Preparation method for insulator mandril

A technology for insulators and mandrels, which is applied in the field of preparation of large-diameter insulator solid mandrels, can solve the problems of low strength and rigidity, unreasonable curing process, lengthy surface treatment process, etc., achieve reasonable process, reduce production cost, avoid The effect of material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

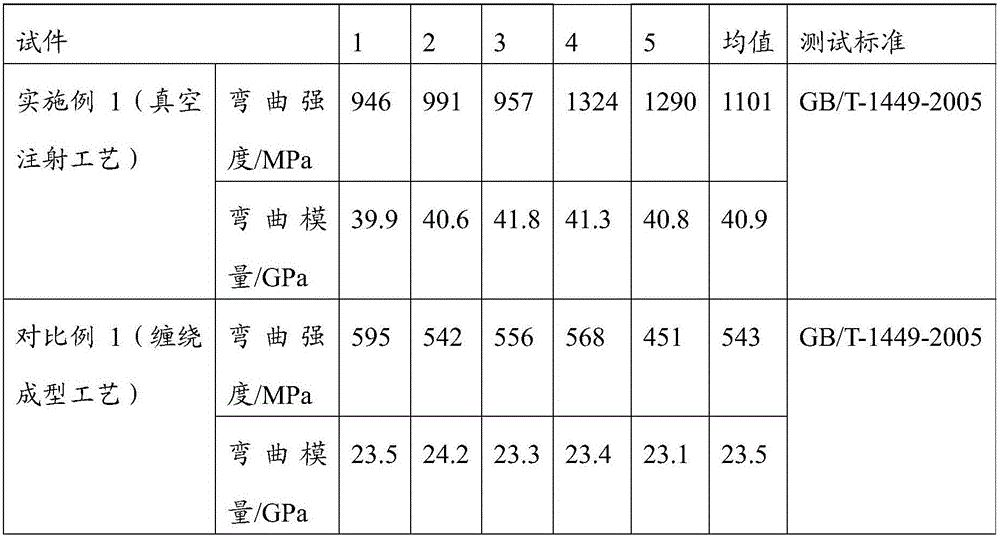

Examples

Embodiment 1

[0032] 1) Select a solid pultruded insulating mandrel with a diameter of 110mm and a length of 2.5m; sandblast its outer surface to remove the resin-rich layer on the outer surface; and scrub the outer surface with alcohol to remove surface impurities.

[0033] 2) Select a glass fiber unidirectional cloth with a width of 2.5m, and wind it onto the solid mandrel processed in step 1), with a winding angle of 0 and a winding diameter of 280mm to form a mandrel prefabricated body, wherein , the angle between the glass fiber and the central axis of the solid mandrel is about 0±3°.

[0034] 3) Place the mandrel prefabricated body obtained in step 2) in a vacuum injection molding mould. After the mold is closed, the vacuum injection process is used for injection molding. The relative vacuum degree of the vacuum injection molding mold is kept at -0.085MPa, and the injection of epoxy resin The speed is 400g / min, and the injection and reflow time of epoxy resin is 5h.

[0035] 4) After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com