Melt-blow filtering core and preparation process thereof

A preparation process and technology of melt-blown filter elements, applied in the field of filter elements, can solve problems such as energy waste, loss of carbon activity function, and increase in water filtration costs, and achieve the effects of avoiding pollution and energy waste, enhancing utilization, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

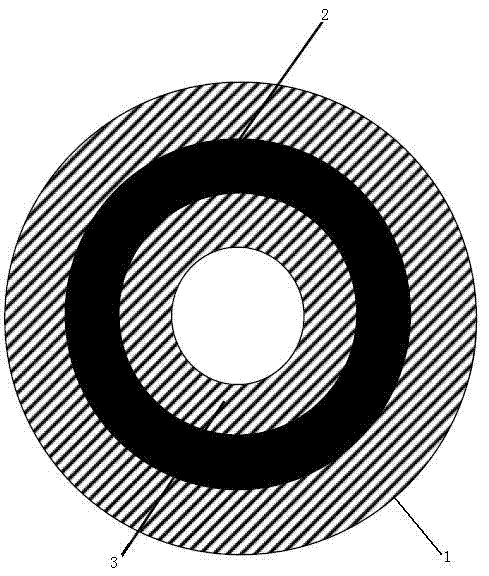

[0040] A kind of melt-blown filter core, its structure refers to figure 1 As shown, the middle is a hollow core of φ28-32mm, and from the outside to the inside are the outer layer of PP cotton 1, the PP carbon cloth layer 2, and the inner layer of PP cotton 3, among which,

[0041] The inner layer of PP cotton is the inner core of a cylindrical structure formed by spinning and winding, and its thickness is set to 12-15mm;

[0042] The PP carbon cloth layer is an intermediate layer arranged between the outer layer and the inner layer, which is formed by spreading fine particles of activated carbon on PP and winding it on the inner layer of PP cotton, and its thickness is set to 15-20mm;

[0043] The outer layer of PP cotton is formed by spinning PP, wrapped on the outer surface of the PP carbon cloth layer, and its thickness is set to 5-15mm.

Embodiment 2

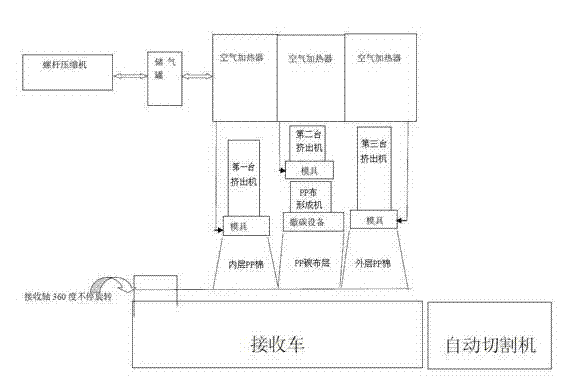

[0045] see figure 2 , the preparation process of the melt-blown filter element is divided into three ranges of extrusion operations. Each range of extrusion operations uses three extruders and three air heaters to work together. The three ranges of extruders are composed of The same receiving car rotates and receives 360 degrees non-stop, and the three air heaters are uniformly distributed from the screw compressor to the air storage tank. The specific steps are as follows:

[0046] Step 1. The first extruder prepares the inner layer of PP cotton

[0047] a. The extruder is heated to the melting point of PP, the PP particles are melted into water, and extruded into the mold with φ38 micro-holes, the hot air is passed through the mold, and the PP in the mold hole is extruded by the screw and the air flow of the hot air Meltblown into filaments;

[0048] b. Use the receiving car to rotate continuously, turn the PP filament melt blown out in step a into a cylinder, and form th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com