Ultra-long harbor basin slope excavation construction method

A construction method and slope technology, applied in water conservancy projects, marine engineering, earth movers/shovels, etc., can solve problems such as easy formation of over-excavation, increased construction costs, safety accidents, etc. The effect of construction safety and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

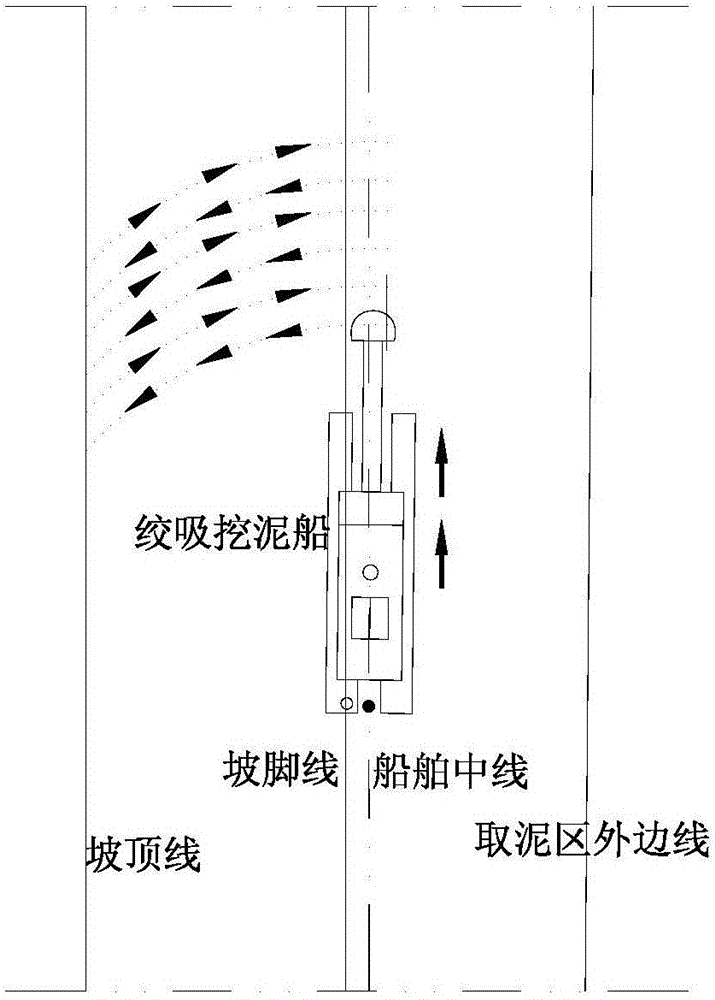

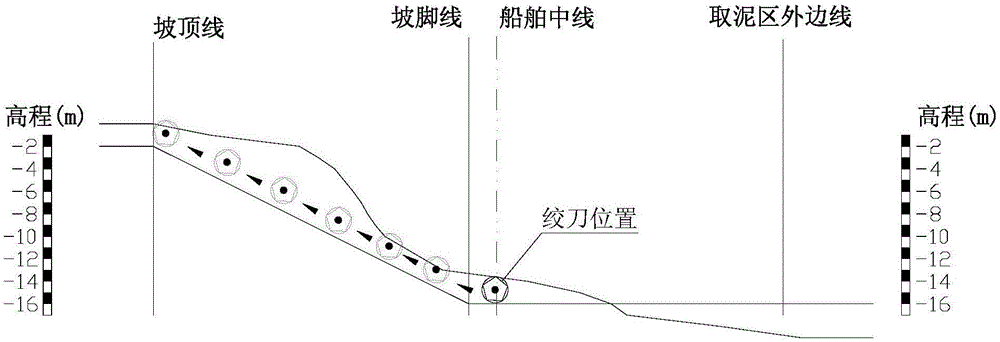

[0052] Example 1, see Figure 1 to Figure 4 According to the characteristics of the main construction task of the excavation of the ultra-long harbor basin with relatively regular slope surface, the main construction task is to clean up the slope surface and sweep the area shallowly. After digging the slope surface, divide the width of the remaining groove into strips after completion, and clean the groove one by one. Specifically include the following steps:

[0053] 1) Before the formal construction, carry out sea-sweeping survey on the existing mud extraction area, especially the slope area, and sort out the accurate water depth map of the slope excavation area;

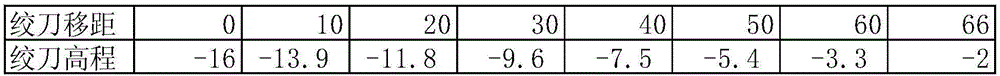

[0054] 2) Analyze the water depth of all slope excavation areas, and formulate the slope excavation process; select the slope hob excavation method for excavation according to the actual situation of the slope, mainly adopt the following process:

[0055] 2.1) Divide the construction strips according to the slop...

Embodiment 2

[0068] Example 2, see Figure 5 , in view of the large amount of soil on the slope surface, the thickness of the mud layer is 4-8 meters, and the construction technology adopted for the excavation of the ultra-long harbor basin slope with shallow areas locally is a step-by-layer excavation process; firstly, according to the characteristics of the mud Divide the slope surface into steps, and excavate the side slope with the overhang and the undercut, so that the earth will naturally collapse to form a slope, and the groove and the side slope will be constructed sequentially in strips and layers; the main process is as follows: including the following steps:

[0069] 1) Before the formal construction, carry out sea-sweeping survey on the existing mud extraction area, especially the slope area, and sort out the accurate water depth map of the slope excavation area;

[0070] 2), analyze the water depth of all slope excavation areas, and formulate the slope excavation process; sele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com