Waterborne inorganic heat-insulating, waterproof and environment-friendly coating for buildings and preparation method of coating

An environmentally friendly coating and construction technology, applied in the direction of fireproof coatings, reflective/signal coatings, alkali metal silicate coatings, etc., can solve the problems of cumbersome procedures, long construction period, and flammable materials, and achieve small surface area to volume ratio, Effect of blocking heat transfer and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

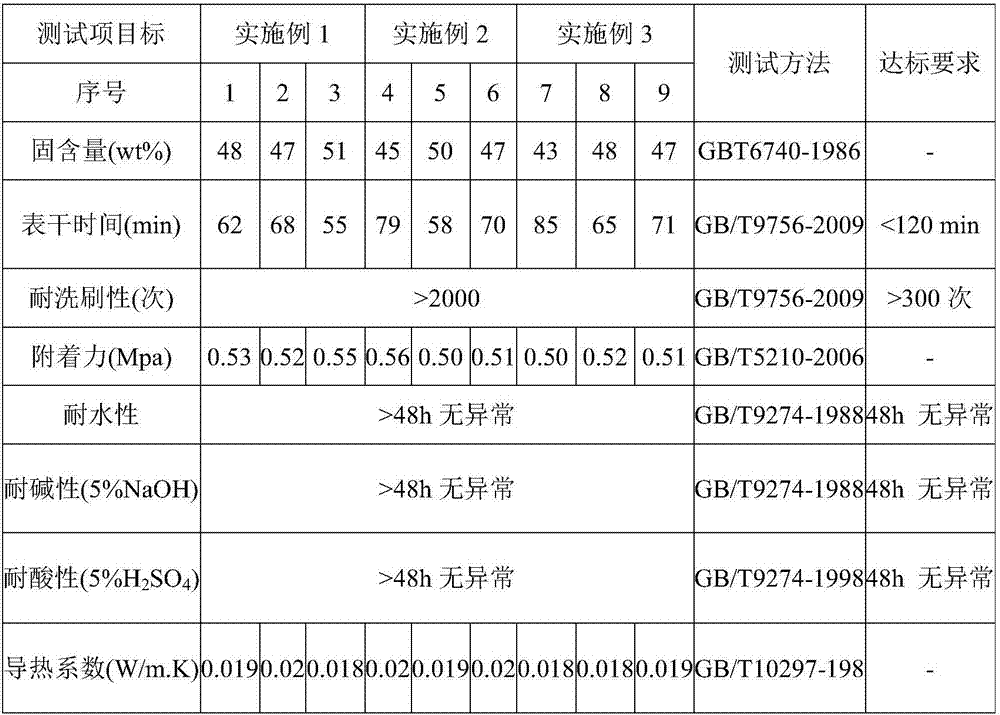

Examples

Embodiment 1

[0048] The water-based inorganic heat-insulating and waterproof environmental protection paint of the building of the present embodiment is prepared according to the following steps:

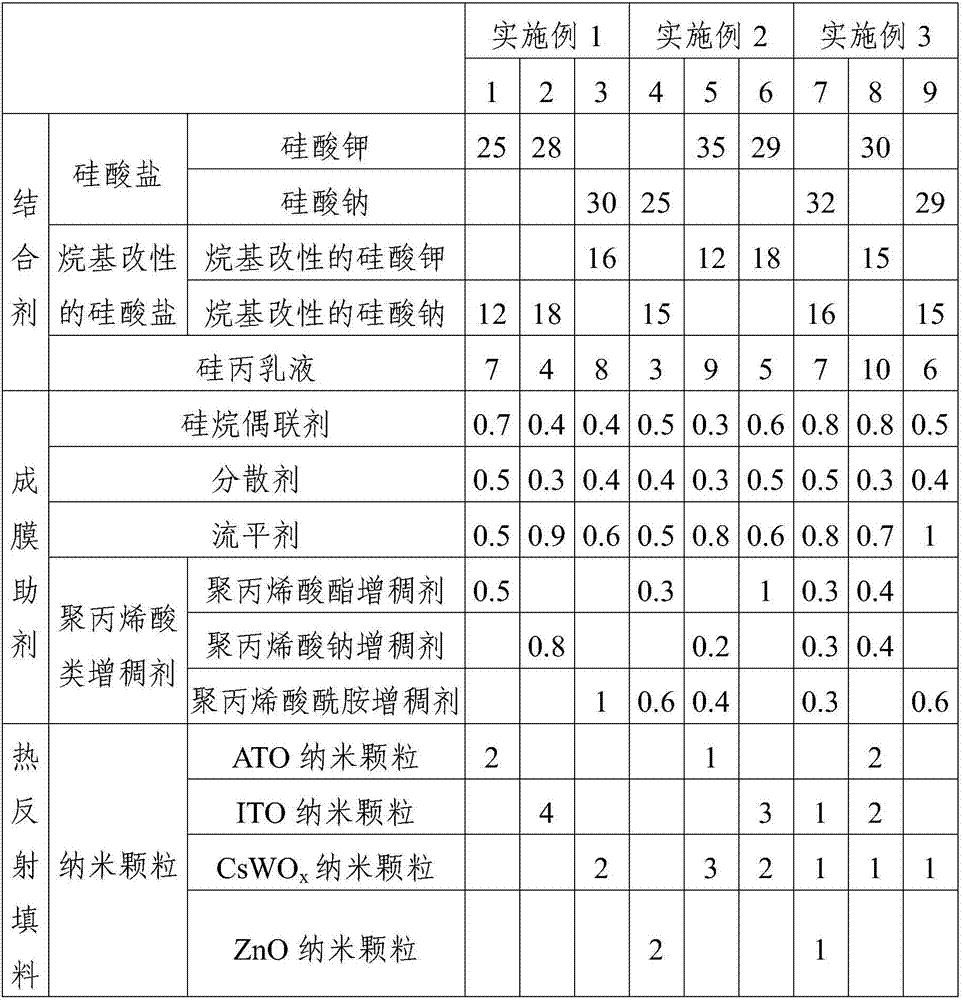

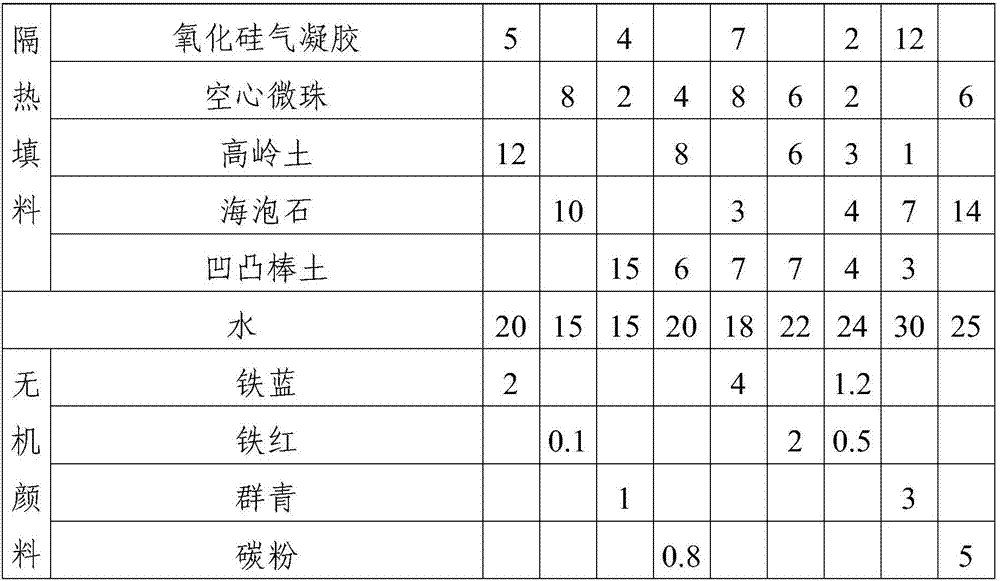

[0049] (1) Take raw materials: take raw materials according to the amount in Table 1;

[0050] (2) At normal temperature, pour water into the mixing tank, add dispersant, and stir at 200r / min until the dispersant is fully dissolved, then add nanoparticles, and continue stirring for 30min to fully disperse the nanoparticles in the water to obtain Suspension 1;

[0051] (3) Add silicate solution, alkyl-modified silicate solution, silicon acrylic emulsion, silane coupling agent, and leveling agent to suspension 1 in sequence, and stir for 10 minutes under the condition of 200r / min to make the raw materials fully Mix well to obtain suspension 2;

[0052] (4) Add silica airgel and kaolin to the suspension 2 (specific surface 50-100m 2 / g, the pore diameter is 1.5~2.5nm), heat-insulating filler, in...

Embodiment 2

[0055] The water-based inorganic heat-insulating and waterproof environmental protection paint of the building of the present embodiment is prepared according to the following steps:

[0056] (1) Take raw materials: take raw materials according to the amount in Table 1;

[0057] (2) At normal temperature, pour water into the mixing tank, add dispersant, and stir at 800r / min until the dispersant is fully dissolved, then add nanoparticles, and continue stirring for 30min to fully disperse the nanoparticles in the water to obtain Suspension 1;

[0058] (3) Add silicate solution, alkyl-modified silicate solution, silicon acrylic emulsion, silane coupling agent, and leveling agent to suspension 1 in sequence, and stir for 10 minutes under the condition of 400r / min to make the raw materials fully Mix well to obtain suspension 2;

[0059] (4) Add silica airgel and kaolin to the suspension 2 (specific surface 50-100m 2 / g, with a pore size of 1.5-2.5nm), heat-insulating fillers, an...

Embodiment 3

[0062] The water-based inorganic heat-insulating and waterproof environmental protection paint of the building of the present embodiment is prepared according to the following steps:

[0063] (1) Take raw materials: take raw materials according to the amount in Table 1;

[0064] (2) At normal temperature, pour water into the mixing tank, add dispersant, and stir at 600r / min until the dispersant is fully dissolved, then add nanoparticles, and continue stirring for 30min to fully disperse the nanoparticles in the water to obtain Suspension 1;

[0065] (3) Add silicate solution, alkyl-modified silicate solution, silicon acrylic emulsion, silane coupling agent, and leveling agent to suspension 1 in sequence, and stir for 10 minutes under the condition of 800r / min to make the raw materials fully Mix well to obtain suspension 2;

[0066] (4) Add silica airgel and kaolin to the suspension 2 (specific surface 50-100m 2 / g, with a pore size of 1.5-2.5nm), heat-insulating fillers, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com