Modular safety railing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

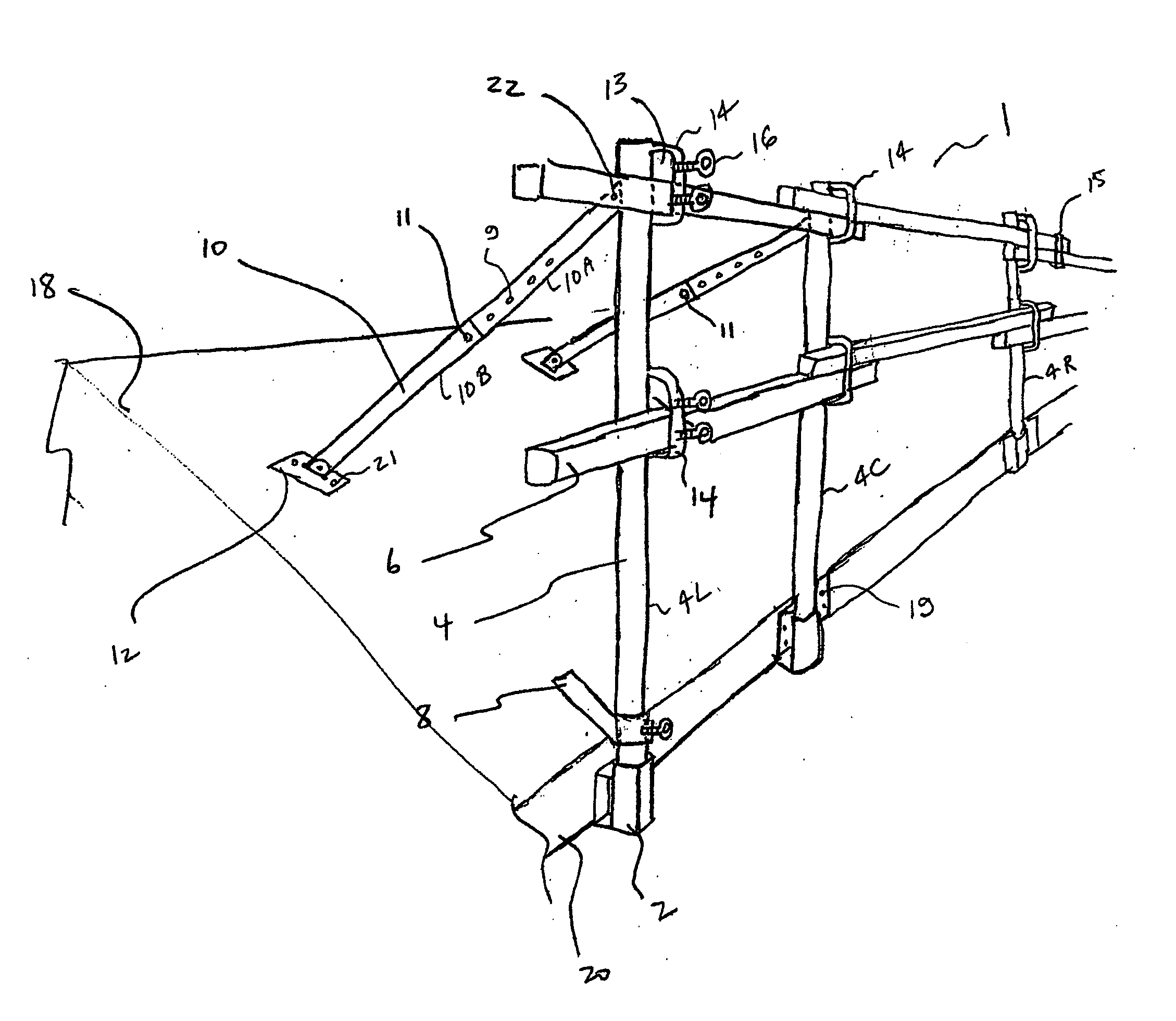

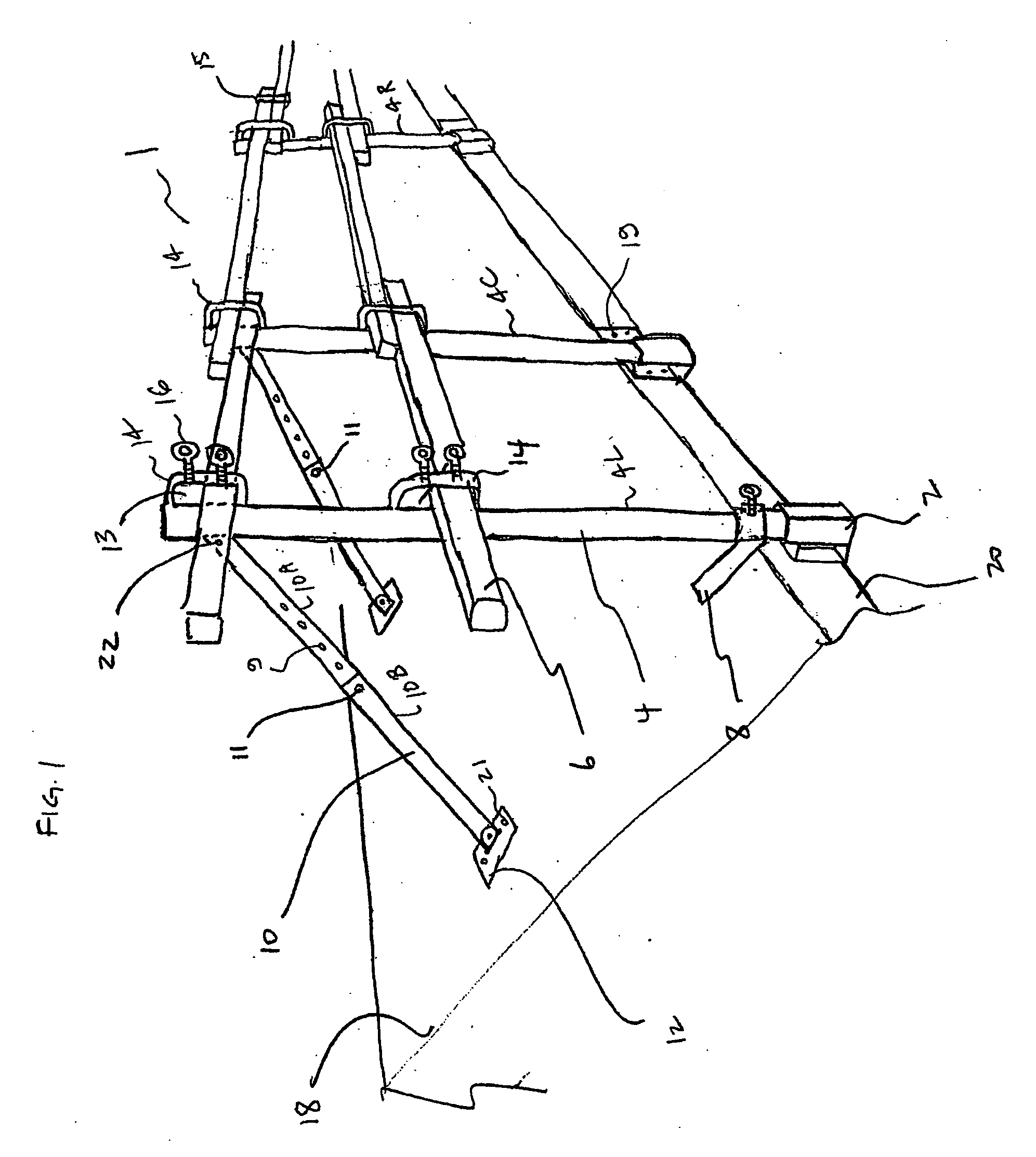

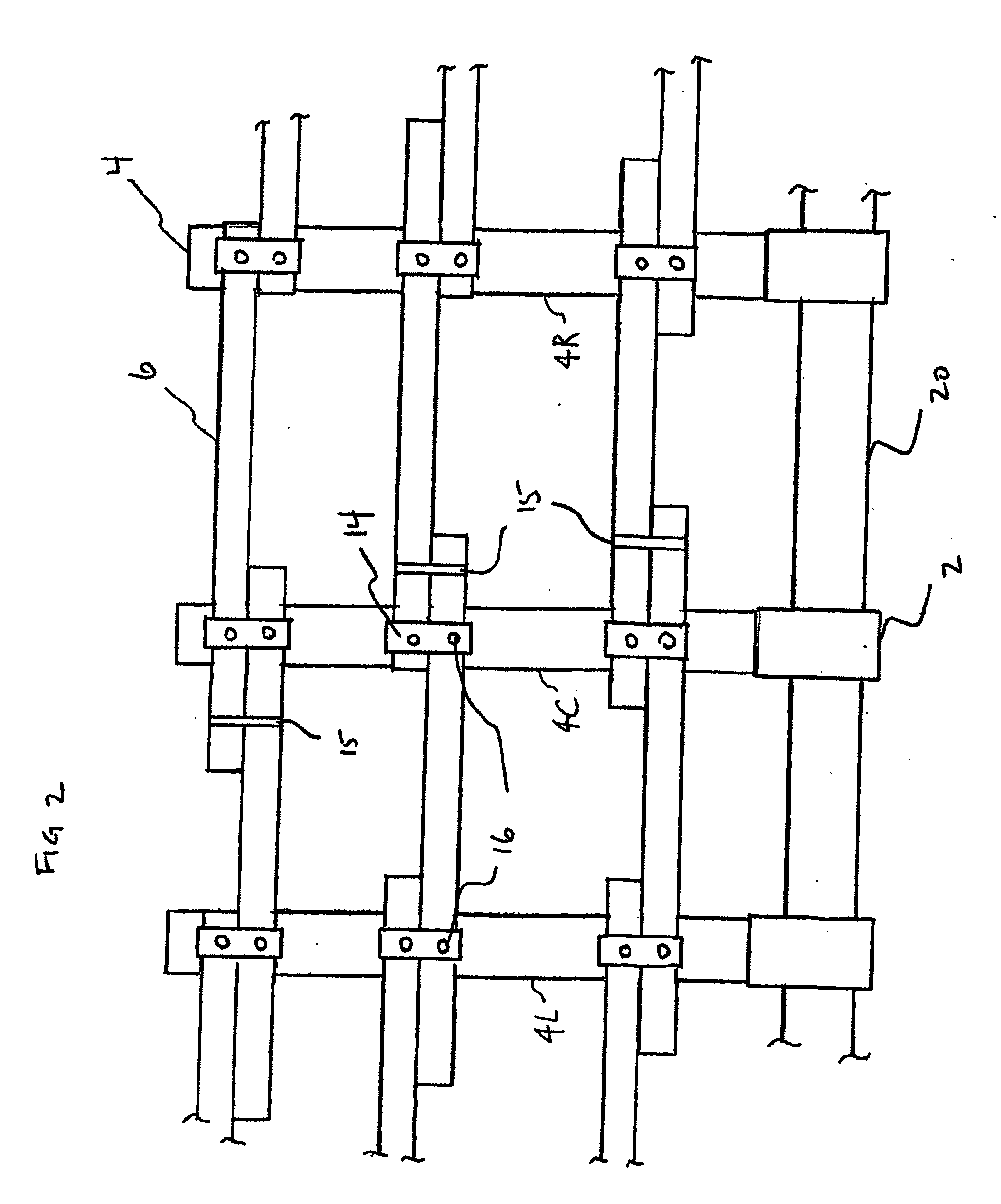

[0022] The invention provides a modular safety railing system comprising roof mounted post brackets, vertically oriented posts that insert into the post brackets and a series of lower and upper braces to further secure the bottom and top of the railing module to the roof. Each of the structural components of the railing system are affixed to the roof or each other using temporary fasteners such as screws or bolts. As such, the system can be easily erected at a desired site, and then broken down into component pieces to move to a new location. All of the components of the railing system of the invention are reusable, providing the advantage of a cost-effective apparatus for enhancing worker safety.

[0023] A safety railing is formed by placing railing modules along the edge of a roof or other area where a temporary safety railing is desired, and then placing horizontally oriented rails through the railing brackets of adjacent posts. The length of the railing is dictated by the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com