Patents

Literature

84results about How to "Avoid waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

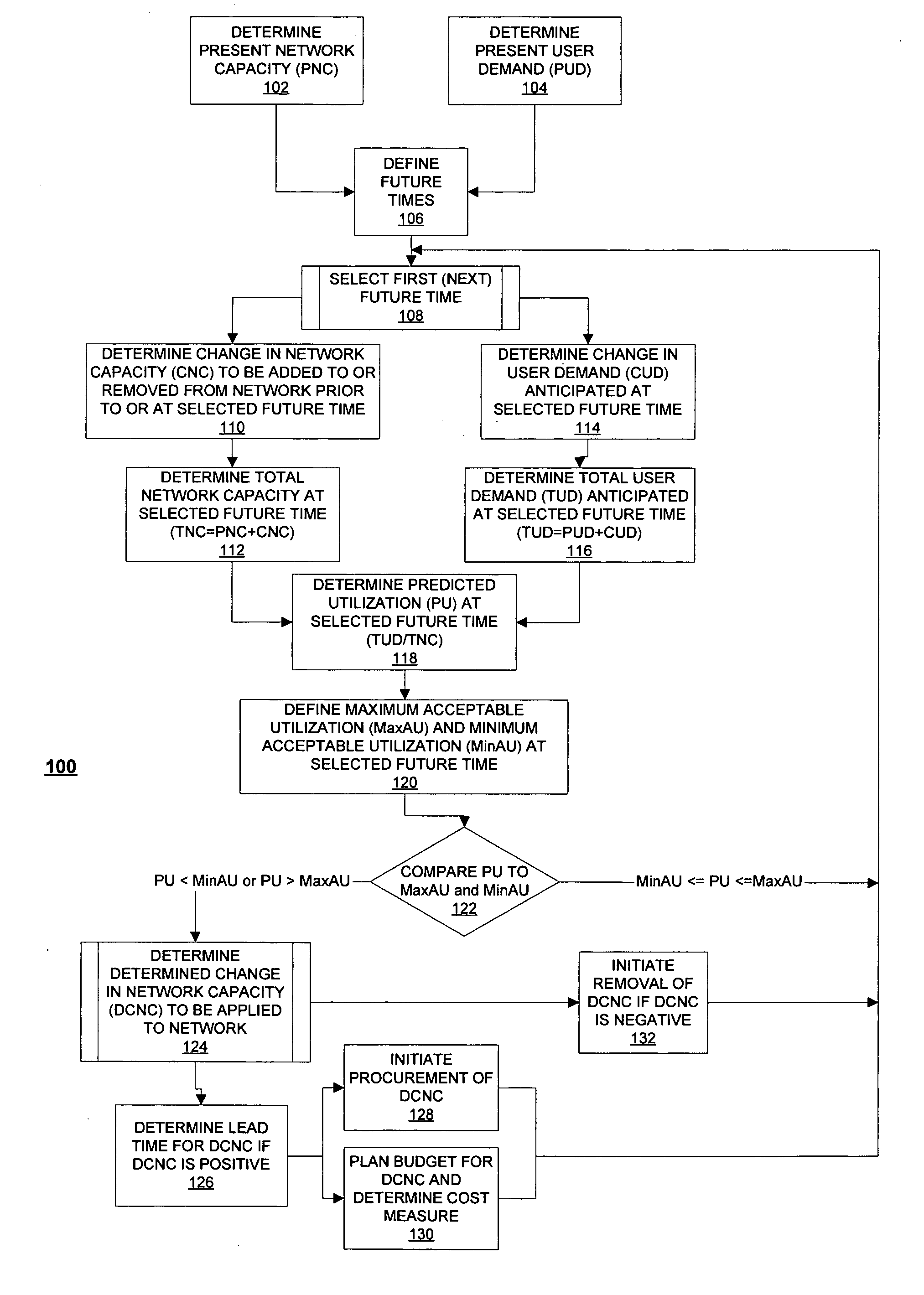

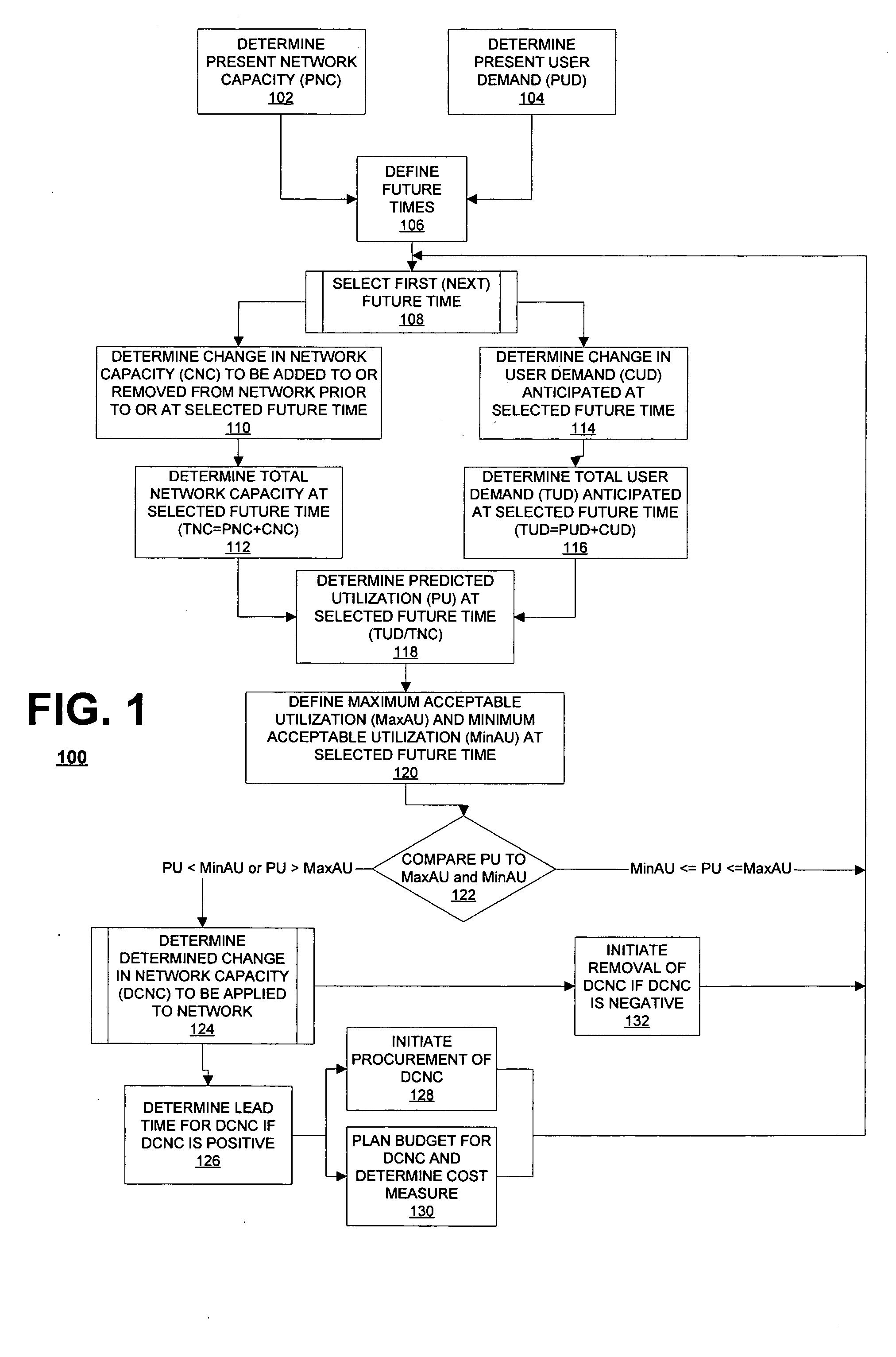

System and method for predicting and managing network capacity requirements

ActiveUS20050132051A1Avoid wasteIncreased user demandDigital computer detailsData switching networksUtilization rateSimulation

A system and method for maintaining capacity of a network. Instructions are adapted to define future times at which a capacity of the network is evaluated. In addition, instructions are adapted to determine a total capacity of the network (TNC) and a total demand of users (TUD) for the network at each of the future times. As a function of the total capacity of the network (TNC) and the total demand of users (TUD), instructions are adapted to determine a predicted utilization (PU) of the network at each of the future times. By comparing the predicted utilization (PU) to a defined acceptable utilization of the network at each of the future times, instructions are adapted to determine a change in network capacity (DCNC) to be applied to the network at each of the future times in order to increase or decrease the capacity of the network.

Owner:CALLAHAN CELLULAR L L C

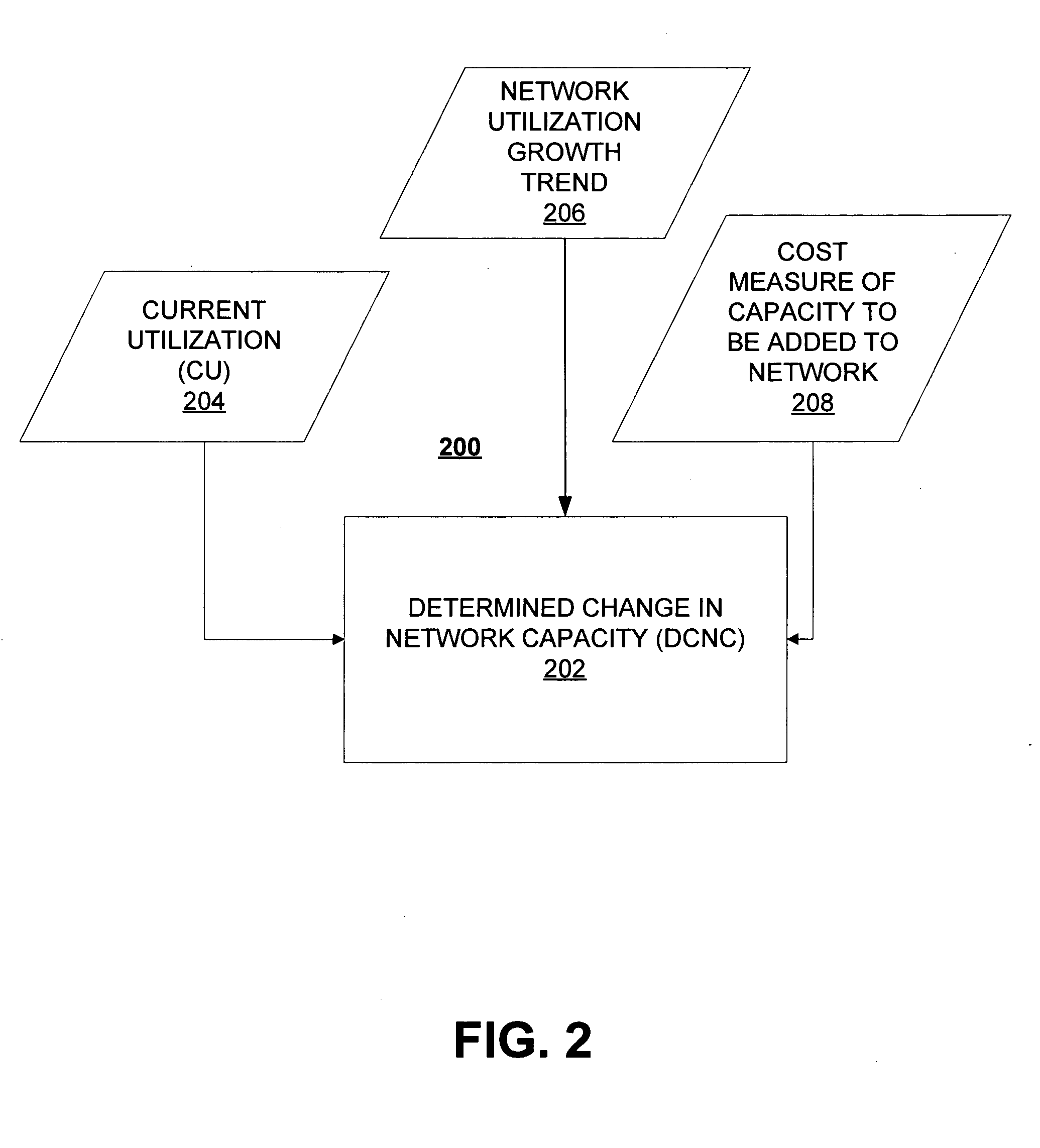

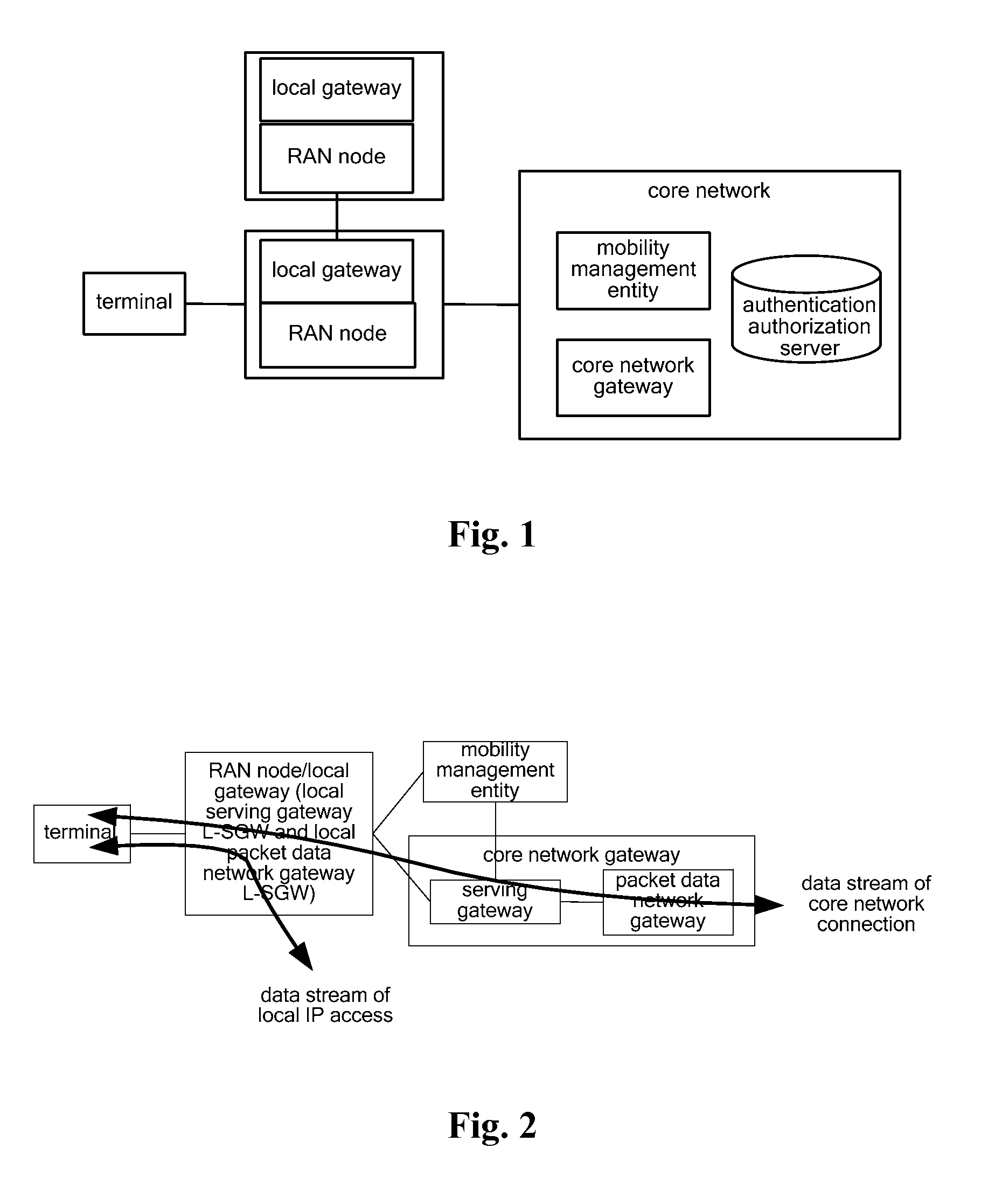

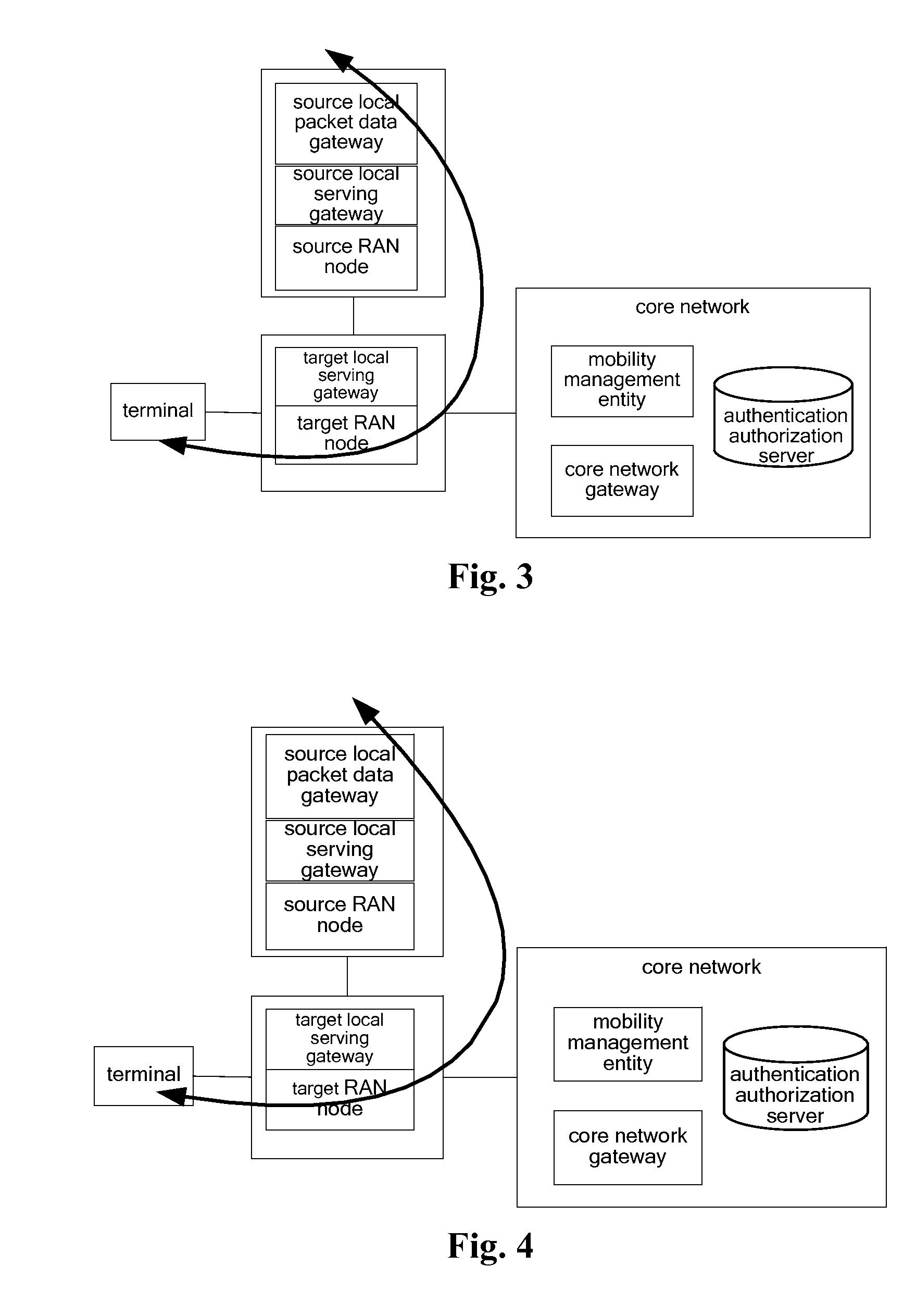

Method for Managing Local IP Access Connection

InactiveUS20120207137A1Improve processing efficiencyAvoid wasteNetwork traffic/resource managementAssess restrictionMobility managementMobile communication systems

Disclosed is a method for managing local IP access connection, wherein the method comprises: determining whether a local IP access connection supports mobility; if yes, then processing the local IP access connection, wherein the processing includes at least one of the following: activate, establish and update. According to the present invention, the source / target mobility management entity or source / target RAN node determines whether a local IP access connection supports mobility according to a CSG identifier or local gateway information, which thus achieves the management operation on the local IP access connection, avoids the waste of system resources and the increasing of system burden and improves the processing efficiency of the mobile communication system.

Owner:ZTE CORP

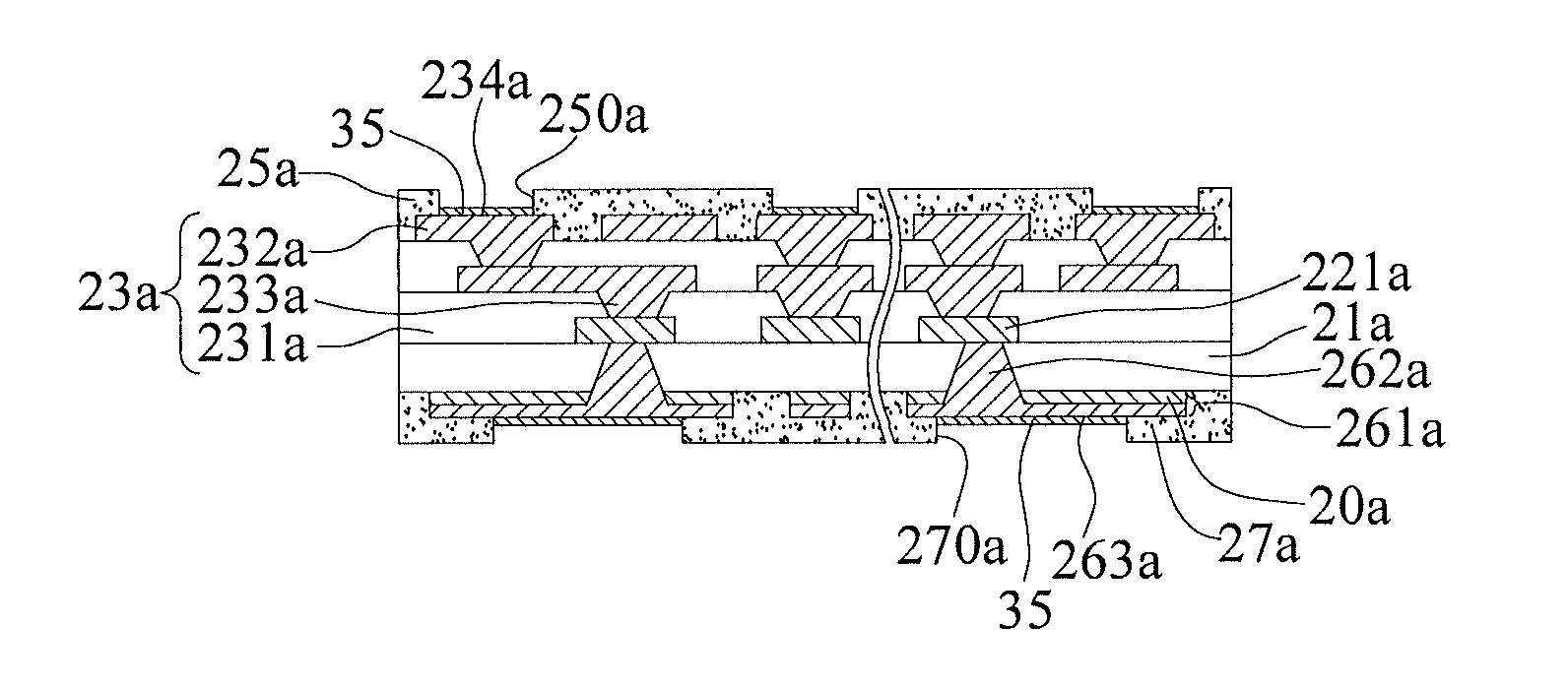

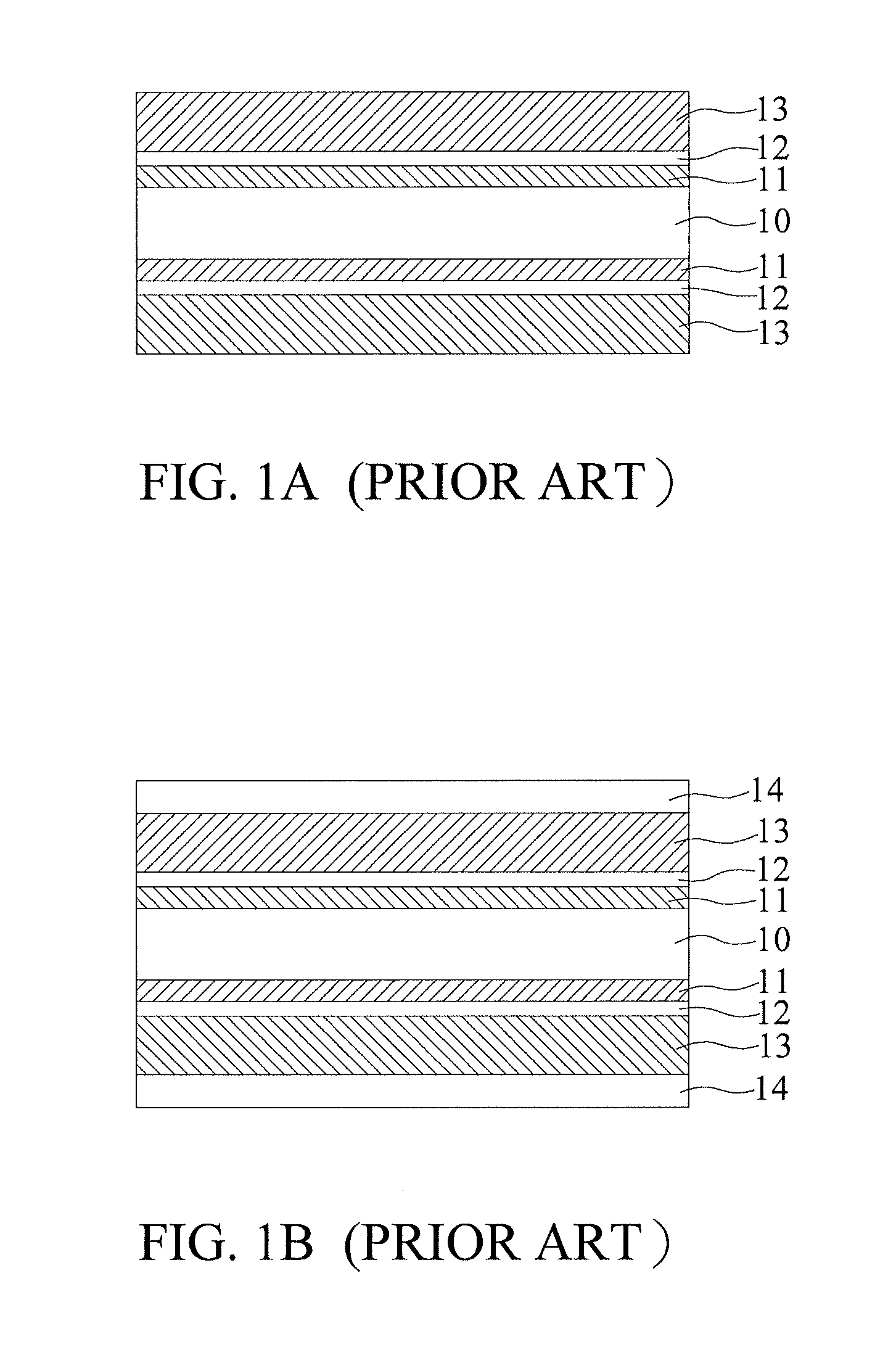

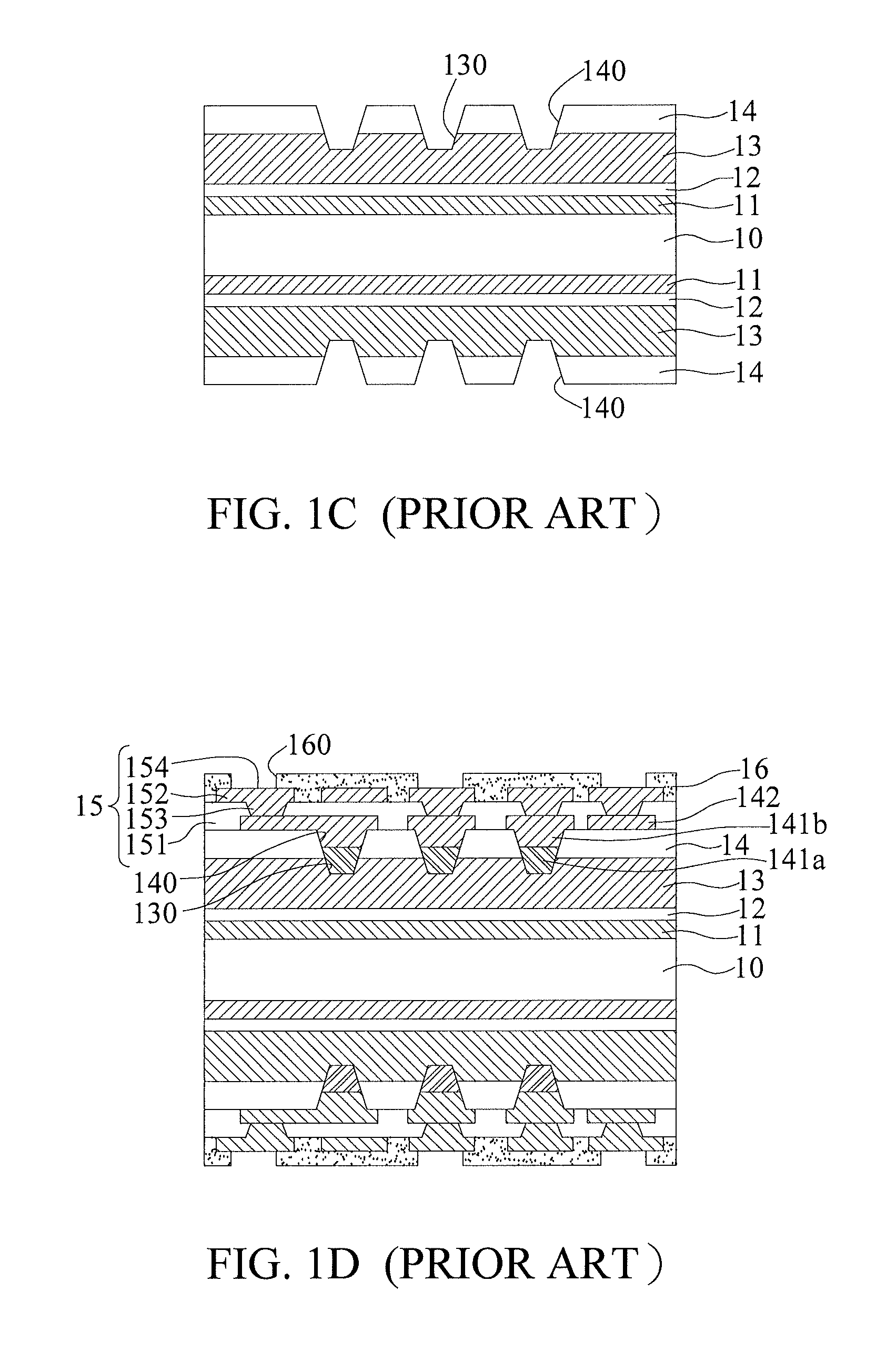

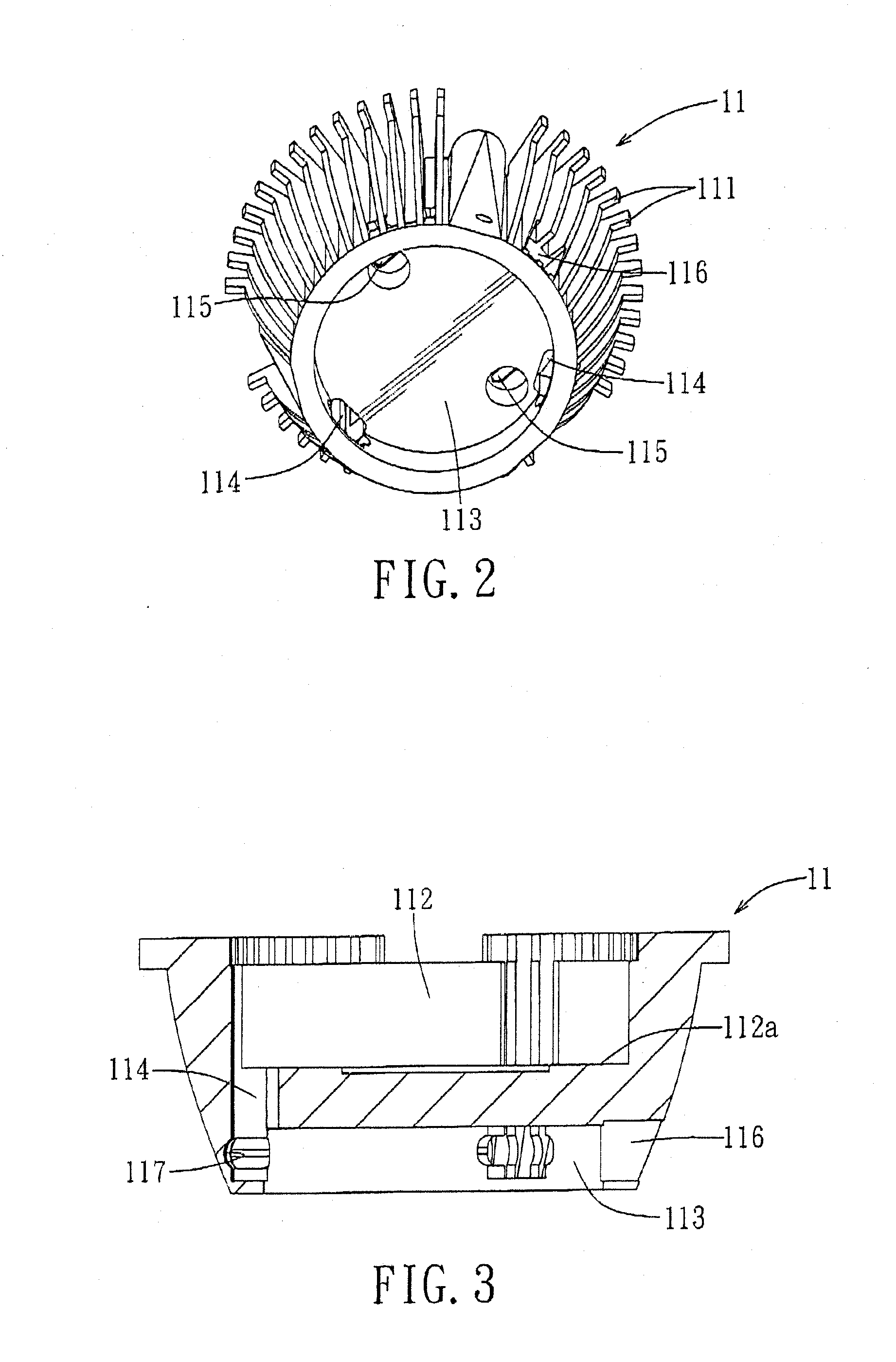

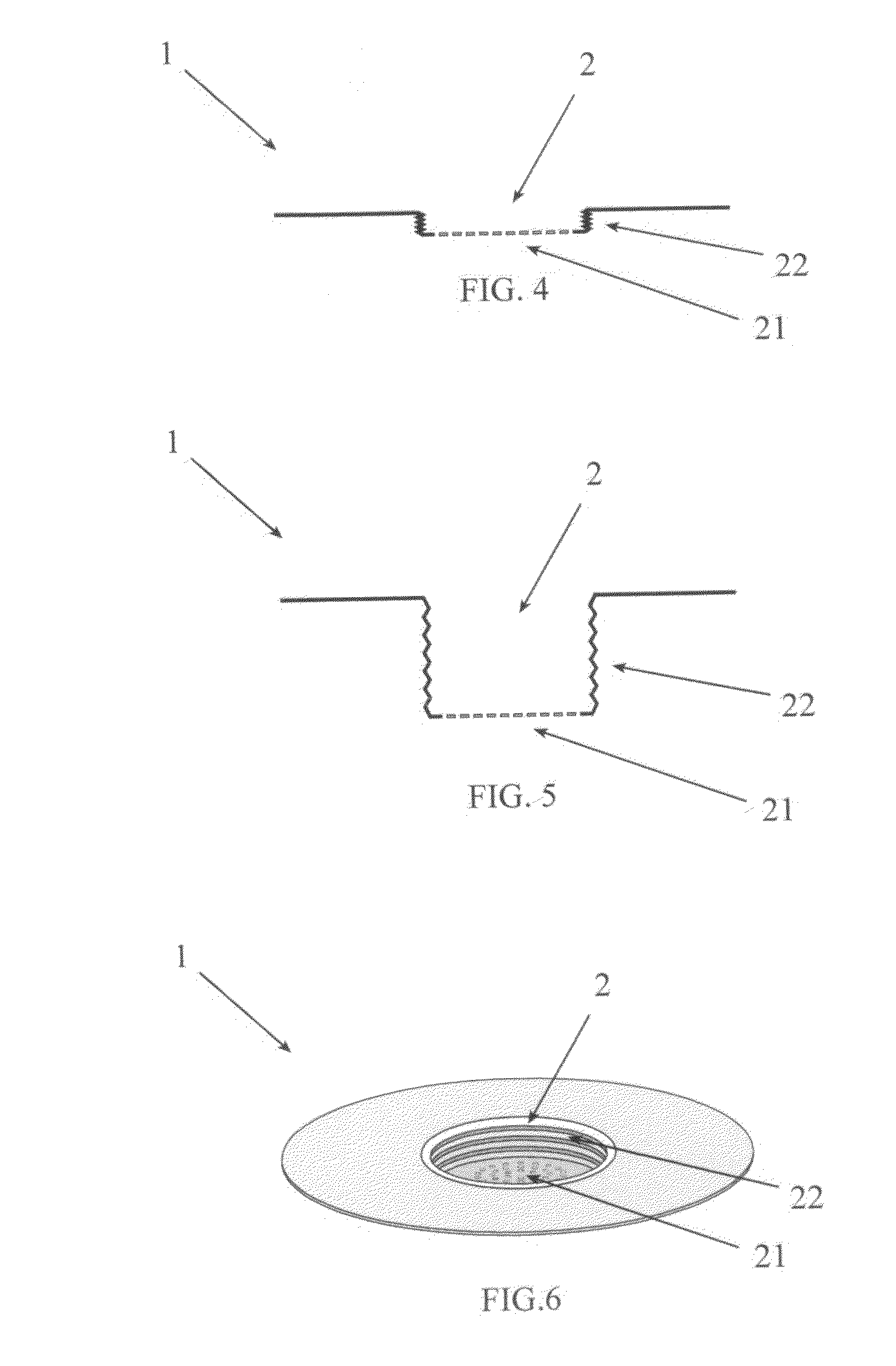

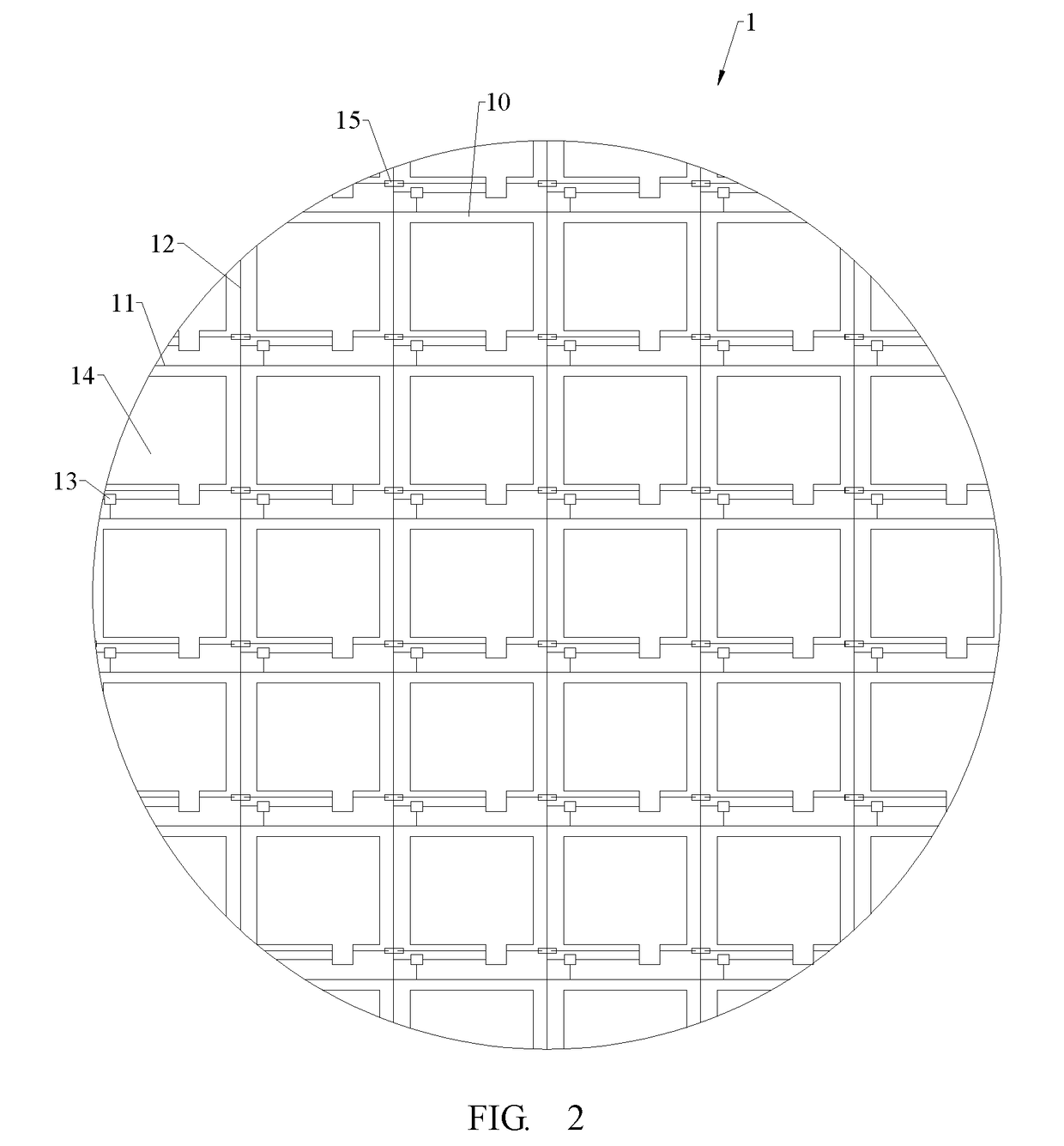

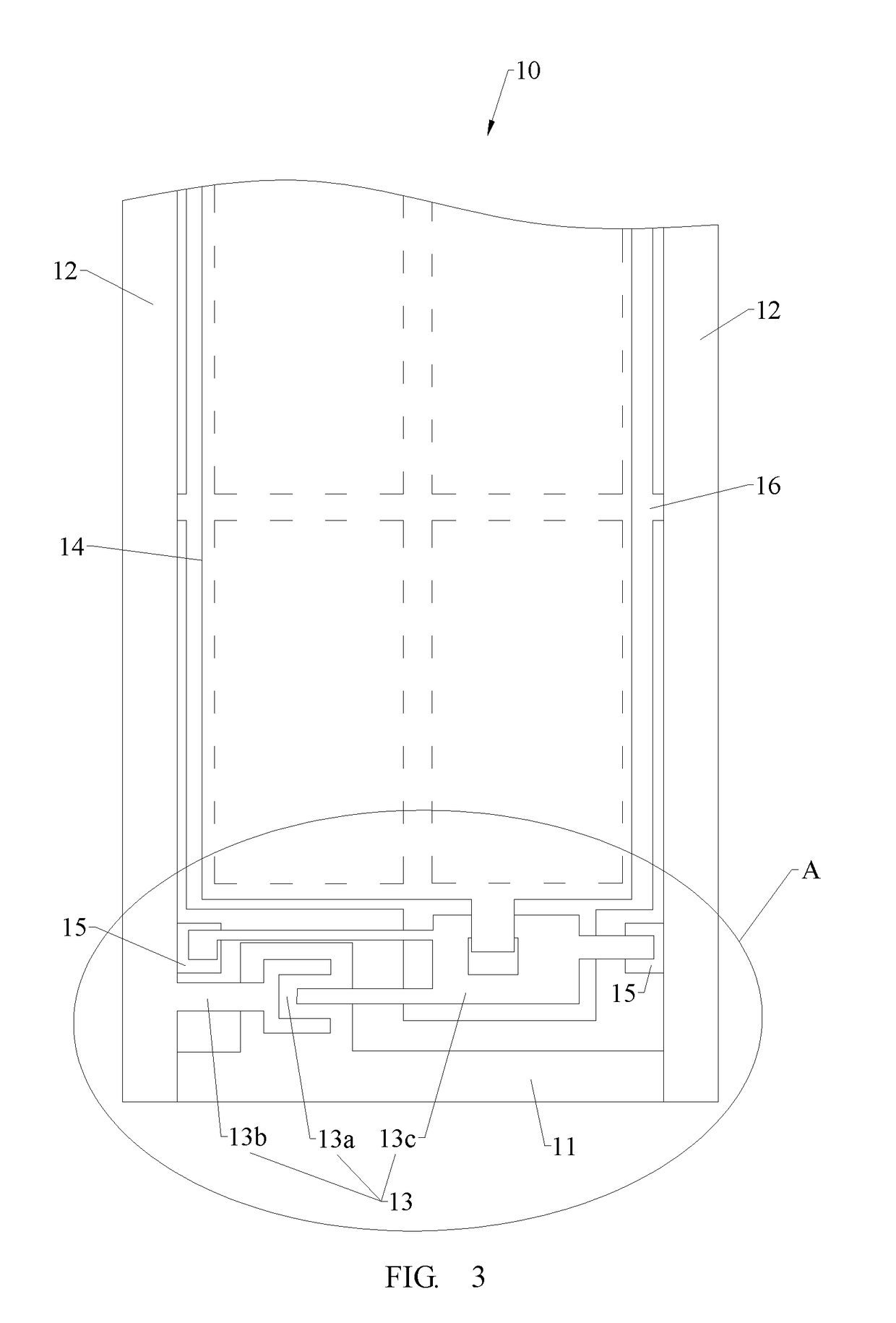

Packaging substrate and fabrication method thereof

ActiveUS20100319966A1Readily separateAvoid wasteLamination ancillary operationsPaper/cardboard articlesMetalDielectric layer

A method for fabricating a packaging substrate includes: stacking two metal layers; encapsulating the two metal layers with assistant dielectric layers; forming built-up structures on the assistant dielectric layers, respectively; and separating the built-up structures along the interface between the two metal layers so as to form two packaging substrates. Owing to the adhesive characteristic of the assistant dielectric layers, the two metal layers are unlikely to separate from each other during formation of the built-up structures. But after portions of the dielectric layer around the periphery of the metal layers are cut and removed, the two metal layers can be readily separated from each other. The two metal layers can be patterned to form wiring layers, metal bumps, or supporting structures to avoid waste of materials. A packaging substrate and a fabrication method thereof are provided.

Owner:UNIMICRON TECH CORP

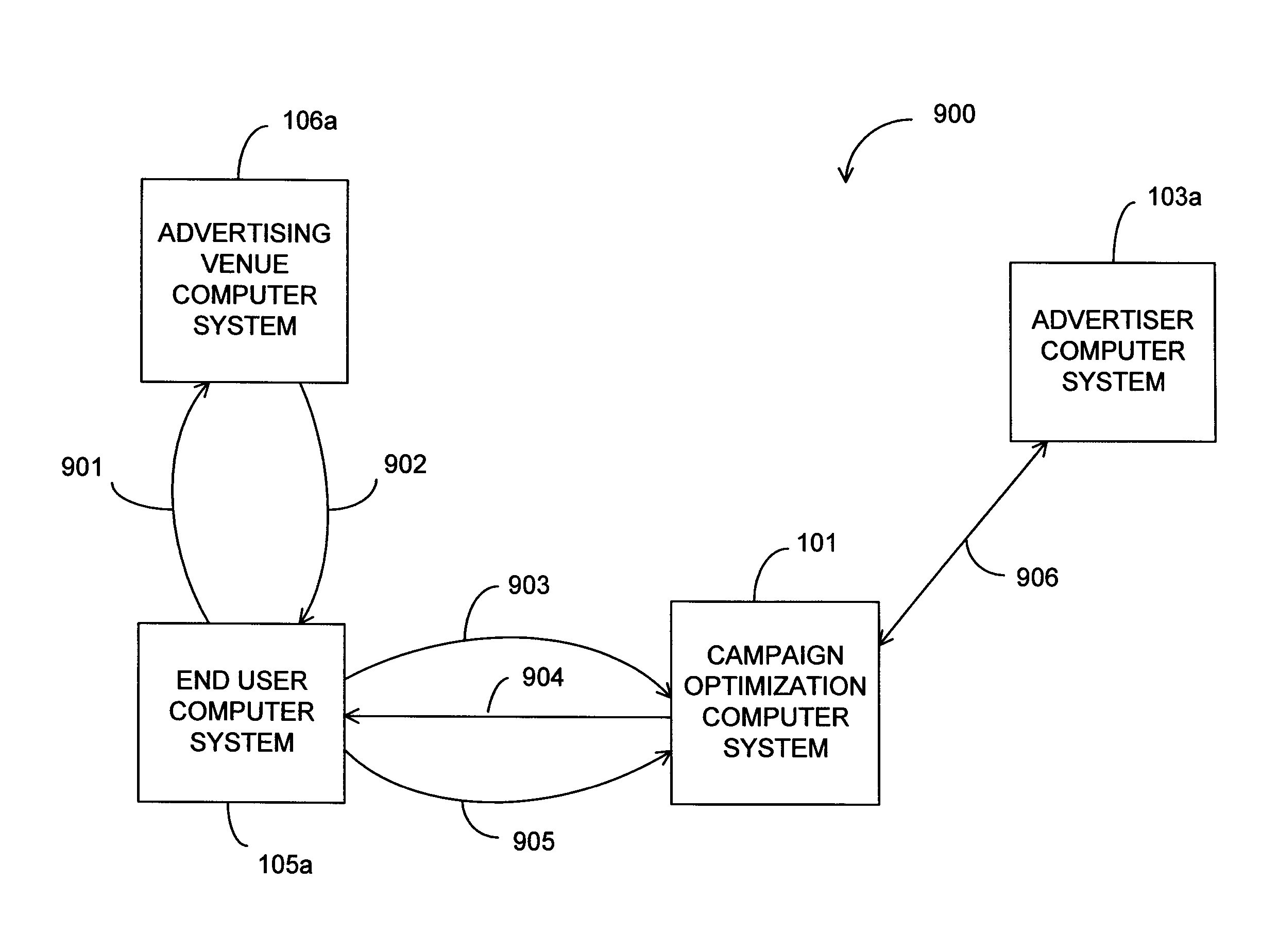

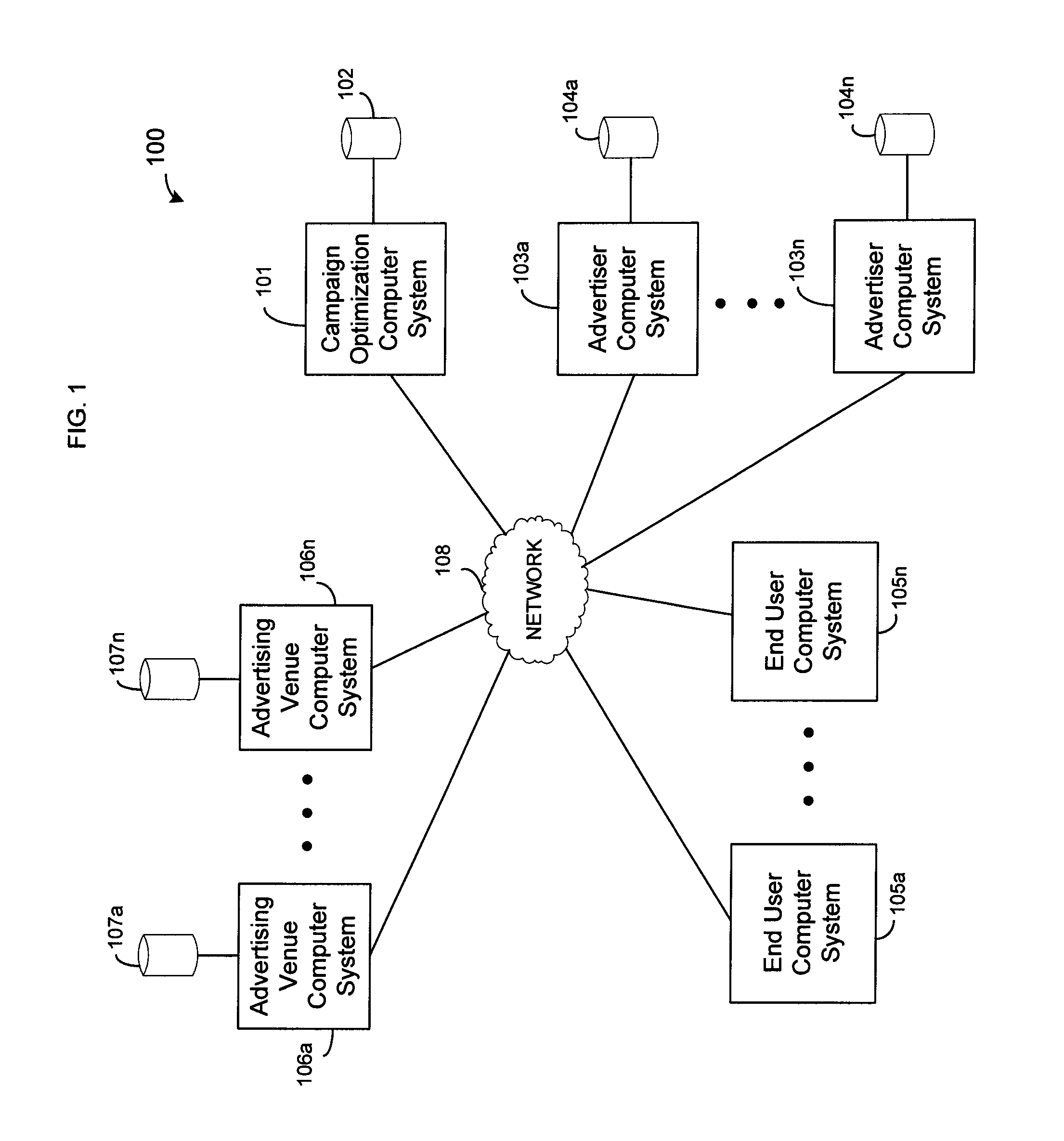

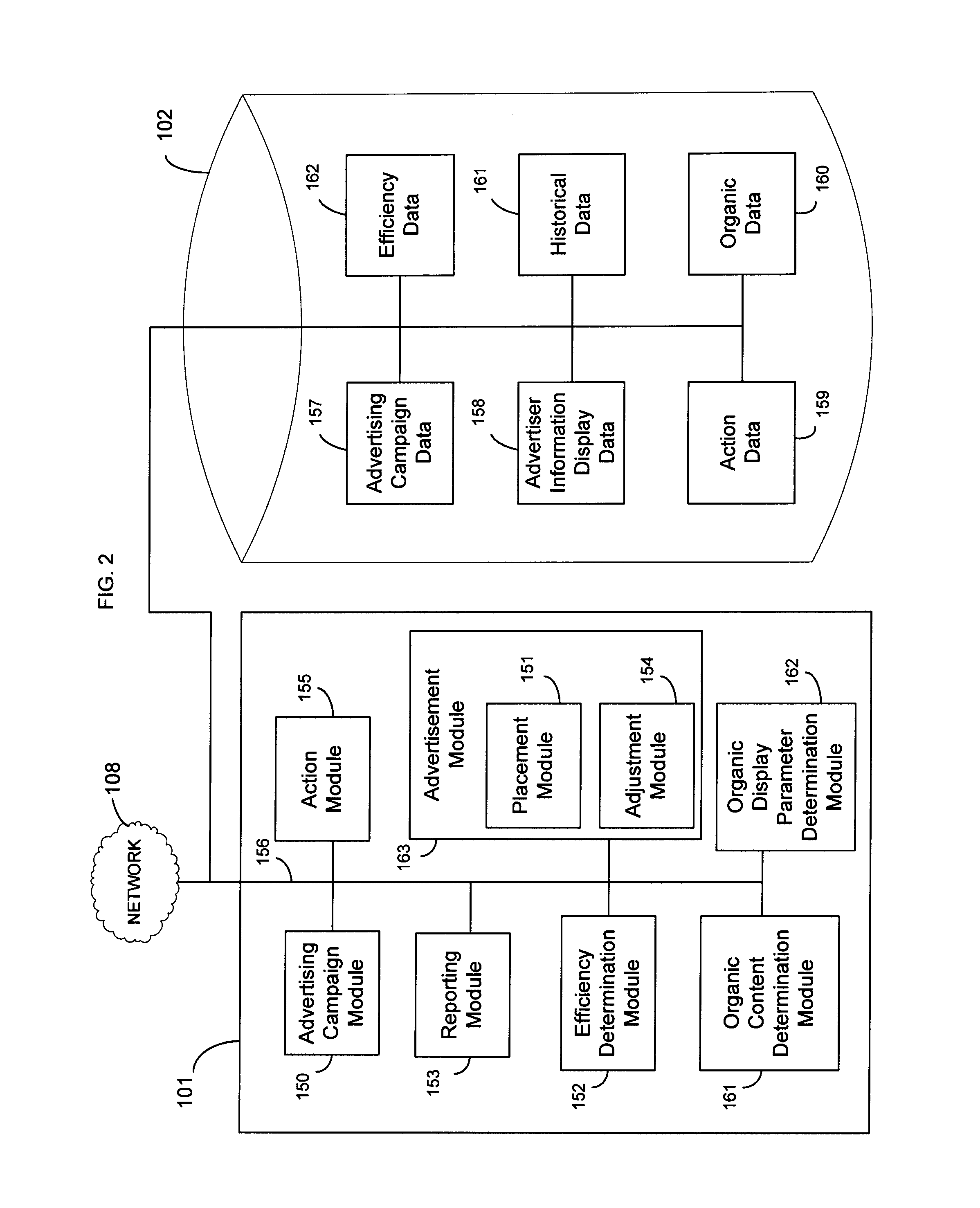

Systems and methods for optimizing an electronic advertising campaign based on organic content

A system and method for optimizing an electronic advertising campaign based on organic content by determining organic content of an advertising venue display, determining an organic display parameter for an advertisement based on organic content of the display, and adjusting one or more advertising parameters based at least in part on the organic display parameter. The advertising parameters may comprise one or more keywords, one or more advertising venues, one or more placement values, the content of the advertisement, or any other parameter.

Owner:METRIX4MEDIA

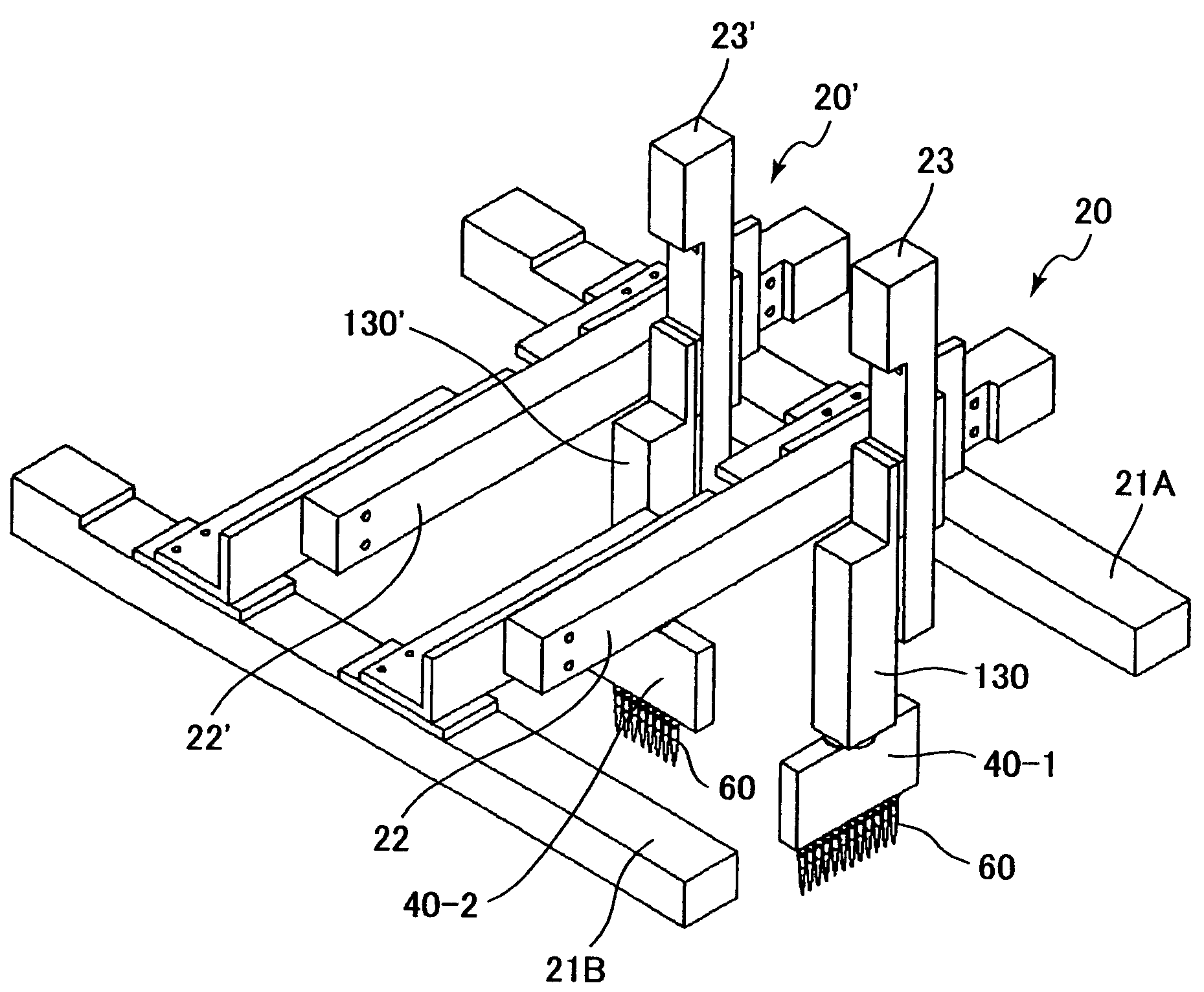

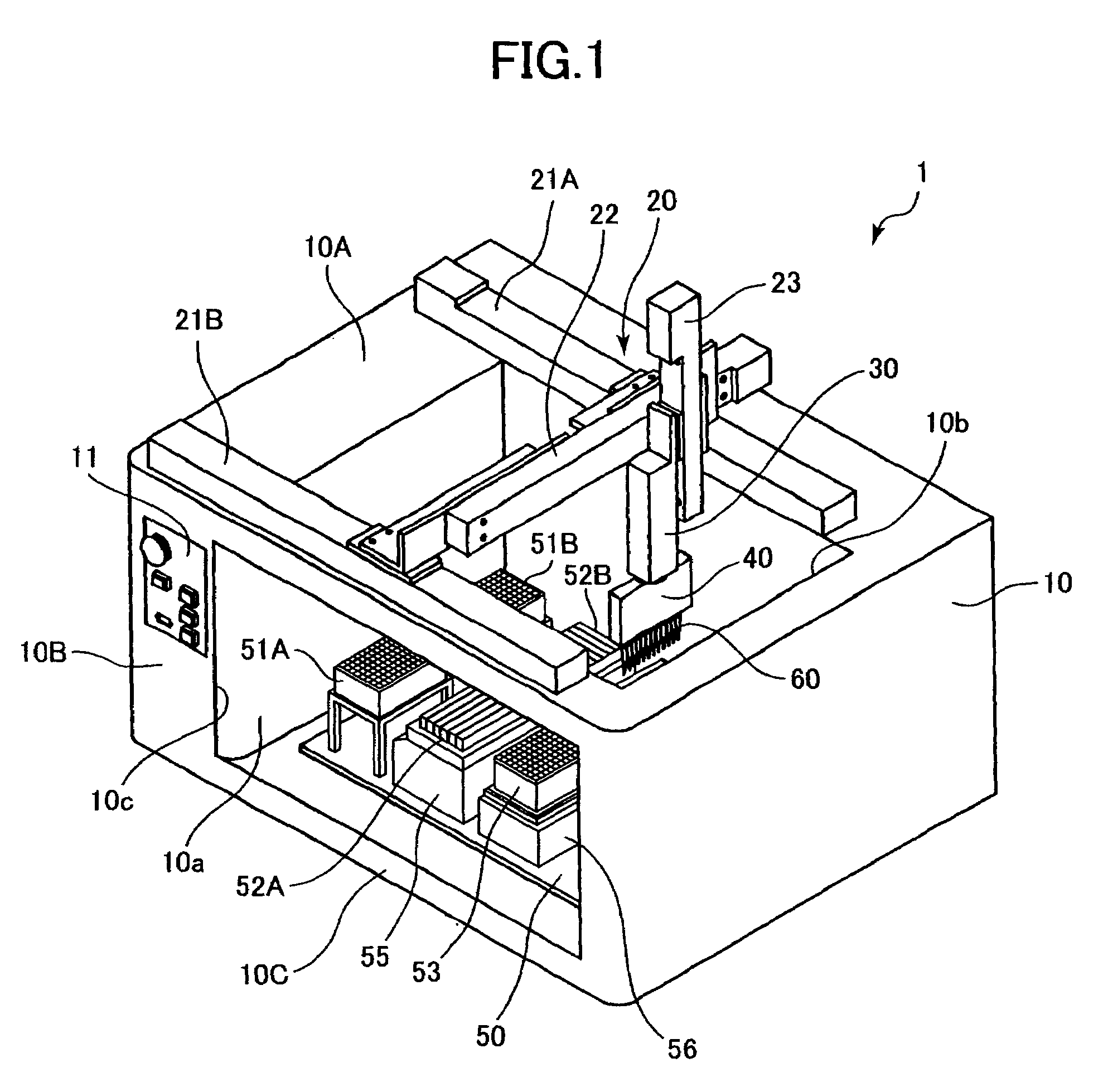

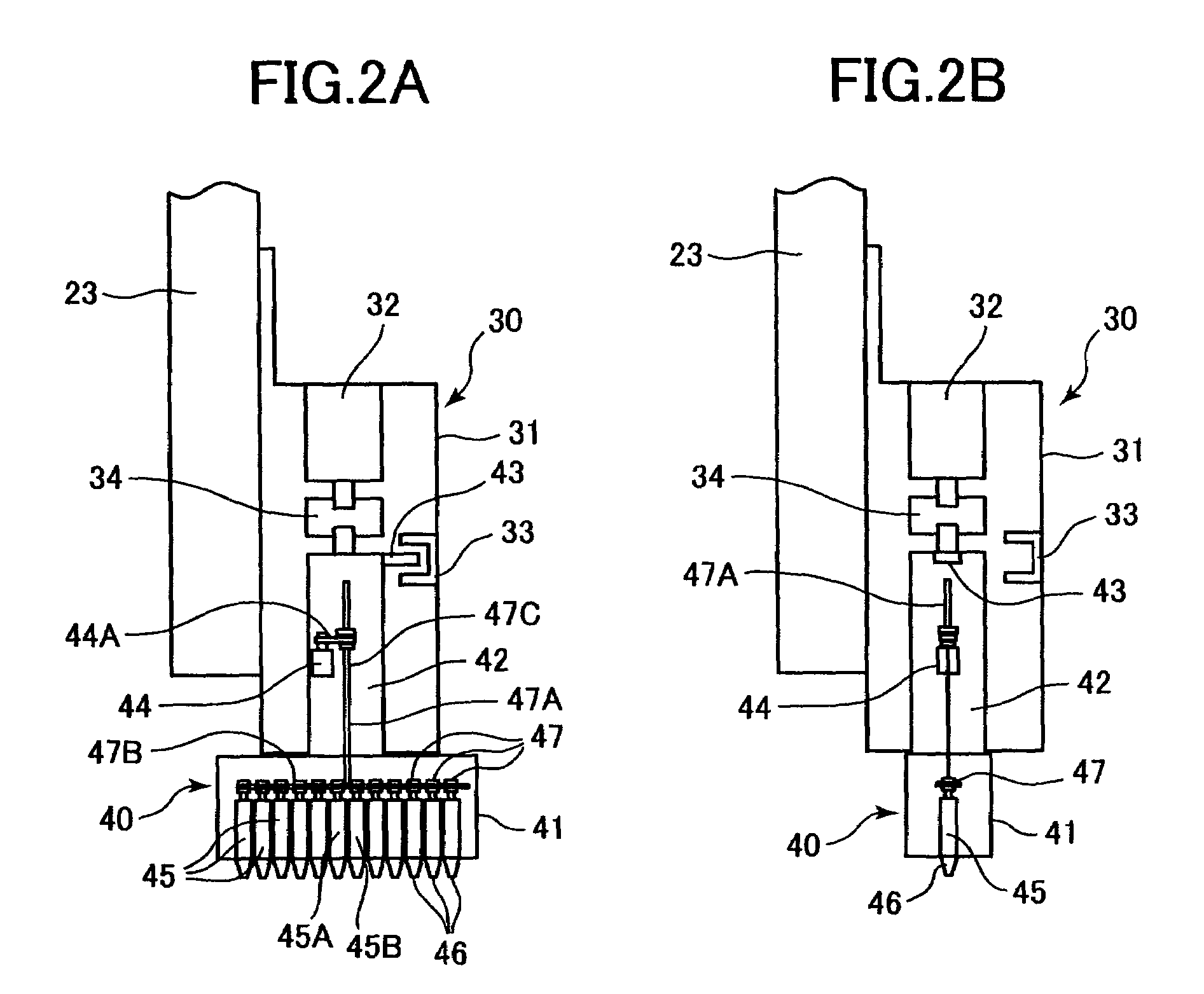

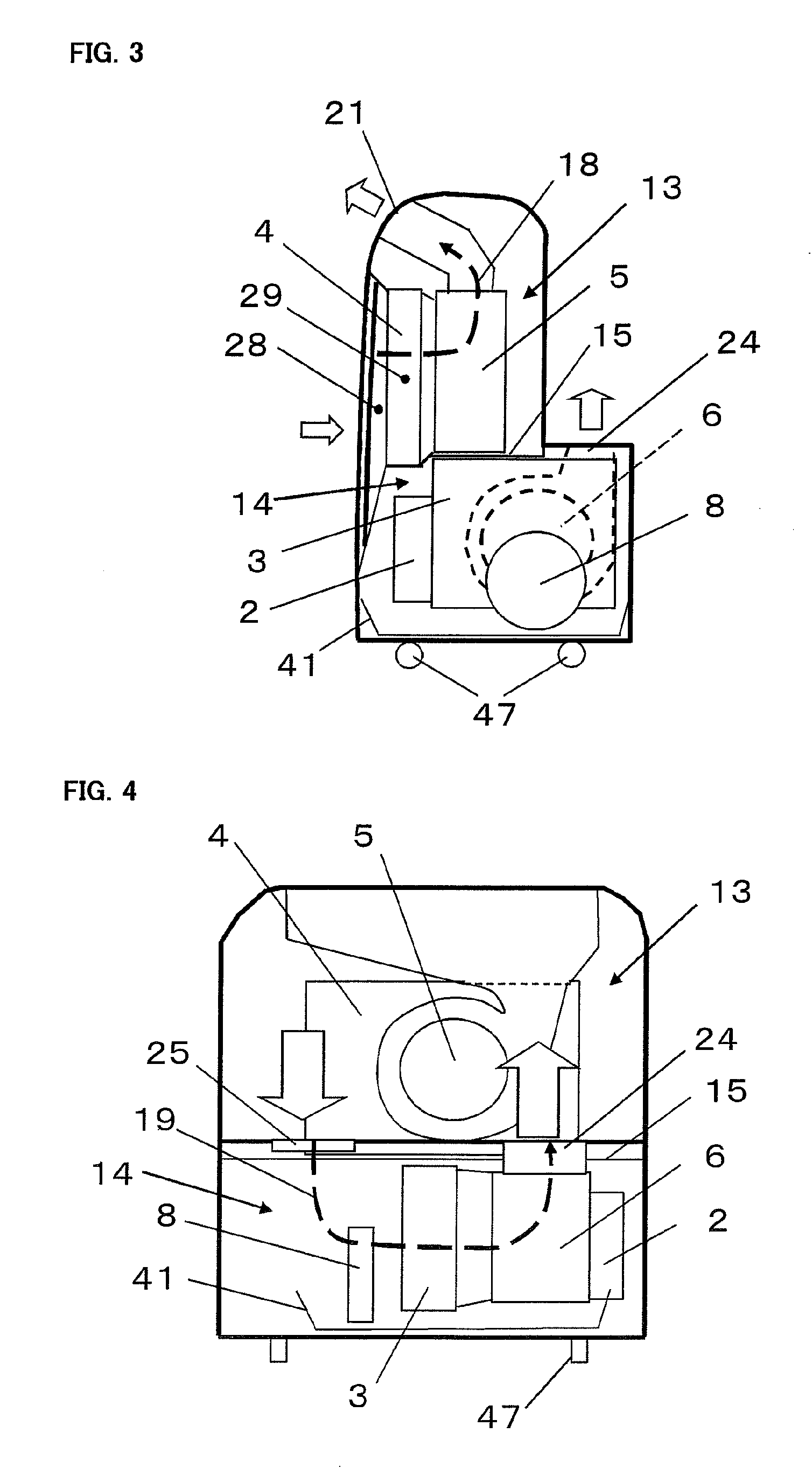

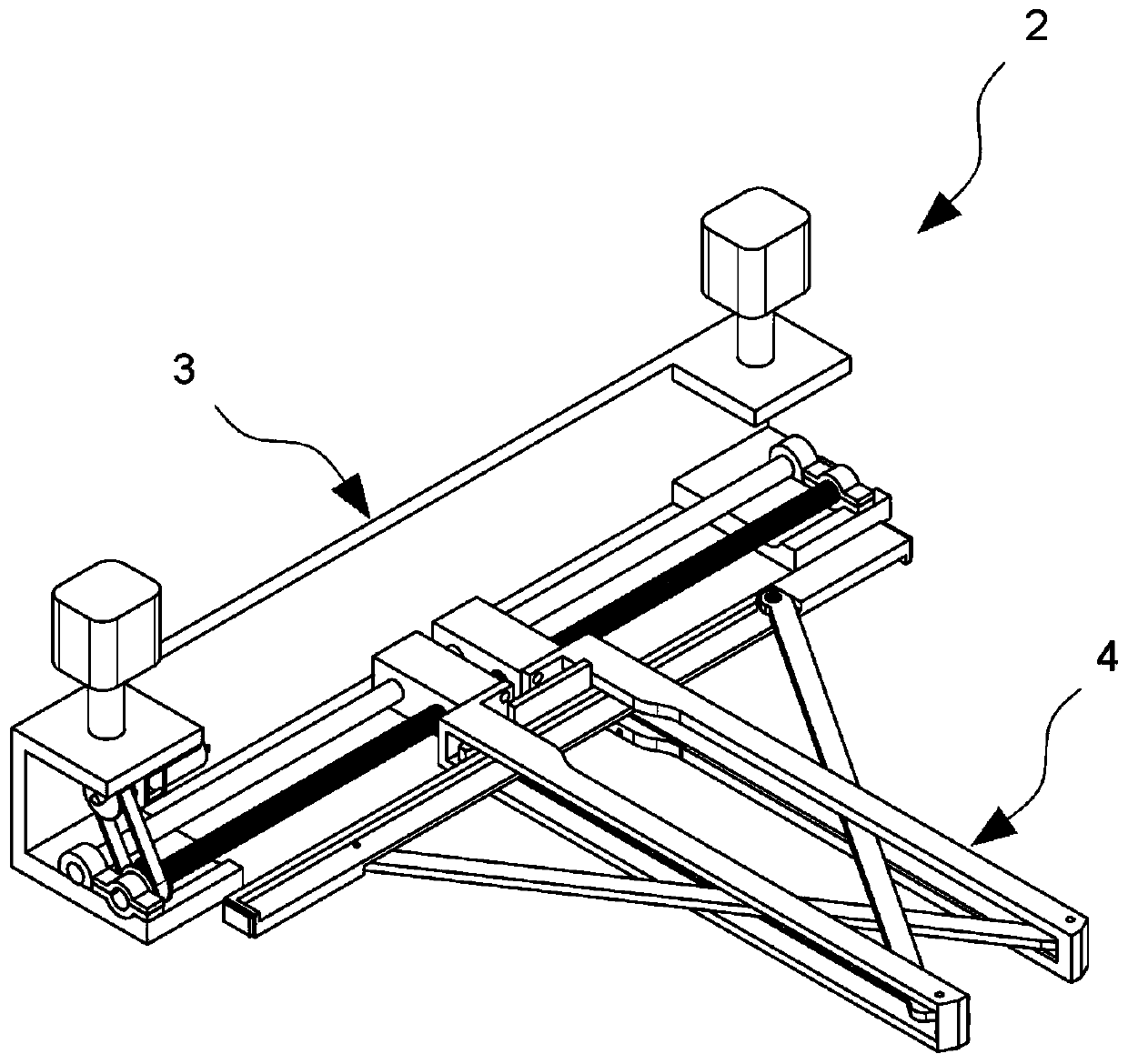

Microplate liquid handling system

InactiveUS7169362B2Avoid wasteMinimal timeChemical analysis using titrationMaterial analysis by optical meansMicrowell PlateMechanical engineering

A microplate liquid handling system requiring minimum installation area, helping to avoid waste of various reagents, and making it possible to perform dispensing the various reagents in the shortest possible time. The microplate liquid handling system has a main frame body provided with a moving mechanism, a dispensing mechanism, and a stage. On the stage, a microplate, two dispensing tip containers, and two reagent vessels are mounted. Formed in the microplate are 12×8 wells, i.e., 96 wells in total, arranged in matrix. The microplate, the dispensing tip containers, and the reagent vessels are substantially of the same, rectangular configuration. Each of the two dispensing tip containers is capable of accommodating 12×8 dispensing tips in total in a matrix fashion.

Owner:HITACHI KOKI CO LTD

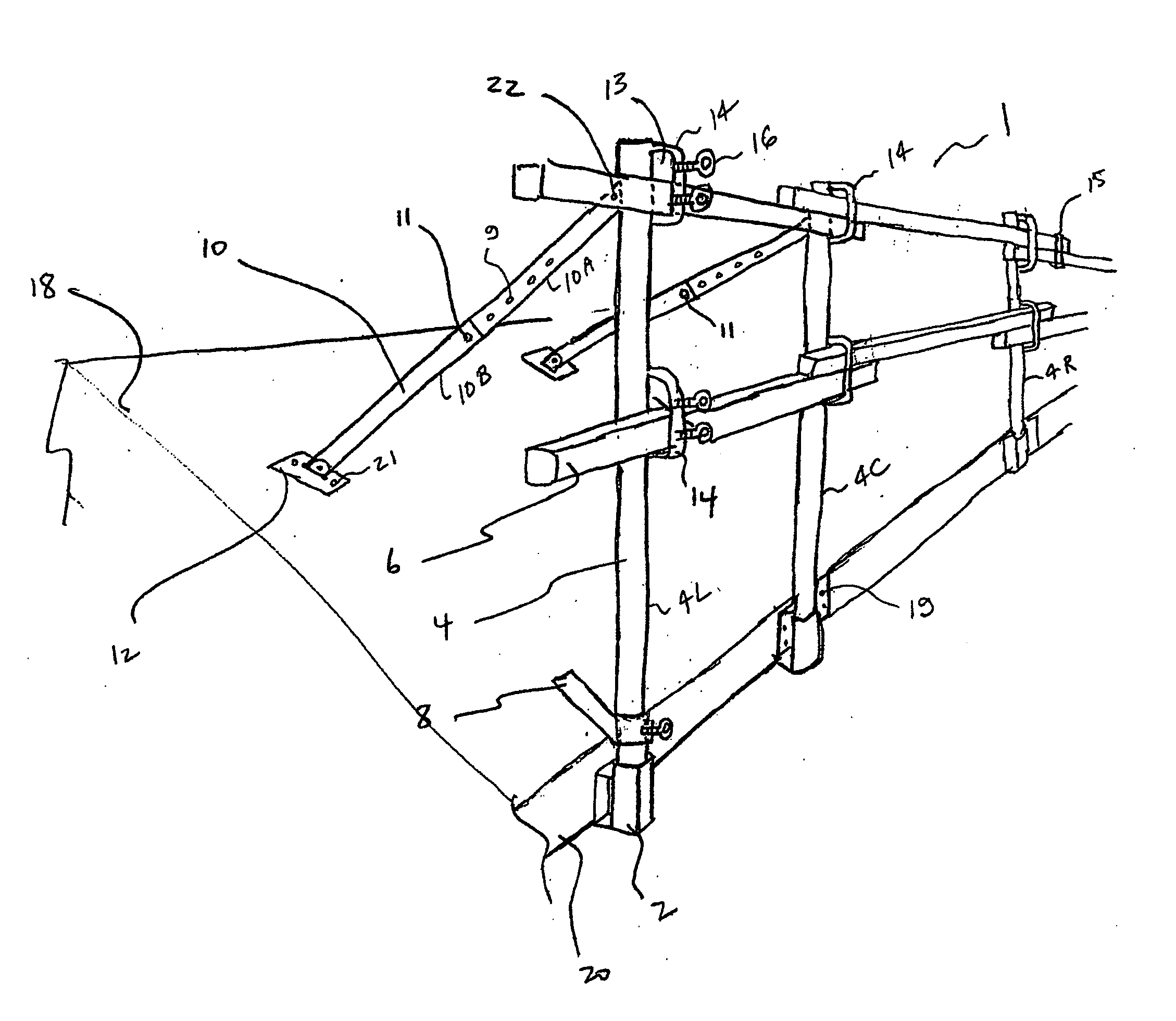

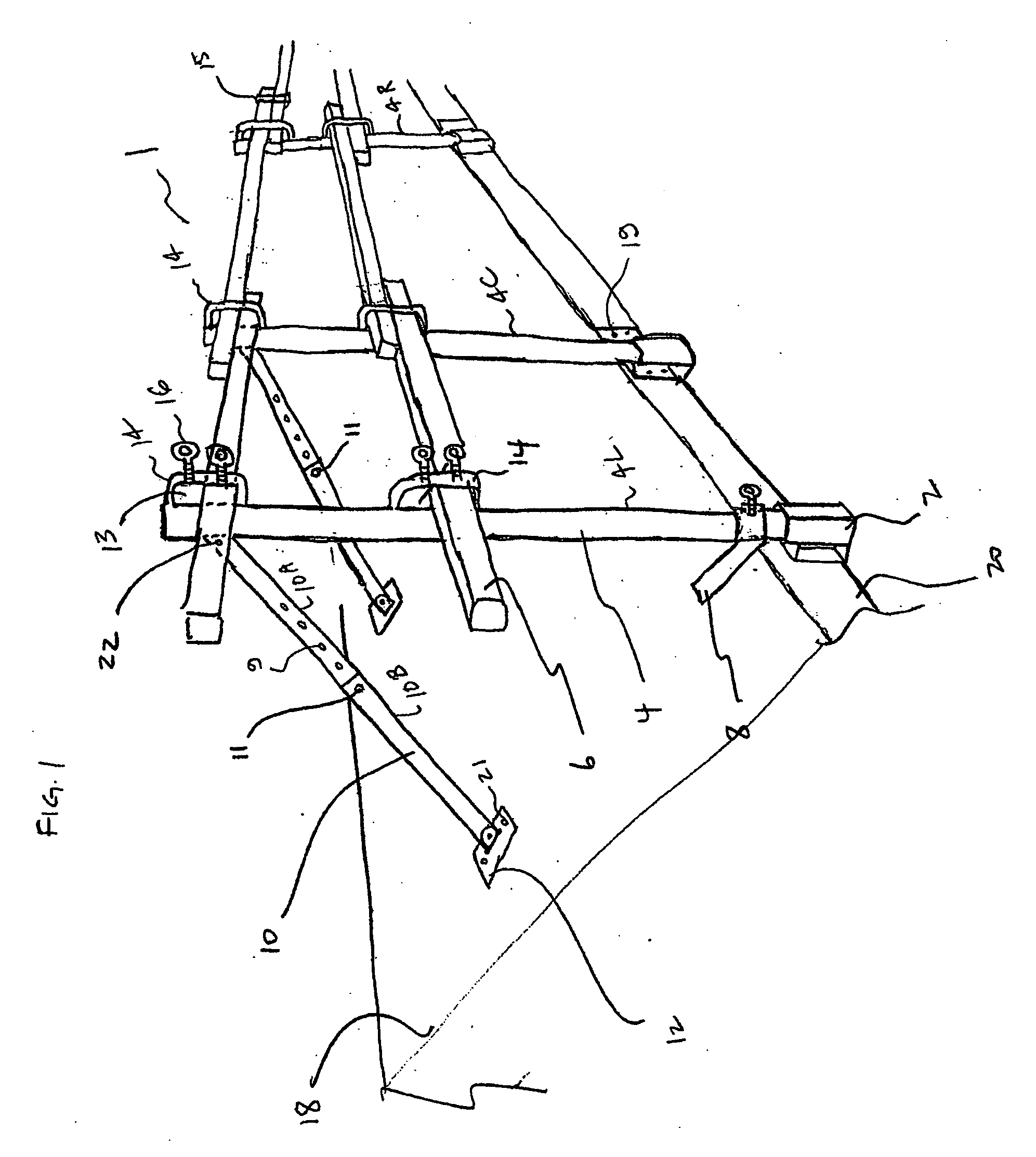

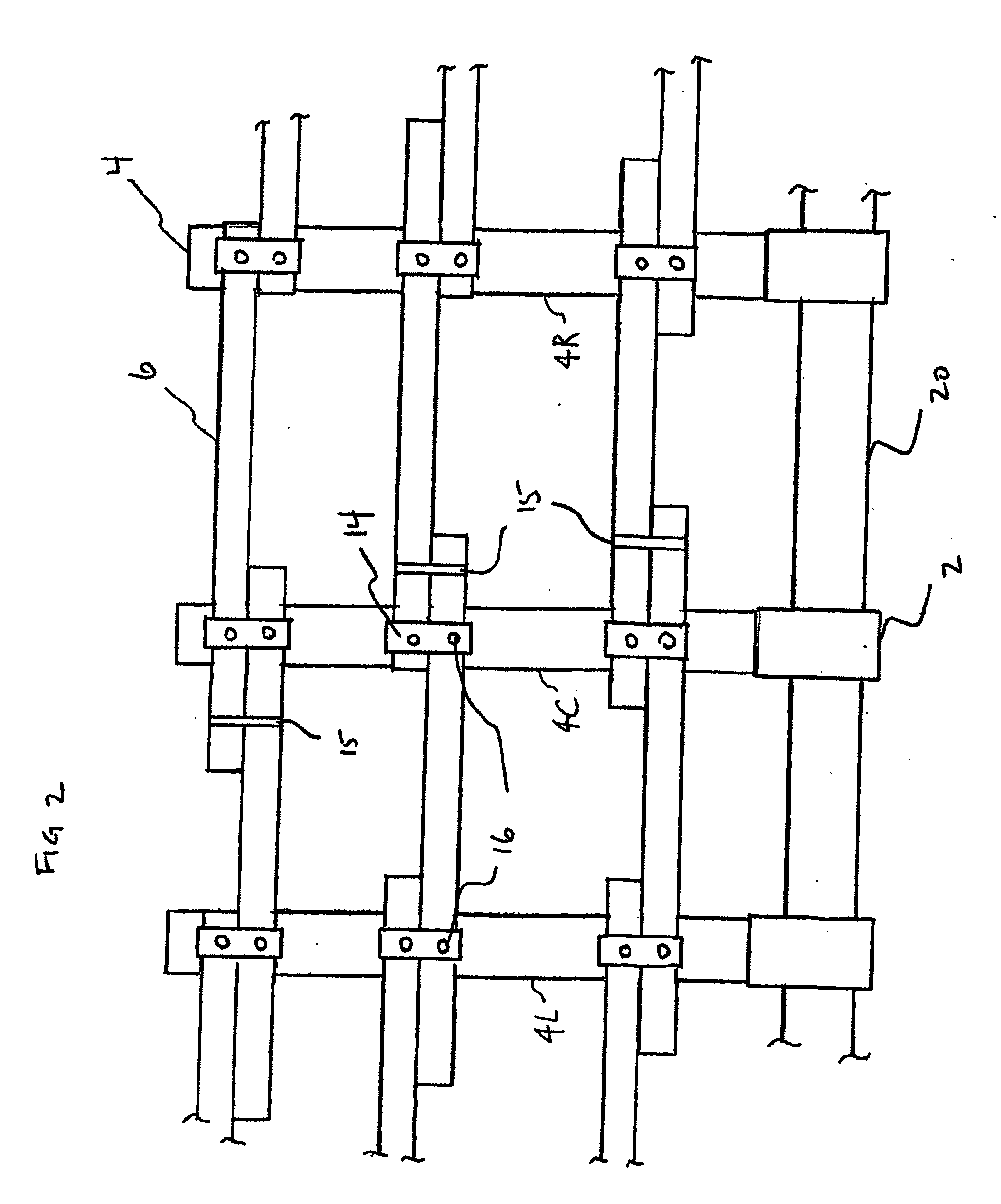

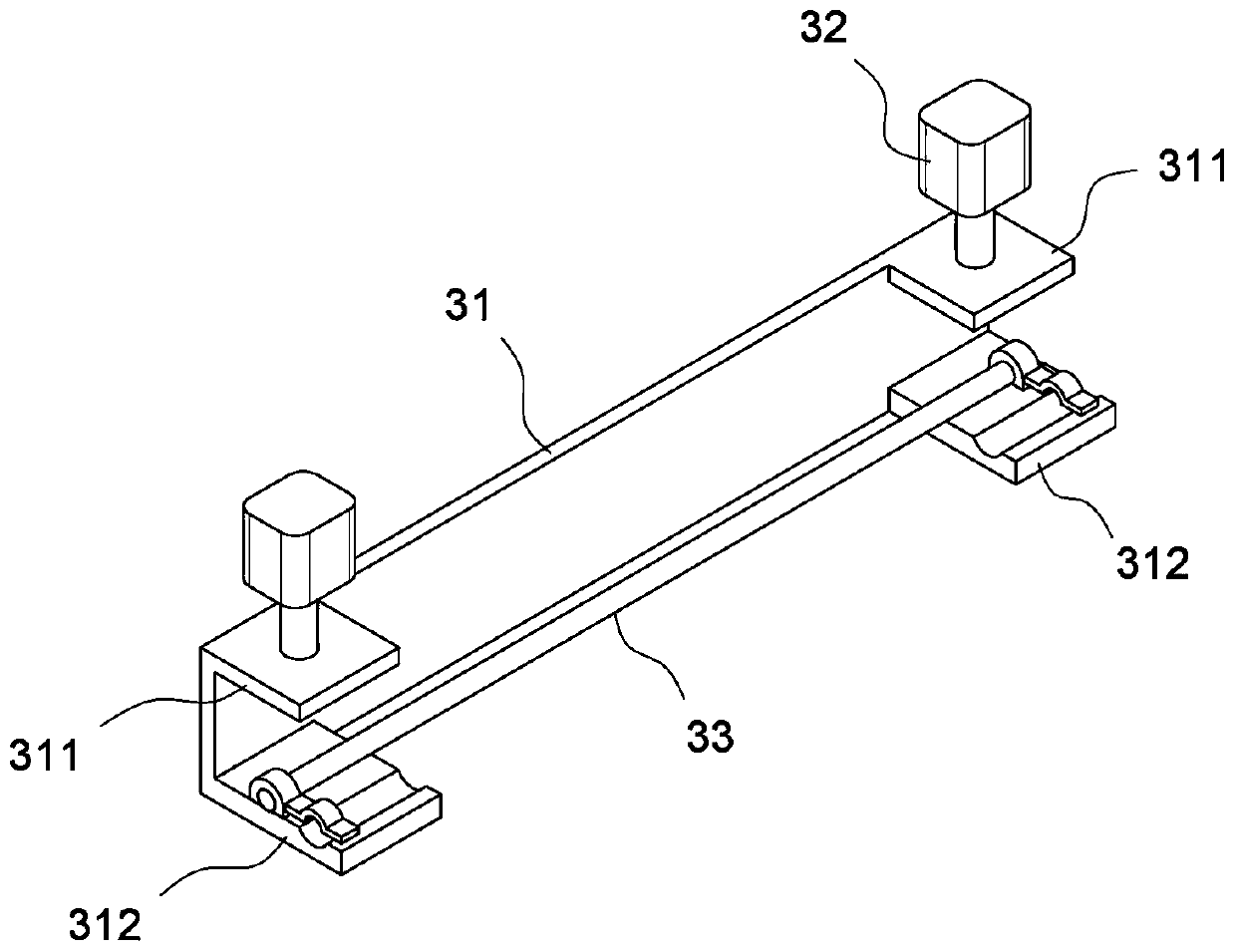

Modular safety railing system

InactiveUS20060054393A1Avoid wasteEasily erectWindow cleanersBuilding material handlingModularityEngineering

A modular safety railing system comprises post brackets adapted for attachment to a building structure. Posts are adapted to engage the post brackets the posts are oriented substantially vertically. Upper and lower rail mounts are located on each post and right and left upper and lower rails are releasably attachable at inner portions thereof to corresponding upper and lower rail mounts of a center post and are releasably attachable at outer portions thereof to upper and lower rail mounts of corresponding right and left posts. An upper brace is attached at an upper end thereof to the post and adapted at a lower end thereof for releasable attachment to the building structure. The upper brace is adjustable such that same can be attached to the building structure at an angle to the center post that is sufficient to support the center post in the substantially vertical orientation.

Owner:EISENKREIN LARRY

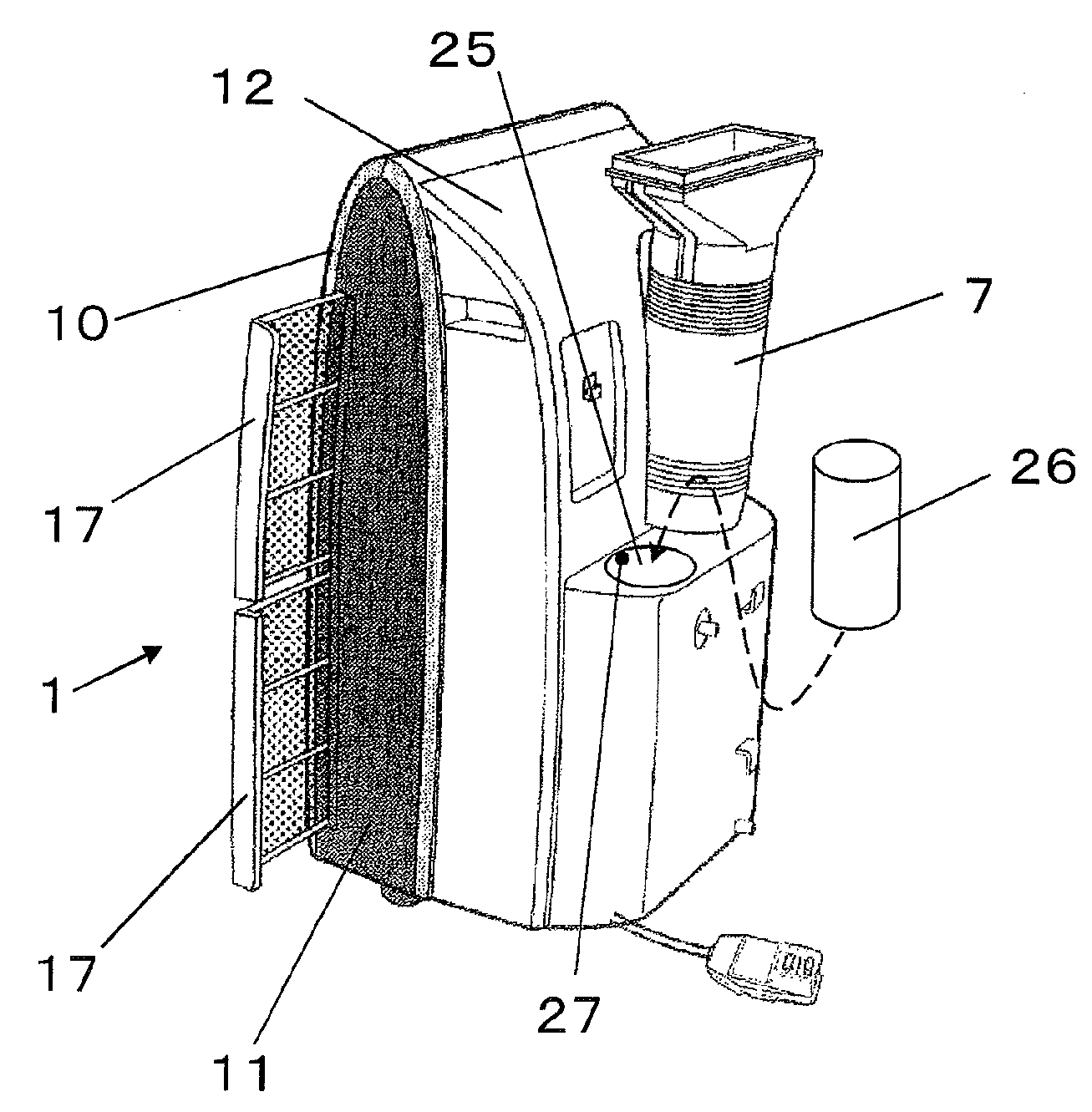

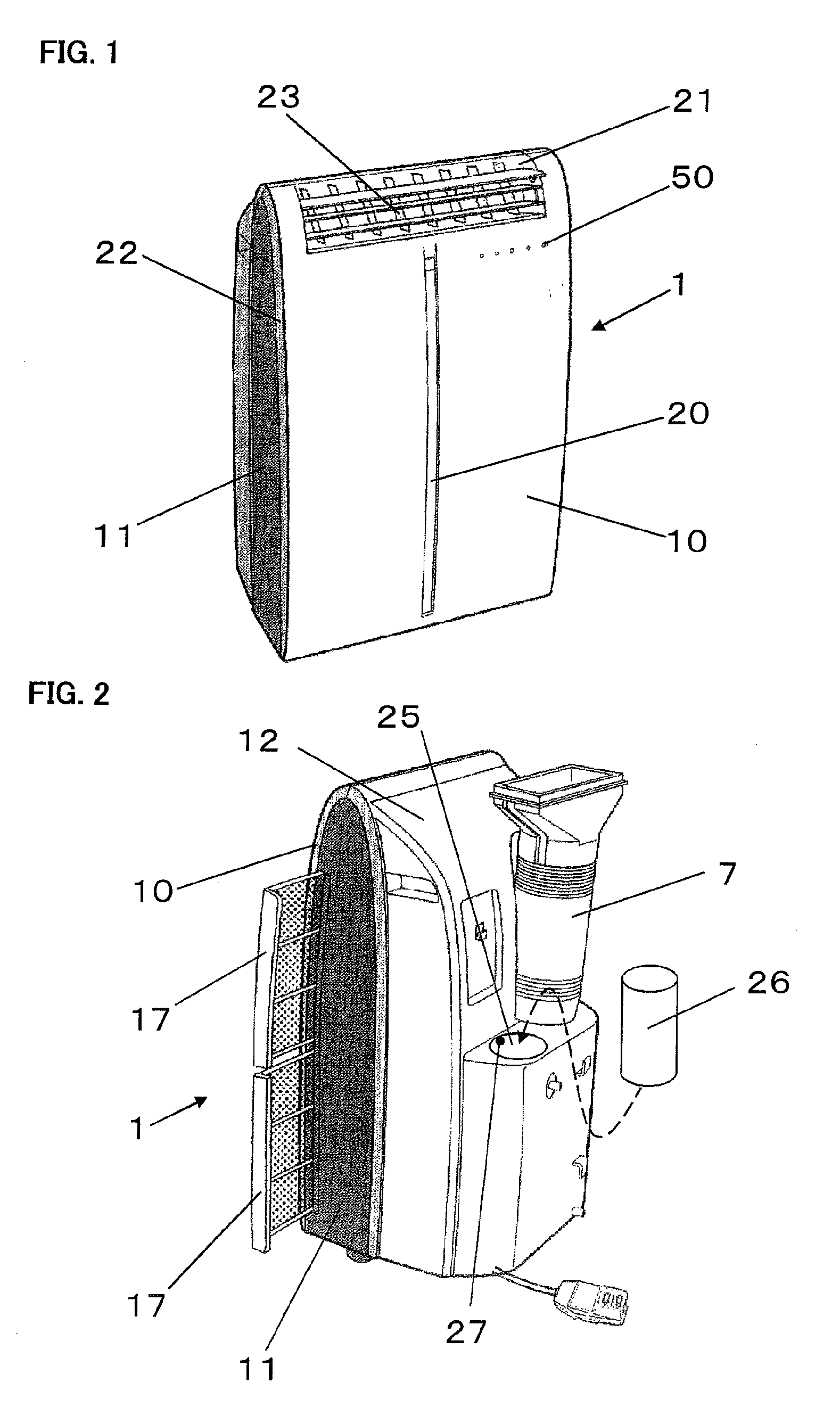

Integrated air conditioner

InactiveUS20100050682A1High convenienceAvoid wasteCondensate preventionSpace heating and ventilation safety systemsEngineeringExhaust heat

An integrated air conditioner of high convenience capable of reducing the frequency of discharge of water collected in a drain pan by suitably controlling the operation of a water feed device according to the mode of use of the air conditioner. The air conditioner of the present invention has an air intake port 25 and an exhaust port 24 for drawing in and expelling of air for cooling a condenser 3. The air intake port 25 and the exhaust port 24 are formed in a cabinet 1. An air intake duct 26 and an exhaust duct 7 can be fitted to the air intake port 25 and the exhaust port 24, respectively. A control section determines whether or not exhaust heat from the condenser 3 is being released outdoors through the exhaust duct 7 according to whether or not the air intake duct 26 or the exhaust duct 7 is fitted, operates a water feed device 8 for leading drain wafer collected in the drain pan to the condenser 3 during both of a cooling operation and a dehumidifying operation if it determines that the heat to be released from the condenser 3 is being released outdoors, and operates the water feed device 8 during the cooling operation and stops the operation of the water feed device 8 during the dehumidifying operation if it determines that the exhaust heat from the condenser 3 is not being released outdoors.

Owner:SHARP KK

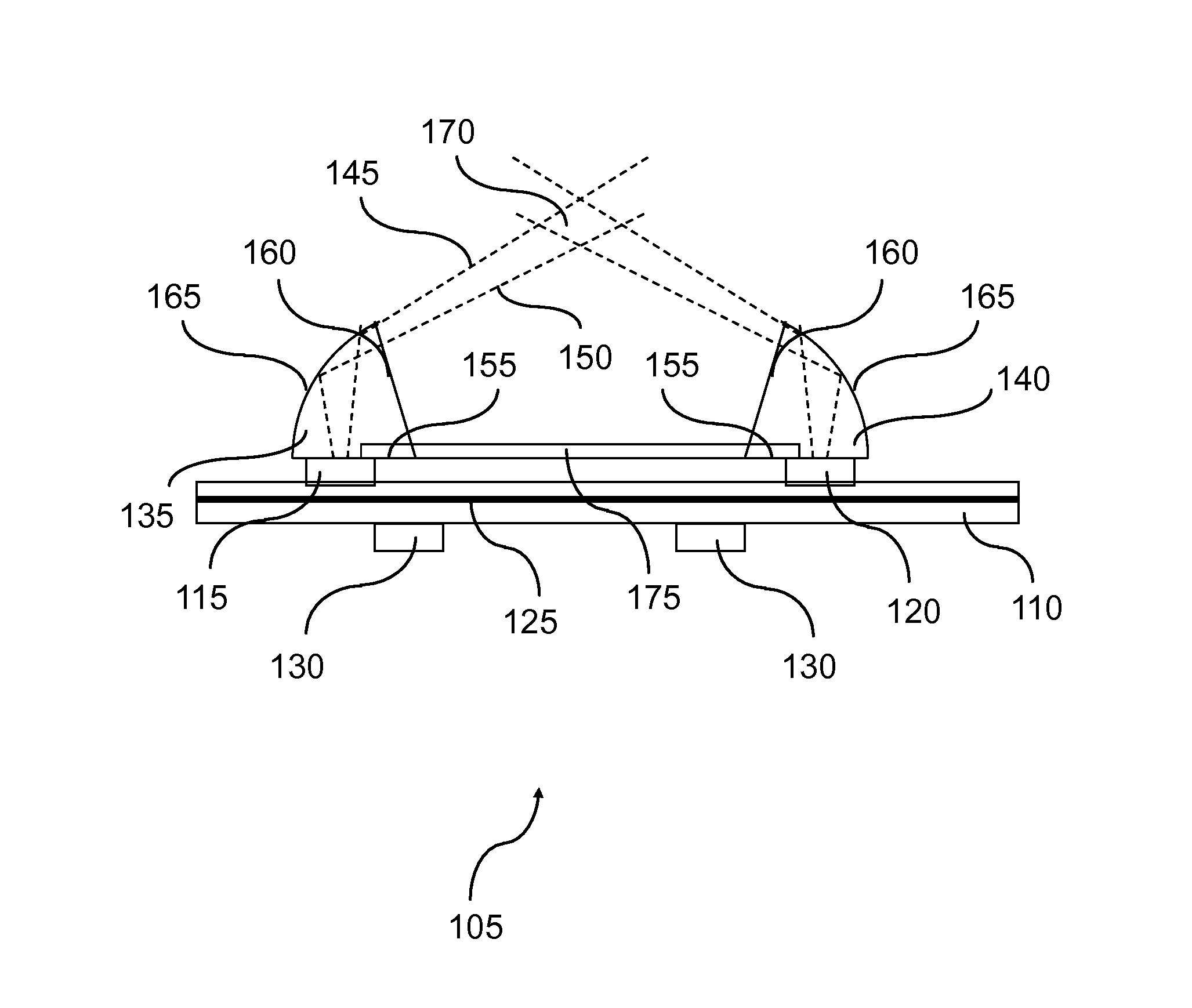

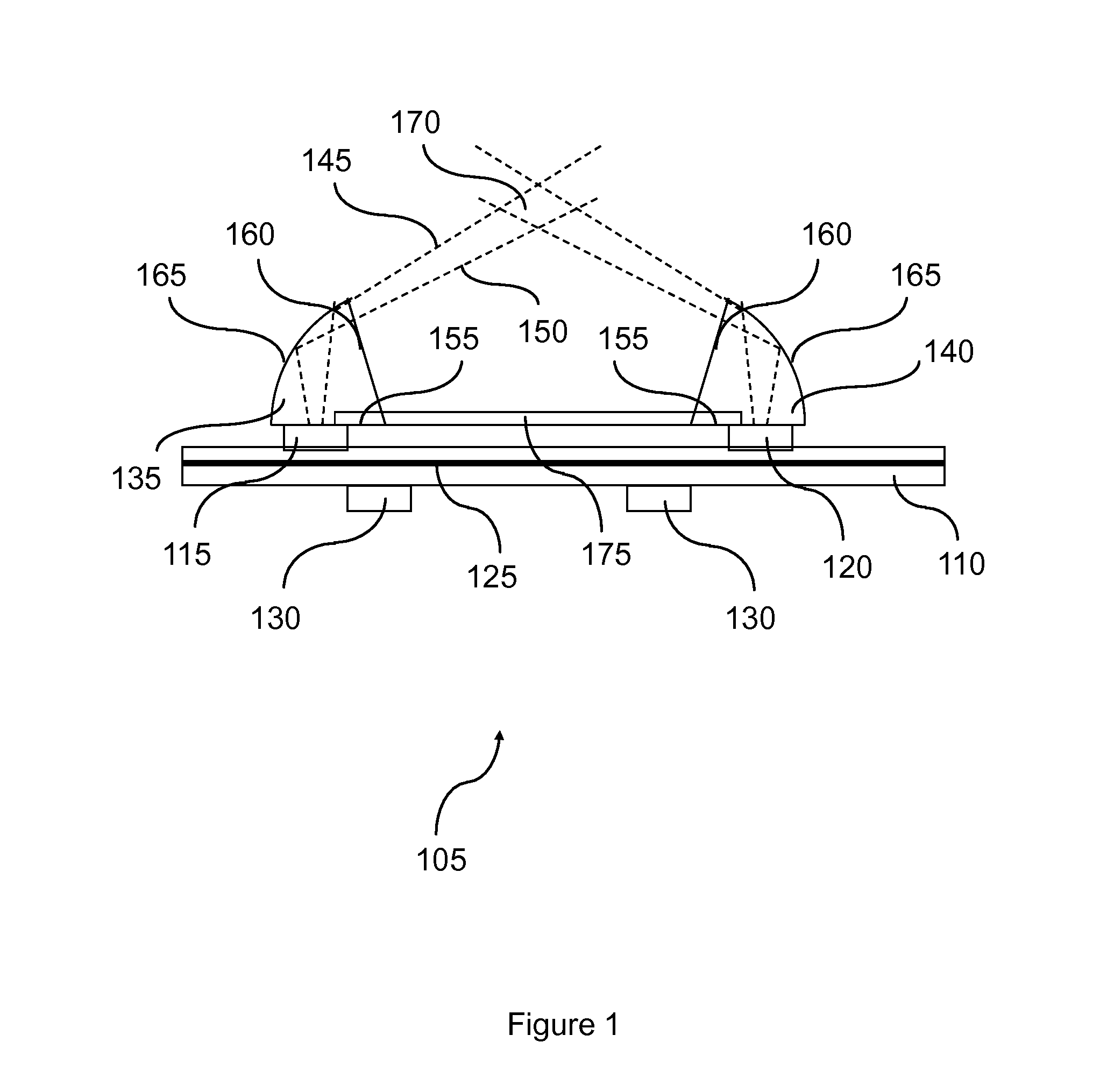

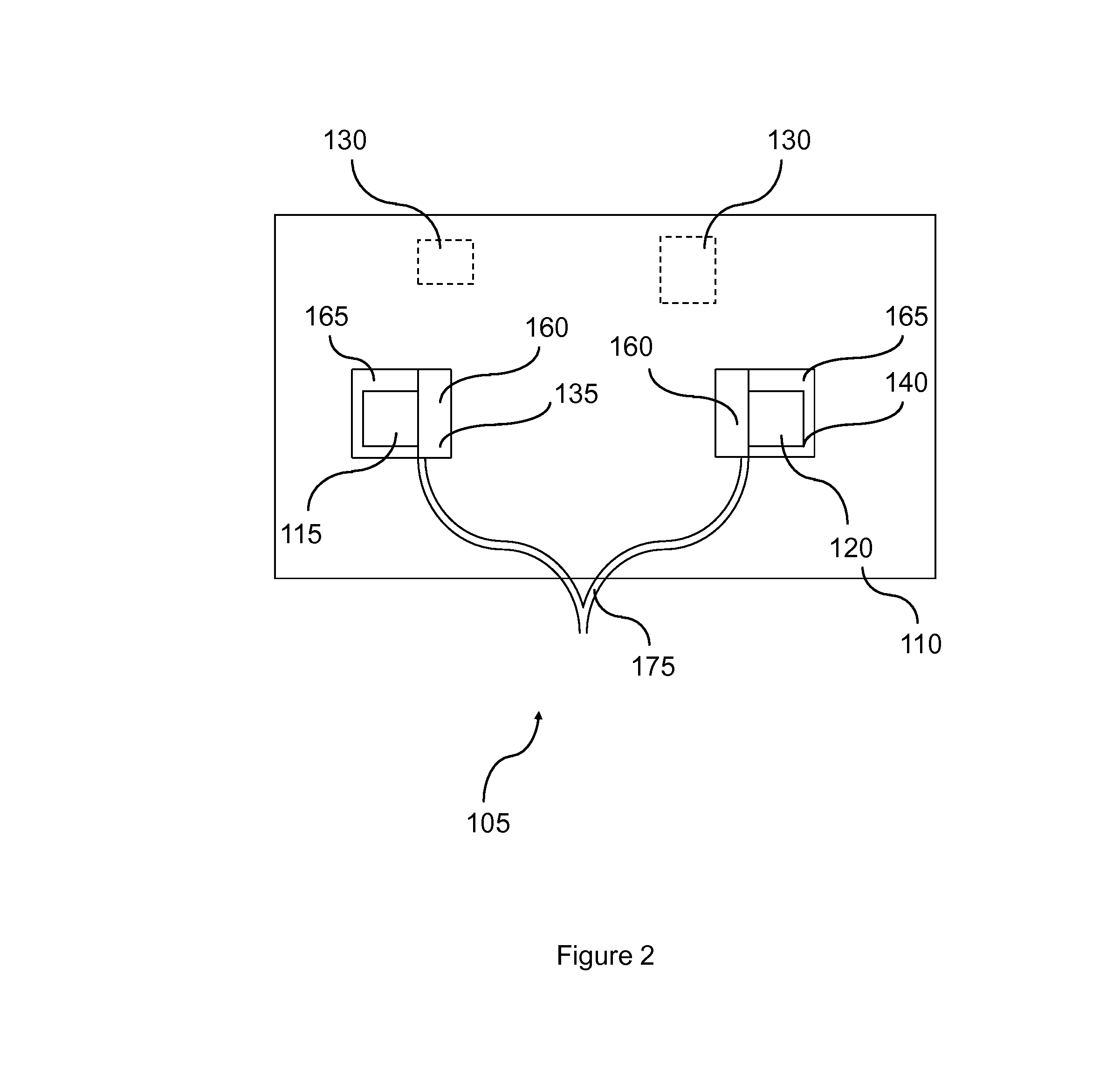

Smoke detection circuit, smoke detector comprising said circuit and alarm device comprising both the circuit and the detector

ActiveUS20130176131A1Avoid wasteEliminates operationPrinted circuit assemblingScattering properties measurementsScattered lightAlarm device

The optical scattering-based smoke detector comprises a scattering zone accessible to the smoke, a printed circuit forming a supporting member and a first and second light reflectors mounted on a common supporting member. An electronic smoke detection unit, a light emitter and a light receiver are mounted on the printed circuit. The receiver is sensitive to at least some of the wavelengths of the light rays emitted by the emitter. The first light reflector facing the emitter to direct the emitted light into a detection zone in the scattering zone. The second light reflector facing the receiver to direct, in the presence of smoke in the scattering zone, the scattered light from the detection zone onto the receiver. A single mechanical part comprises the first and second light reflectors and a link resistant to the passage of the light from the first light reflector to the second light reflector.

Owner:FINSECUR

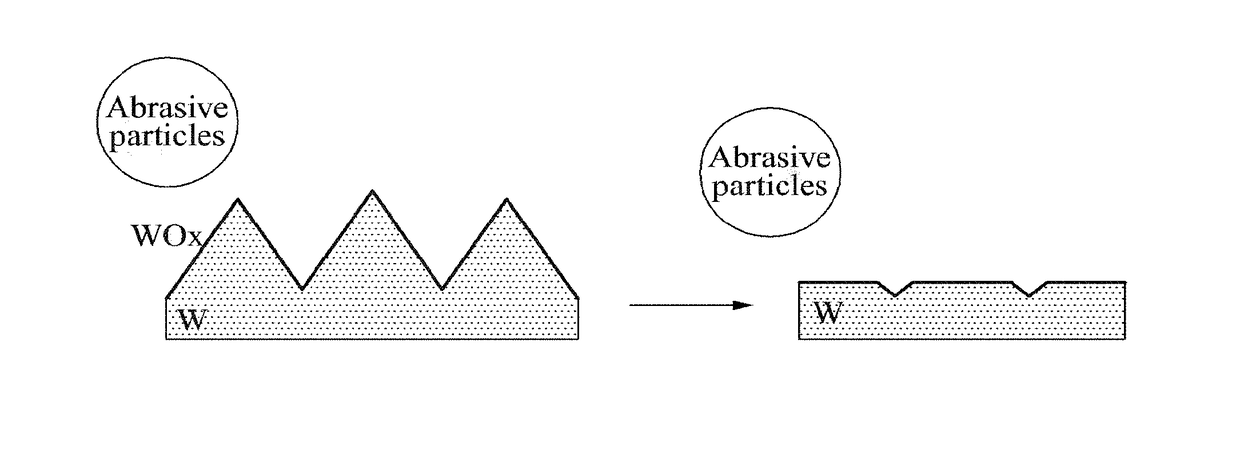

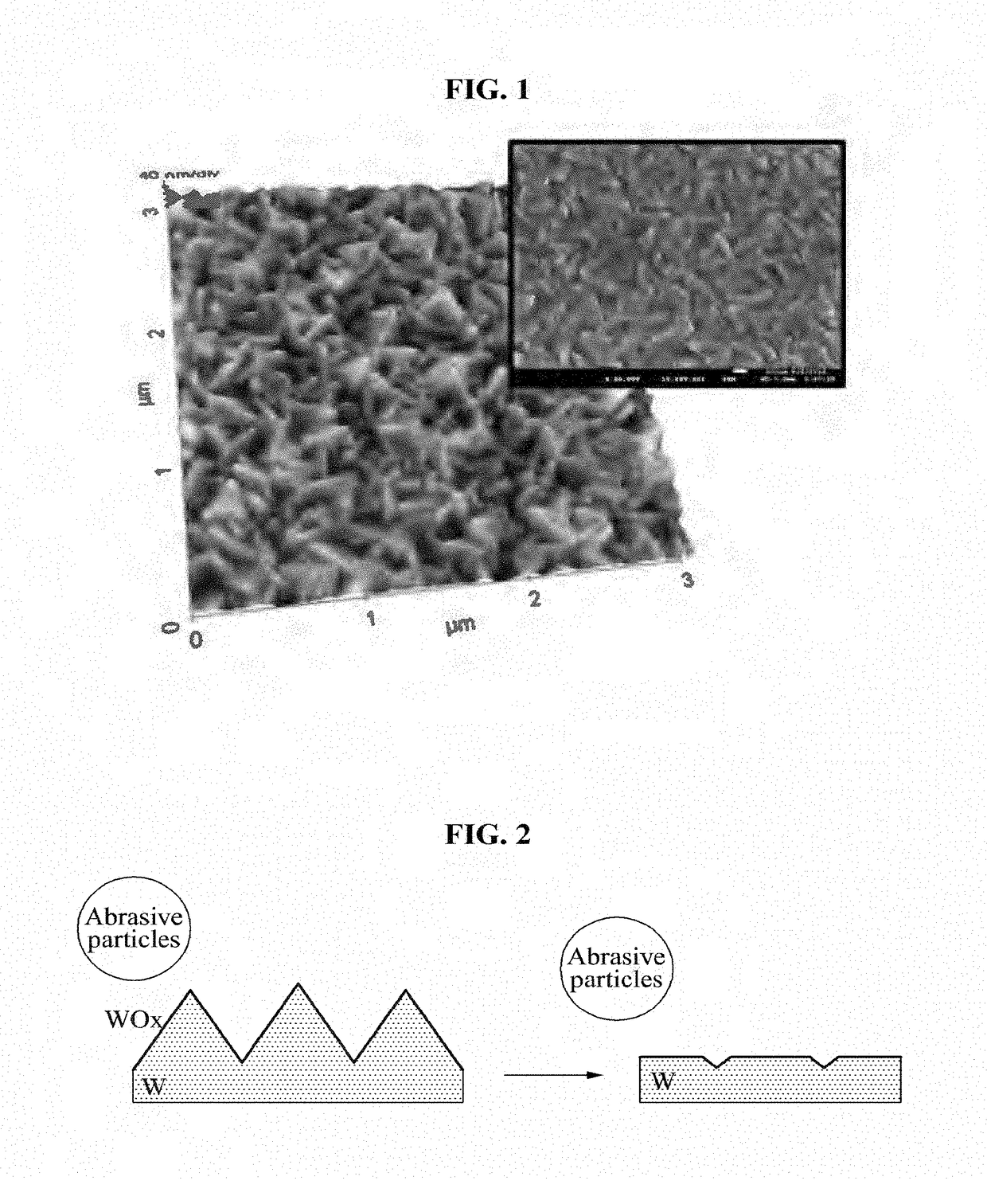

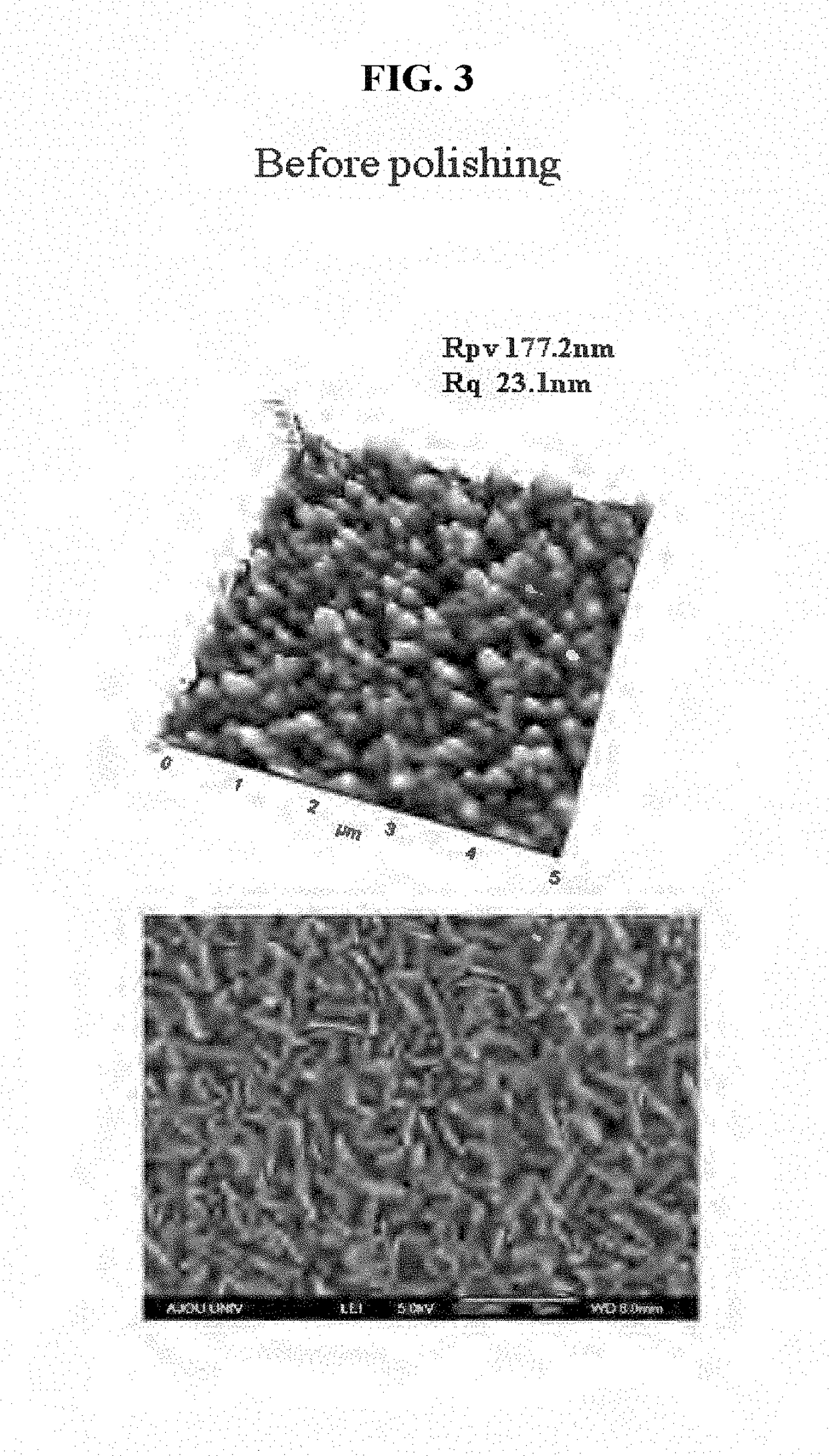

Polishing slurry composition

InactiveUS20170183537A1Improved yieldAvoid wasteOther chemical processesSemiconductor/solid-state device manufacturingTungstenOxidizing agent

The present invention relates to a polishing slurry composition. A polishing slurry composition according to a first aspect of the present invention comprises abrasive particles and an oxidant, polishes tungsten having a thickness of 10-1,000 Å, and improves the topography of tungsten. Additionally, the polishing slurry composition according to a second aspect of the present invention comprises: at least two abrasive particles among first abrasive particles, second abrasive particles and third abrasive particles; and an oxidant, wherein the primary particle size of the first abrasive particles is 20 nm or more and less than 45 nm, the primary particle size of the second abrasive particles is 45 nm or more and less than 130 nm, and the primary particle size of the third abrasive particles is 130 nm or more and less than 250 nm.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV) +1

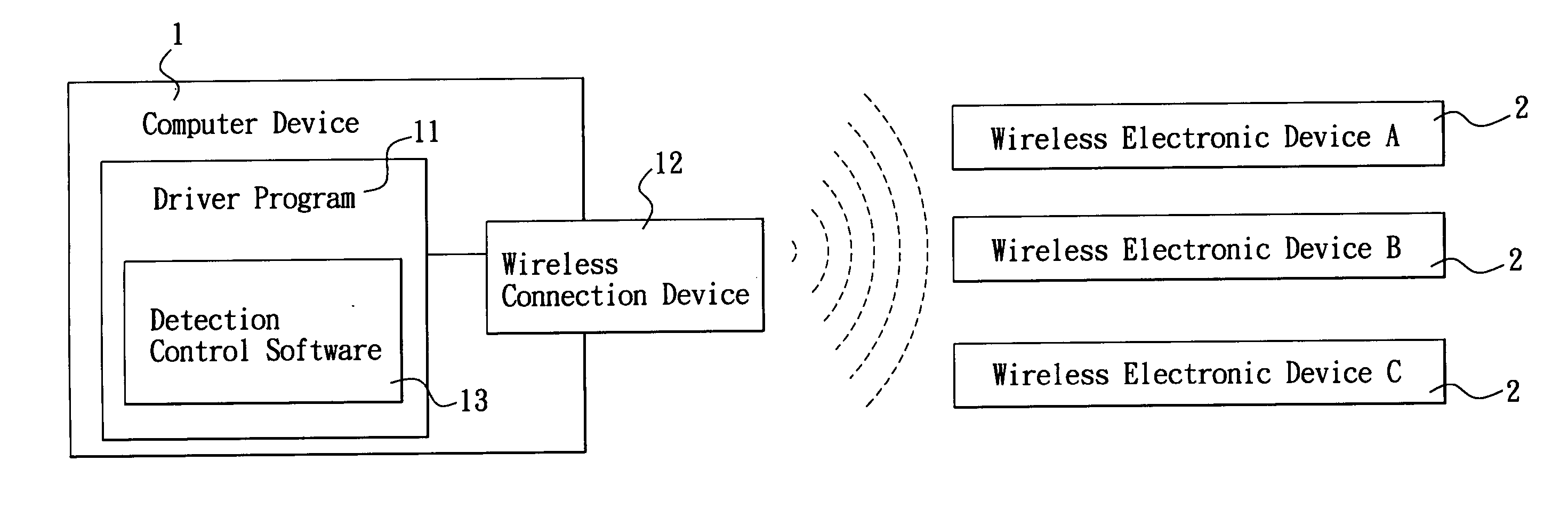

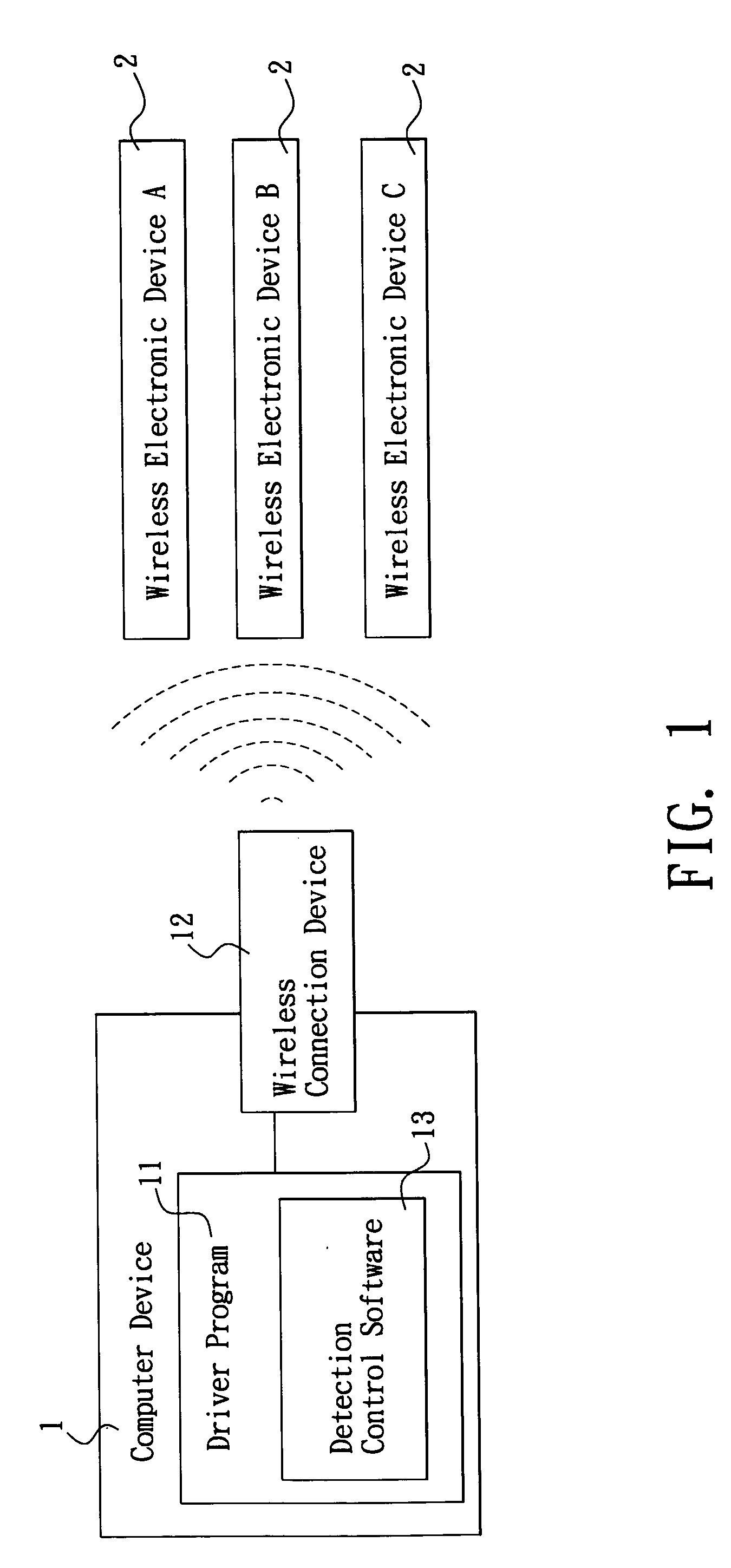

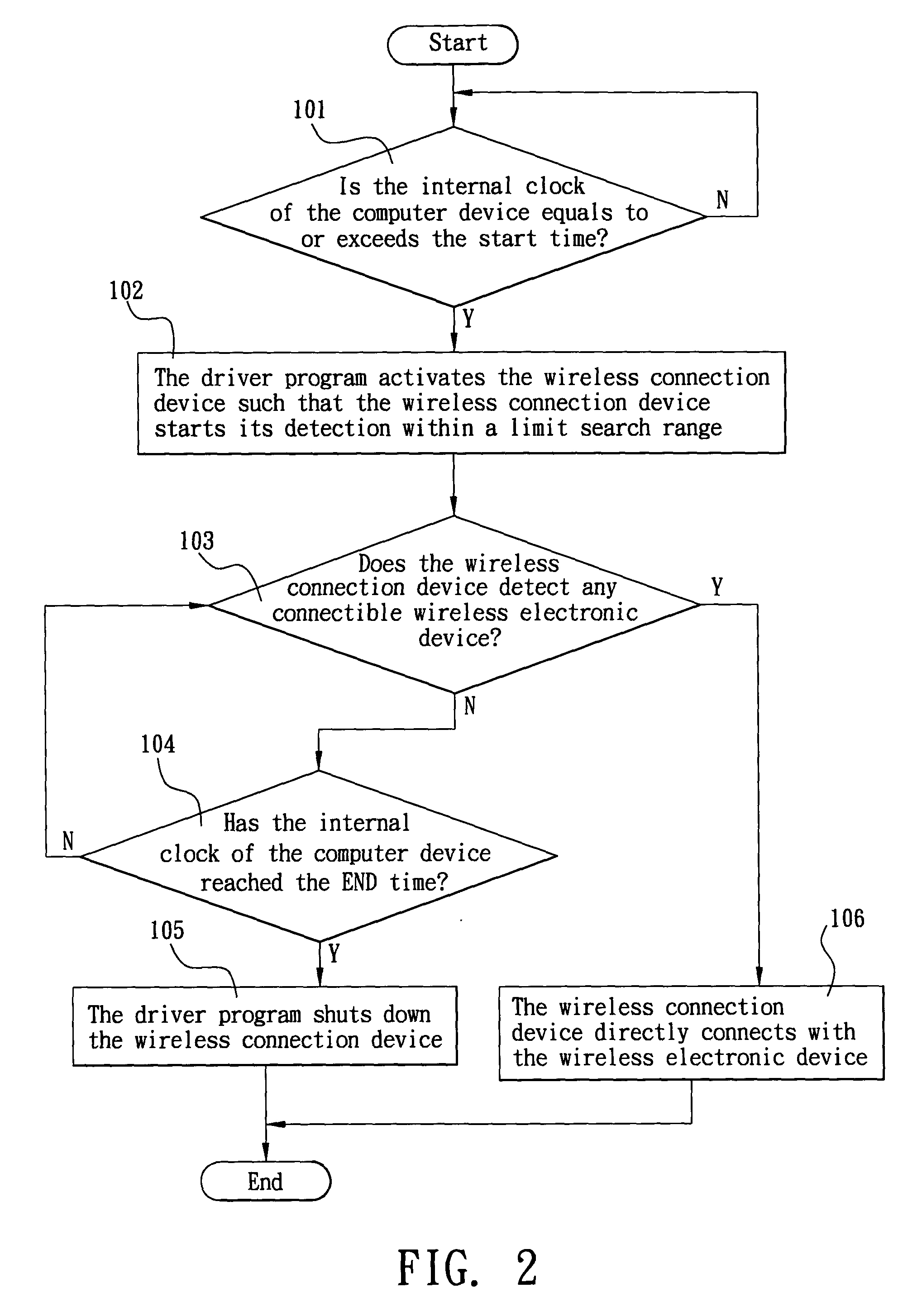

Control method for setting up operation time of wireless connection device

InactiveUS20050050195A1Avoid of riskAvoid wastePower managementDigital computer detailsControl softwareElectric power

The present invention discloses a control method for setting up the operation time of a wire connection device by installing a detection control software in a driver program, and the detection control software sets up the detection operation time of the wireless connection device such that when a computer device is turned on, the detection control software controls the ON / OFF time of the wireless connection device according to the setup of the detection operation time through the driver program to avoid unnecessary waste of electric power and any possible risk to pathological changes caused by exposing our body under the electromagnetic waves for a long time.

Owner:INVENTEC CORP

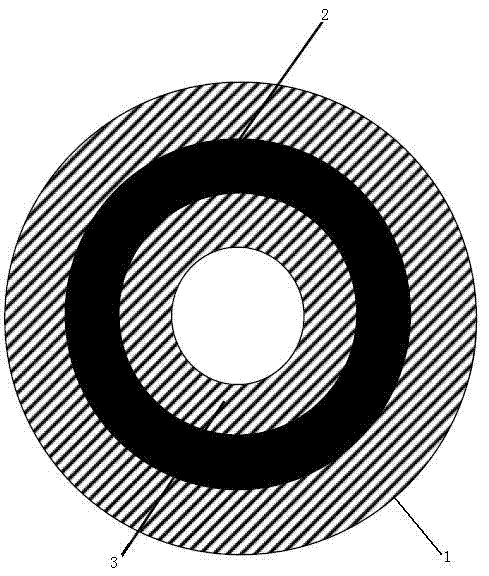

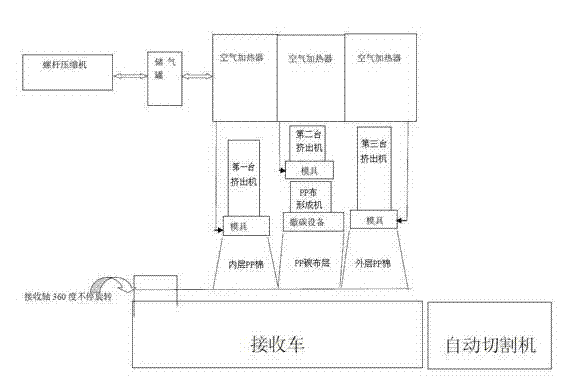

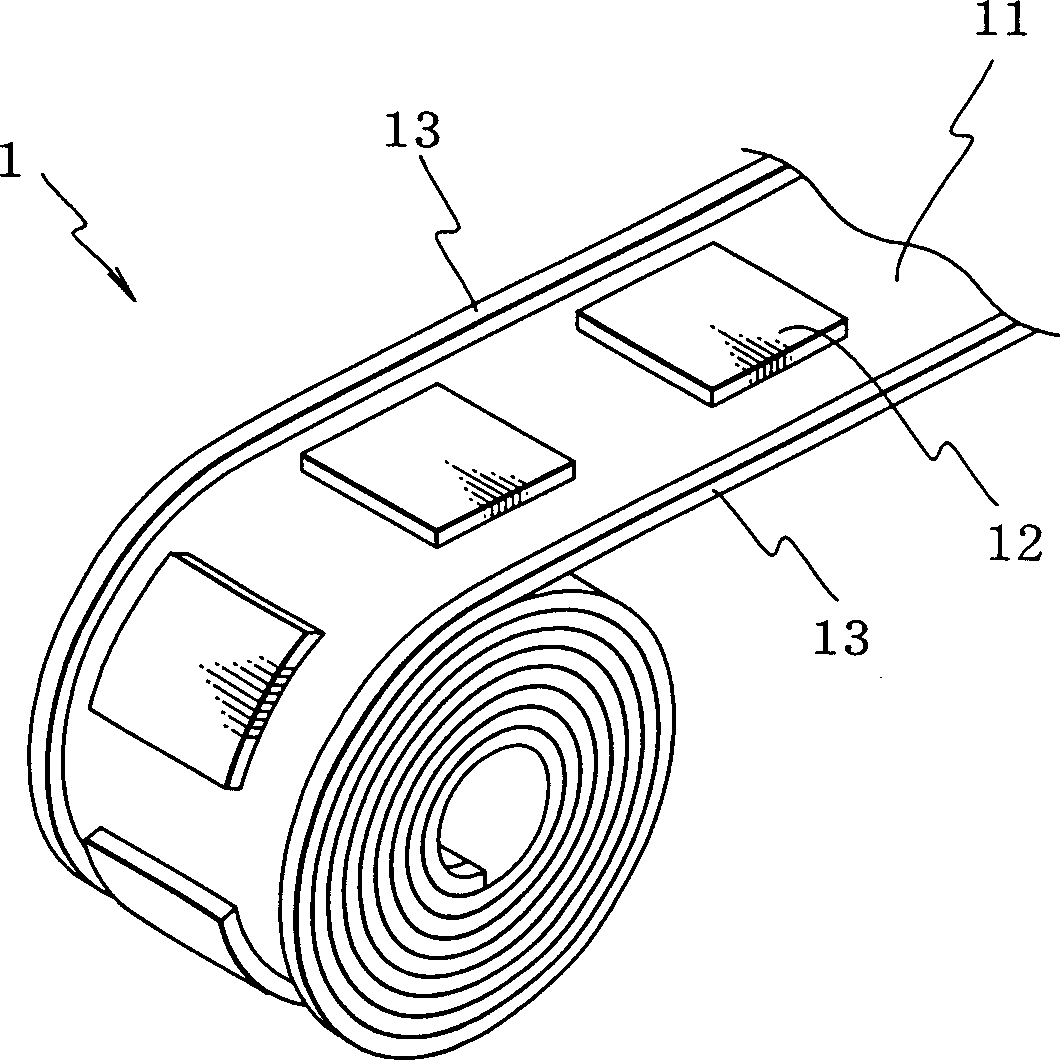

Melt-blow filtering core and preparation process thereof

InactiveCN103084006APrevent outflowReduce outputFiltration separationActivated carbonEnvironmental engineering

The invention discloses a melt-blow filtering core. The melt-blow filtering core is successively provided with an outer layer PP cotton, a middle PP carbon cloth layer and an inner layer PP cotton from the exterior to the interior, wherein the outer layer PP cotton is formed through spraying silks; the PP carbon cloth layer is a middle layer arranged between an outer layer and an inner layer, and active carbon fine grains are scattered on the PP cotton through enwinding; and the inner layer PP cotton is formed by the spraying silks through winding. The melt-blow filtering core provided by the invention has the advantages that the arrangement of the inner layer PP cotton can prevent the active carbon fine grains from flowing out along the water; after the filtering core is changed and a faucet is opened, the clean water is directly flowed out, a water return valve is not needed to match, the structural complication of a filter is reduced, meanwhile, the output of black water is reduced, the operation is simple and convenient, and the environmental pollution and energy source waste are avoided; the middle PP carbon cloth layer adopts the PP cloth to closely pack the active carbon fine grains, a gluewater compound principle in the prior art is abandoned, the novel active carbon filtering core is exploited, the active carbon grains are fully contacted with the water, and the contacting ratio can achieve more than 90%; and the utilization ratio of active carbon is greatly strengthened, the filtering effect is improved, and the service life of the active carbon filtering core is prolonged.

Owner:WUXI HONGTENG PLASTIC FAB

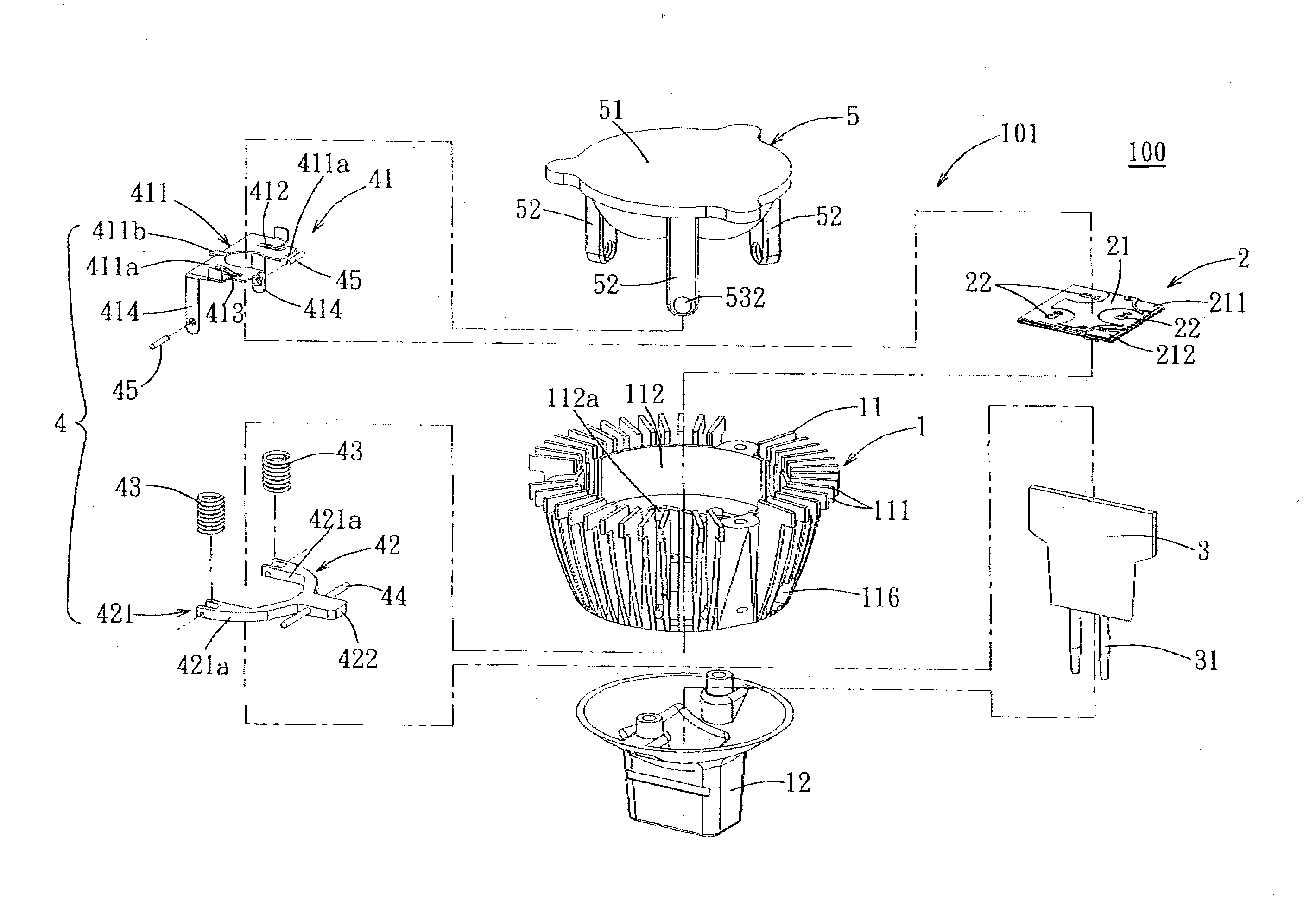

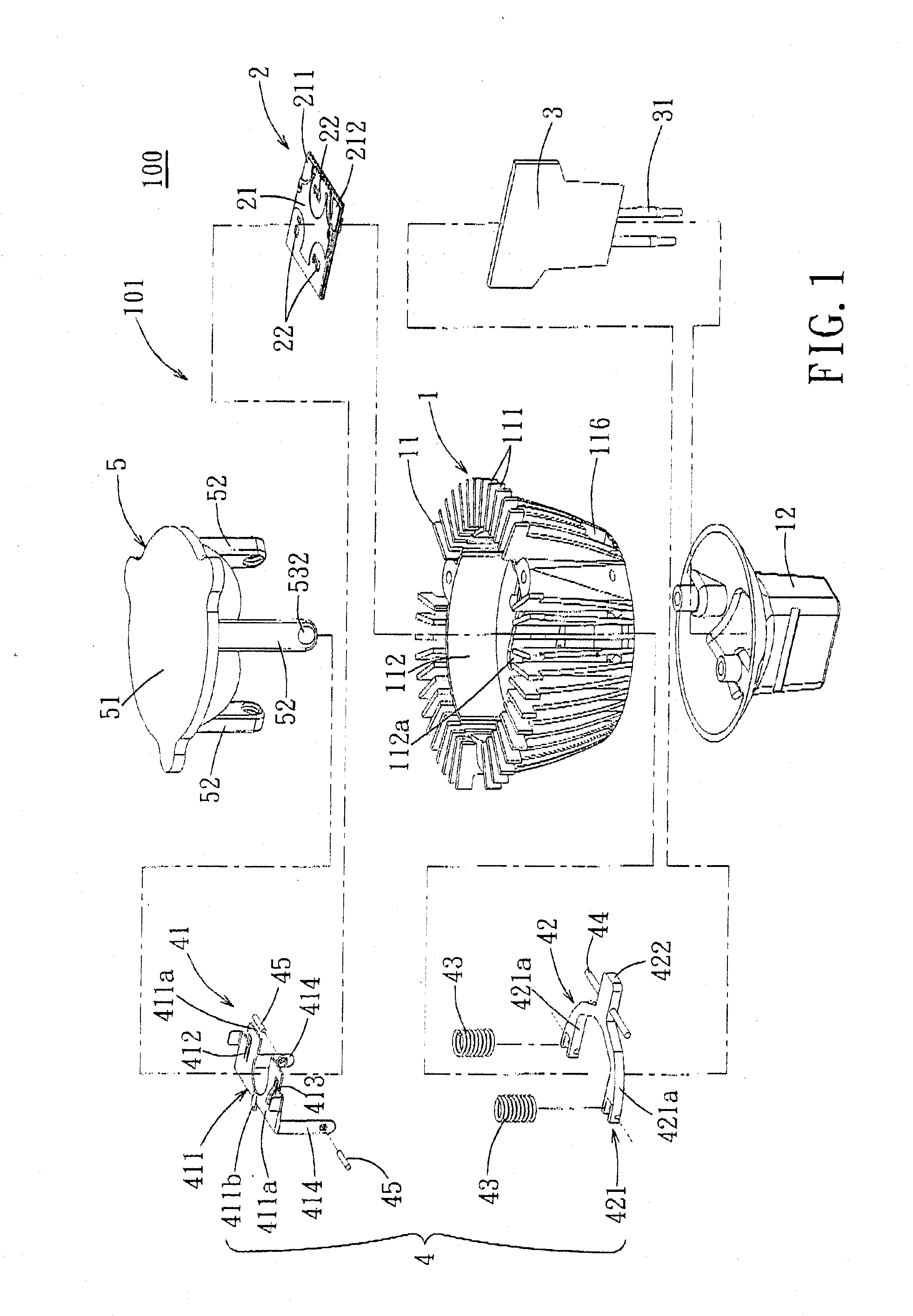

Lamp and lamp holder module thereof

InactiveUS20110156567A1Reduce maintenance and replacement costAvoid wasteCoupling device connectionsPoint-like light sourceEngineeringMechanical engineering

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

Connecting tape for semiconductor chip loading, carrier and package for semiconductor chip

InactiveCN1388566AImprove yieldAvoid wasteFilm/foil adhesivesSemiconductor/solid-state device detailsBand shapeSemiconductor chip

Owner:LINTEC CORP

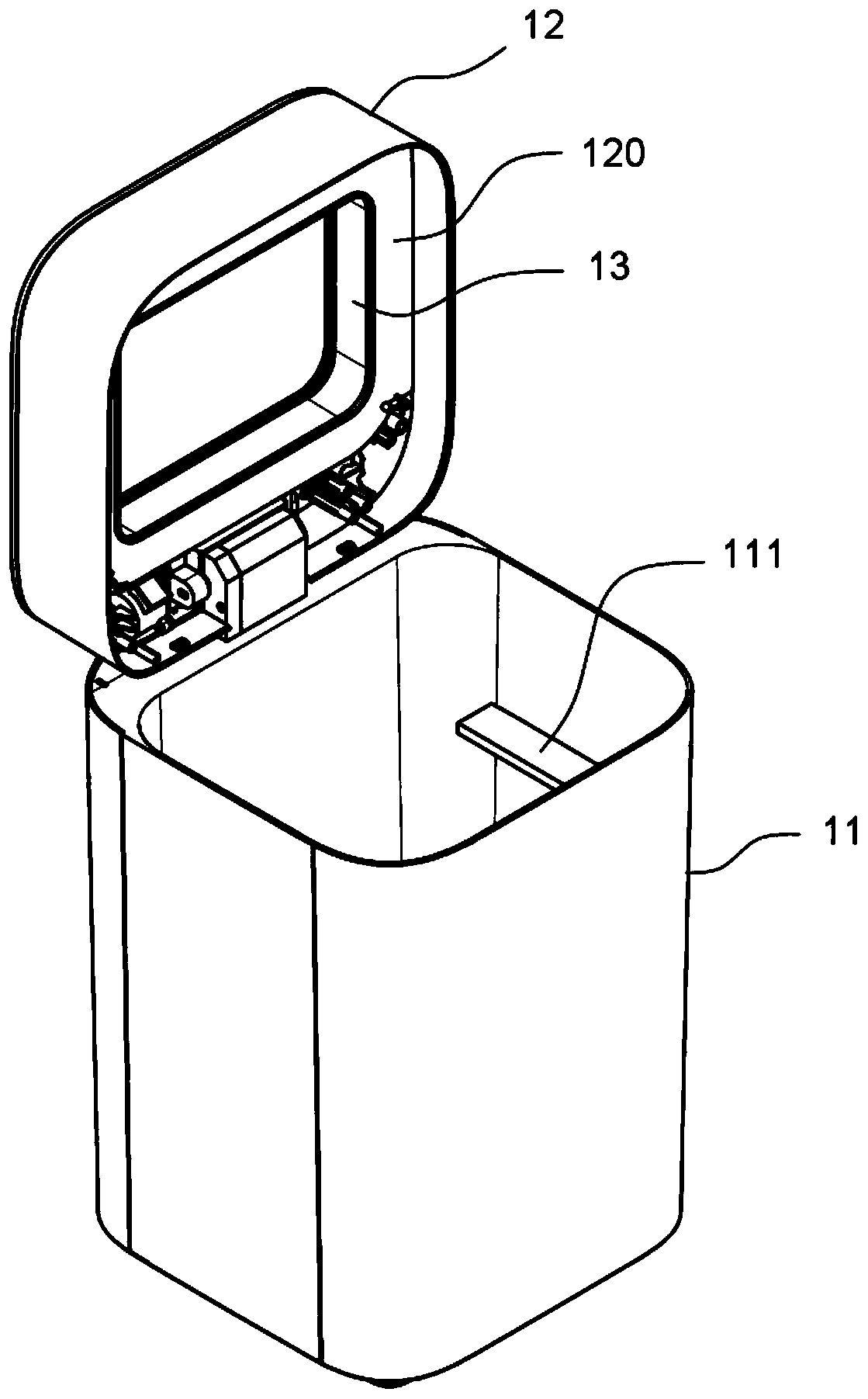

Intelligent garbage can provided with liftable type heat-sealing device

PendingCN110510295AAvoid wasteSolve the sealing problemRefuse receptaclesWrapper twisting/gatheringEngineeringWaste management

Owner:DREAME TECH TIANJIN CO LTD

Agrocybe cylindracea culture medium and preparation method thereof

InactiveCN103382137AAvoid wasteAvoid wasting resourcesBio-organic fraction processingOrganic fertiliser preparationAgrocybe cylindraceaCulture mediums

The invention discloses an agrocybe cylindracea culture medium and a preparation method thereof. The culture medium comprises main materials and auxiliary materials, the main materials comprises following components in parts by weight: 22 to 26 parts of cotton seed hulls, 28 to 32 parts of mixed wood chips, 8 to 10 parts of chicken manure, 3 to 6 parts of cow dung and 15 to 16 parts of corncob, and the auxiliary materials comprises following components in parts by weight: 6 to 9 parts of wheat bran and 2 to 5 parts of quicklime. The invention also discloses a method of using the culture medium to culture agrocybe cylindracea. The method has the advantages that: first, wasting of the waste materials of the agrocybe cylindracea culture medium is avoided, resource waste is avoided, and the nutrition in the culture medium is absorbed more easily; secondly, the yield of agrocybe cylindracea is increased and the conversion rate of agrocybe cylindracea is prominently increased.

Owner:WUHU YESHULIN BIOTECH

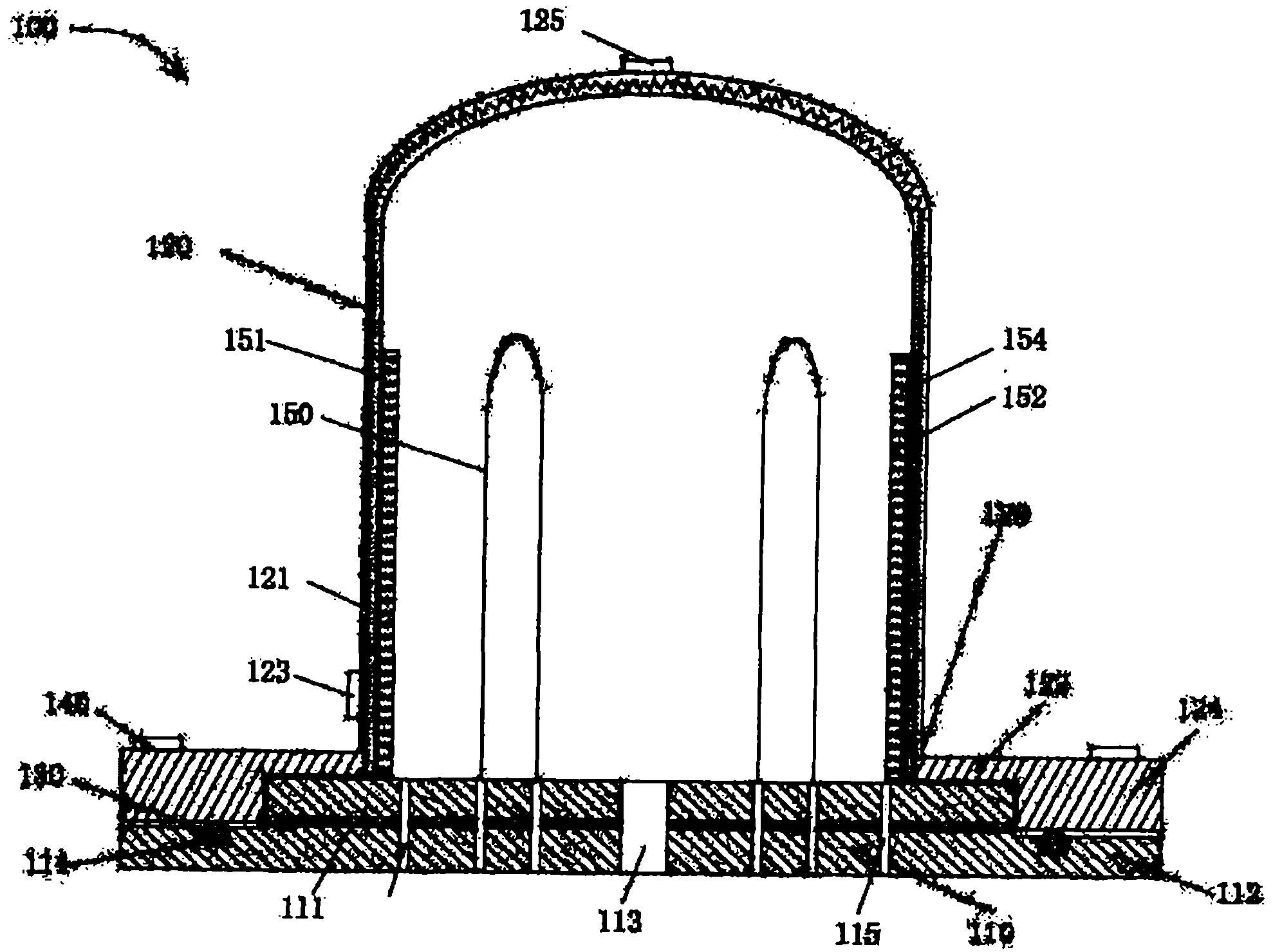

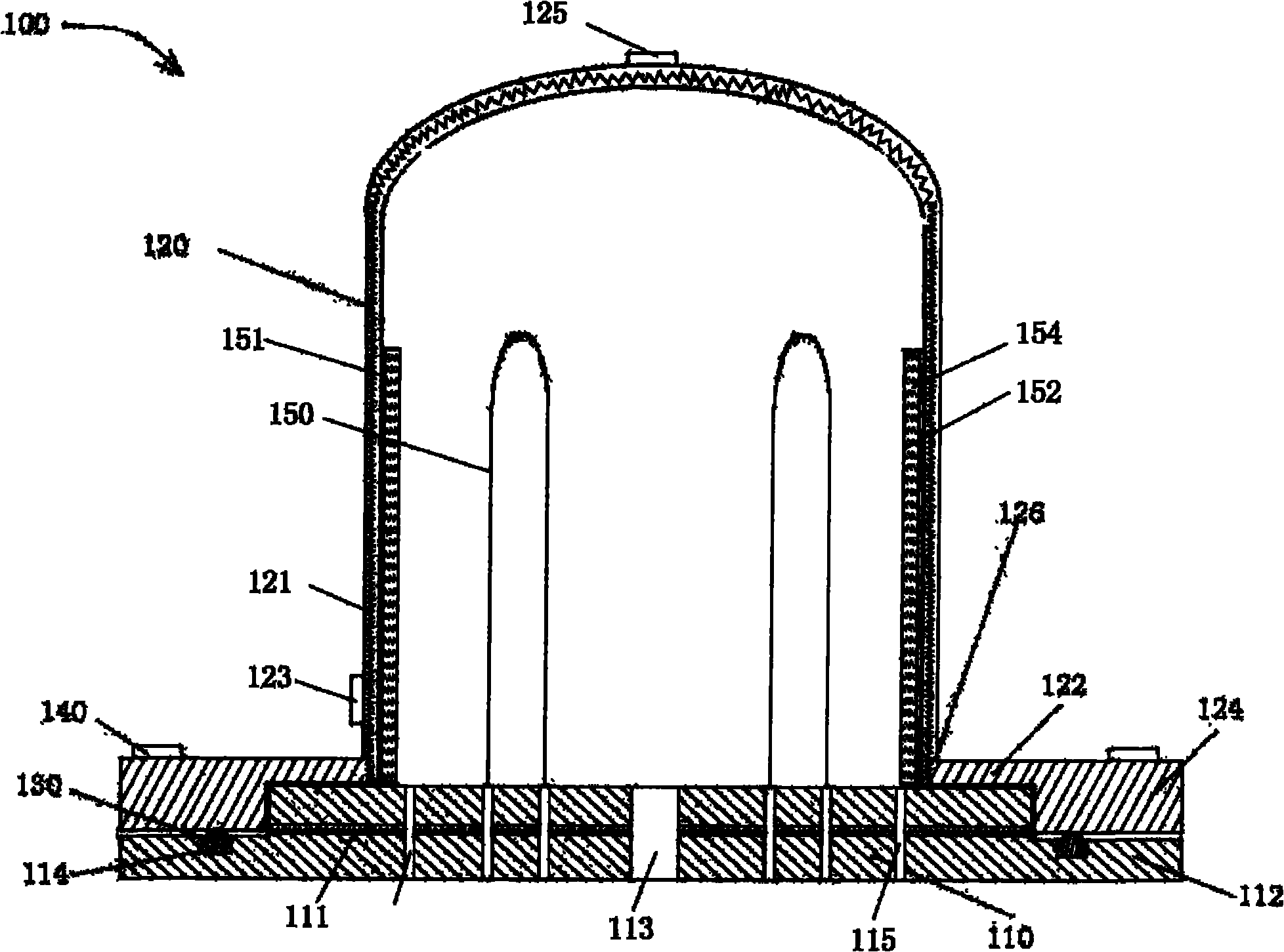

Polysilicon reduction furnace

ActiveCN102092717APlay a role in heat preservationAvoid damageSilicon compoundsMetallurgyPolycrystalline silicon

Owner:王琛茜

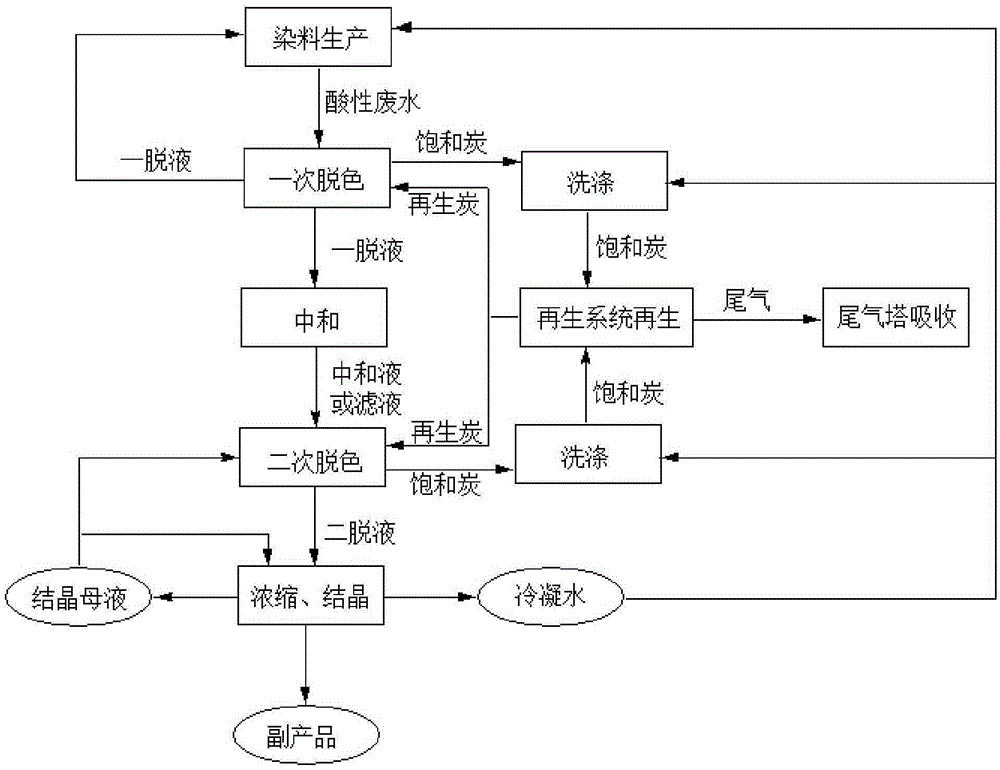

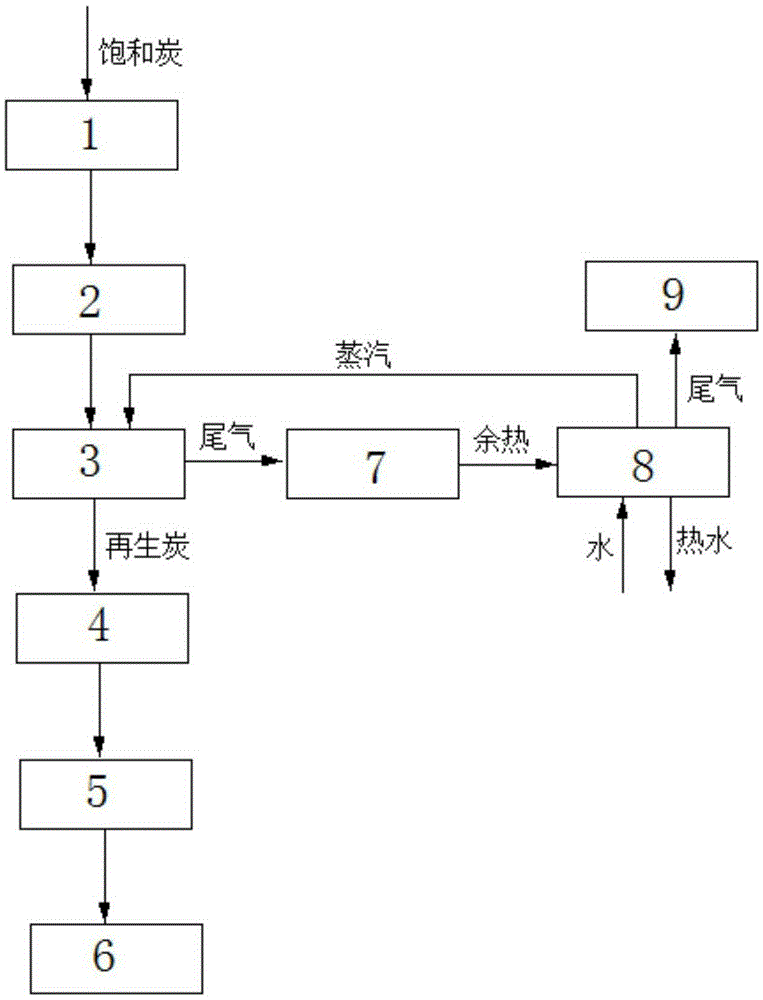

Continuous treatment method for dye industry acid wastewater

ActiveCN105417816AReduce manufacturing costAvoid wasteSpecific water treatment objectivesWater contaminantsExhaust gasChemistry

The invention provides a continuous treatment method for dye industry acid wastewater. The method includes the steps of A, primary decoloring, wherein the sulfuric acid or hydrochloric acid containing acid wastewater generated in the production process of the dye industry continuously enters the bottom of a granular activated carbon adsorption column, adsorption decoloring is conducted from bottom to top, and primarily-decolored liquid is obtained; B, neutralizing, wherein the primarily-decolored liquid is neutralized to the state that the pH value ranges from 2.5 to 7, and neutralized liquid is obtained; C, secondary decoloring, wherein the neutralized liquid continuously enters the bottom of the granular activated carbon adsorption column, secondary adsorption decoloring is conducted from bottom to top, and secondarily-decolored liquid is obtained; D, concentration and crystallization; E, activated carbon regeneration, wherein saturated granular activated carbon discharged in the step A and the step C is washed with water to the state that the pH value ranges from 2 to 7, then the washed saturated granular activated carbon is fed into a regeneration system to be regenerated, the regenerated granular activated carbon enters the granular activated carbon adsorption column to be recycled, but tail gas generated by the regeneration system is absorbed by a tail gas tower.

Owner:ZHEJIANG LONGSHENG GROUP +1

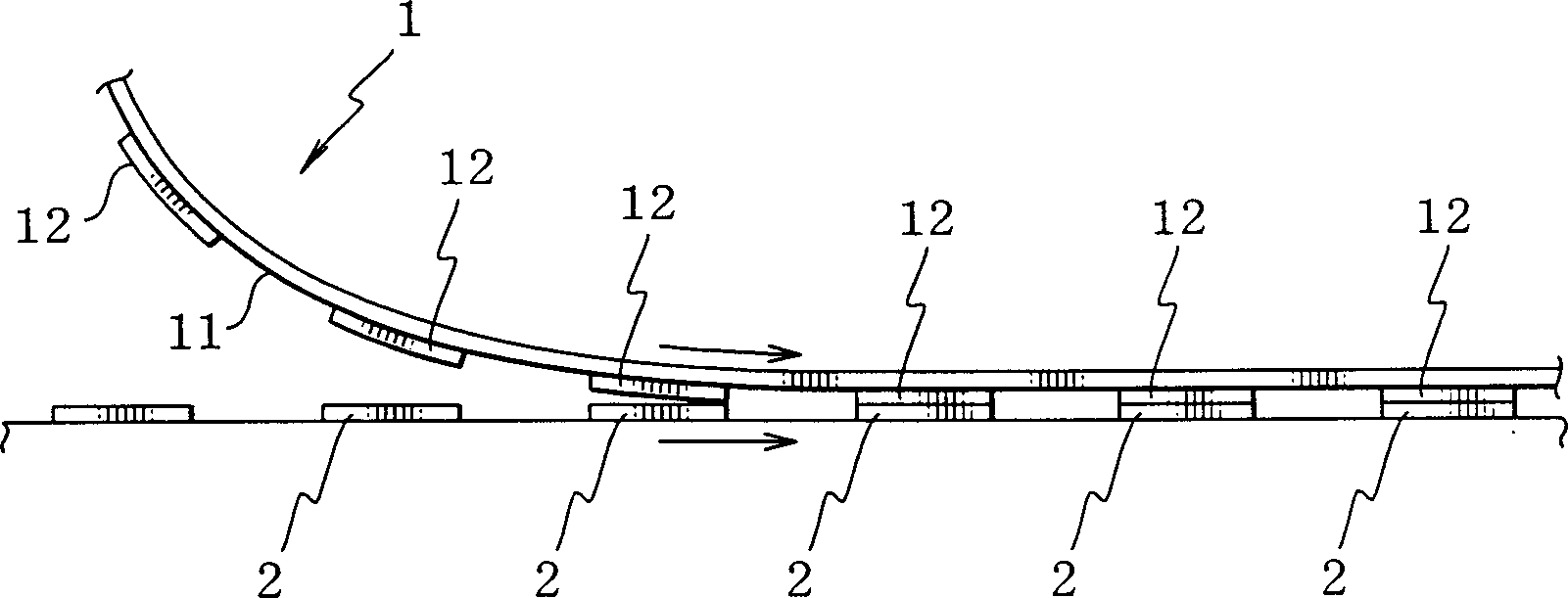

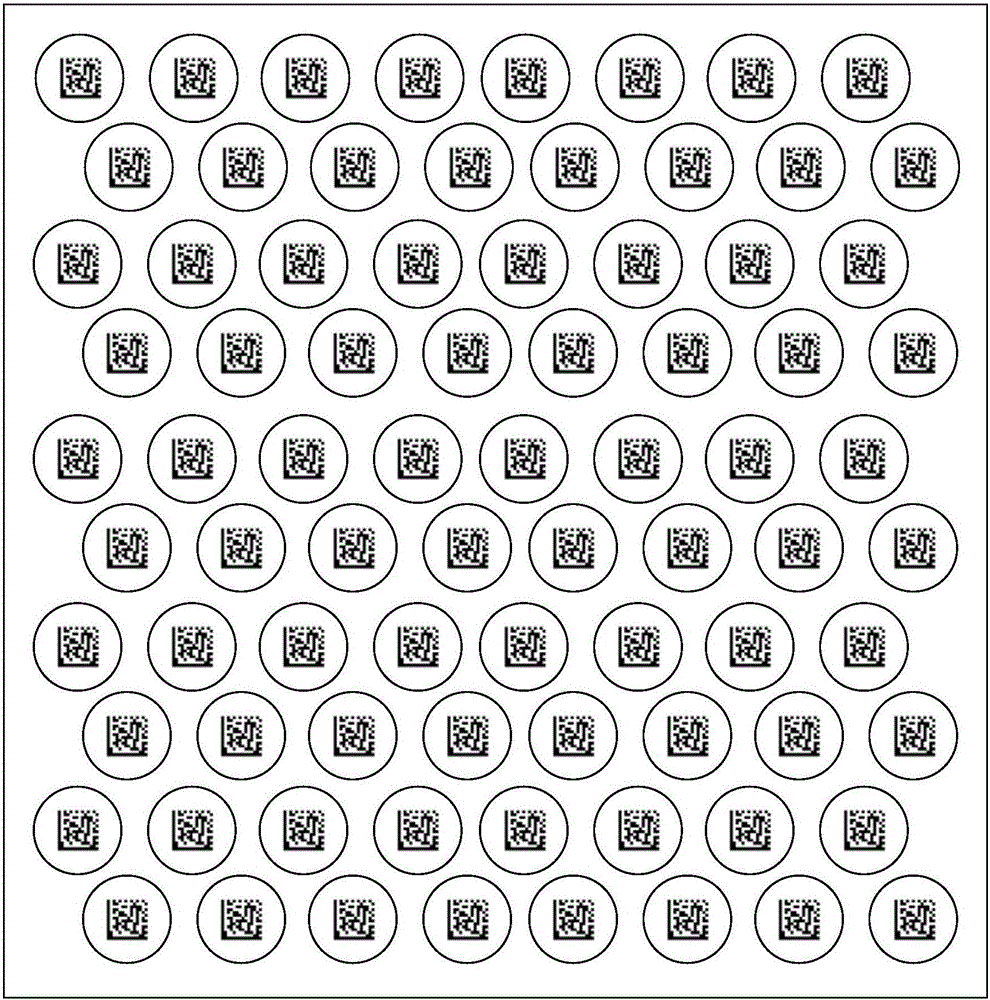

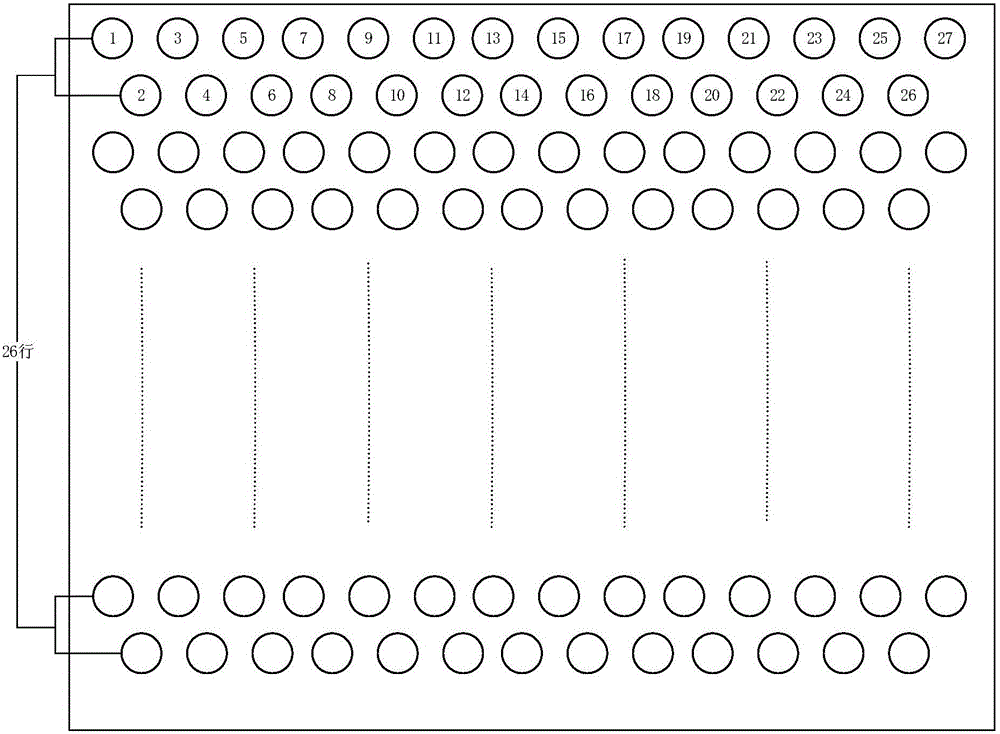

Method for detecting identification code tagging quality of large-breadth printing material

InactiveCN105894182AAvoid wasteLow costResourcesRecord carriers used with machinesWaste productComputer hardware

The invention discloses a method for detecting identification code tagging quality of large-breadth printing material. The method includes the steps of reading the identification code on the surface of the large-breadth printing material through an identification code reader, conducting rejecting or shutdown processing if the reading failure number exceeds a predetermined threshold, further examining relevance between an internal code and an external code if the reading failure number does not exceed the predetermined threshold, determining that the identification code tagging is qualified if the internal code and the external code are relevant, and determining that the identification code tagging is unqualified if the internal code and the external code are irrelevant. The tagging quality problem of an identification code can be timely discovered during mass printing identification codes on the surfaces of the large-breadth printing material, thereby preventing batch waste products, substantially saving cost and improving production efficiency of identification code tagged products.

Owner:SIGMATRIX TECH CO LTD

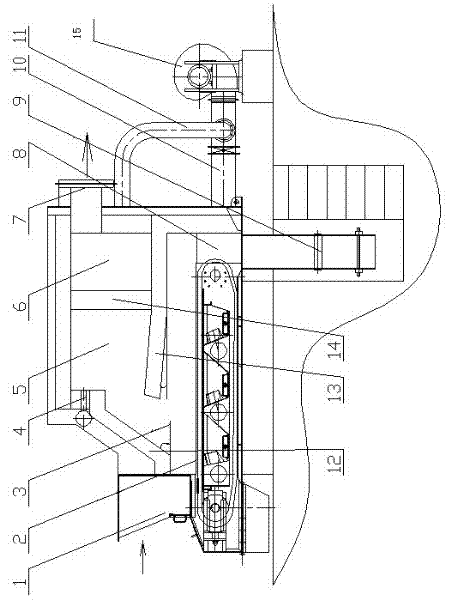

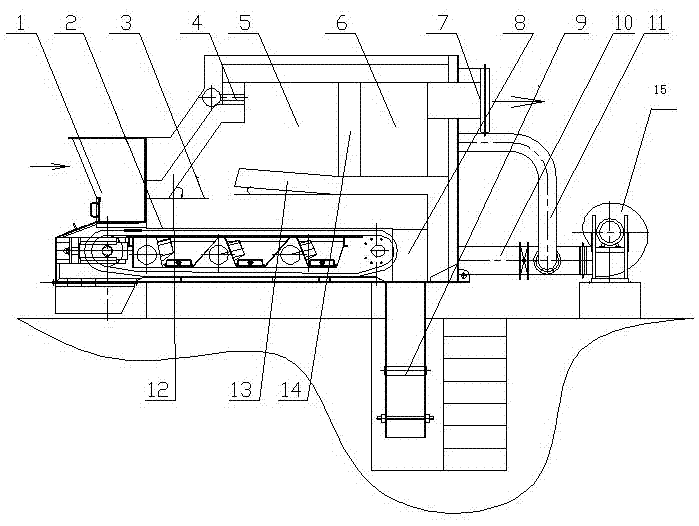

Integrated device for producing carbon continuously and utilizing hot blast by utilizing biomass fuels

ActiveCN102241997AImprove carbon production efficiencyAvoid wasteBiofuelsSpecial form destructive distillationHot blastProcess engineering

The invention relates to an integrated device for producing carbon continuously and utilizing hot blast by utilizing biomass fuels. The device comprises a chain fire grate and a kiln furnace, wherein the chain fire grate is arranged in the kiln furnace; one end of the chain fire grate is provided with a feed inlet; and the inside of a kiln is divided into a carbonization chamber, a combustion chamber and a dust chamber, wherein the carbonization chamber is arranged at the upper part of the chain fire grate, the combustion chamber and the dust chamber are separated by a rear arch at the upper part of the carbonization chamber and a hole division wall, the combustion chamber is arranged next to one side of the feed inlet, and the dust chamber is connected with a hot blast outlet. The device can be used for solving the problems of incapability of continuous production and ineffective utilization of heat in the process of producing carbons by utilizing the biomass fuels. A carbon-producing furnace and a hot blast furnace are organically integrated into a whole so that carbon can be produced continuously, heat is effectively utilized, the yield and the quality of carbon can be controlled through adjusting a running speed of the chain fire grate in the furnace at the same time, and generation of wastes is avoided.

Owner:云南腾众新能源科技有限公司 +1

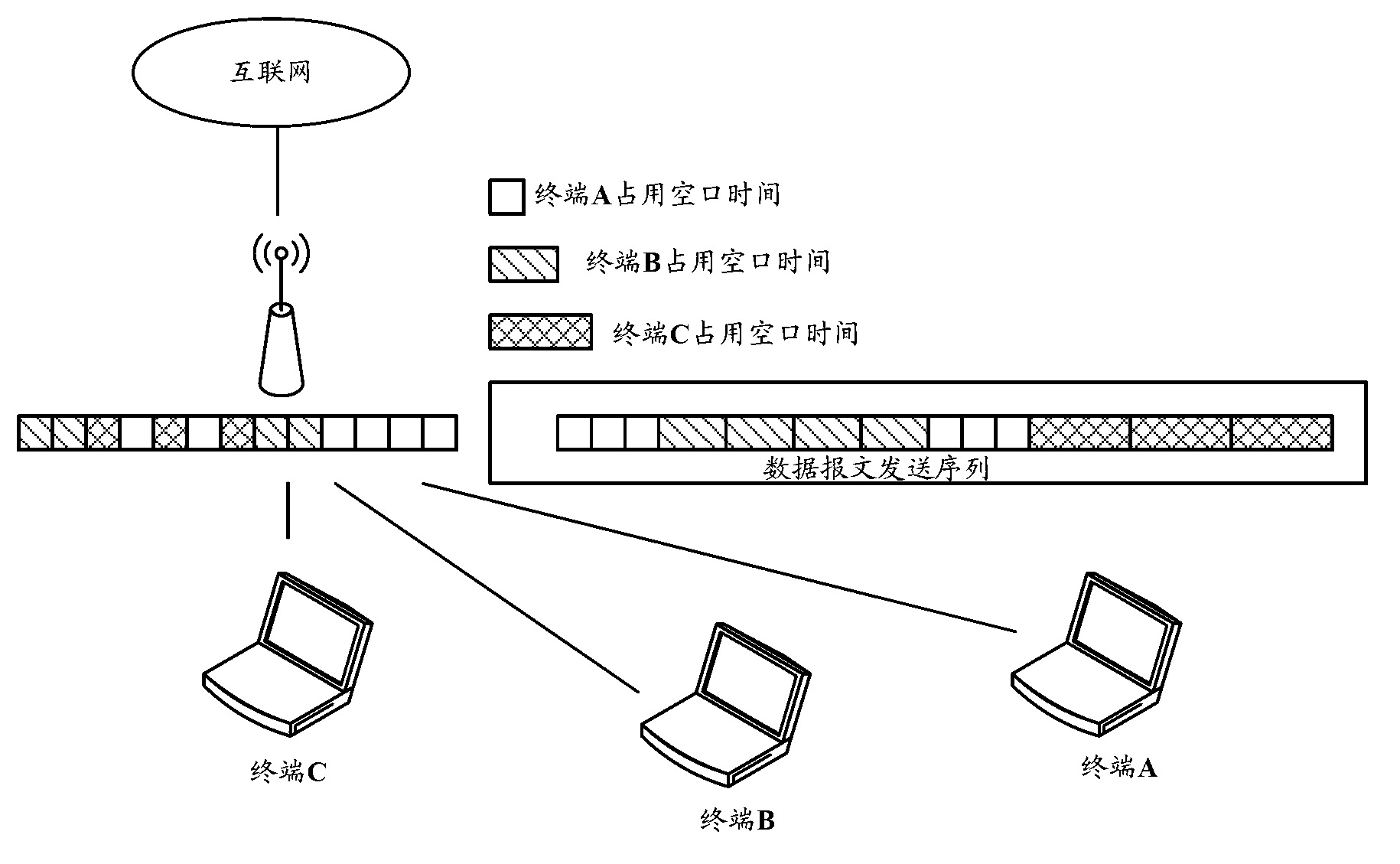

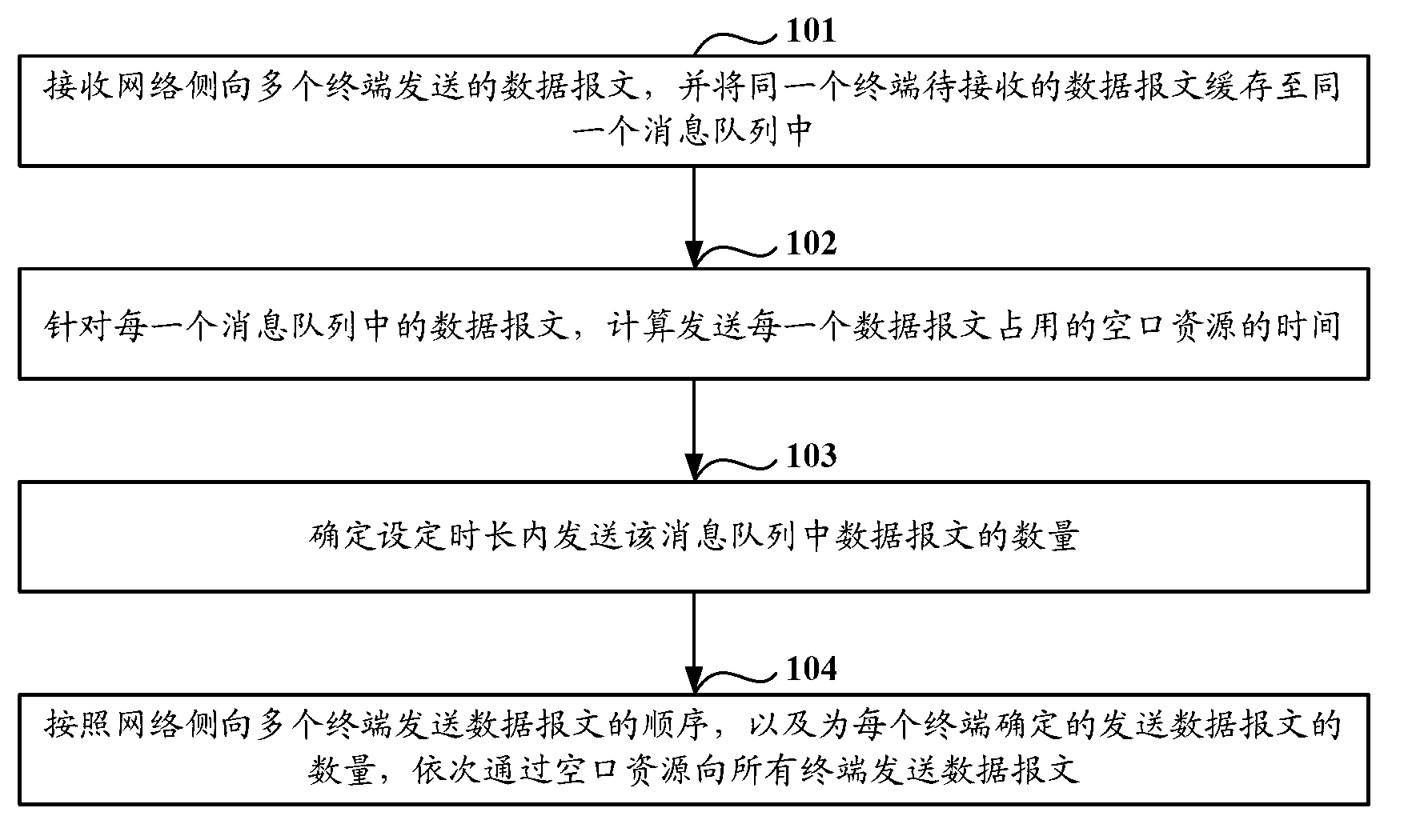

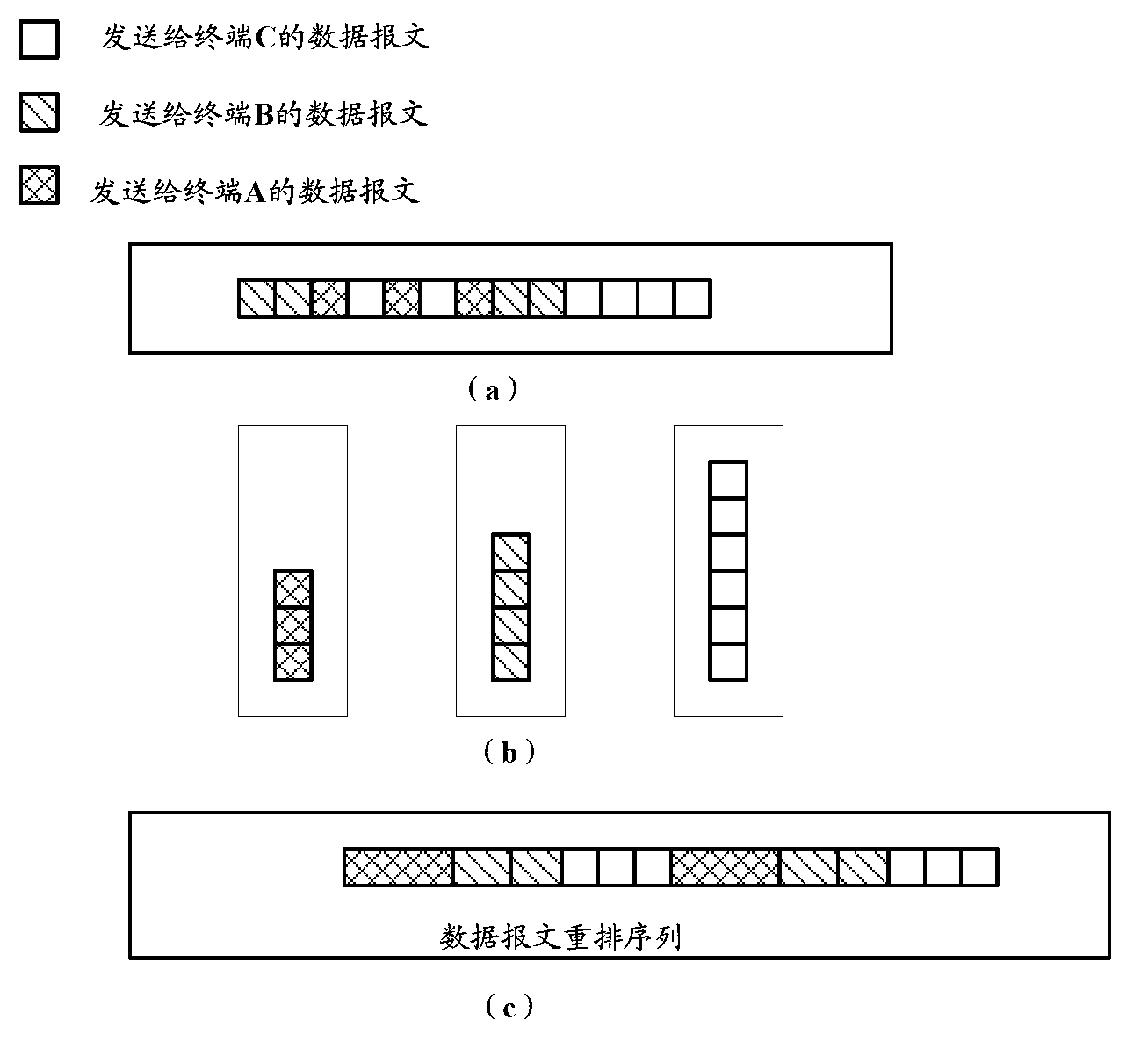

Data message sending method and equipment

The invention discloses a data message sending method and data message sending equipment. The data message sending method mainly comprises the steps of: caching received data messages in a message queue, calculating the time of occupying air interface resources by sending each data message, further determining the quantity of the data messages sent within set duration, and when a plurality of terminals need to receive the data messages sent from a network side, sending the data messages to all terminals through the air interface resources according to the sending sequence of the data messages from the network side to the plurality of terminals and the quantity, determined for each terminal, of the data messages sent one time. According to the invention, the air interface resources can be ensured to be used reasonably when each terminal needs the data messages, so that the problem of wastes during utilization of the air interface resources because network resources are distributed in an unbalanced way is solved.

Owner:RUIJIE NETWORKS CO LTD

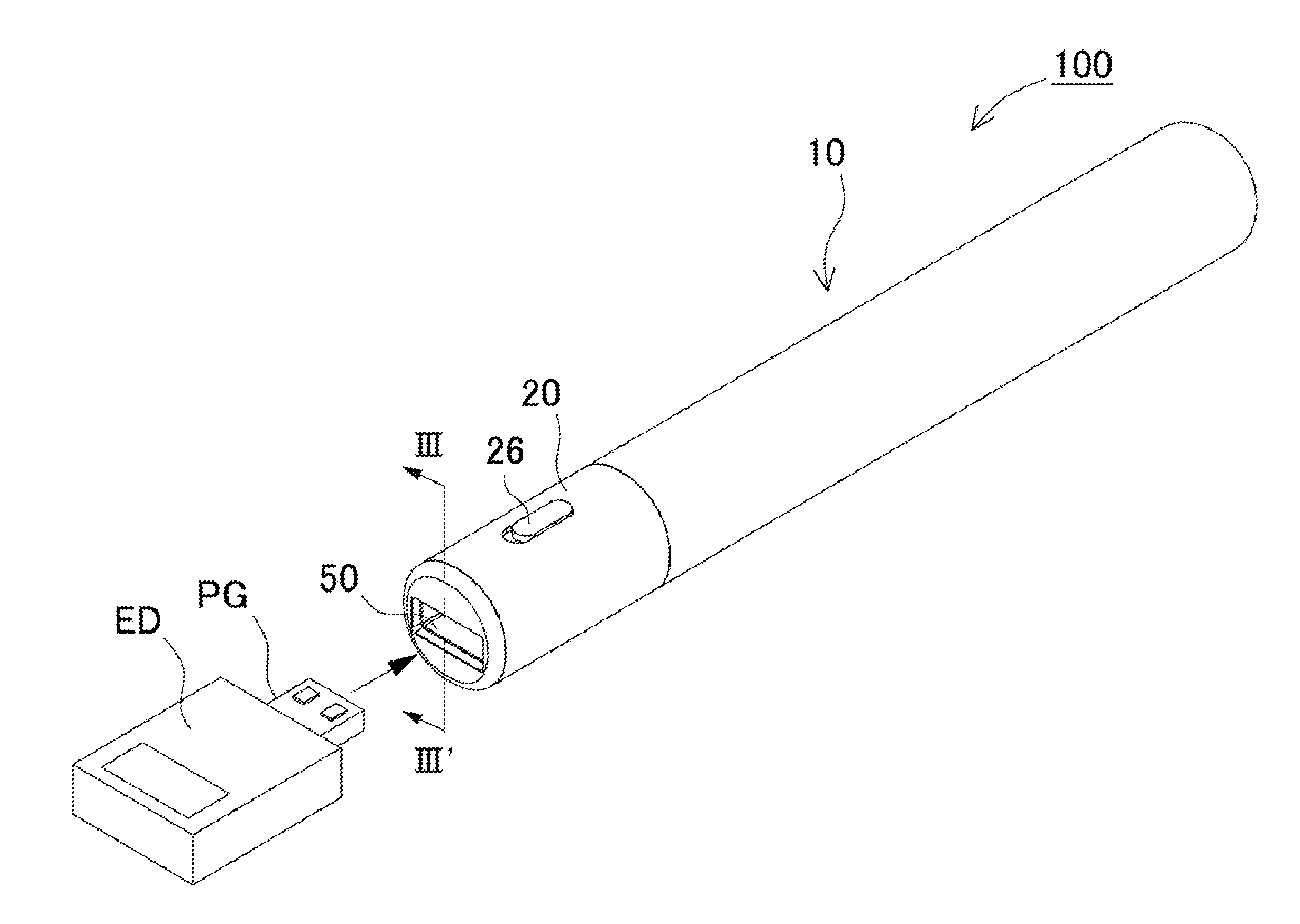

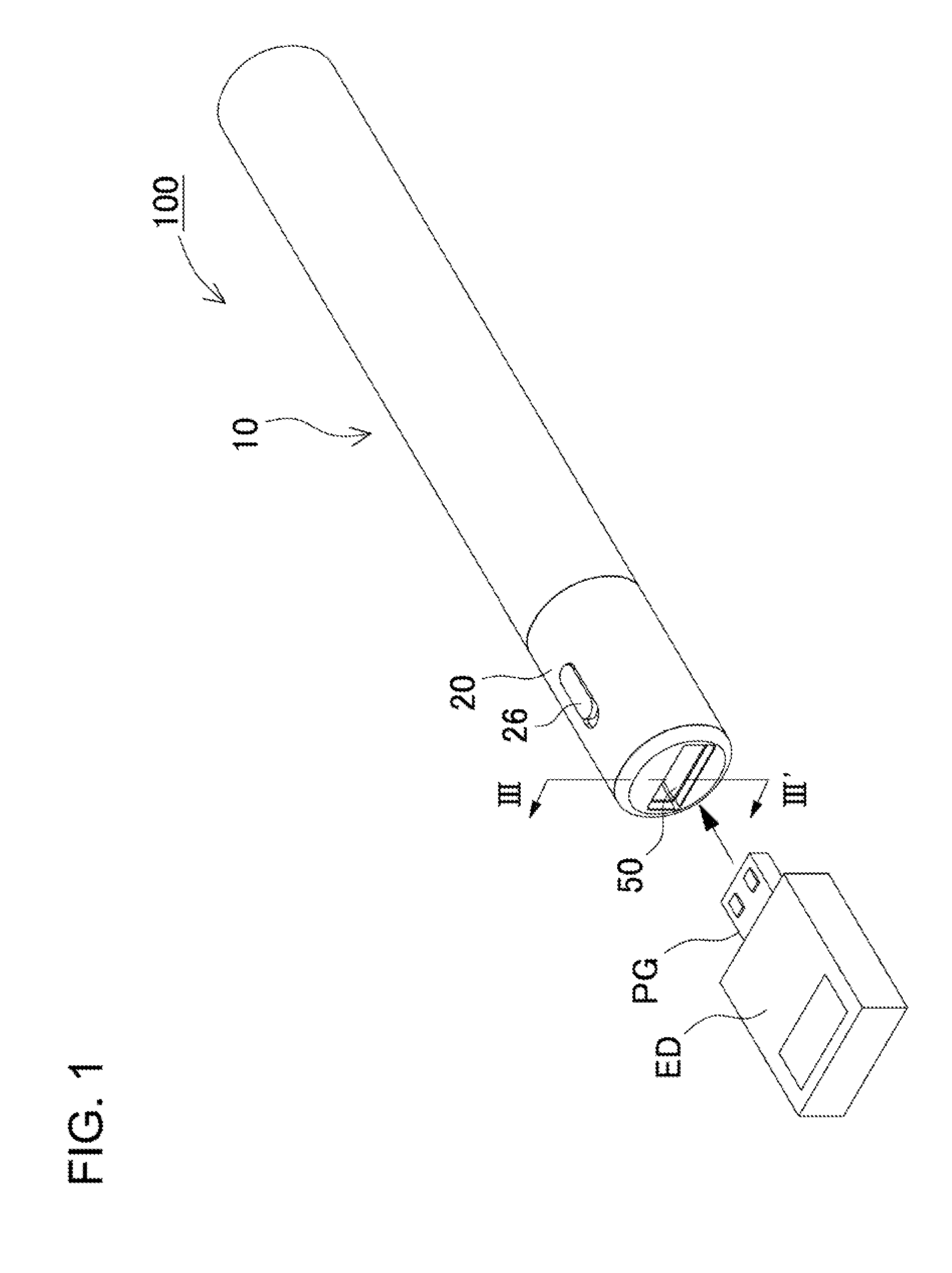

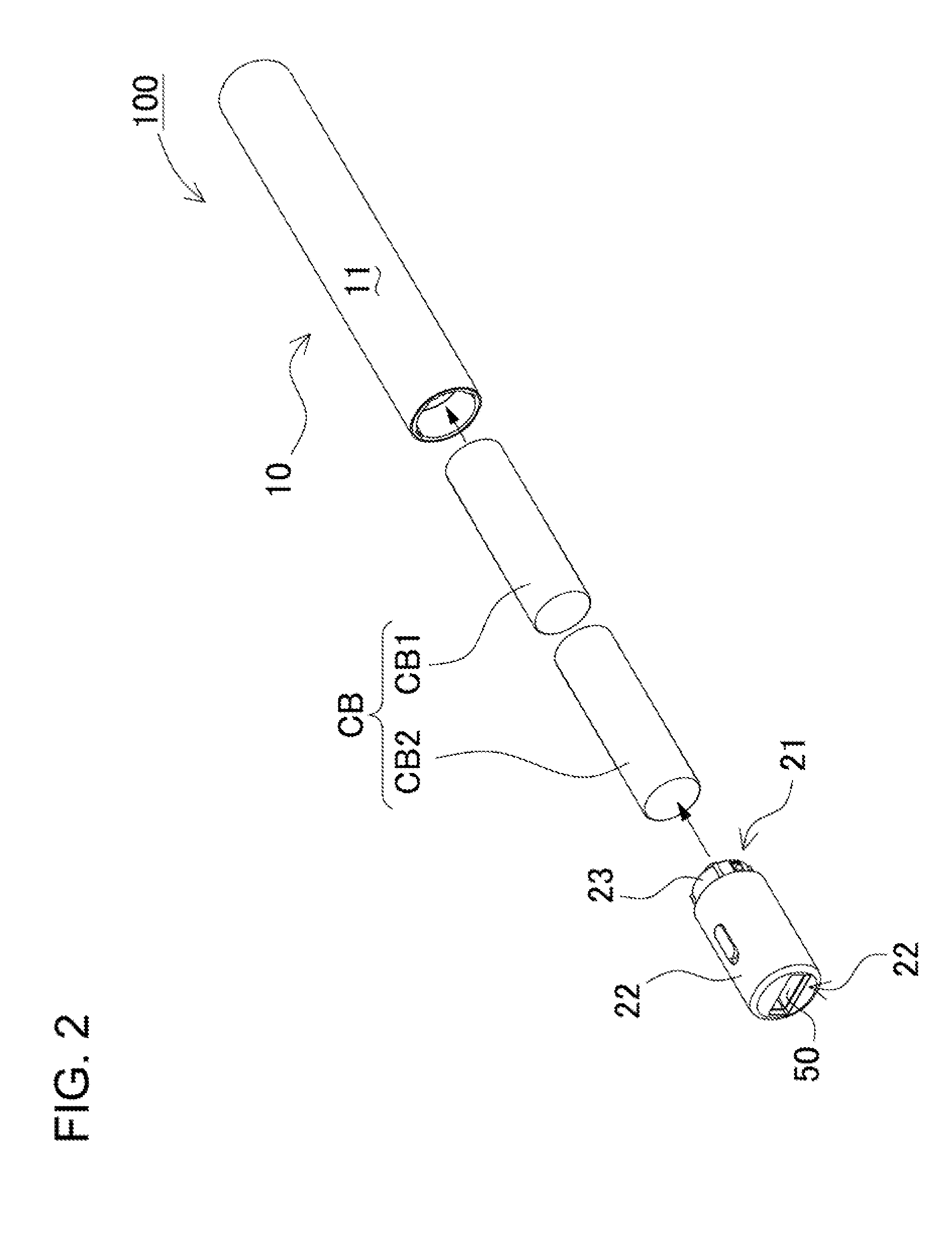

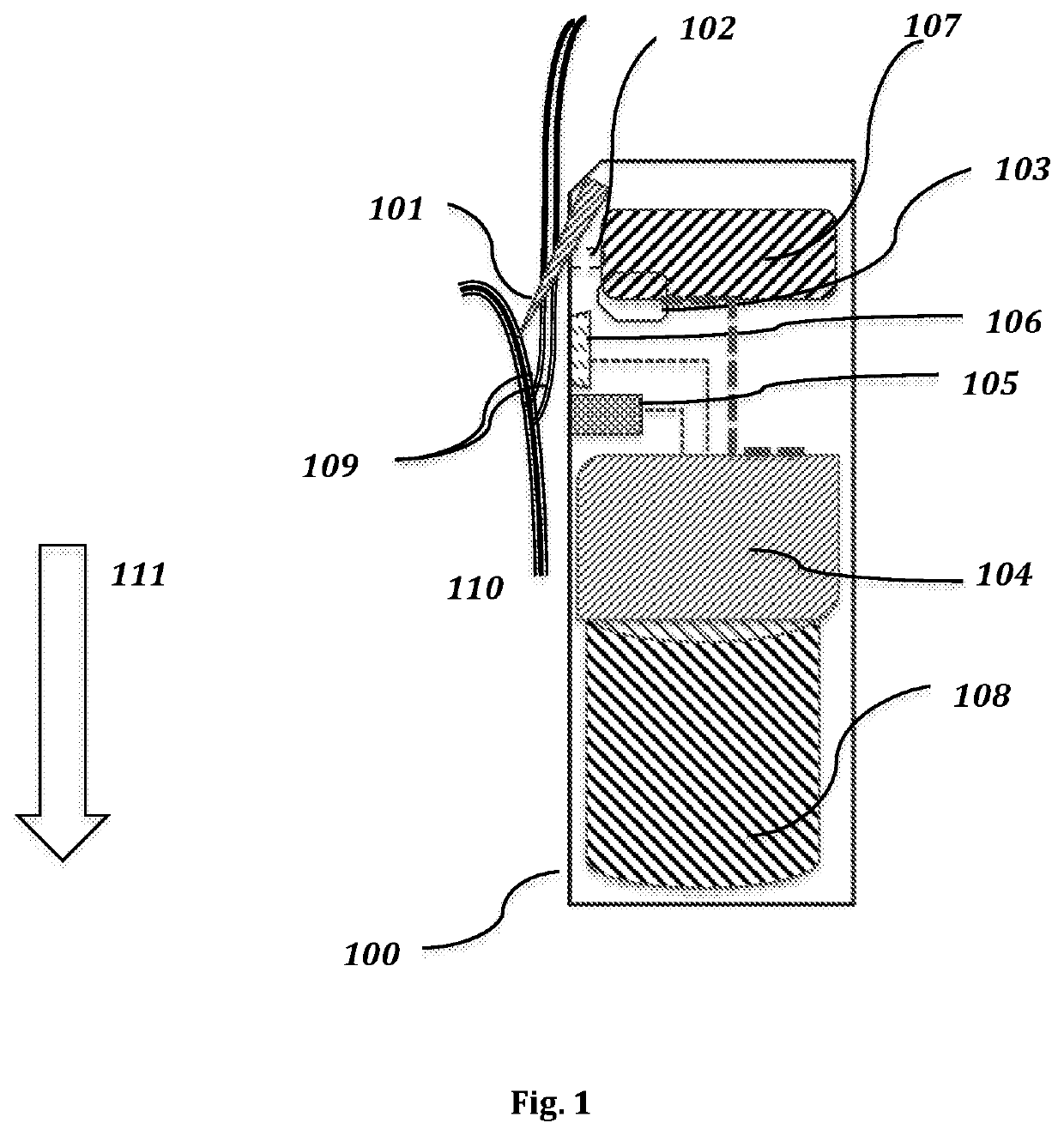

Portable power source apparatus capable of holding circular cylindrical batteries

InactiveUS20110104522A1Stably placeAvoid wasteBatteries circuit arrangementsCell lids/coversVoltageEngineering

A portable power source apparatus has a closing surface 21 facing the open end of the main case 10 and an exposed surface 22 externally exposed at the opposite end of the cap section 20 from the closing surface 21; a planar circuit board 38 housed in the cap section 20 with voltage conversion circuitry mounted to convert the voltage of the circular cylindrical batteries CB contained in the main case 10; and a power supply terminal 50 disposed in the exposed surface 22 of the cap section 20 and capable of outputting power from the circular cylindrical batteries CB contained in the main case 10. The circuit board 38 is disposed diametrically across a circular cross-section of the cap section 20, and a pair of ribs 42 are provided approximately perpendicular to the circuit board 38.

Owner:SANYO ELECTRIC CO LTD

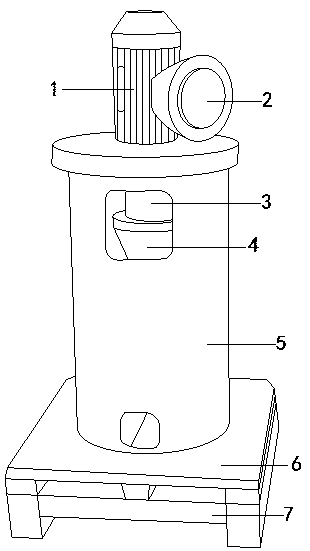

Traditional Chinese medicine continuous extraction device for pharmacy

The invention discloses a traditional Chinese medicine continuous extraction device for pharmacy. The structure of the device comprises a driving machine, a feeding pipe, a stirring tank, an extraction mechanism, a shell, a base and a damping plate. The beneficial effects are as follows: an extraction mechanism is arranged on the structure, a grinding device is arranged in the extraction mechanism, and a filter bucket and a grinder are mainly arranged in the grinding device to extract medicinal residue again on the basis of traditional extraction, the surface of a grinding wheel of the grinder is in a crisscross blade structure, the grinding wheel can form transverse and longitudinal cutting and tearing effects to crush the medicinal residue and extrude the contained medicinal juice in the medicinal residue through the interaction with a pressure-bearing wheel, and the extraction structure can maximize the extraction rate of traditional Chinese medicinal materials and avoid causing insufficient concentration of the medicinal liquid and waste in the use of the medicinal materials.

Owner:南昌大学第一附属医院

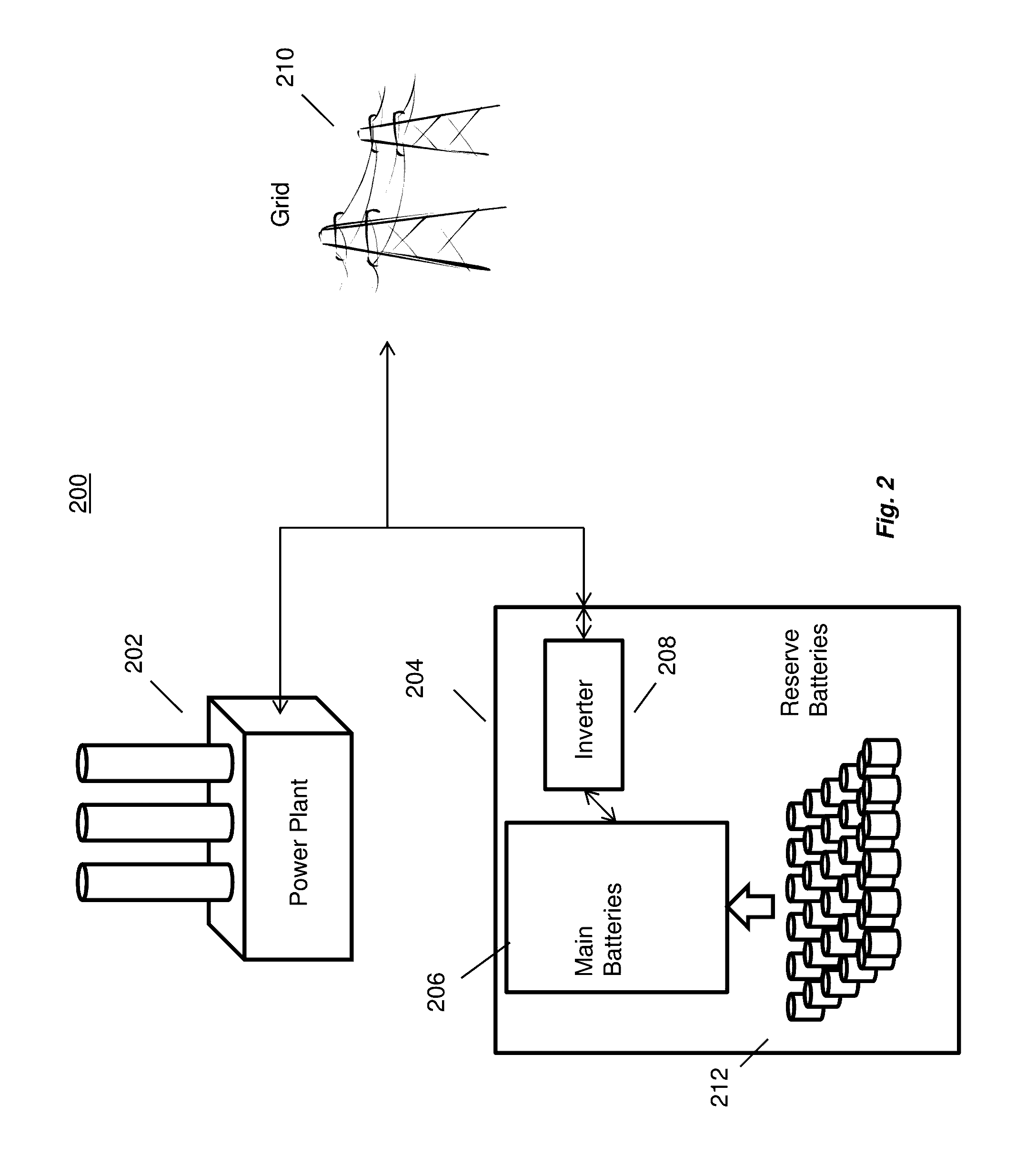

Ultra-long harbor basin slope excavation construction method

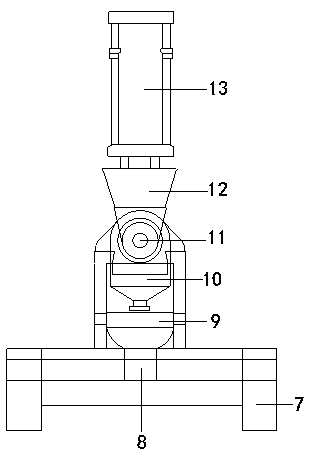

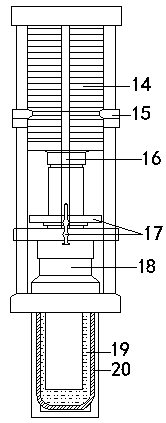

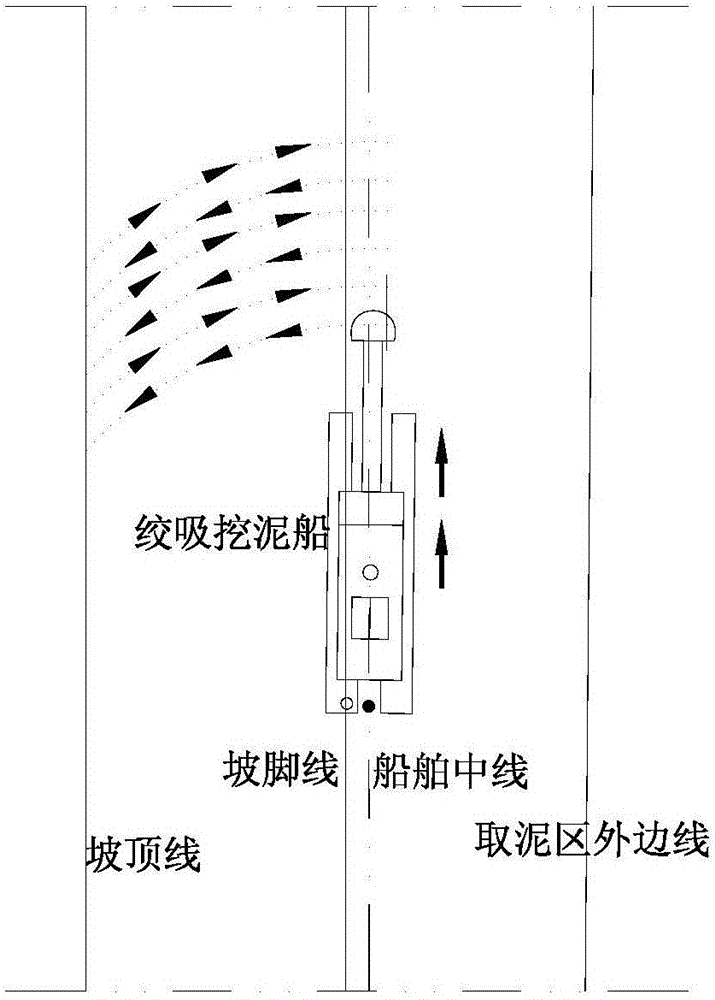

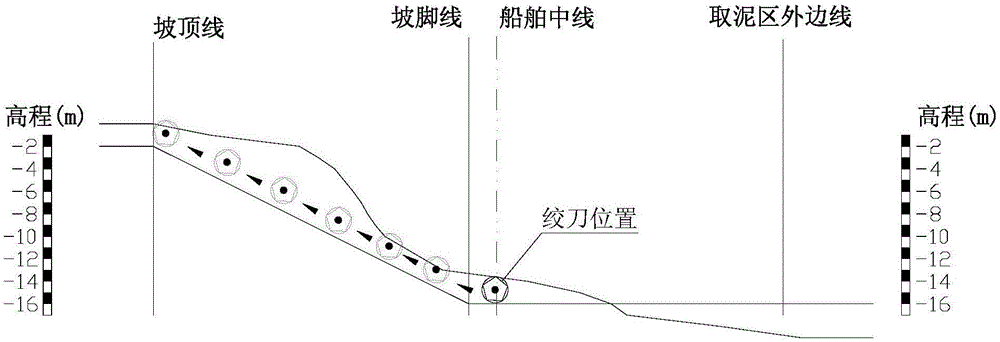

ActiveCN106320261AImprove productivityAvoid wasteSoil-shifting machines/dredgersMarine site engineeringProduction rateGeomorphology

The invention relates to an ultra-long harbor basin slope excavation construction method. The method comprises the following steps that 1, sweeping measurement is carried out on an existing mud taking-out area, particularly a slope area before formal construction, and an accurate slope excavation area bathymetric chart is sorted out; 2, the water depths of all slope excavation areas are analyzed, and a slope excavation process is made; according to the practical situation of the slope, two slope construction processes are made for regularity or irregularity of the slope for on-site construction, and the two slope construction processes comprise a slope hob excavation method and a layered excavation method; 3, the slope to which the two processes are applicable is scientifically and approximately divided into a plurality of areas to which different processes are applicable; 4, the subsection construction situation of each process is reasonably divided according to the width of each section of slope; and 5, different slope excavation construction processes are adopted in different areas through on-site organization for organizing on-site construction. According to the slope excavation scheme with on-site operability, on the basis of the original production rate, the production rate is improved by 20% or above on the premise that the time-benefit rate is not changed.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

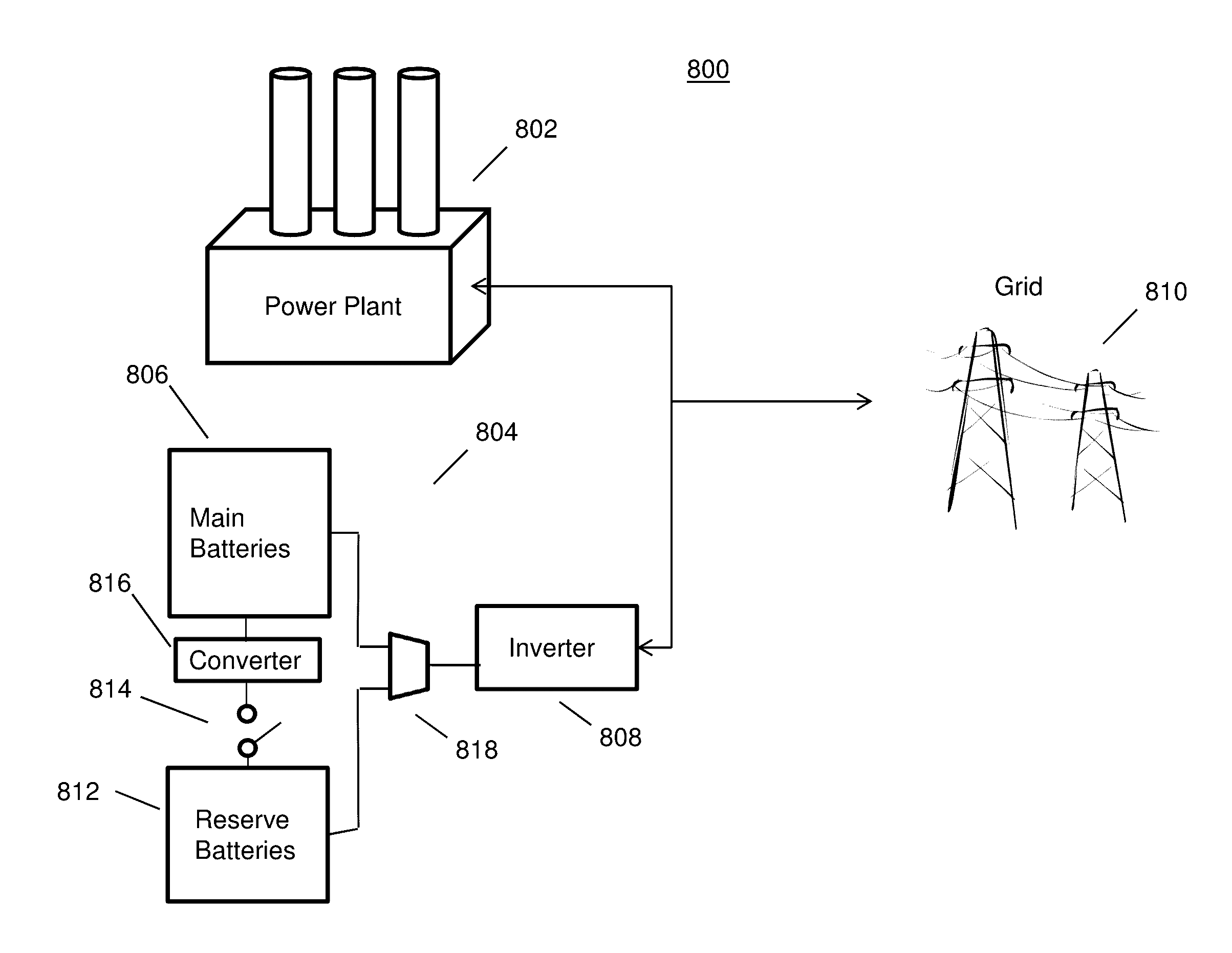

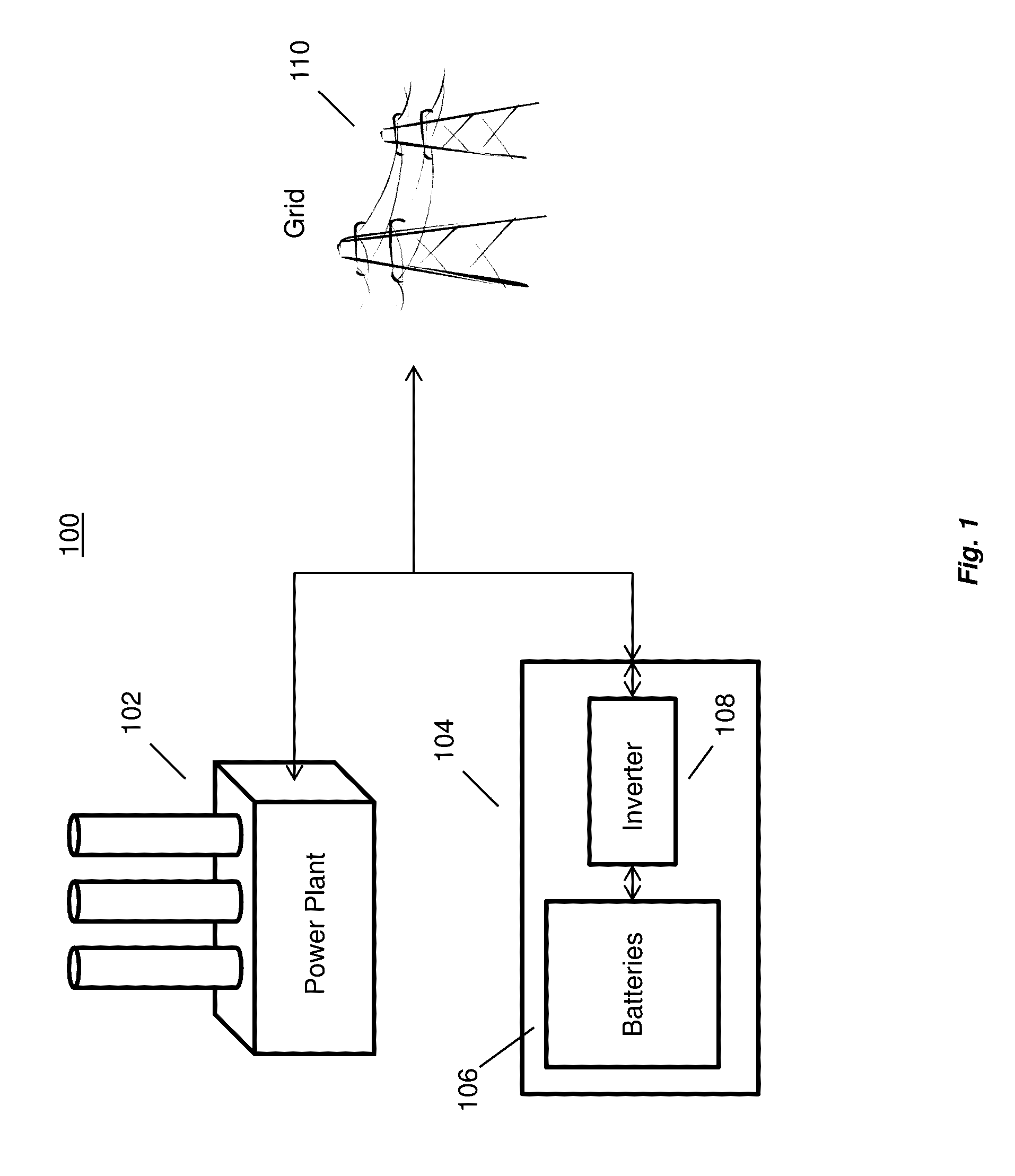

Battery Backup Capacity Method and System

InactiveUS20170063127A1Avoid wasteEfficient and economicalCircuit monitoring/indicationIndicating/monitoring circuitsAC powerPower grid

Approaches for providing backup energy services for a power grid are disclosed. In embodiments, methods and systems for obtaining a first group of reserve backup energy batteries of a first type, which have a different cost structure than a second group of main batteries of a second type. The first group of reserve batteries are combined with the second group of main batteries of the second type to increase a total amount of available energy that is stored and converting DC power from the first group of batteries and the second group of batteries to AC power to be used for power distribution to the grid.

Owner:FLUENCE ENERGY LLC

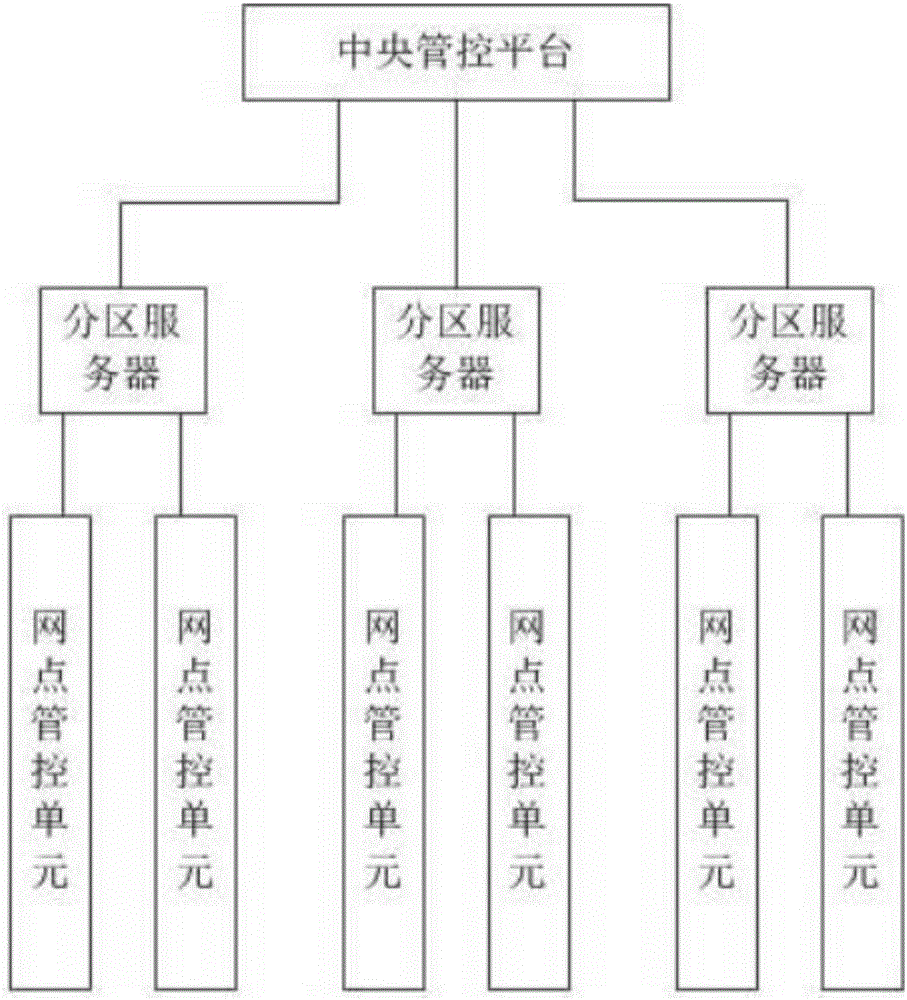

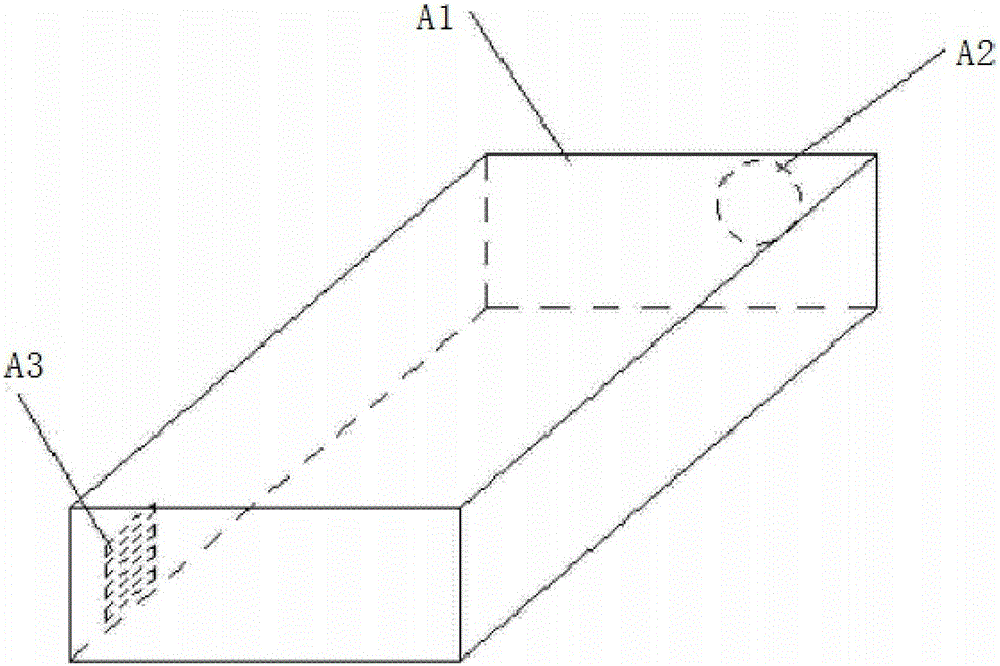

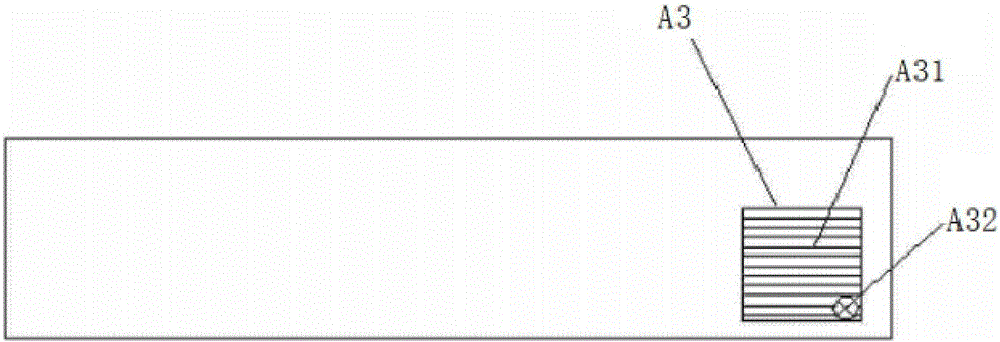

Comprehensive intelligent management and control system and method of banking network sites

InactiveCN105869046AImprove cooling efficiencyAvoid wasteFinanceDigital data processing detailsElectricityEngineering

The invention provides an comprehensive intelligent management and control system and method of banking network sites. Terminal display equipment is erected in a box body; the back side of the box body is provided with a communication cavity used for air outlet; a communication cavity used for air supply is formed in the side surface of the box body; the communication cavity used for air outlet is arranged in inclined and opposite direction to the communication cavity used for air supply; a screen mesh is formed in a position of the communication cavity used for air supply; a fan used for air supply is erected on the lower part surface of the communication cavity used for air supply; the concrete position of the communication cavity used for air outlet is positioned on the upper part of the back side surface of the box body; the defects that the air sufficient flowing is difficult to generate, the flowing performance is poor, and terminal equipment cannot realize efficient temperature reduction are overcome; the information transmission efficiency is improved; the electricity is saved; the cost is reduced.

Owner:JINLING INST OF TECH

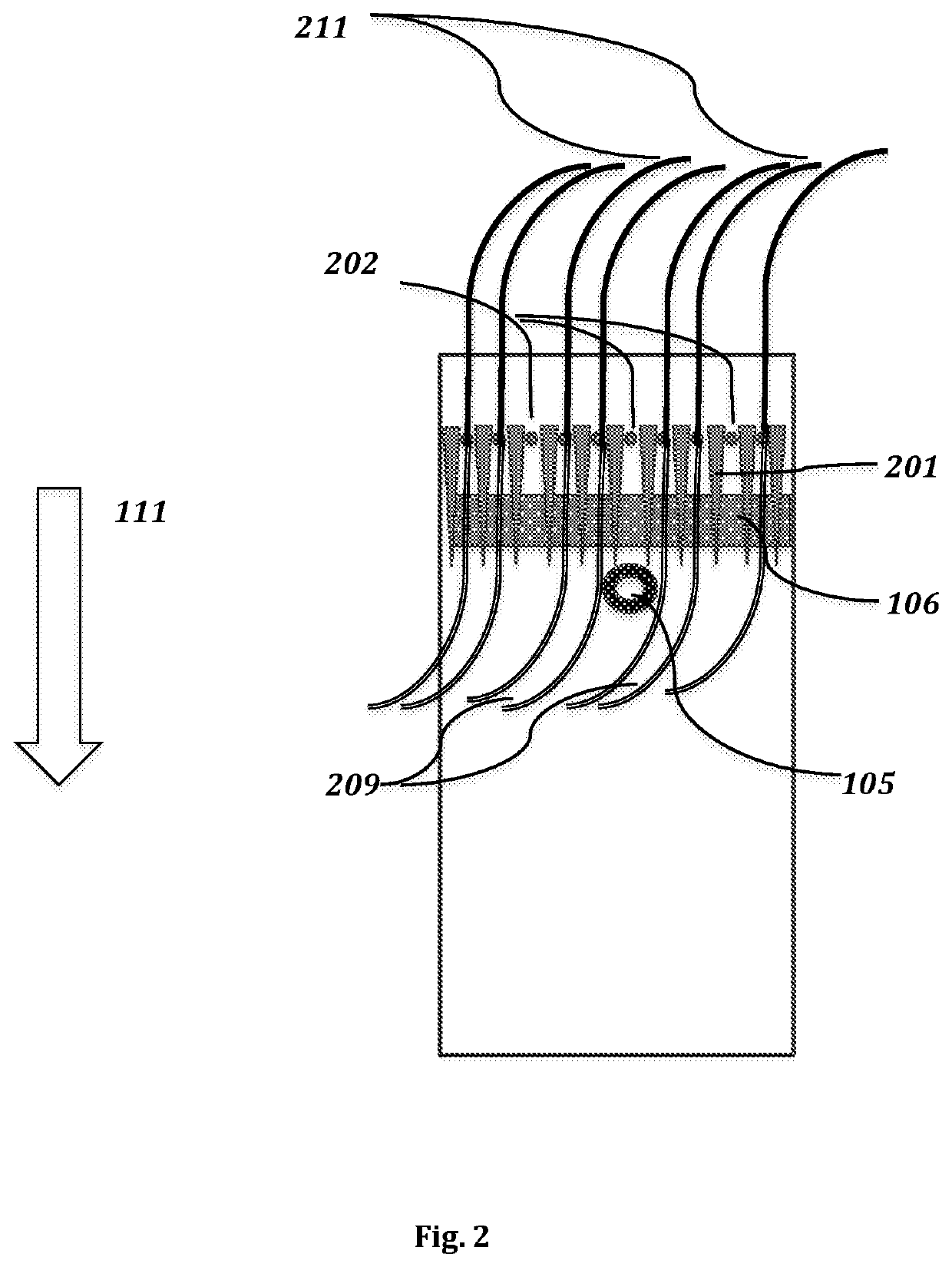

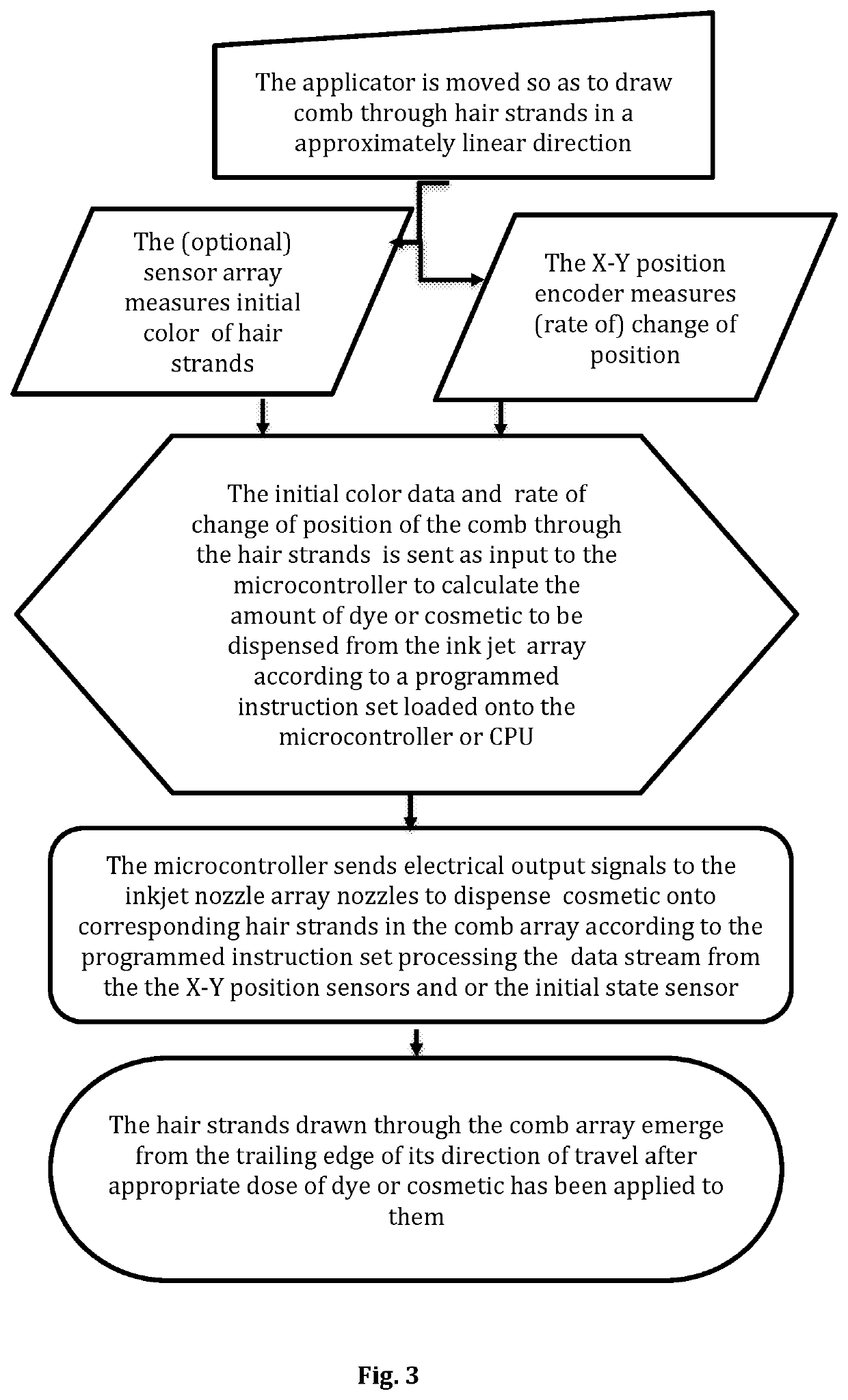

Smart Cosmetic Applicator

InactiveUS20200196937A1Avoid wasteAvoid wastingHair combsDiagnostic recording/measuringBiomedical engineeringSkin surfaces

Owner:GOPALAN RAMESH

Single-use sink strainer

Owner:YCHIE SHARON

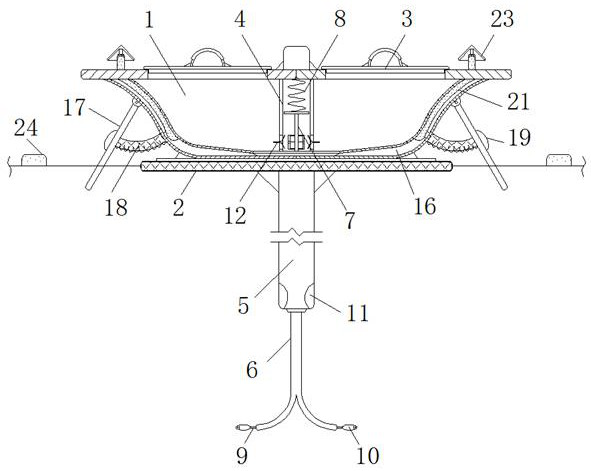

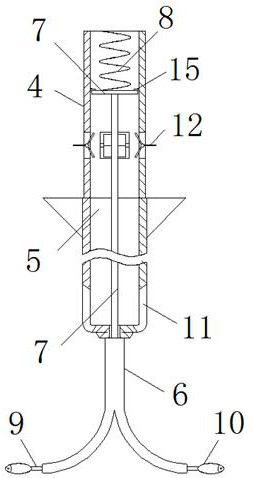

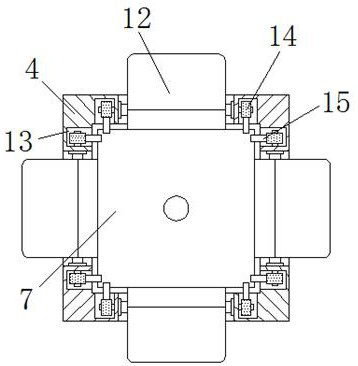

Automatic feeding device capable of effectively reducing eutrophication of aquaculture environment

InactiveCN112471034AReduce deliveryAvoid wasteClimate change adaptationPisciculture and aquariaEutrophicationEngineering

The invention discloses an automatic feeding device capable of effectively reducing eutrophication of an aquaculture environment. The automatic feeding device comprises a feeding cavity, a middle pipe, a storage cavity and a floating net, wherein a floating air cushion is fixedly installed at the bottom of the feeding cavity, a cover plate is movably installed at the top of the feeding cavity, themiddle pipe is fixed to the middle of the interior of the feeding cavity in a penetrating mode, the upper end of a vertical pipe is fixed to the lower end of the middle pipe, a forked thin pipe is fixed to the lower end of the vertical pipe in a penetrating mode, a pull shaft is movably installed in the middle pipe, a fishing line pull rope is fixed to the bottom of the pull shaft, and the feeding cavity and the floating air cushion are fixedly installed in the floating net. According to the automatic feeding device capable of effectively reducing the eutrophication of the aquaculture environment, through foraging movement of fishes, intermittent small-amount and multi-time casting of baits in a culture pond is achieved, the feeding amount of the baits at a time and human-assisted labor consumption are reduced, and the problems of use waste of the baits and eutrophication in the culture pond are prevented.

Owner:张宝

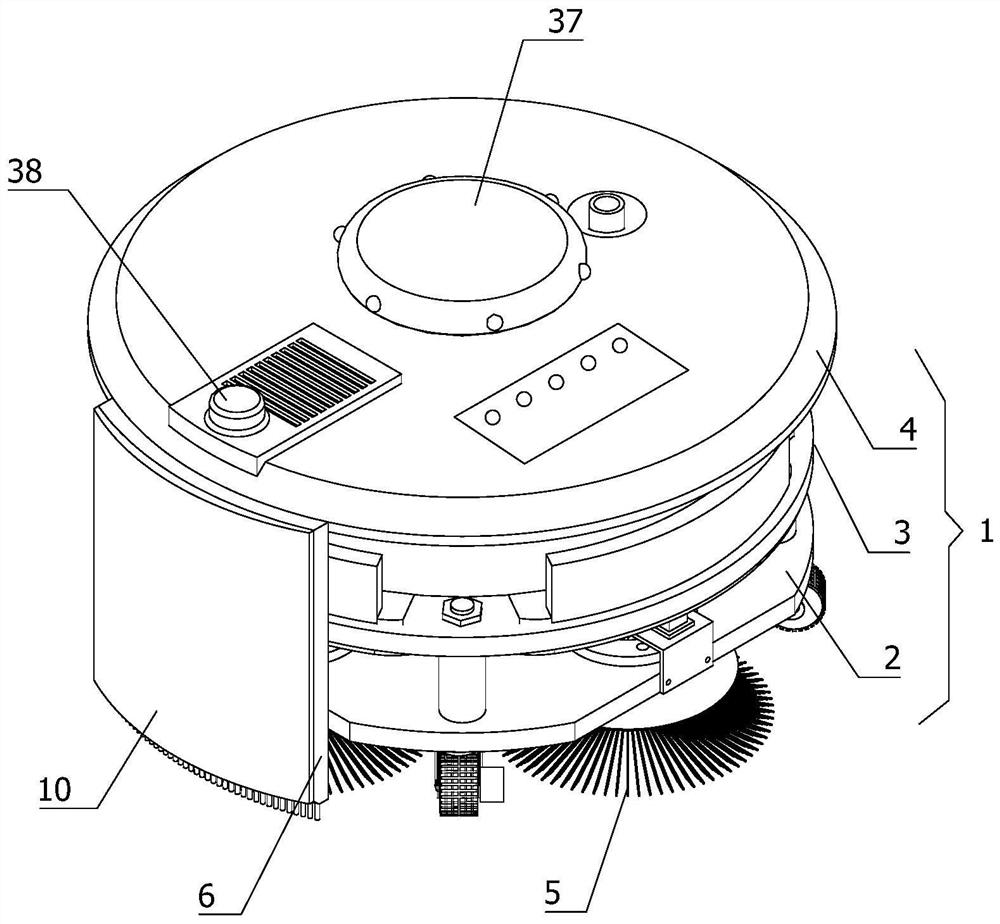

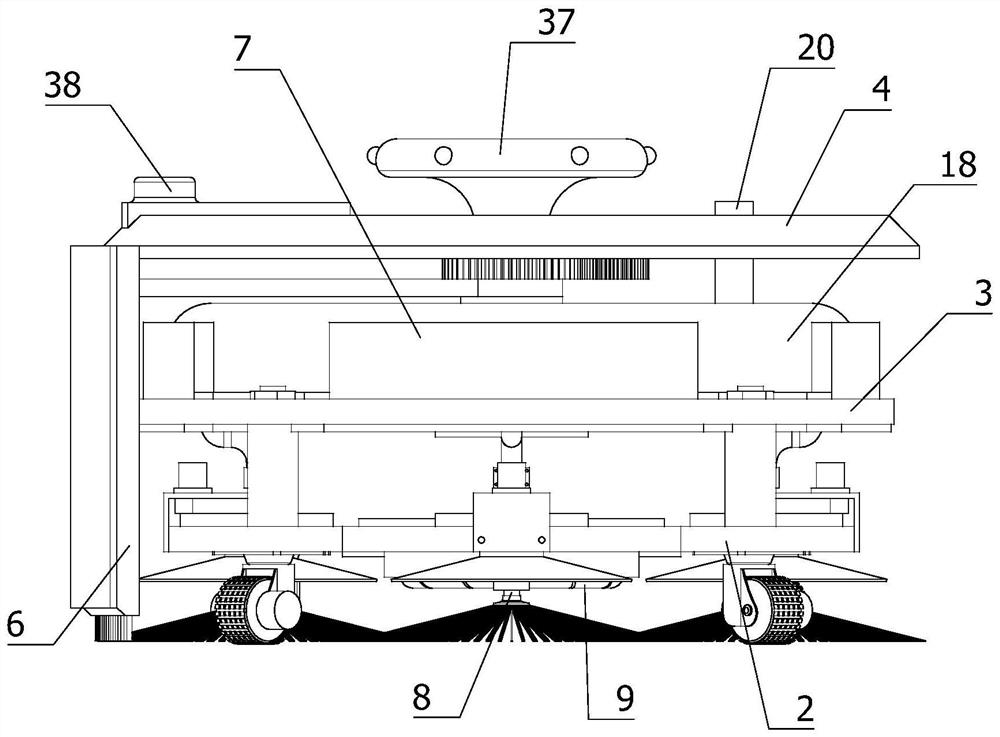

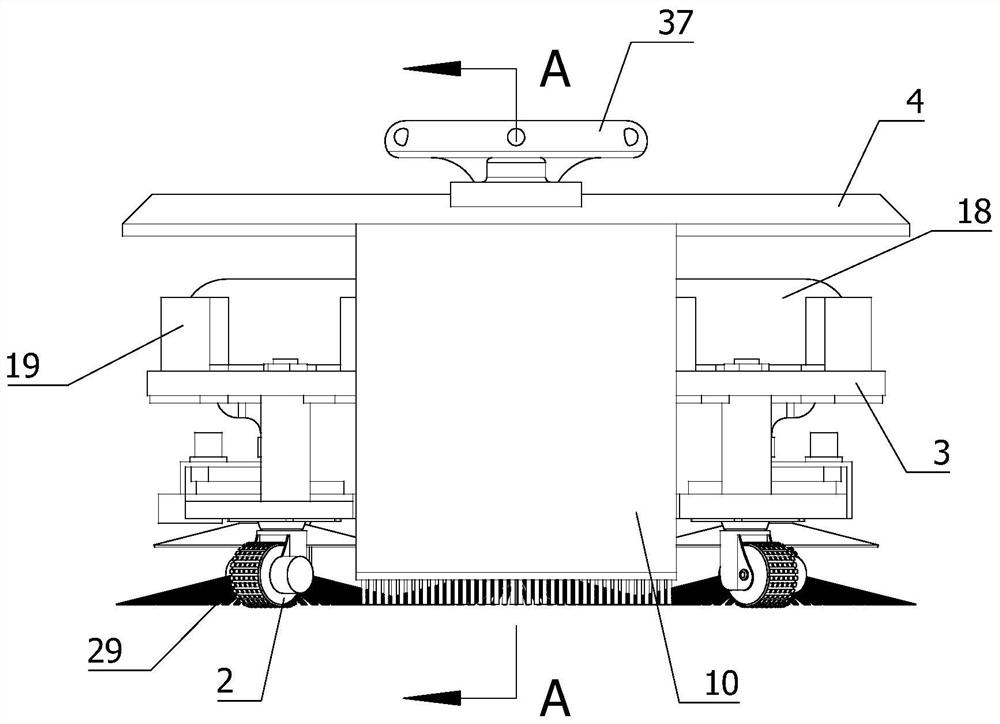

Automatic disinfection robot for ground of medical department

ActiveCN113842482AApply evenlyDo not polluteAutomatic obstacle detectionTravelling automatic controlMedical departmentEnvironmental engineering

The invention relates to the technical field of medical instruments, in particular to an automatic disinfection robot for ground of medical department. The automatic disinfection robot comprises a walking device, an alarm device and a disinfection device, the walking device is a disc-shaped robot, and the walking device is composed of a chassis walking vehicle, a middle end supporting disc and a top disc which are sequentially installed from bottom to top; the disinfection device comprises a uniform disinfection assembly and a baffle, the uniform disinfection assembly comprises a liquid supply mechanism, a liquid spraying mechanism and an air blowing fan. According to the automatic disinfection robot for the ground of the medical department, through cooperation between the walking device and the disinfection device, automatic and comprehensive disinfection of the ground of the medical department is achieved, and through blocking of the baffle on obstacle; the obstacles cannot be contaminated by disinfectant, the disinfectant only disinfects the floor, the disinfectant is evenly smeared through a liquid spraying mechanism and the air blowing fan, and even smearing of the disinfectant is guaranteed while the floor is comprehensively disinfected.

Owner:SOUTHWEST JIAOTONG UNIV +1

Array substrate, display panel and pixel patching method

ActiveUS20190088683A1Improves sensory experienceAvoid wasteSolid-state devicesNon-linear opticsData linesElectrical and Electronics engineering

The present application provides an array substrate, which comprises a plurality of gate lines, a plurality of data lines, a plurality of thin film transistors, a plurality of pixel electrodes, and a plurality of conductive members. In each of the pixel regions, a control terminal of the TFT is electrically connected with the gate line, an input terminal of the TFT is electrically connected with the data line, and an output terminal of the TFT is electrically connected with the pixel electrode. The output terminal comprises a body, and a first contact and a second contact which are connected with the body. The first contact and one of the conductive members extending into the pixel region are overlapping-disposed and insulated from each other. The second contact and another of the conductive members extending into the pixel region are overlapping-disposed and insulated from each other.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com