Intelligent garbage can provided with liftable type heat-sealing device

A heat-sealing device and lift-type technology, applied in trash cans, garbage collection, packaging sealing/fastening, etc., can solve problems such as increased production costs, waste of garbage bags, and difficulty in sealing, avoiding waste and saving production costs. , the effect of small installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

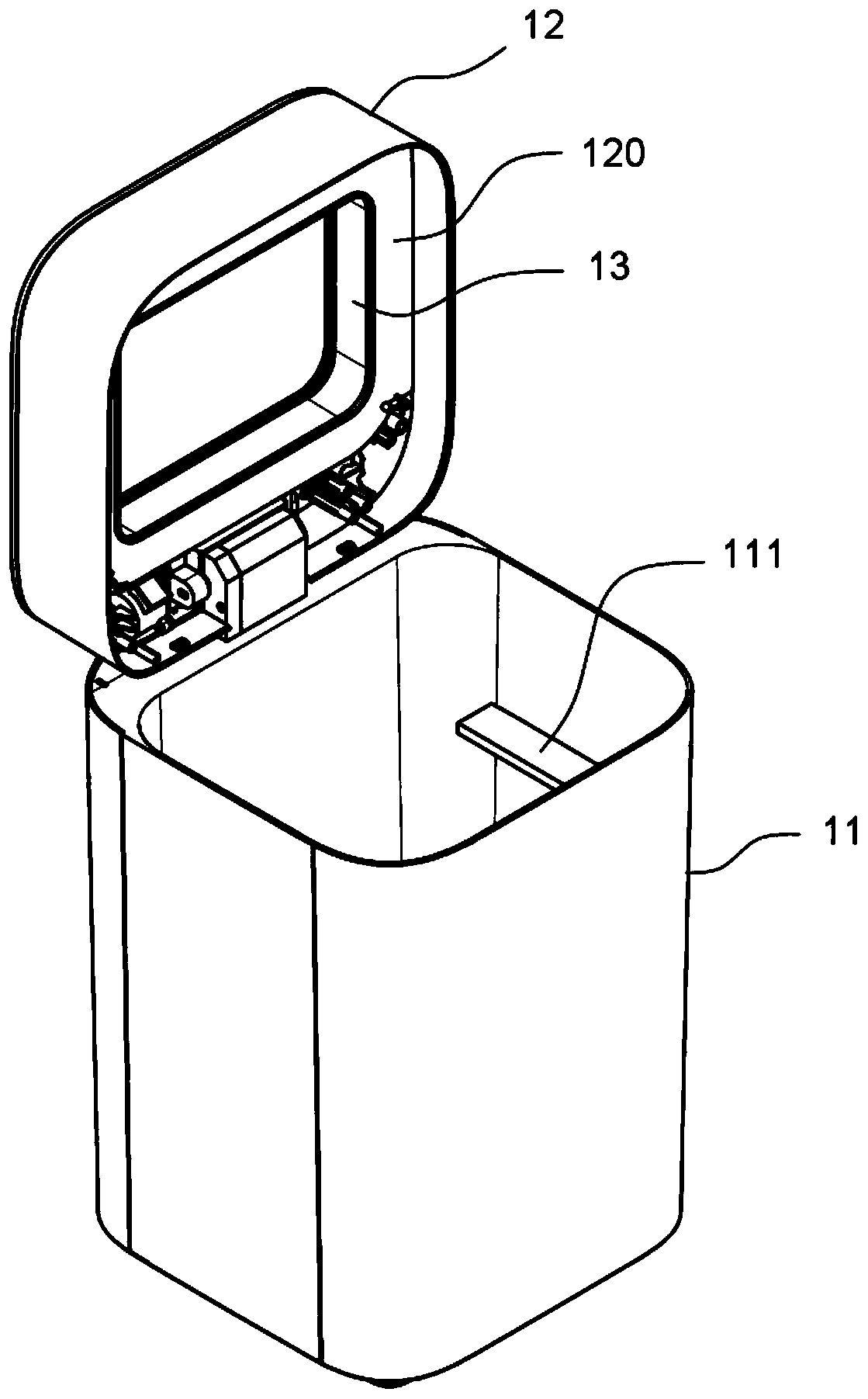

[0029] refer to figure 1 — Figure 5 , the present invention provides an intelligent trash can equipped with a liftable heat-sealing device, including:

[0030] The bucket body 11, which can be stably seated on the ground, has a garbage bag insertion cavity in the bucket body 11;

[0031] A bucket cover 12, which is rotatably mounted on the top rear end of the bucket body 11 through a flip connector, and a garbage bag box 13 is installed on the bucket cover 12; and

[0032] Liftable heat-sealing device 2, which is set in the intelligent trash can, is used to seal and fuse the garbage bag at an appropriate position;

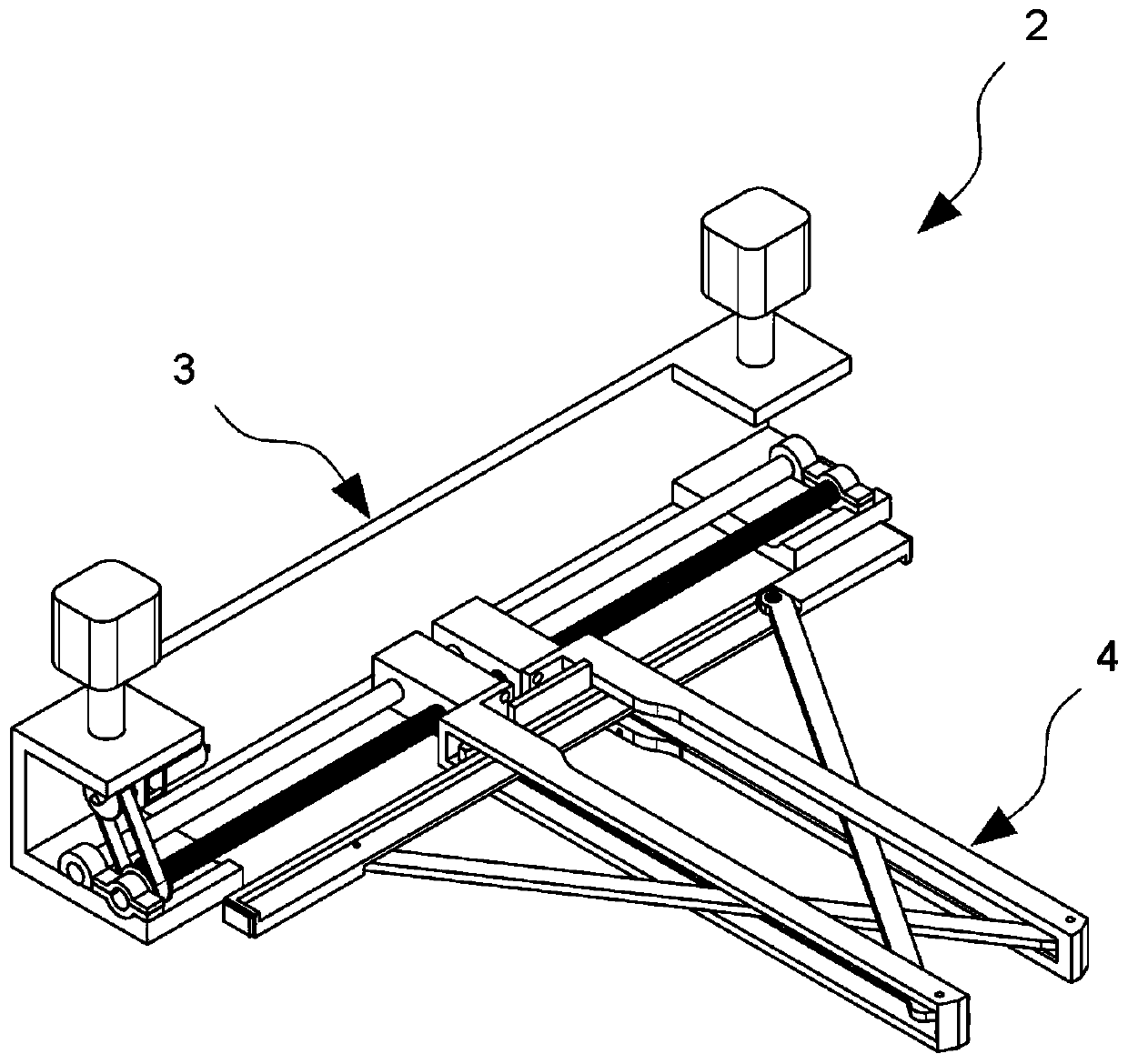

[0033] Wherein, the liftable heat-sealing device 2 is composed of three parts: a lifting unit 3 , a closing unit 4 and a heating wire module 47 .

[0034] As an embodiment of the present invention, the closing unit 4 includes

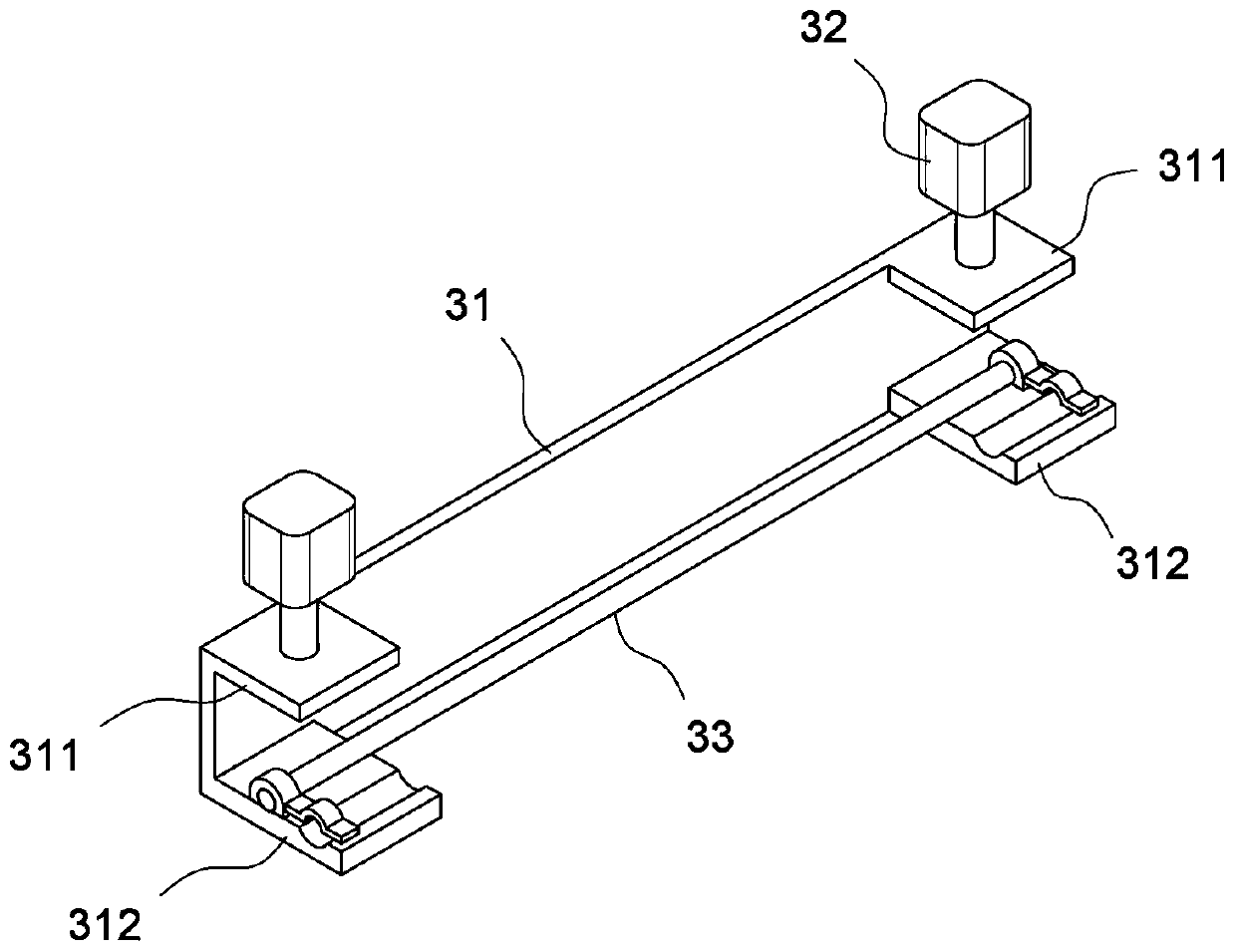

[0035] The lifting support frame 31 has a first plate 311 formed on both sides of its top and a second plate 312 formed on both sides ...

Embodiment 2

[0059] On the basis of retaining a part of the technical solution of the embodiment, the structure of the lifting unit 3 and its related structures are replaced. refer to Image 6 and Figure 7 , as an embodiment of the present invention, the lifting unit 3 includes

[0060] Lifting stepper motor 340, which is fixed in the inner space of barrel body 11, is used to drive the vertical lifting of lifting support frame 31, and the output shaft end of lifting stepper motor 340 is connected with the second screw mandrel 34; With

[0061] The second polished rod 35, which is fixed in the inner space of the barrel body 11, is used to guide the vertical lifting of the lifting support frame 31;

[0062] Wherein, one end of the lifting support frame 31 is provided with a threaded hole, and the second screw rod 34 is screwed and installed in the threaded hole; Three guide holes.

[0063] As an embodiment of the present invention, the barrel body 11 is provided with a bearing seat for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com