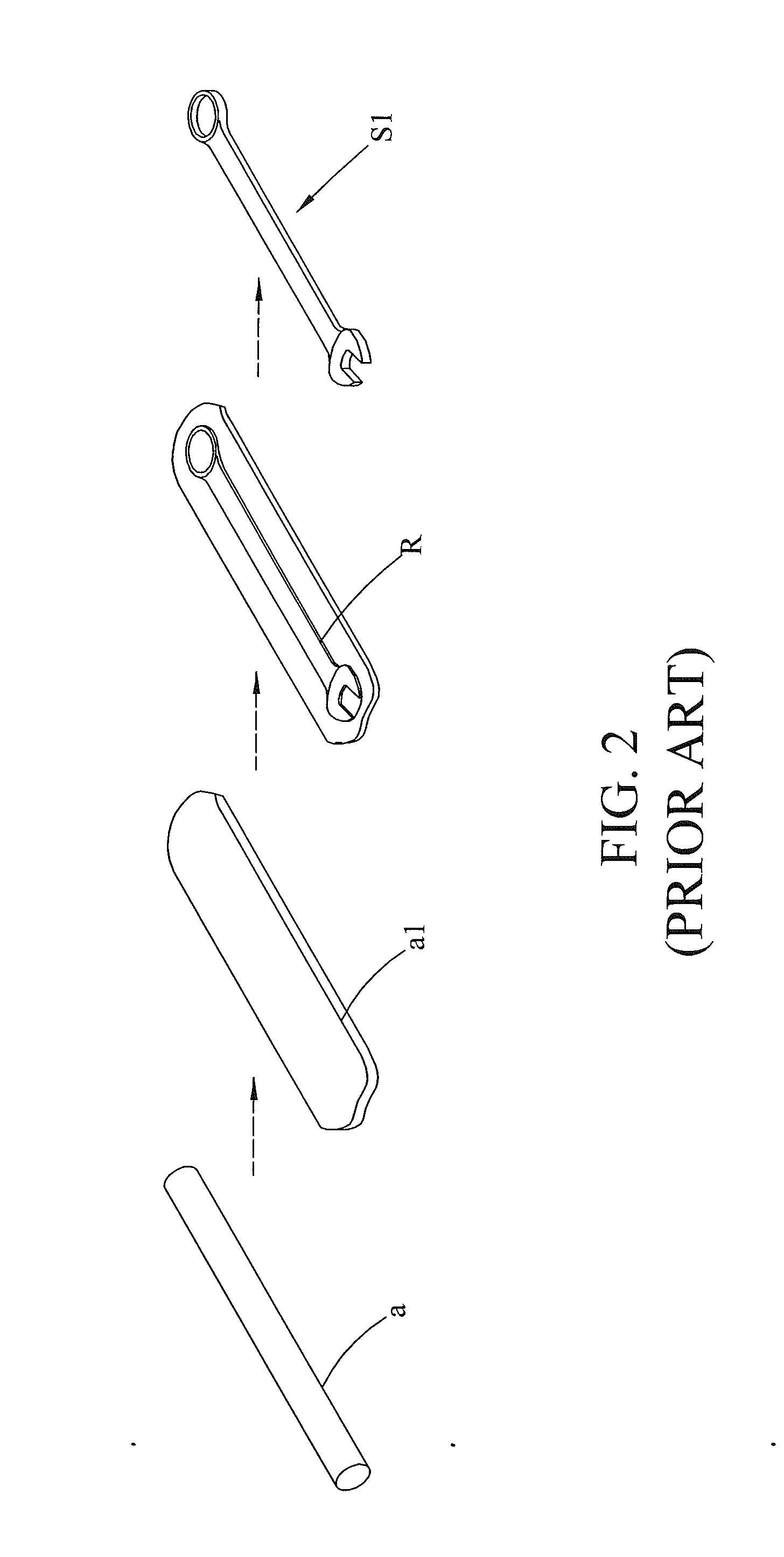

Method of Making a Spanner

ActiveUS20160158827A1Reduce material wasteReduce processing timeCutting toolsEngineeringProcessing cost

A method of making a spanner comprises the steps of preparing a flat metal blank, forging and pressing a part of the metal blank to form a head and a shank whose width is smaller than a width of the head, pressing the head to form a first arch-shaped part, pressing a shank end of the shank to expand the shank end and thence form a second arch-shaped part, and pressing the head and the shank end again to remove redundant scrap projecting from the first arch-shaped part and the second arch-shaped part and also punch finished holes in the head and the shank end respectively, thereby completing the finished spanner. Accordingly, the method reduces the waste of the material and the processing cost, decreases the use frequency of high-cost machines and promotes the processing efficiency by using the flat metal blank.

Owner:CHEN MING CHANG +1

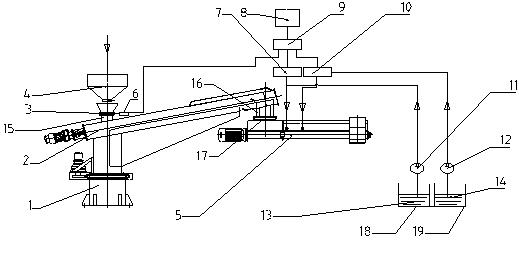

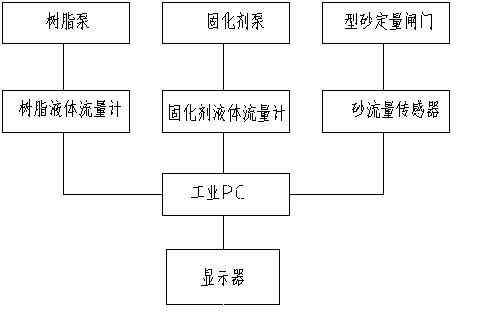

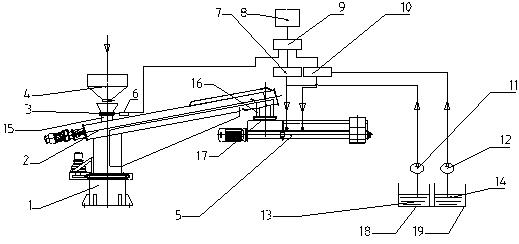

Liquid material addition synchronous display system for resin sand continuous sand mill

InactiveCN102000765AConducive to production adjustmentAvoid material wasteFoundry mouldsMould handling/dressing devicesComposite materialPolymer chemistry

The invention discloses a liquid material addition synchronous display system for a resin sand continuous sand mill. The resin sand continuous sand mill is set; a resin pump and a curing agent pump of the resin sand continuous sand mill are respectively connected with a resin barrel filled with resin and a curing agent barrel filled with curing agents; molding sand is fed into a sand delivery stirring cage through a molding sand storage hopper, is stirred and is fed into a mixing stirring cage from a discharge port of the sand delivery stirring cage; the molding sand, the resin and the curing agents are continuously input into the mixing stirring cage; a sand flow sensor, a liquid flowmeter and a curing agent liquid flowmeter respectively measure the flow of the molding sand, the resin and the curing agents and transmit signals to an industrial personal computer (PC); and the industrial PC computes data through programs and displays the data on a display. The invention is a novel liquid material addition synchronous display system for the resin sand continuous sand mill, which can solve the problem that a liquid material addition proportion of the resin sand continuous sand mill cannot be intuitively acquired in real time in practical production.

Owner:漯河市大华铸造机械有限责任公司

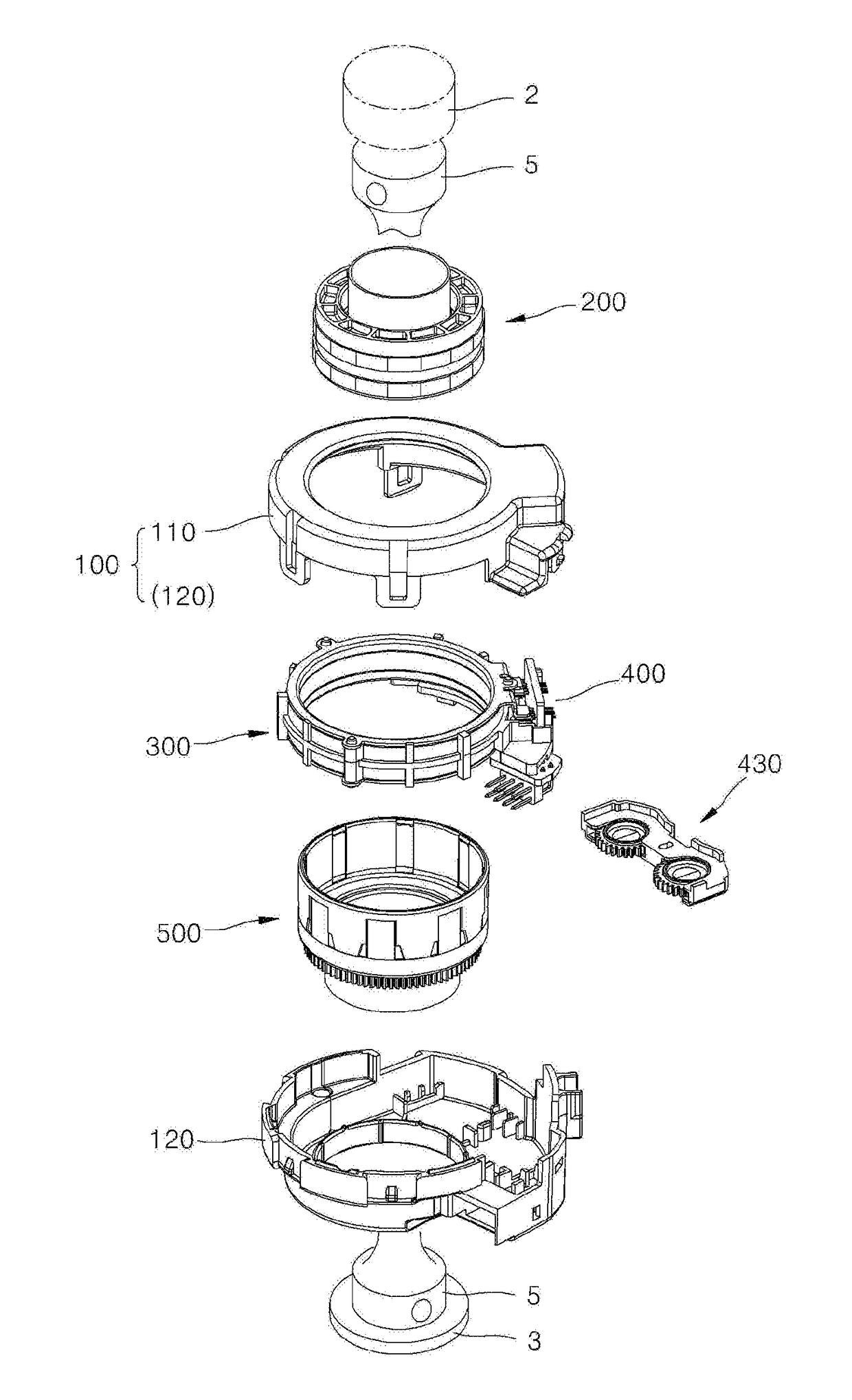

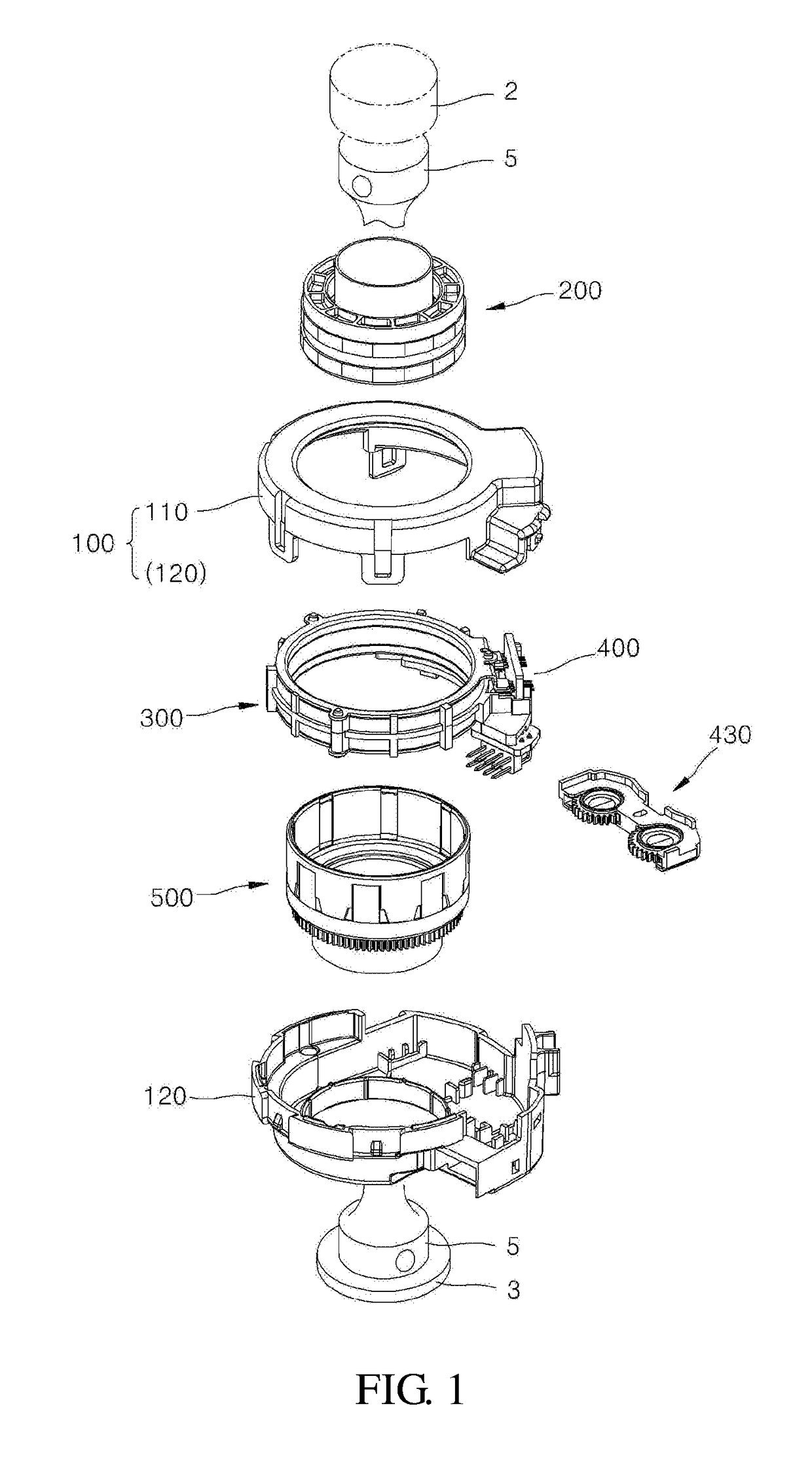

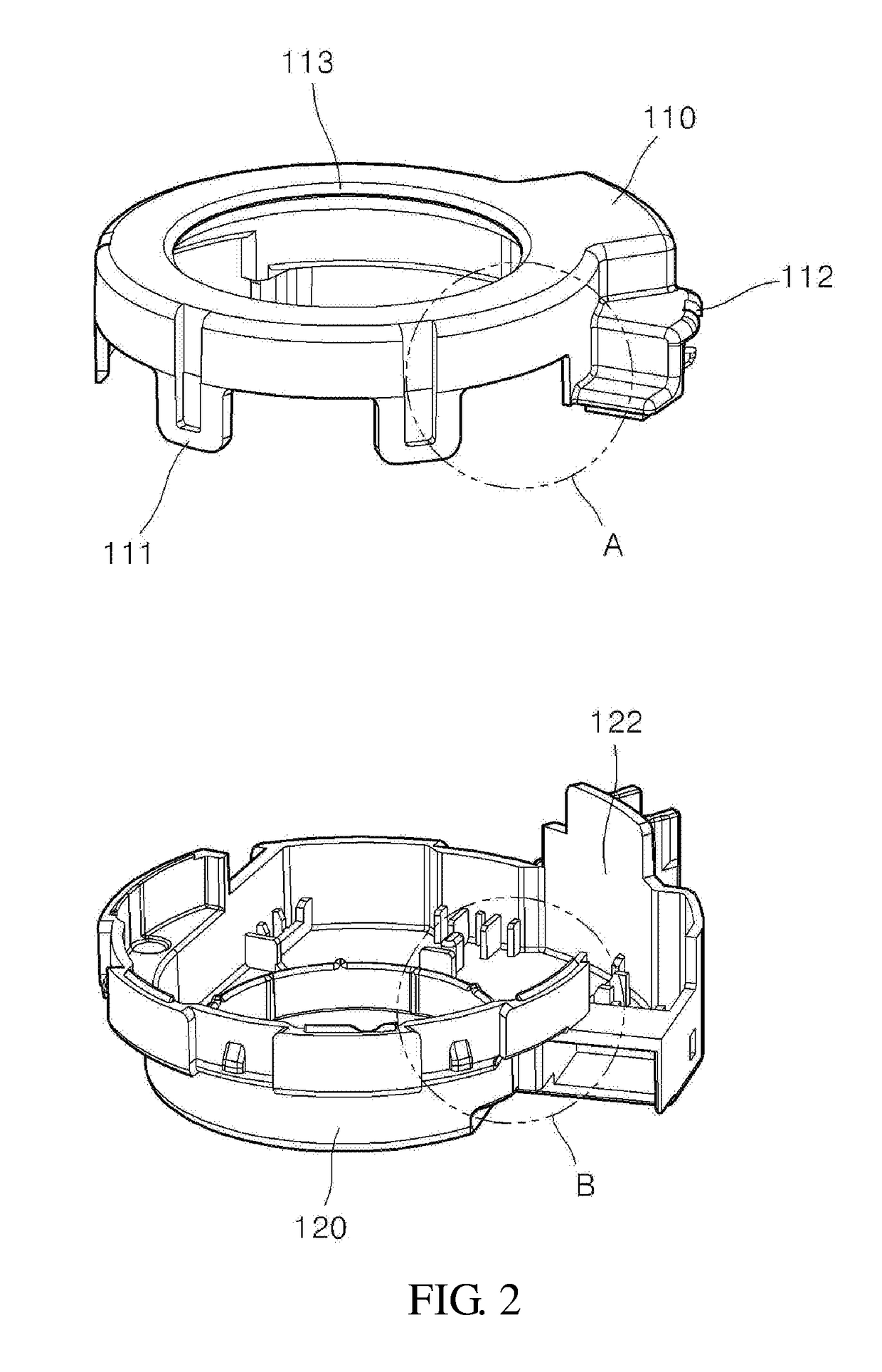

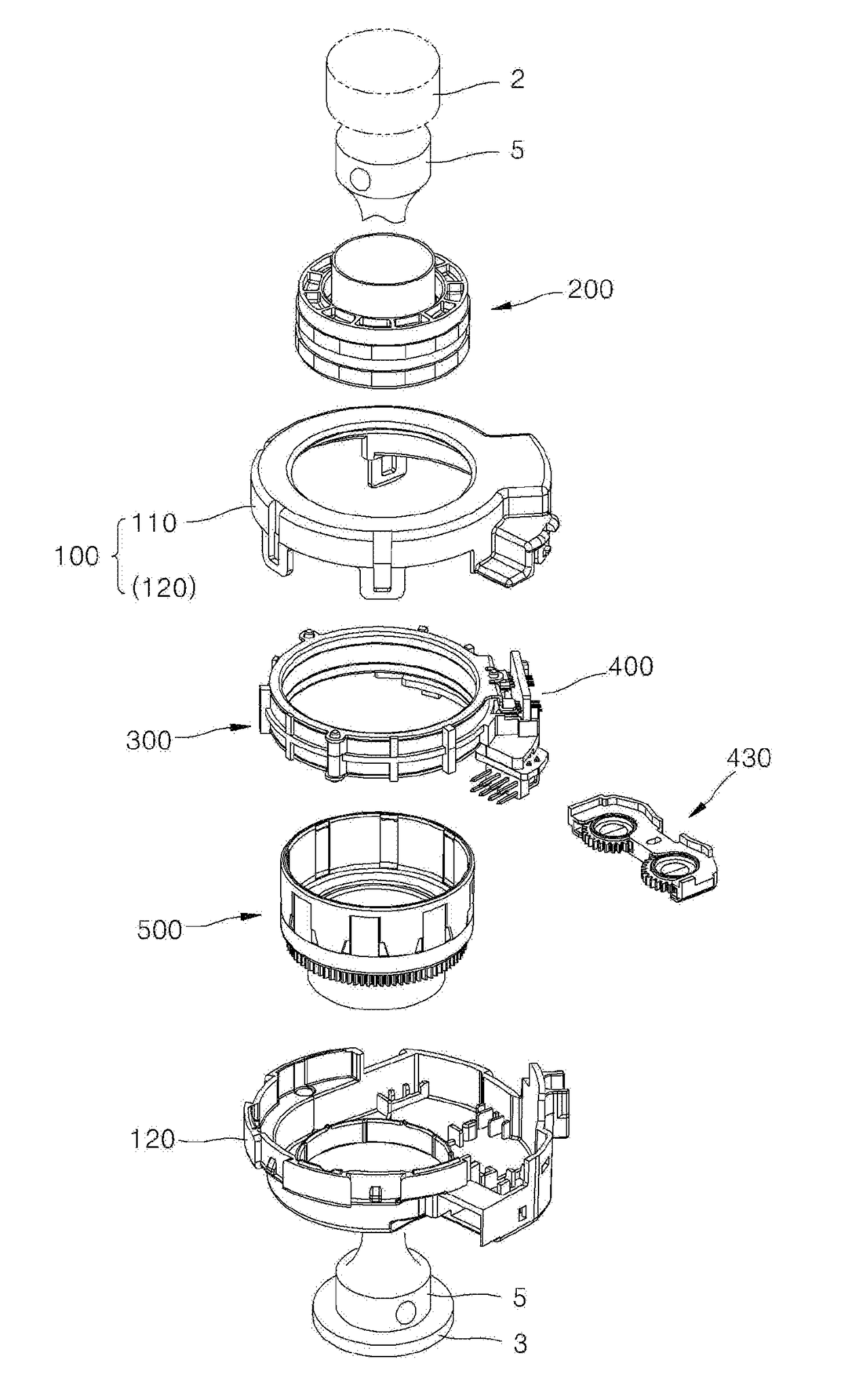

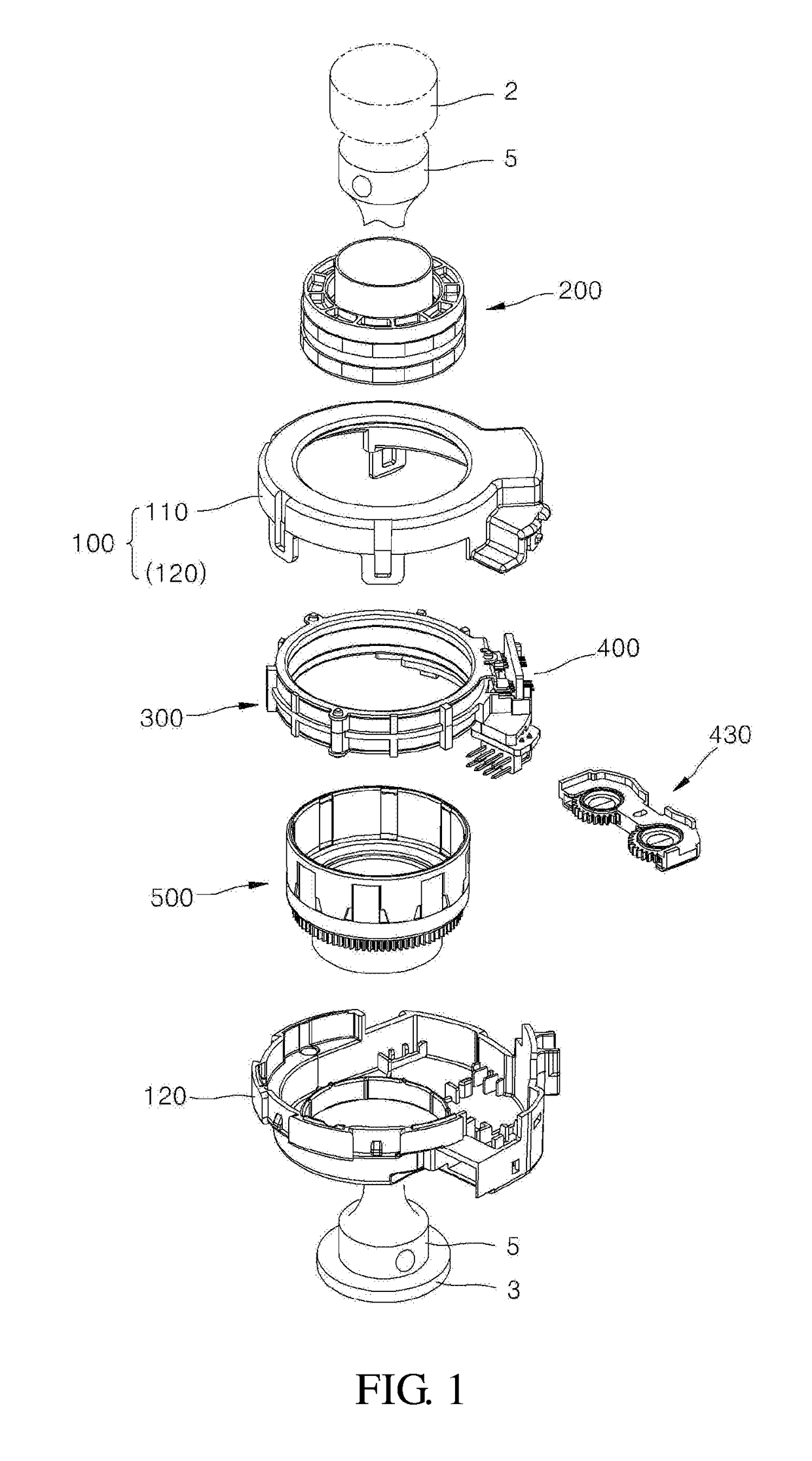

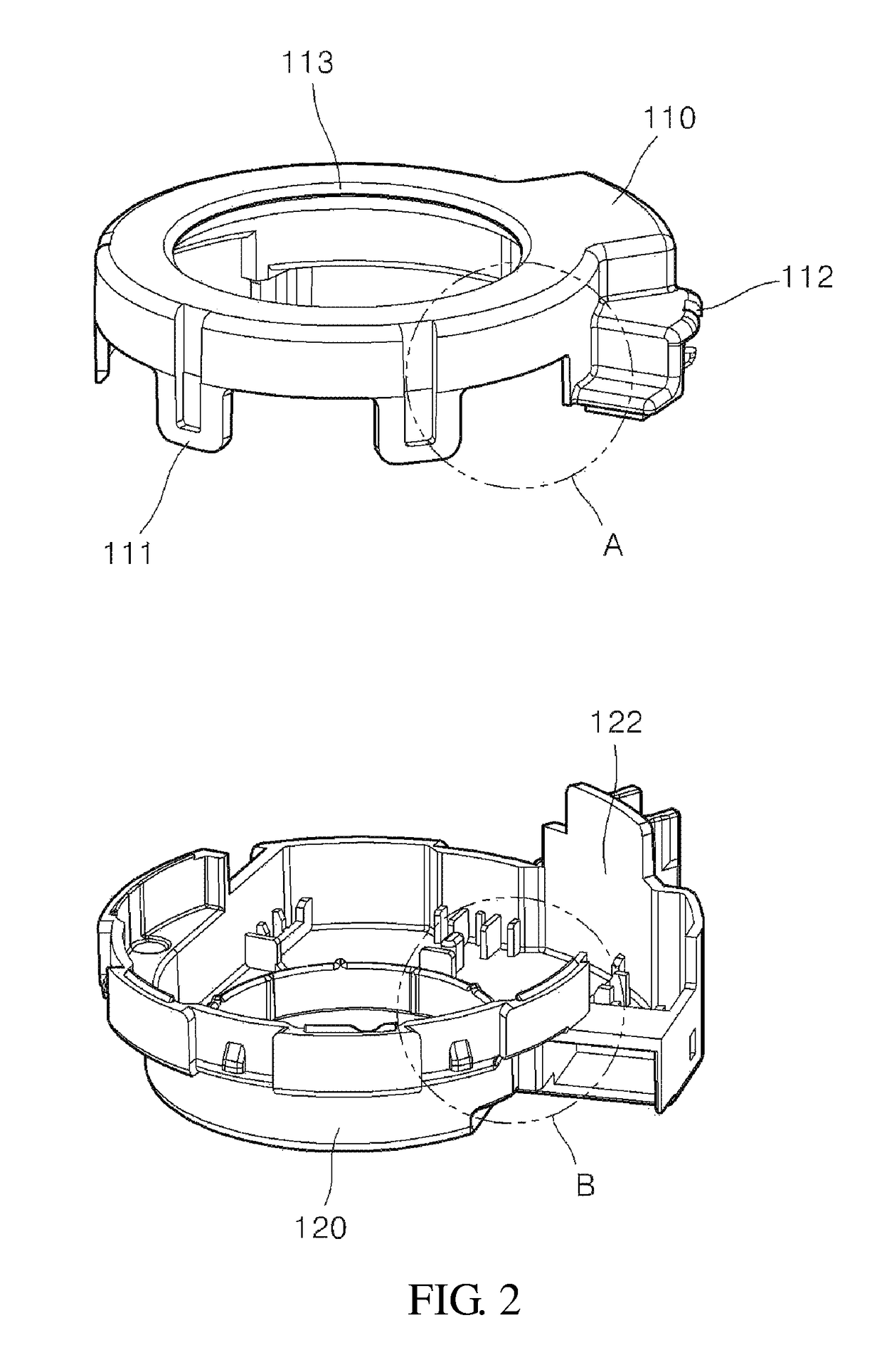

Torque sensor device

ActiveUS20170254710A1Improve AssemblabilityMinimizing assembly errorWork measurementAutomatic steering controlControl theoryMagnet

The present invention provides a torque sensor device disposed between an input shaft and an output shaft and configured to detect a torque between the input shaft and the output shaft through a relative rotation displacement therebetween. The torque sensor device includes: a housing configured to accommodate an end of the input shaft and an end of the output shaft and fixed in position to be able to perform a relative rotation with respect to the input shaft and the output shaft: a magnet unit accommodated in the housing and including a magnet ring connected to one end of one of the input shaft and the output shaft so as to be rotatably accommodated in the housing; a collector unit fixed in position to the housing in such a manner as to be disposed at the outside of the magnet unit, and configured to focus a magnetic field generated from the magnet unit; a sensing unit including a torque sensor disposed at the outer circumference of the collector unit and configured to detect the magnetic field focused by the collector unit; and a shield ring unit interposed between the collector unit and the magnet unit in such a manner as to be connected to one end of the other of the input shaft and the output shaft, and configured to change the magnetic field from the magnet unit, which is focused by the collector unit, by means of the relative rotation between the input shaft and the output shaft.

Owner:LS AUTOMOTIVE TECH CO LTD

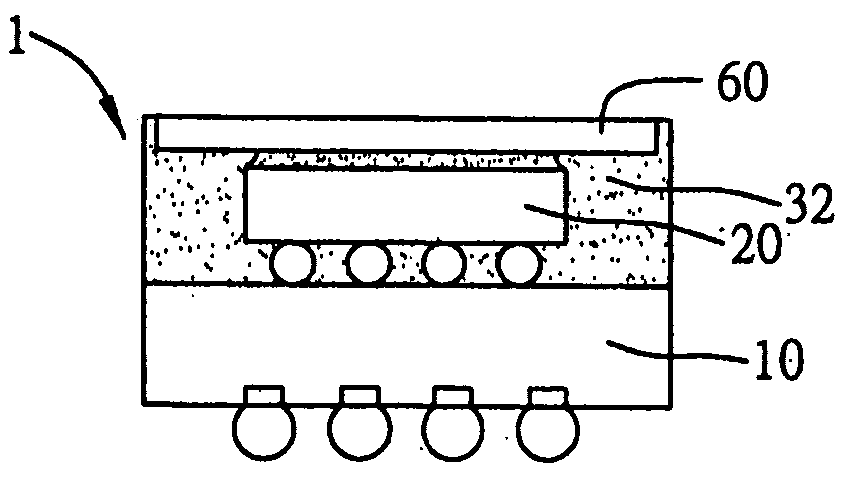

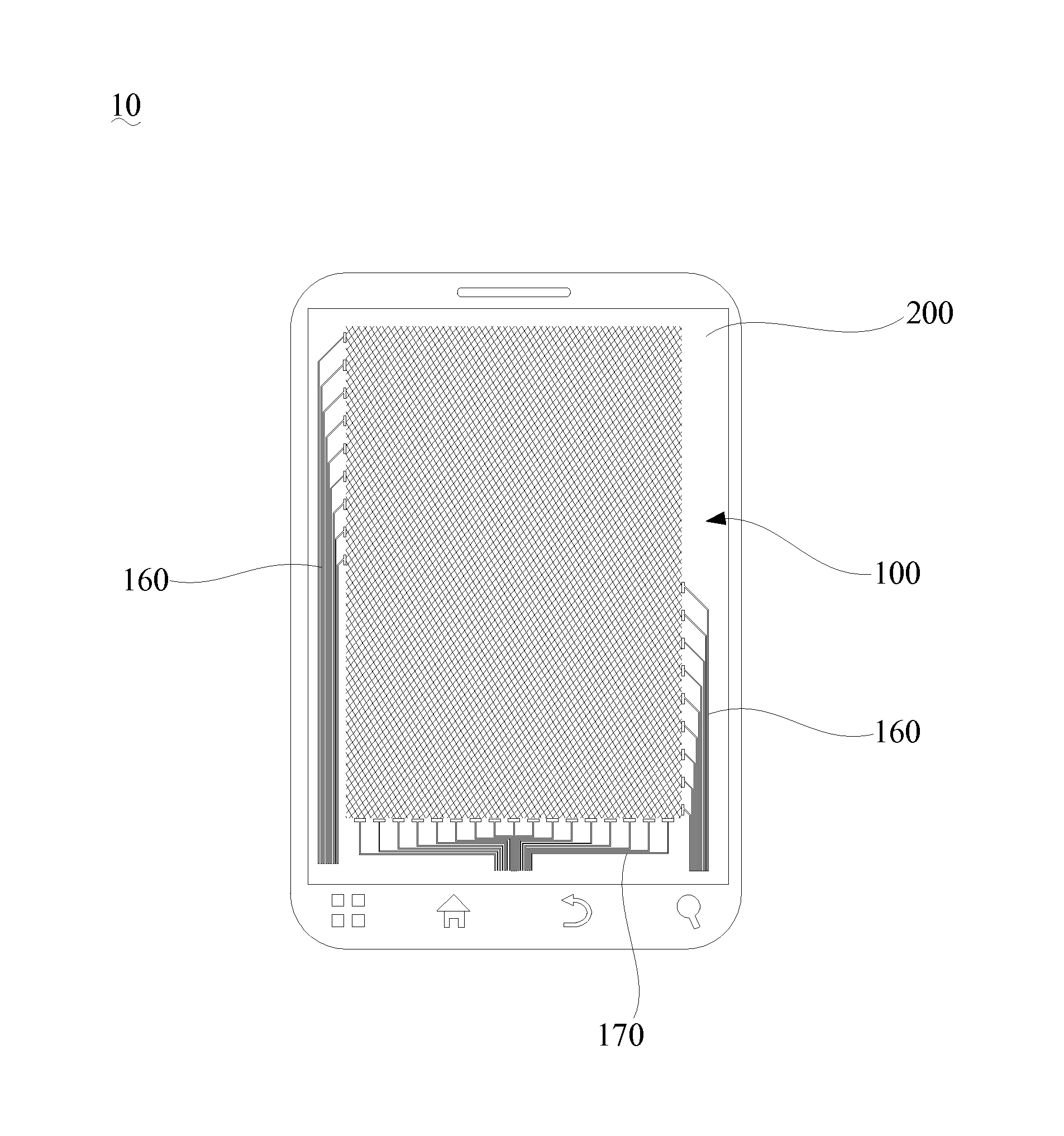

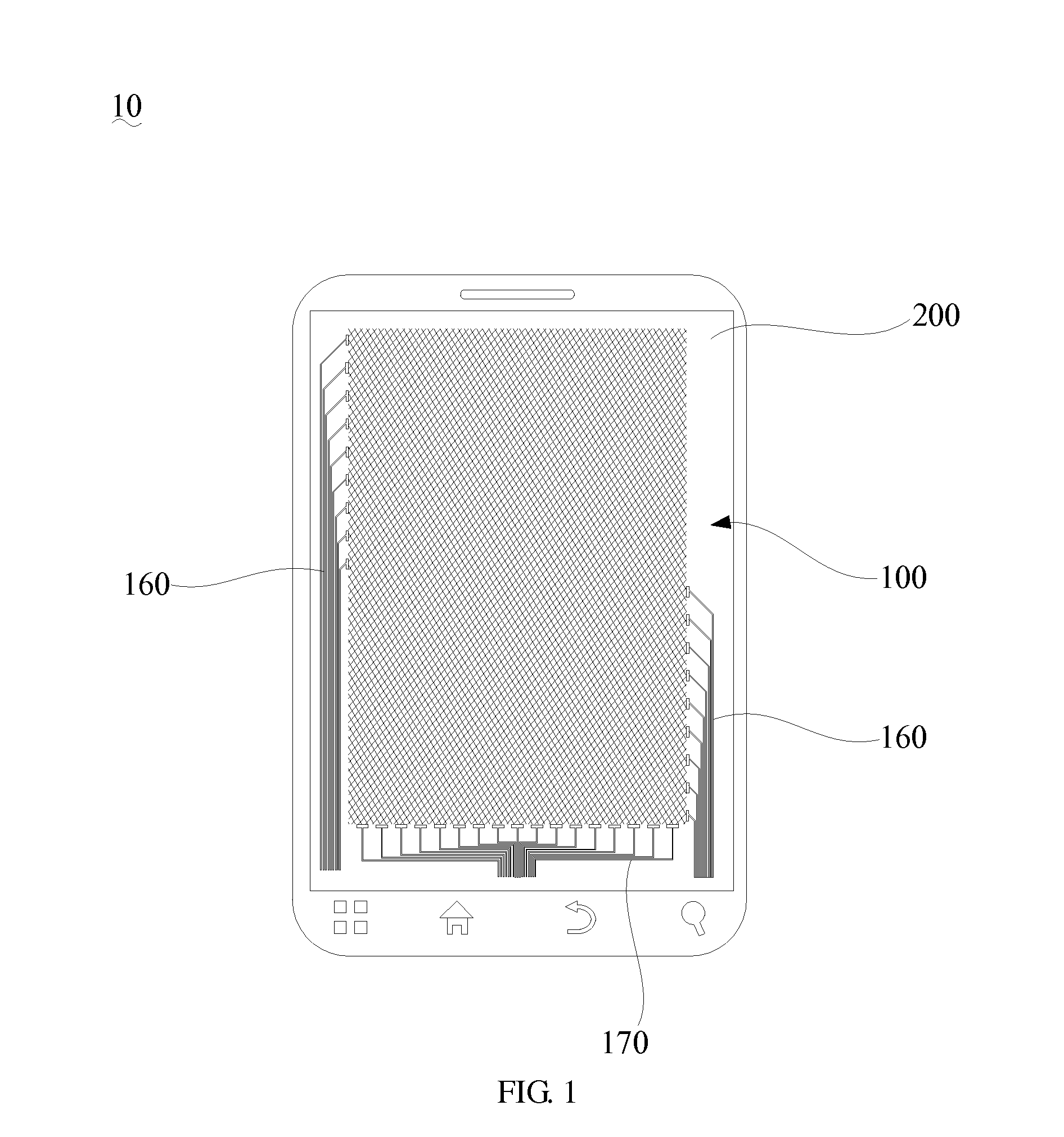

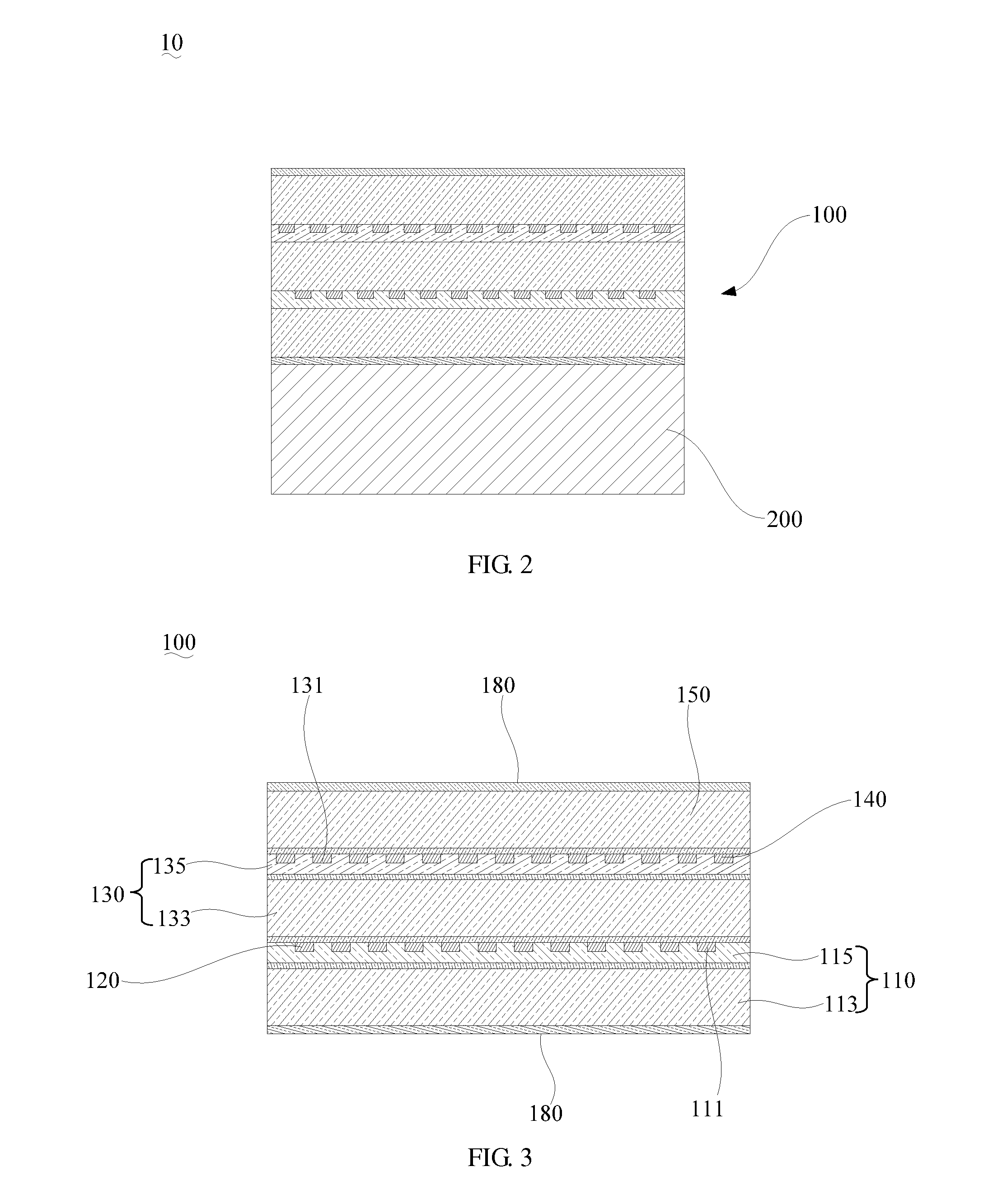

Monitor, touchscreen sensing module thereof, and method for manufacturing the touchscreen sensing module

ActiveUS20140218636A1Avoid material wasteLow costPrinted circuit aspectsElectric switchesEtchingComputer module

A touchscreen sensing module includes a first baseplate, a first conductive layer, a second baseplate, a second conductive layer, and a supporting substrate. A first groove in a predetermined shape is defined on a side of the first baseplate. The first conductive layer matches with the first groove in shape, and the first conductive layer is received in the first groove. A second groove in a predetermined shape is defined on a side of the second baseplate. The second conductive layer matches with the second groove in shape, and the second conductive layer is received in the second groove. The first conductive layer and the second conductive layer respectively match with the first groove and the second groove in shape, no etching is needed to obtain electrodes when forming the conductive layers, which avoids material waste and reduces costs In addition, a monitor is also provided by the present invention.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

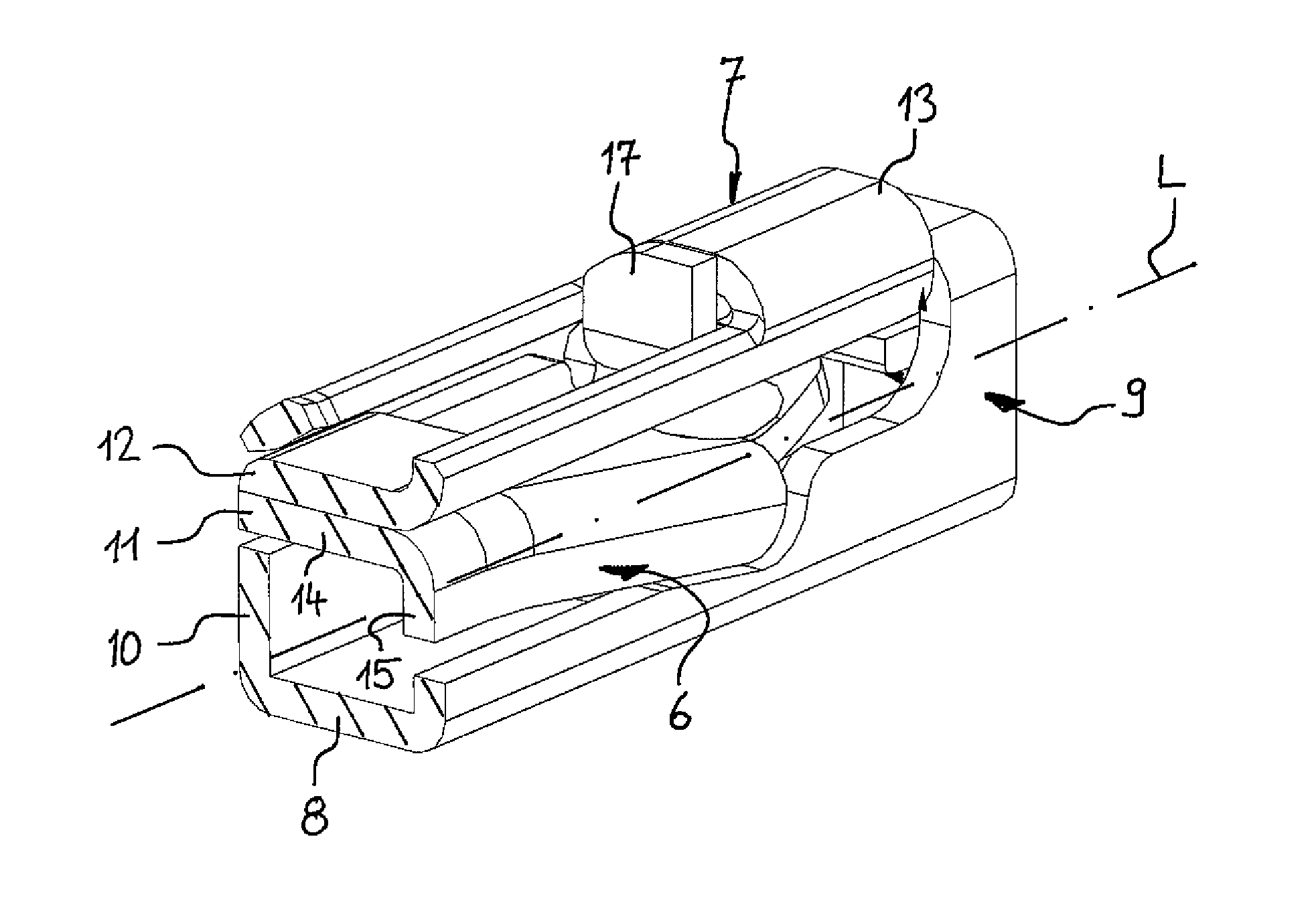

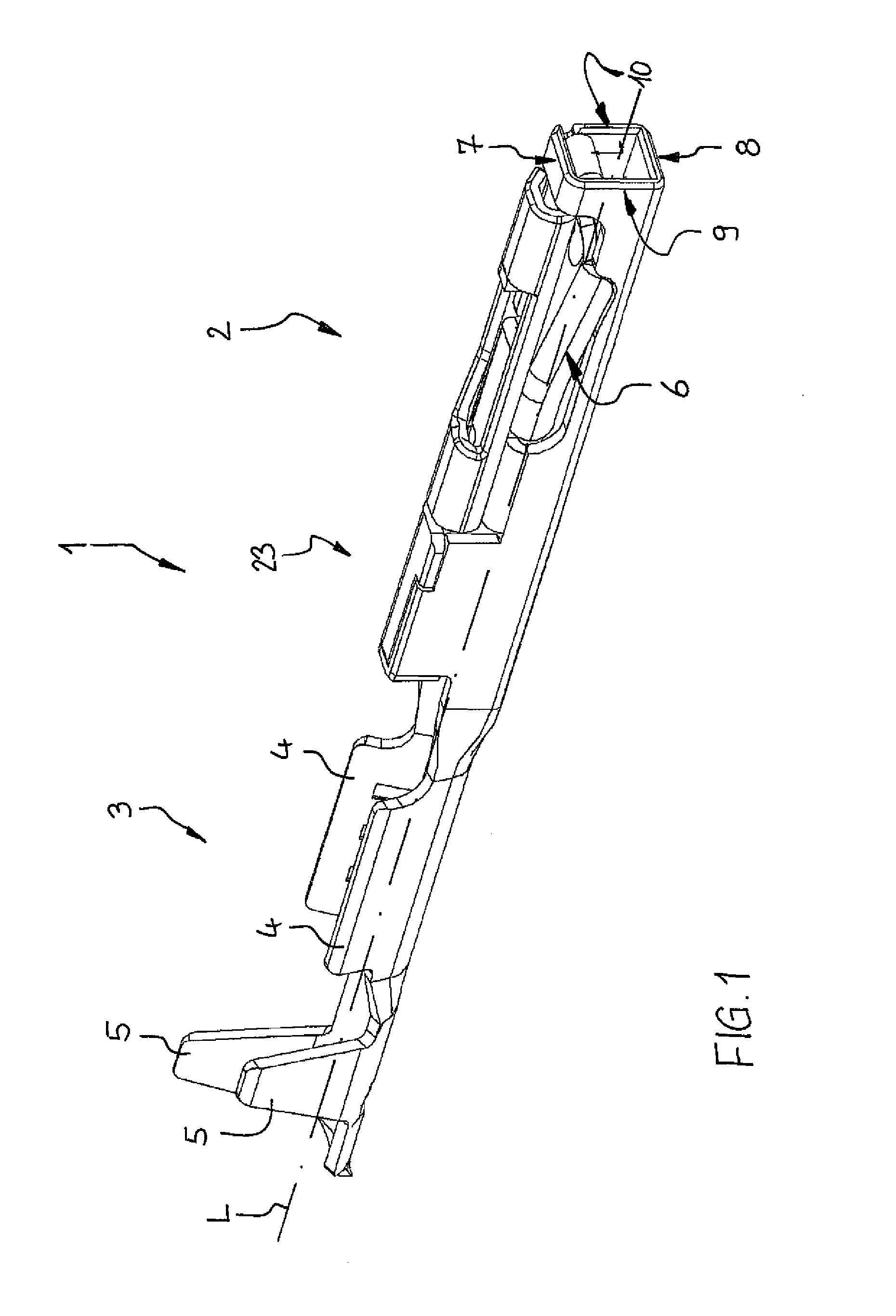

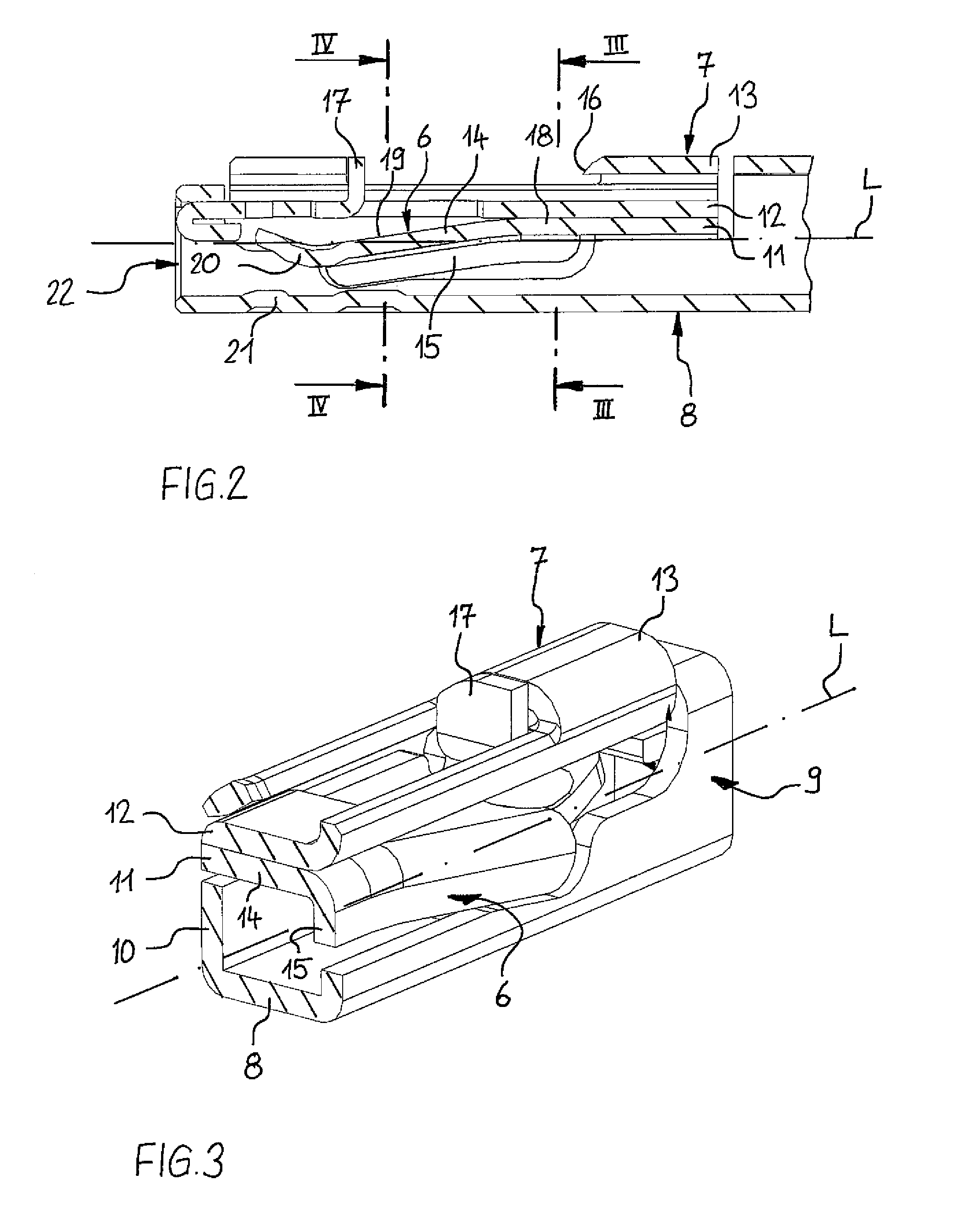

Electrical terminal

ActiveUS9118131B2Easy to processReduce internal stressContact member manufacturingCoupling contact membersElectricityEngineering

An electric terminal (1) made of sheet metal having a contact portion (3) including a top wall (7), a bottom wall (8), a first side wall (9) and a second side wall (10) and a contact spring arm (6) having: a contact beam (14) for achieving an electric contact with a complementary contact element and being integrally connected to the top wall (7) and a reinforcement beam (15), wherein the contact beam (14) and the reinforcement beam (15) together form an L-shaped cross-section, wherein the reinforcement beam (15) is only connected to the contact beam (14).

Owner:YAZAKI EURO

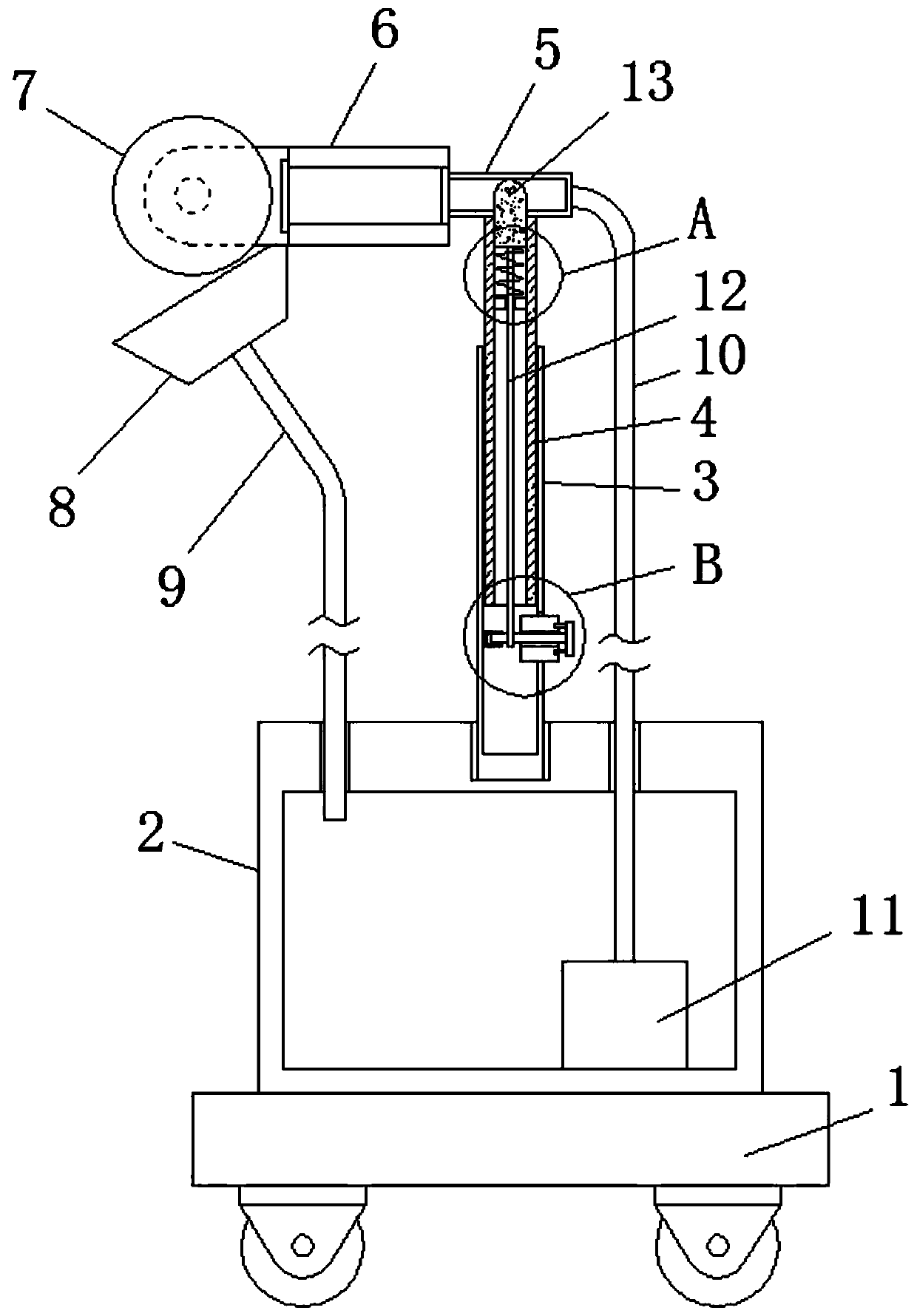

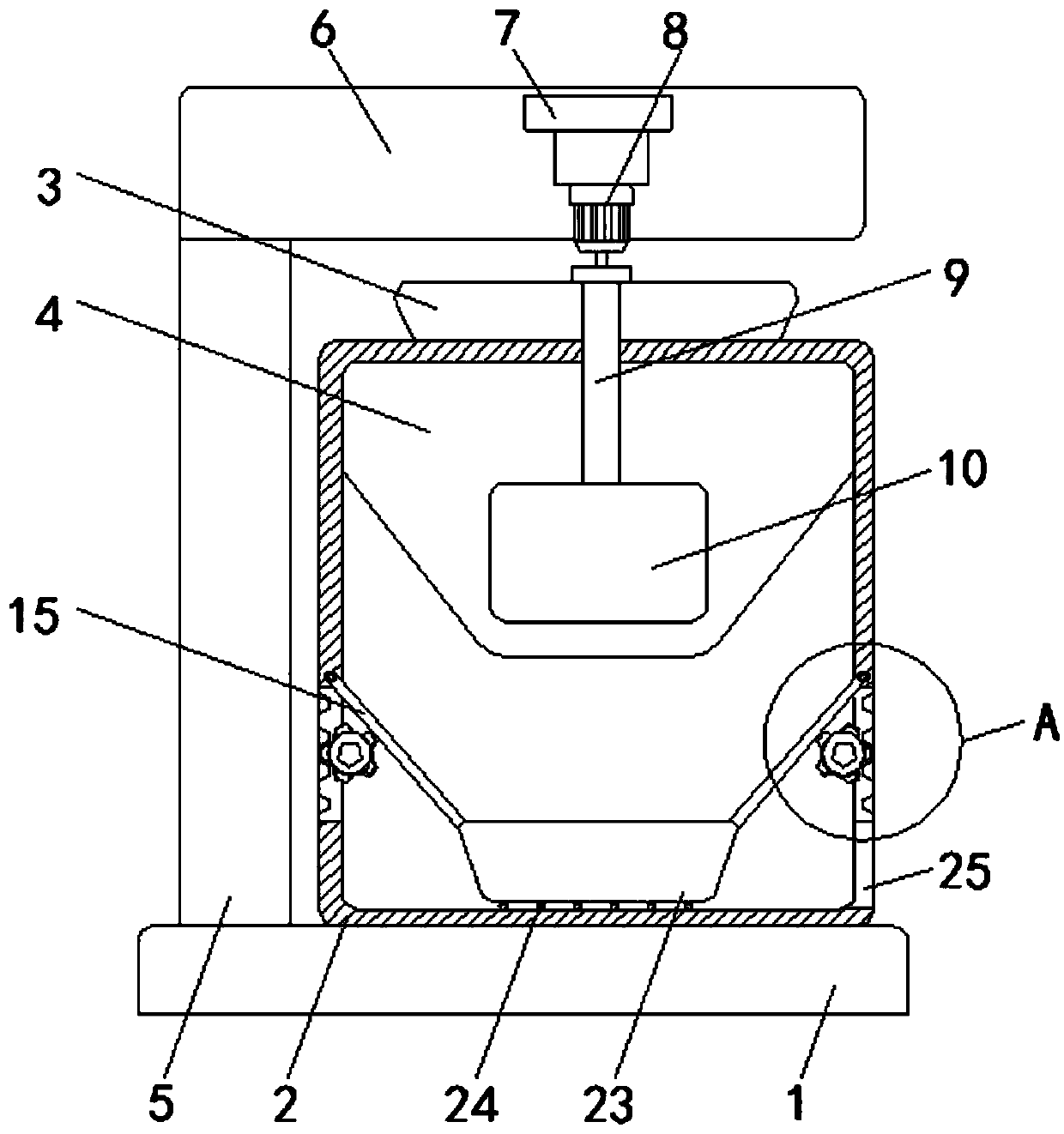

Wall painting device for building decoration

InactiveCN111236585AImprove brushing efficiencyAvoid material wasteBuilding constructionsStructural engineeringMechanical engineering

The invention discloses a wall painting device for building decoration, and relates to the field of building decoration. The wall painting device aims at solving the problem that the painting efficiency is reduced due to the fact that the existing wall painting operation needs to frequently use a painting roller to dip materials. According to the scheme, the wall painting device comprises a bottomplate, a material box is fixedly arranged at the top end of the bottom plate, a first supporting rod is movably arranged at the top end of the material box, a second supporting rod is slidably arranged in the first supporting rod, the first supporting rod and the second supporting rod are of a hollow structure, the end of the first supporting rod extends to the upper portion of the first supporting rod and is fixedly provided with a connecting pipe, and a material blocking block is hermetically and slidably arranged in the connecting portion of the connecting pipe and the second supporting rod. The wall painting device is novel in structure, the device can be suitable for wall surfaces with different heights, meanwhile, the step of frequently dipping the materials can be omitted, the painting efficiency is improved, the device can effectively avoid material waste, and the device is suitable for popularization.

Owner:龙门县山水之邦装饰有限公司

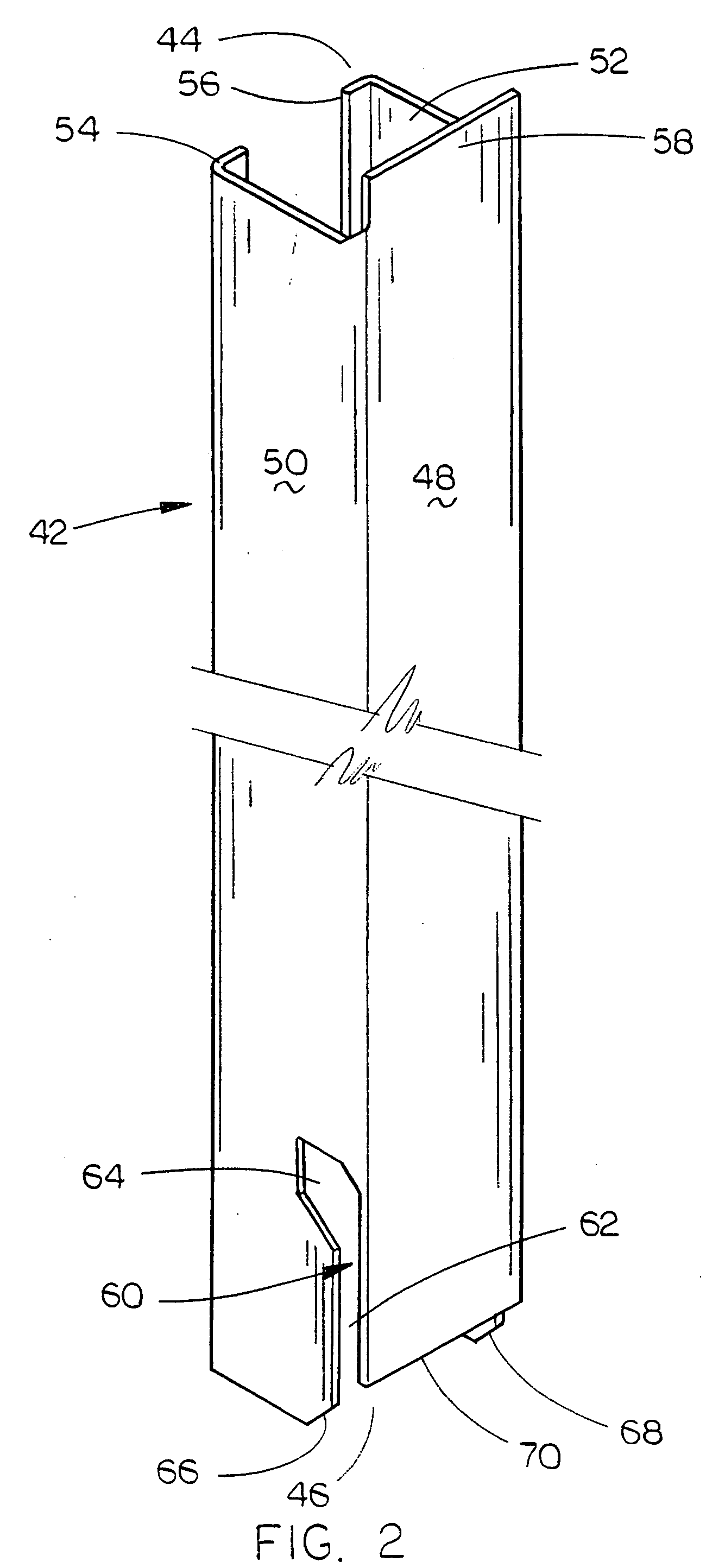

Metal stud for a wall or roof system

A metal stud for use in a metal building wherein the studs are secured to horizontally extending and vertically spaced-apart girts which are either C-shaped or Z-shaped. A metal stud is generally C-shaped and includes a base wall portion and opposite side wall portions with upper and lower ends. The lower ends of the side wall portions each have slot formed therein wherein which are adapted to receive a wall portion and flange of a girt. The upper end of the stud has a tab which extends upwardly therefrom to enable the tab to be secured to a girt. The stud may also be used in the roof system of the building.

Owner:KESTER JEFF

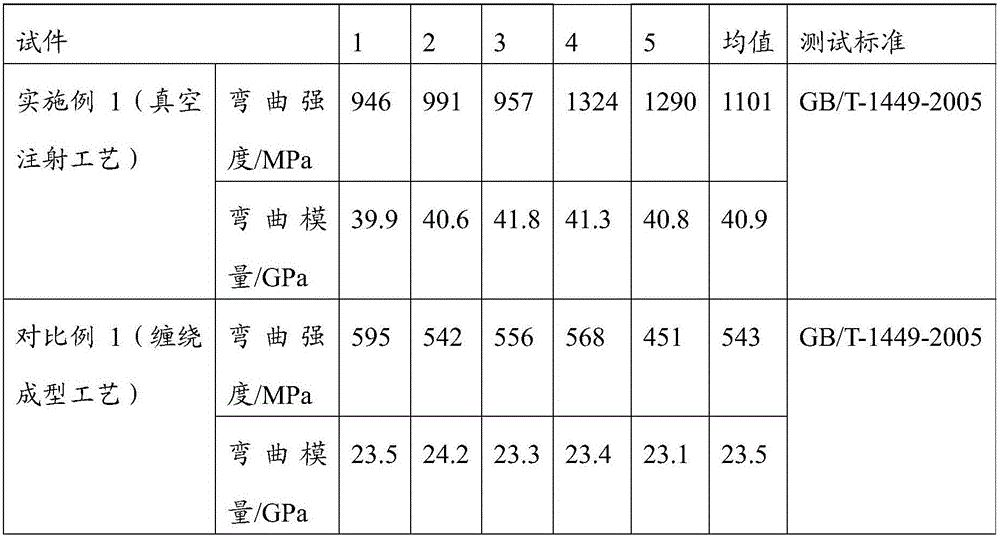

Preparation method for insulator mandril

ActiveCN106158170AReasonable processAvoid material wasteSupporting insulatorsMANDRILSurface processing

The invention discloses a preparation method for an insulator mandril. The preparation method comprises: (1), carrying out surface processing; (2), carrying out winding; (3), carrying out vacuum infusion moulding; and (4), carrying out solidification. According to the invention, an included angle between a glass fiber of a piece of unidirectional glass fiber cloth and a central shaft of a solid mandril is controlled to be between 0 to 10 degrees; the breadth of the unidirectional glass fiber cloth is close to the length of the solid mandril; and the winding angle of the unidirectional glass fiber cloth is basically zero, so that the insulator mandril with high strength can be obtained. With the method, a large-diameter insulator mandril can be produced rapidly; the procedures are reasonable; material wasting can be avoided; and the production cost can be lowered.

Owner:北玻电力复合材料有限公司

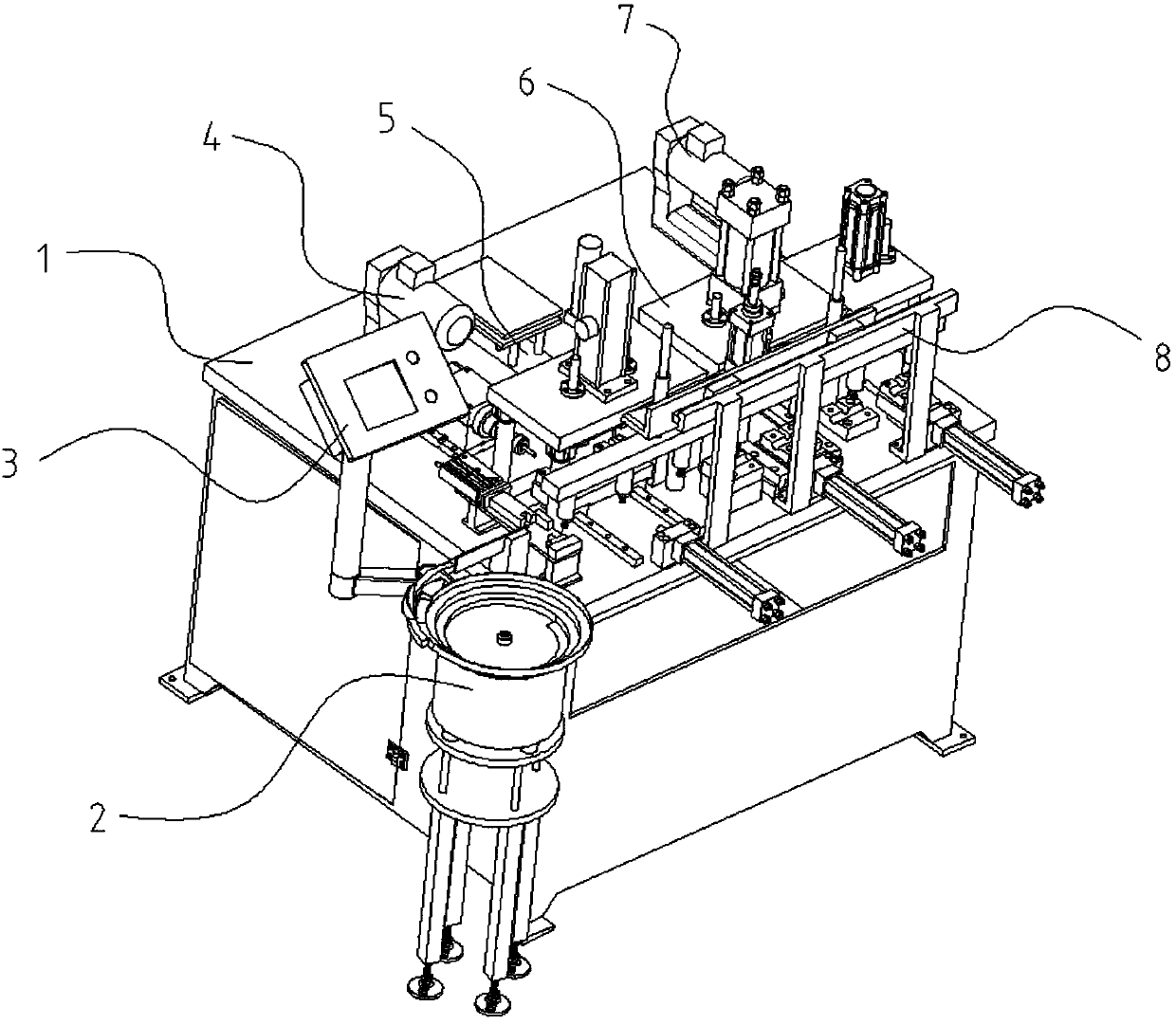

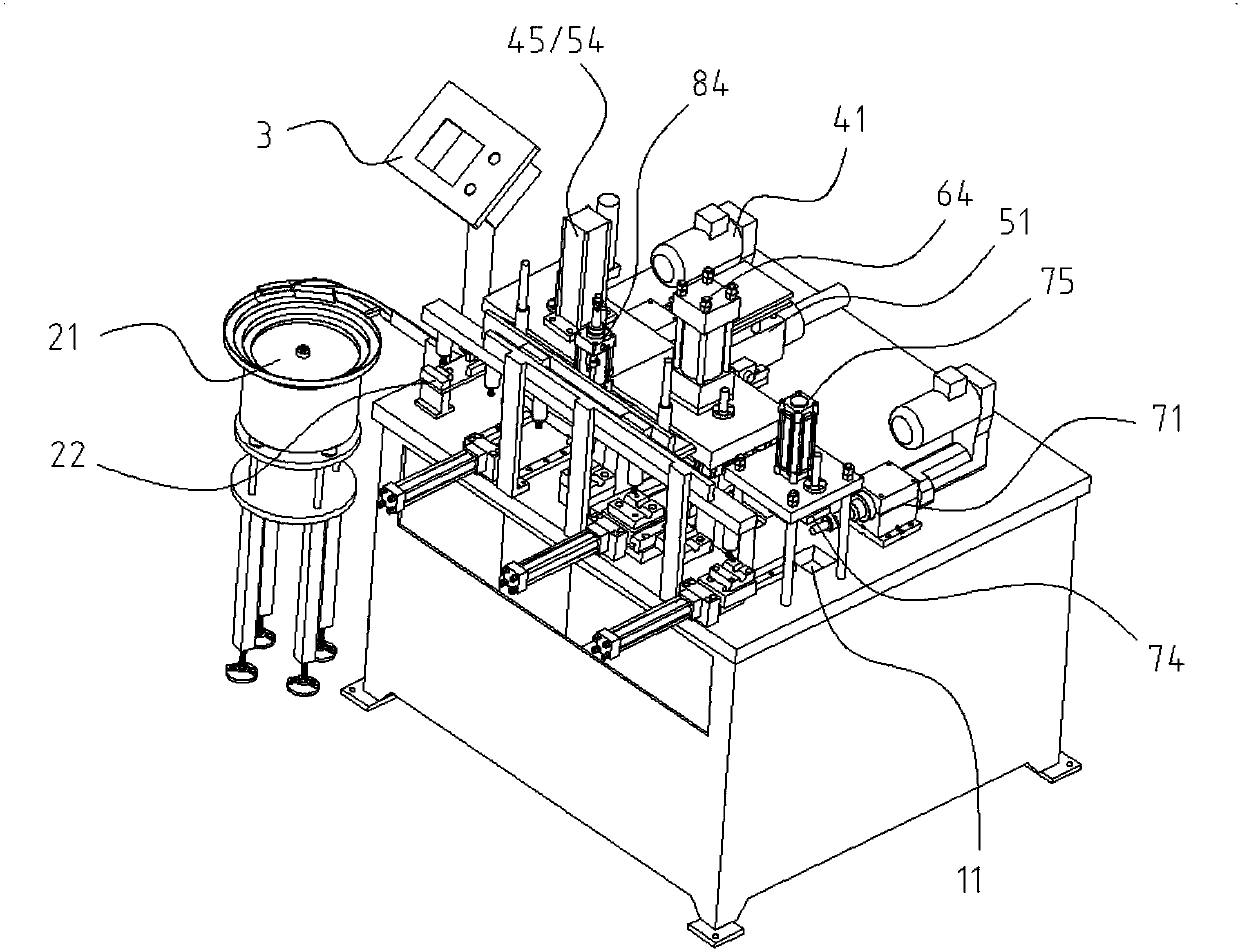

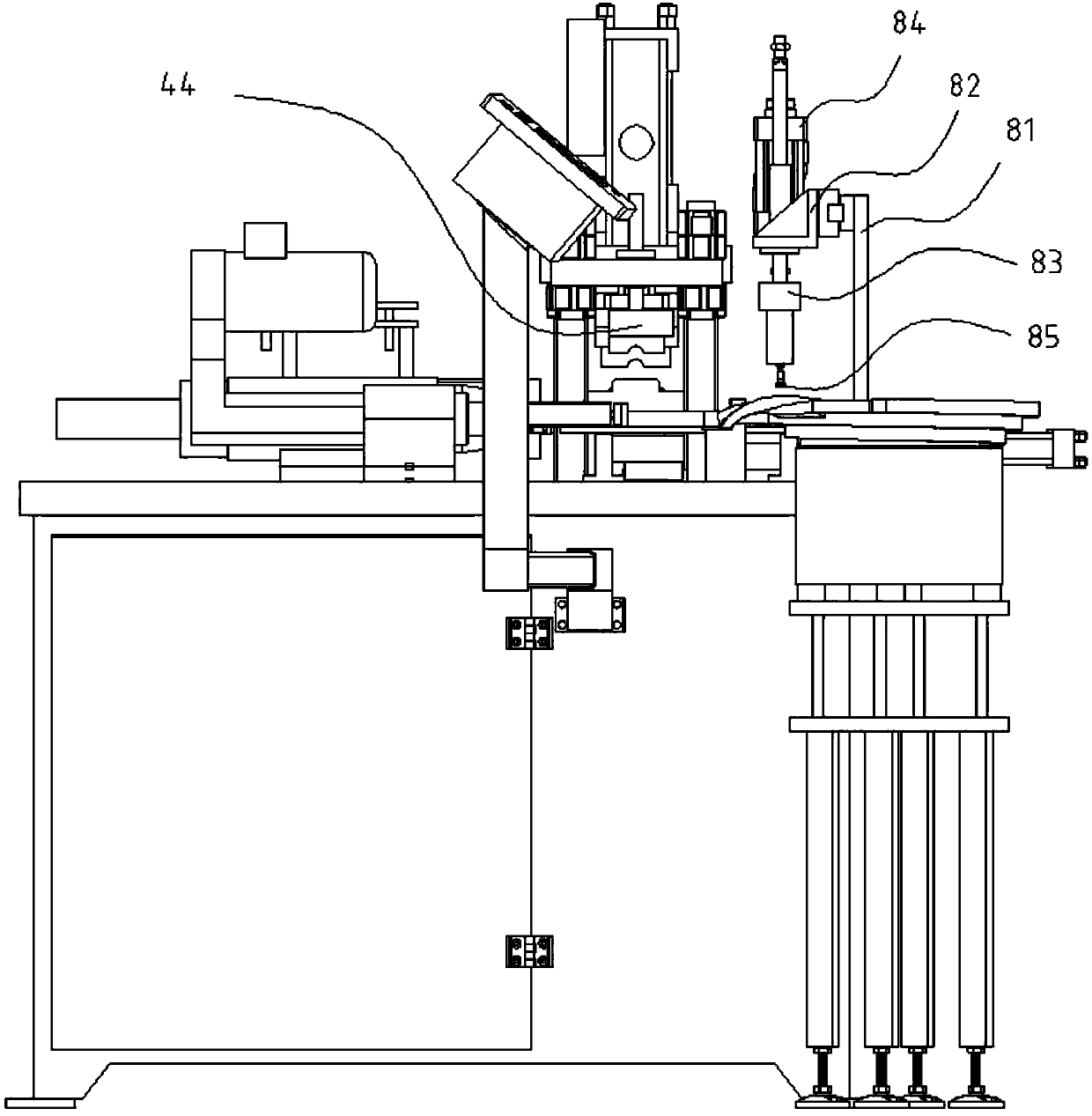

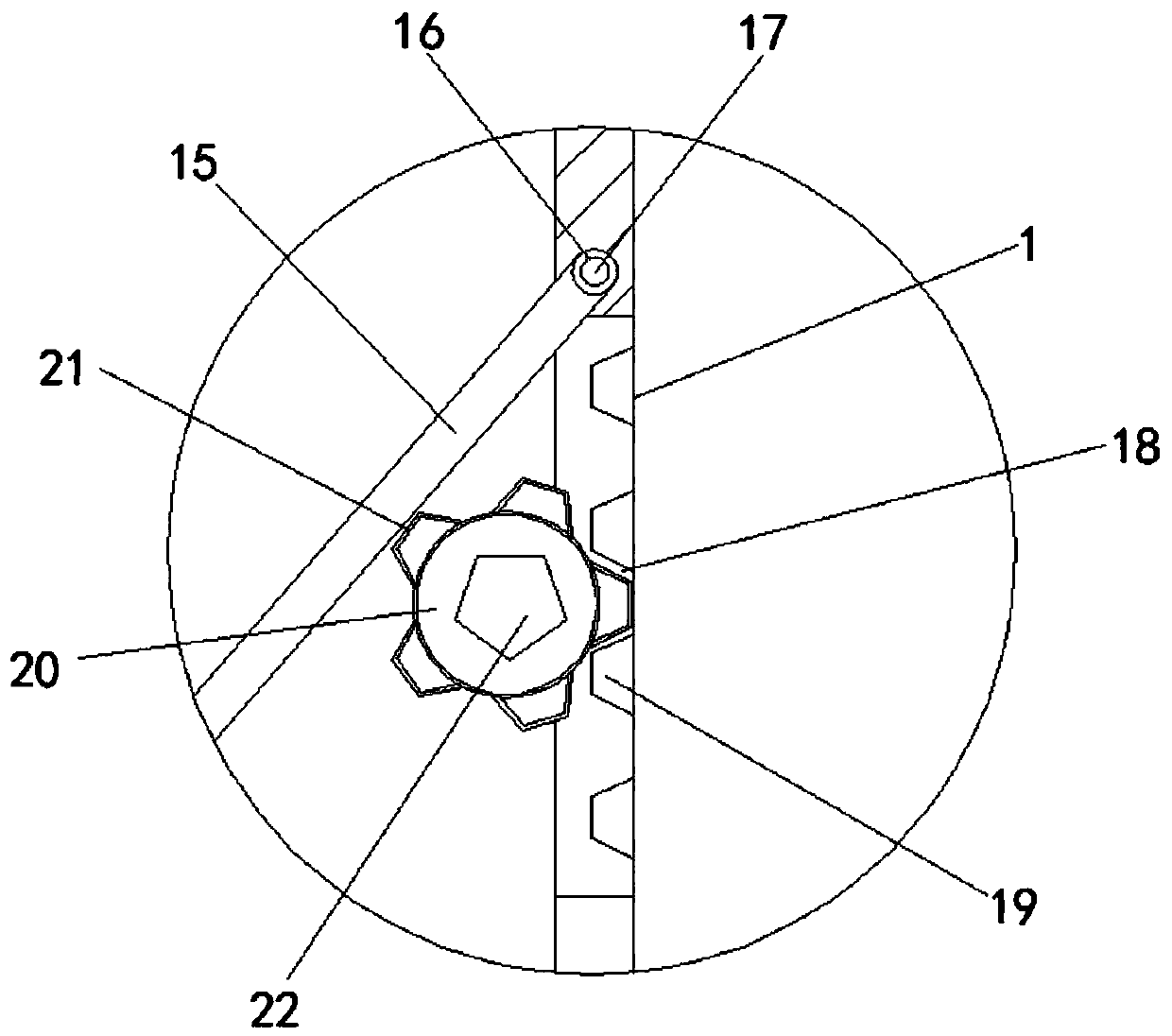

Machining equipment for three-way copper pipe fitting

ActiveCN107617673AFully automatedAchieve equidistant distributionMetal-working feeding devicesPositioning devicesPunchingAutomatic control

The invention provides machining equipment for a three-way copper pipe fitting and belongs to the technical field of automatic processing equipment. The machining equipment comprises a feeding mechanism, a punching mechanism, a flaring mechanism, a shaping mechanism and an end flatting mechanism which are arranged on a workbench and sequentially arranged in the same direction, wherein a transportmechanism is arranged perpendicular to the workbench, and all the mechanisms are connected in series through the transport mechanism. As the punching mechanism, the flaring mechanism, the shaping mechanism and the end flatting mechanism are arranged on the same workbench, and the mechanisms are connected through the transport mechanism, the machining process, including, punching, spin-flaring, shaping and end flatting, of the three-way copper pipe fitting, is finished on the same equipment, and the working efficiency is improved; the punching mode replaces a head cutting mode, so that the yield is improved, and material waste is avoided; and meanwhile, as a program controller is arranged, automatic control is achieved, the labor intensity of staff is reduced, and the production security isimproved.

Owner:NINGBO JINTIAN COPPER TUBE

Torque sensor device

ActiveUS10067015B2Improve AssemblabilityMinimizing assemblyWork measurementAutomatic steering controlControl theoryMagnet

Owner:LS AUTOMOTIVE TECH CO LTD

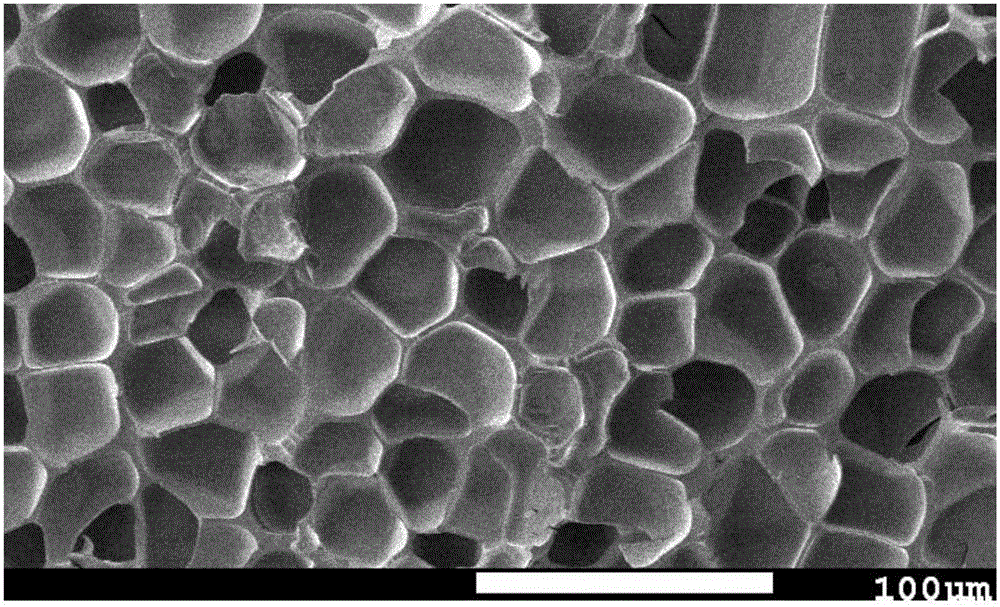

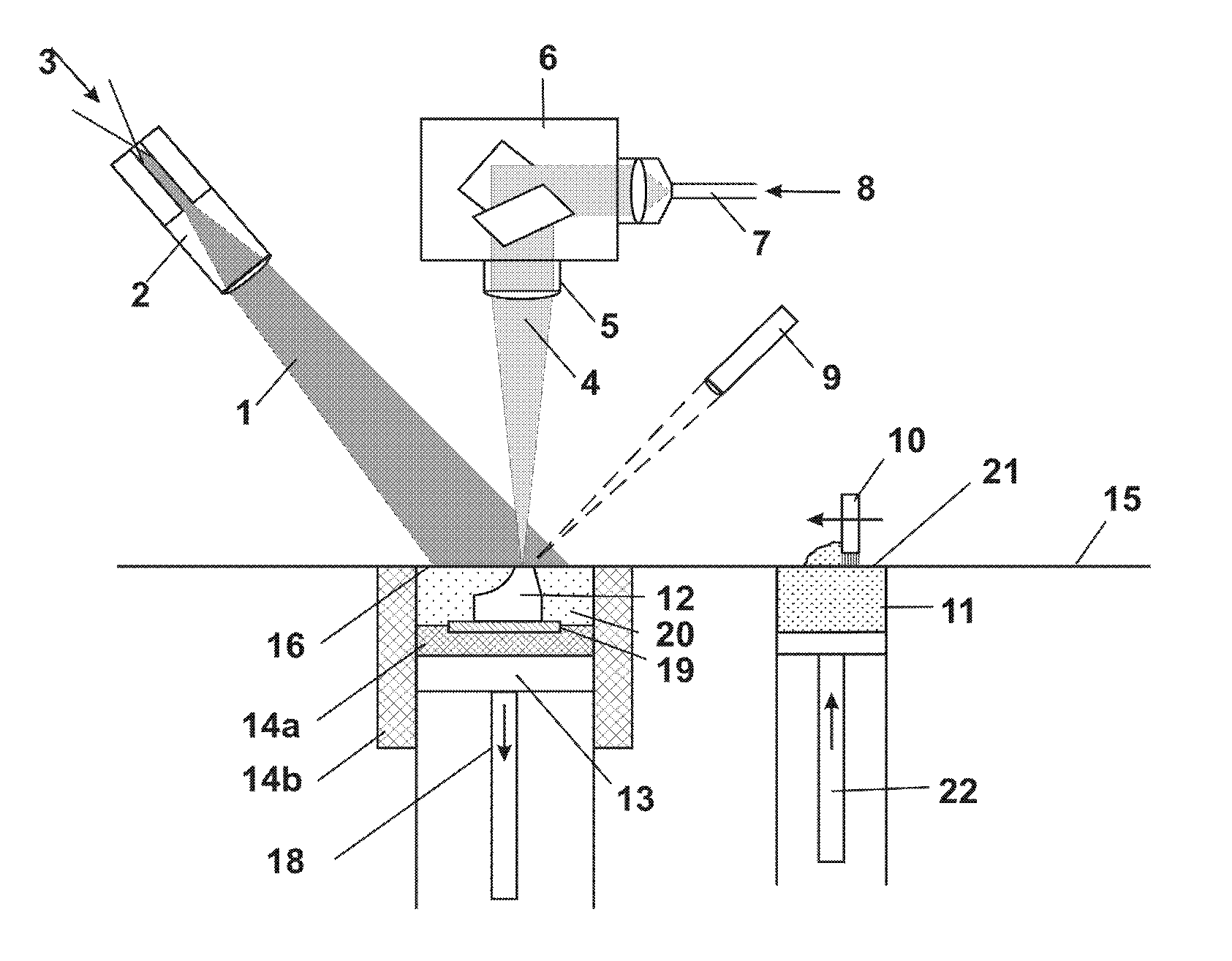

Ceramic or glass-ceramic article and methods for producing such article

ActiveUS9556525B2Simple preparation processSimple compositionImpression capsRadiation applicationsPowder mixtureMetallurgy

The present invention relates to a method of producing a (shaped) ceramic or glass-ceramic article, involving the steps of: (a) providing a powder or a powder mixture comprising ceramic or glass-ceramic material, (b) depositing a layer of said powder or powder mixture on a surface, (d) heating at least one region of said layer by means of an energy beam or a plurality of energy beams to a maximum temperature such that at least a part of said ceramic or glass-ceramic material in said at least one region is melted and (e) cooling said at least one region of said layer so that at least part of the material melted in step (d) is solidified, such that the layer is joined with said surface in said at least one region. The invention also relates to ceramic or glass-ceramic articles and their use.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +3

Selective metal surface treatment process and apparatus for circuit board and resist used in the process

InactiveUS20070281388A1Reduce wasteReduce processing timePrinted circuit aspectsSemiconductor/solid-state device manufacturingSolder maskResist

A selective metal surface treatment process of a circuit board, which has a solder mask and a multiple of selective metal treatment surface areas, wherein the solder mask covers the surface of the circuit board but exposes the selective metal surface treatment areas, is provided. The selective metal surface treatment process includes using a printhead to selectively print a resist on a selective metal surface treatment area, performing a surface treatment of the other selective metal surface treatment areas, and removing the resist. A selective metal surface treatment apparatus used for performing the selective metal surface treatment process of the circuit board is also provided. Through the present invention, unnecessary waste of the materials in the process is reduced and the processing time is shortened.

Owner:UNIMICRON TECH CORP

Plugging device for sealing gap between glass curtain wall and civil wall

InactiveCN108756290AAvoid material wasteIncrease maintenance costsBuilding repairsPistonInternal cavity

The invention relates to the technical field of building equipment, and discloses a plugging device for sealing a gap between a glass curtain wall and a civil wall. The plugging device comprises a barrel. The left end of the barrel fixedly communicates with a discharging pipe. Fixing blocks are fixedly mounted at the left ends of the upper surface and the lower surface of an inner cavity of the barrel correspondingly. A partition plate is movably mounted on the side face between the two fixing blocks through a movable shaft. A moving rod is fixedly mounted on the left side face of the partition plate. A stabilizing sleeve rod is movably mounted at the other end of the moving rod in a sleeving mode. According to the plugging device for sealing the gap between the glass curtain wall and thecivil wall, a rotating rod rotates to adjust convex blocks to be in different mounting grooves, so that the size of a left side inner cavity of a material pushing piston is adjusted, the size of a polyurethane foam sealing agent injected into the inner cavity of the plugging device every time is controlled, the size of the polyurethane foam sealing agent used every time can be controlled artificially and precisely, the problem that the amount of the smeared polyurethane foam sealing agent is excessively high, consequently materials are wasted, and accordingly the maintenance cost is increasedis solved, and the practicability of the plugging device is improved.

Owner:蔡锁

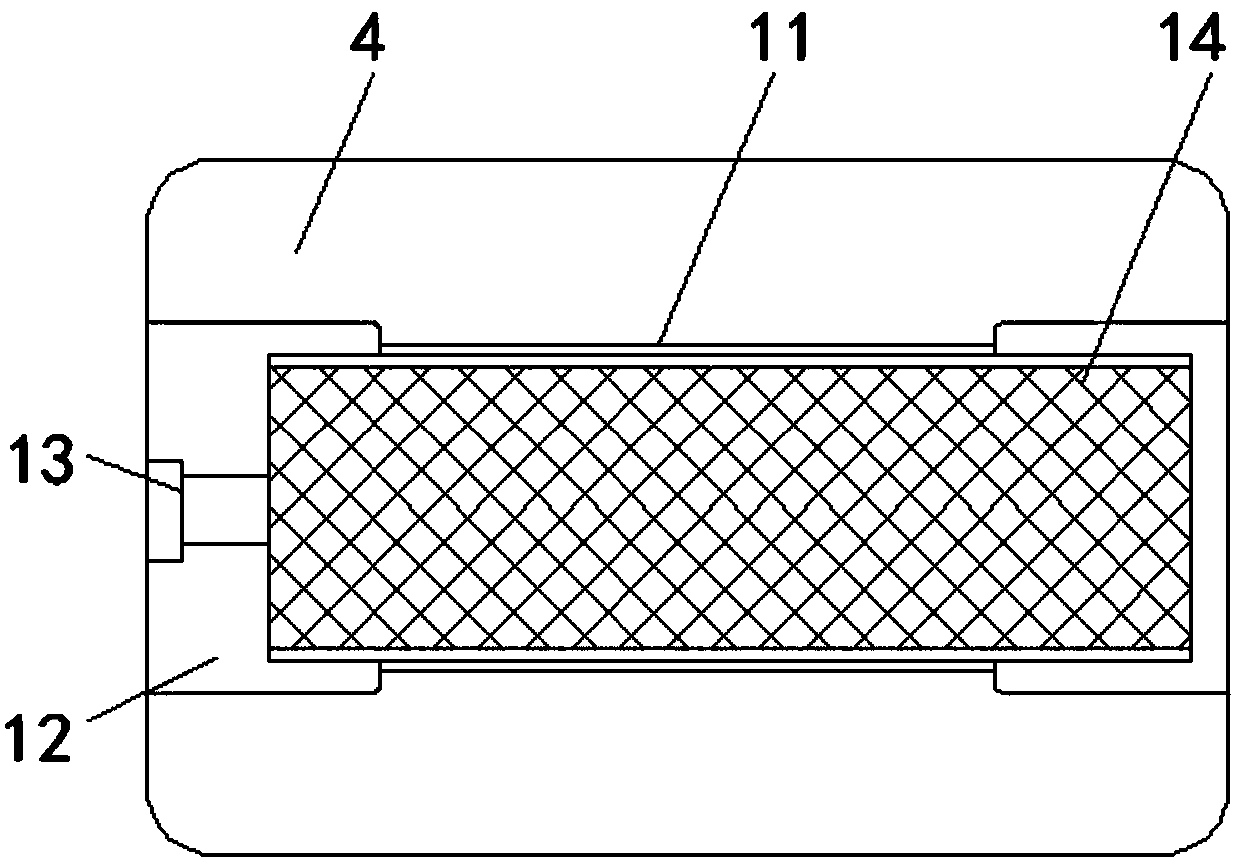

Grinding device for cosmetic production

The invention relates to the technical field of cosmetic manufacturing and discloses a grinding device for cosmetic production. The grinding device comprises an installation base. A shell is fixedly installed on the top of the installation base. The top of the shell communicates with a feeding bin. A grinding bin is fixedly installed on the top of an inner cavity of the shell. A supporting arm located on the top of the installation base is fixedly installed on the left side of the shell. A fixing transverse plate is fixedly installed on the top of the supporting arm. A hydraulic rod is fixedlyinstalled on the front surface of the fixing transverse plate. A driving motor extending to the top of the fixing transverse plate is fixedly installed on the top of the hydraulic rod. A rotating rodpenetrating and extending in the grinding bin is fixedly installed at the position of an output shaft of the driving motor. By means of the grinding device for cosmetic production, a baffle is arranged, a material receiving bin is arranged in the shell, the baffle can has an isolating effect on materials in the process that the materials flow towards a material receiving bin, the materials are prevented from being deposited in the shell, and material waste is avoided.

Owner:MYC PACKAGING TECH (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com