Polysilicon reduction furnace

A reduction furnace and polysilicon technology, applied in the direction of silicon compounds, inorganic chemistry, non-metallic elements, etc., can solve the problems of low output, high energy consumption, high cost, etc., and achieve the effect of improving utilization rate, avoiding damage, and avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below with reference to the drawings.

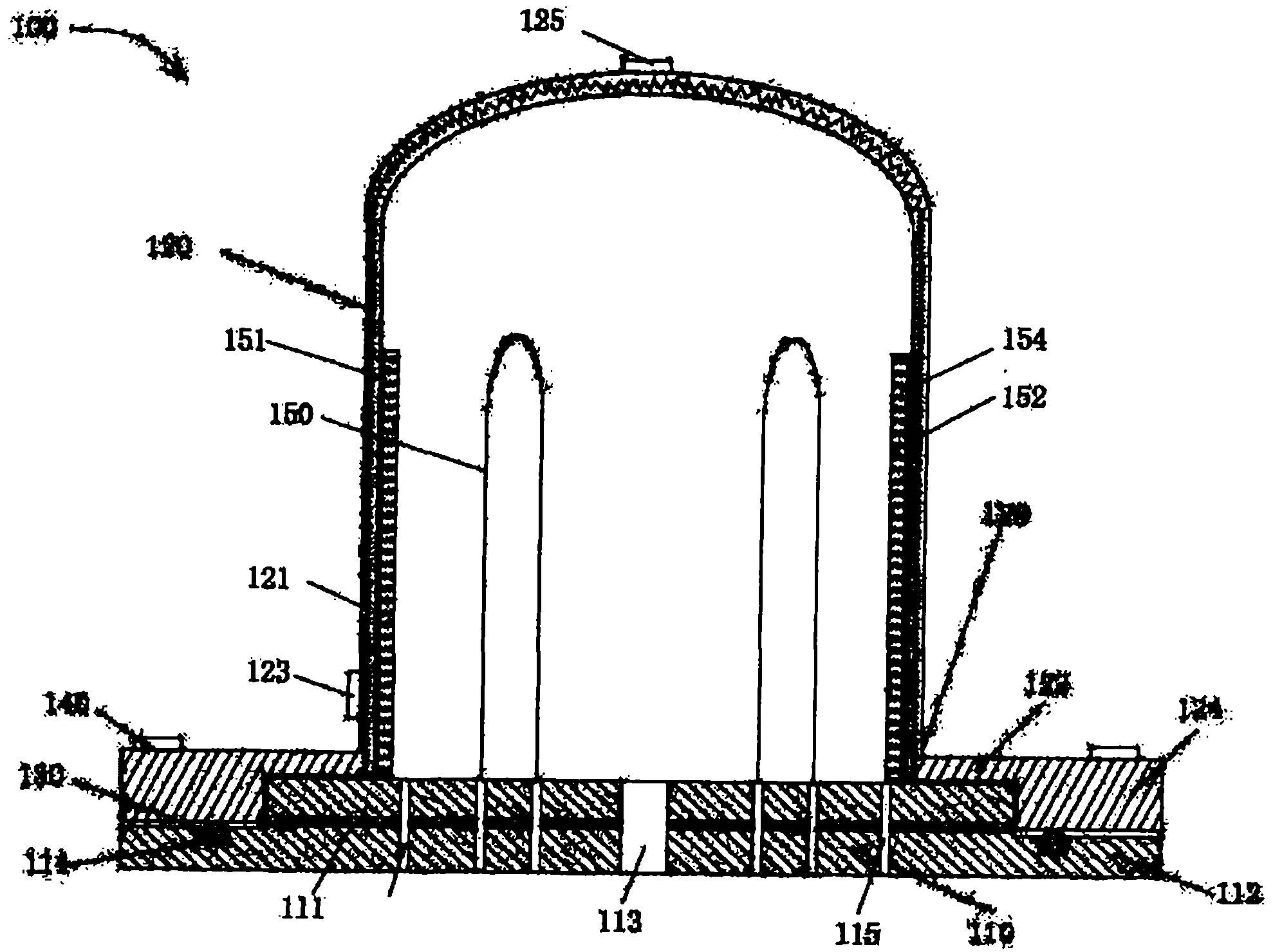

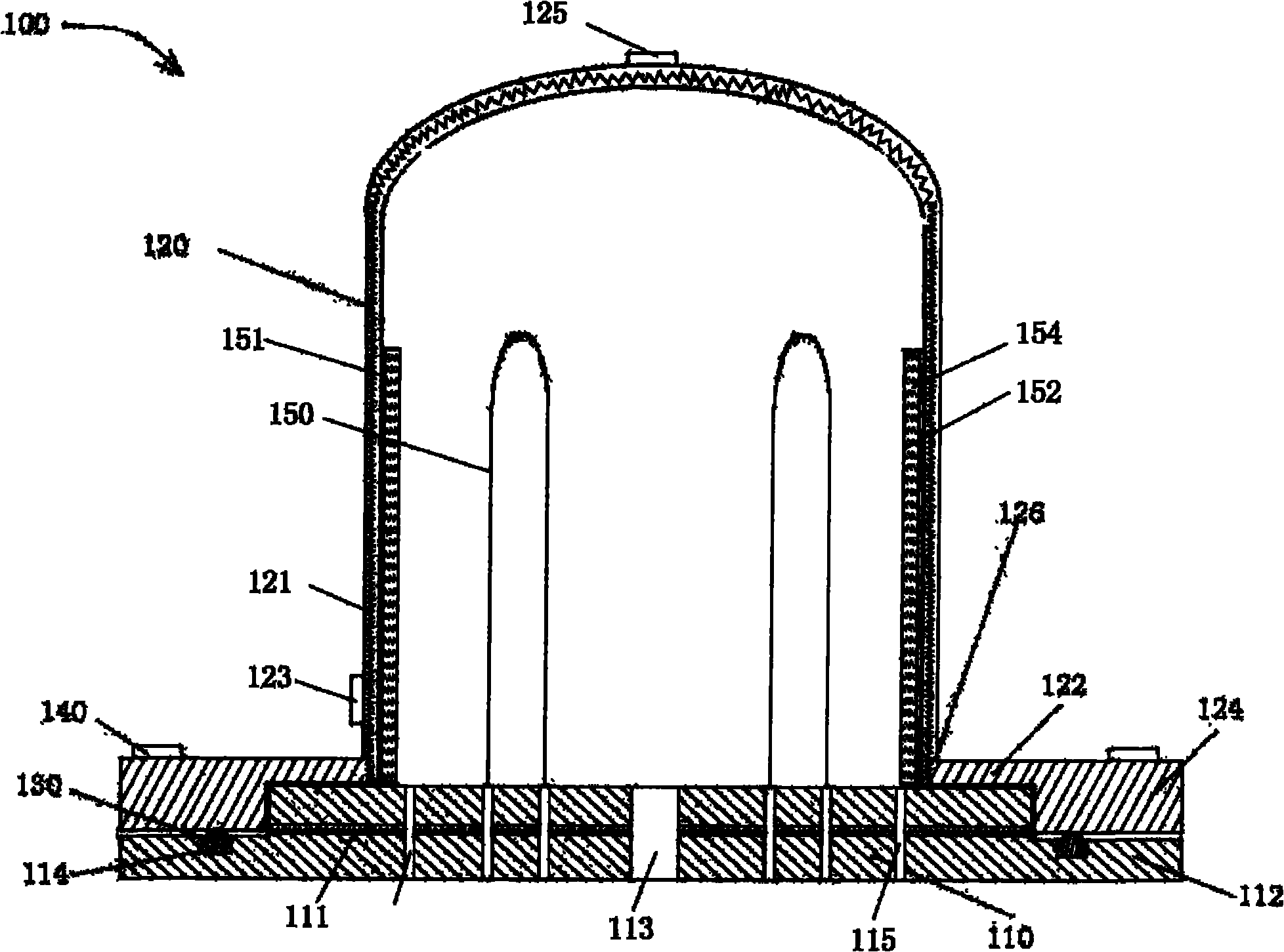

[0023] See figure 1 As shown, the present invention relates to a paracrystalline silicon reduction furnace 100 for producing polysilicon, which includes a base 110 and a furnace body 120 disposed on it. Two U-shaped electrode heaters 150 are fixed on the base 110. The base 110 is also provided with an air inlet 113 and a plurality of air outlets 115. The furnace wall of the furnace body 120 is double-layered, and spirally rising cooling pipes or diversion grooves are arranged between the double-layer furnace walls, and cooling water or cooling oil 121 and cooling water or cooling oil 121 are passed through the cooling pipes or diversion grooves. The inlet 123 is set at the bottom of the furnace body 120, and the outlet 125 is set on the top of the furnace body 120. The cooling water or cooling oil 121 is pressurized by a pump (not shown) to make it flow co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com