Patents

Literature

55results about How to "Will not dilute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

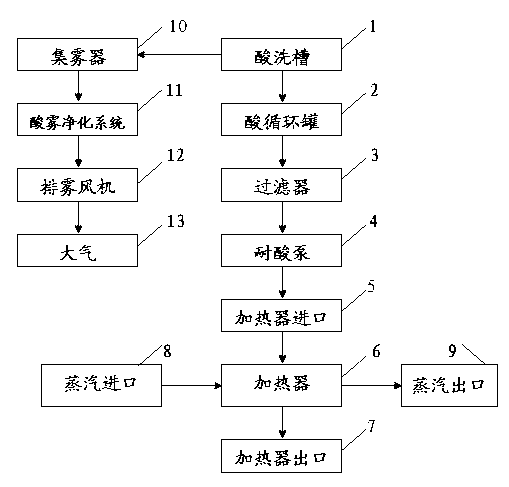

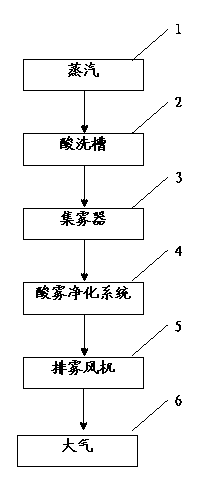

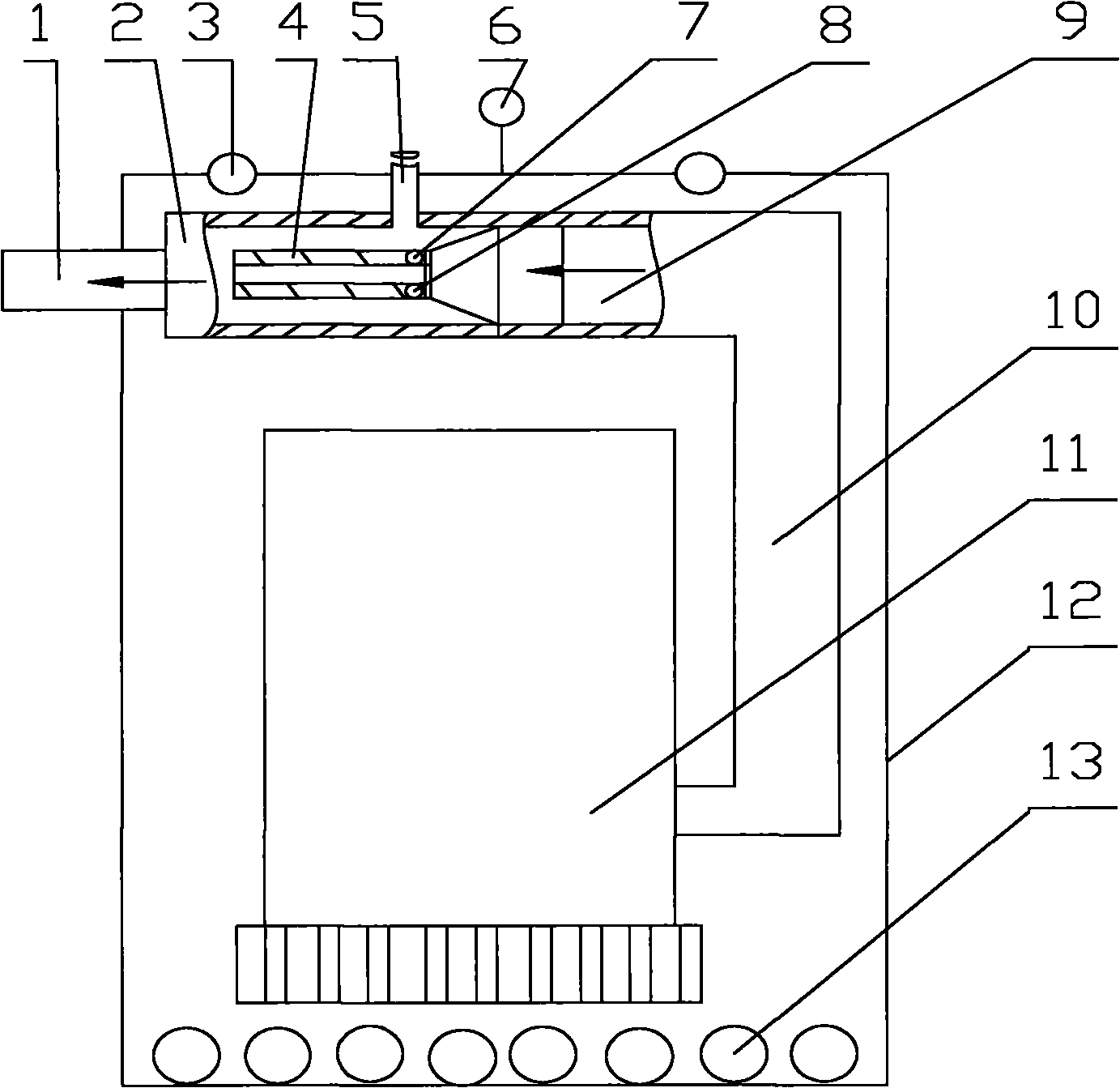

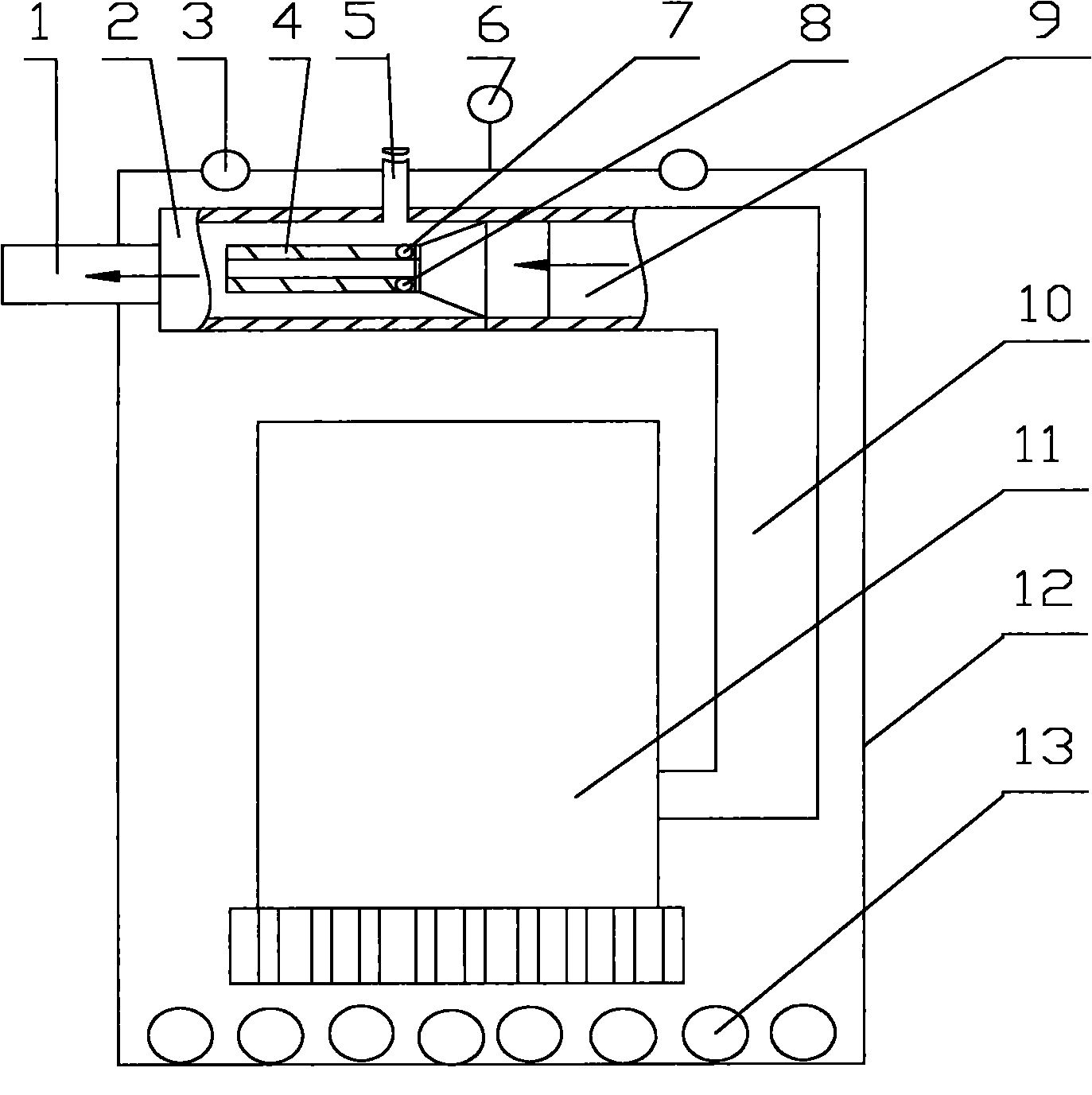

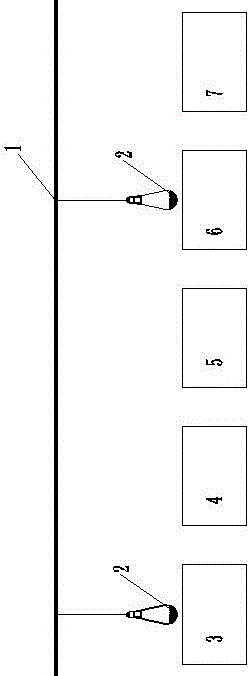

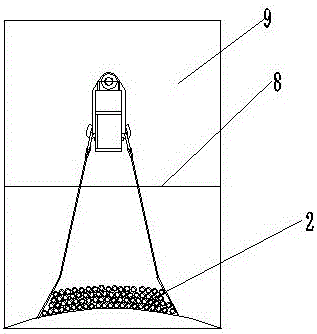

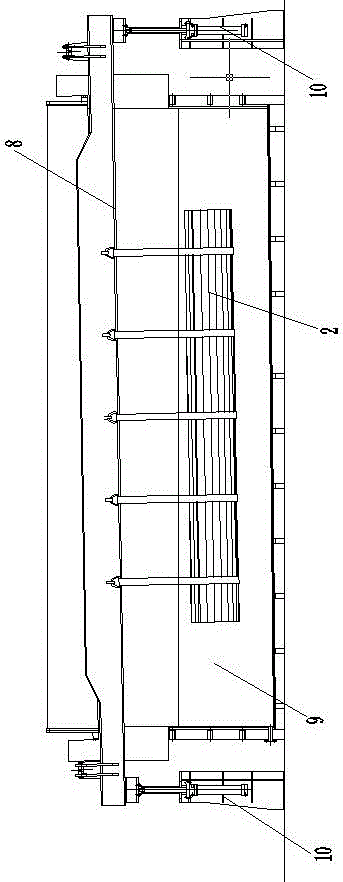

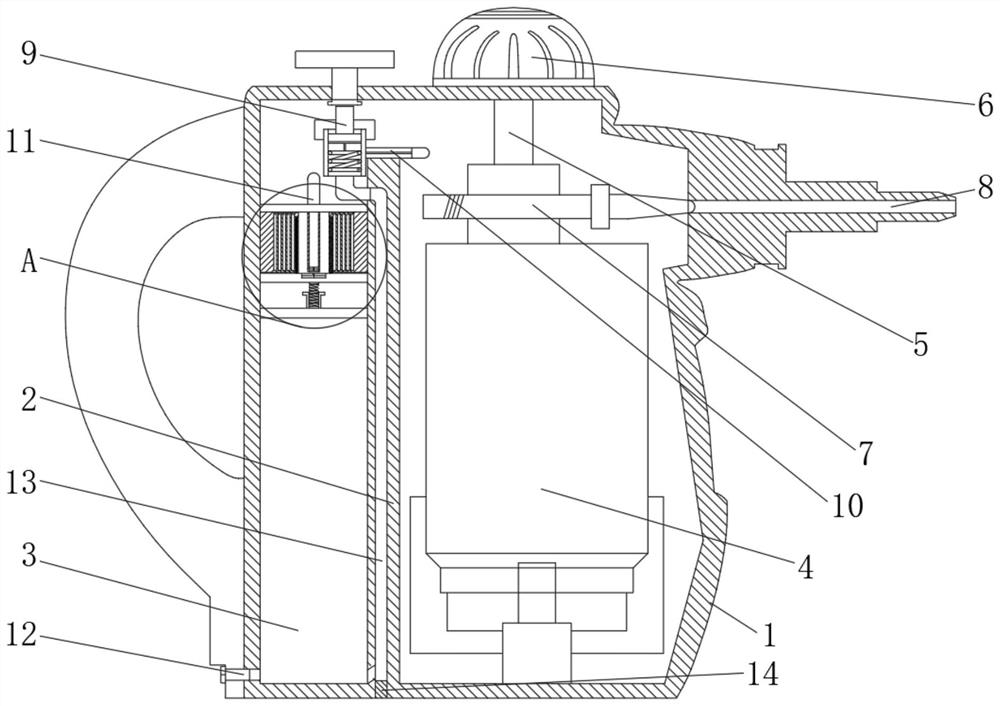

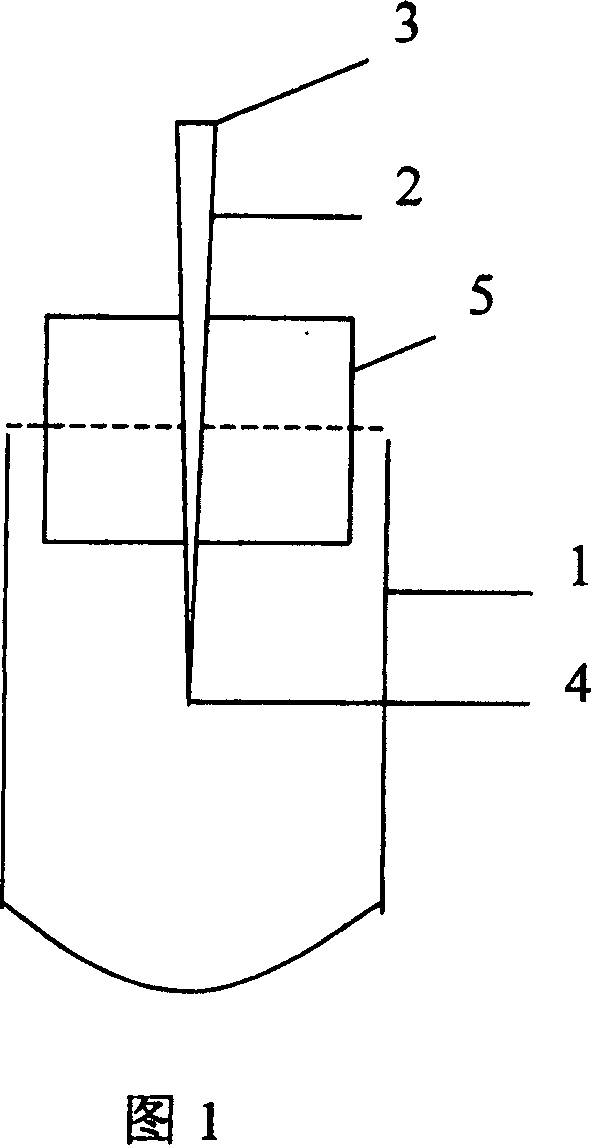

Method for heating acid washing solution

The invention discloses a method for heating acid washing solution. The method comprises: (1) the acid washing solution in an acid washing tank 1 flows back into an acid circulation tank 2, is filtered through a filter 3 and is pumped into a heater 6 by an acid-resistant pump 4 through an inlet 5 of the heater, the heated acid washing solution is pumped into the acid washing tank 1 through an outlet 7 of the heater to form circulation, and the circulation is repeated in the way; (2) heating steam enters through a steam inlet 8 and is discharged through a steam outlet 9, so that the acid washing solution is kept at normal technological temperature all the time; and (3) acid mist which is generated during the acid washing process is concentrated through a mist collector 10 under the action of a mist exhaust fan 12 and enters an acid mist purification system 11 to be purified, and the mist which meets the emission standards is discharged to the atmosphere 13 through the mist exhaust fan 12. By the method, heat exchange is indirectly realized, the acid washing solution cannot be diluted, excessive acid mist is not generated, the acid mist cannot be leaked during the heat exchange process, and the heating process of the acid washing solution and the temperature of the acid washing solution can be automatically controlled through adopting a heat exchanger.

Owner:TIANJIN YIBO STEEL MAKING

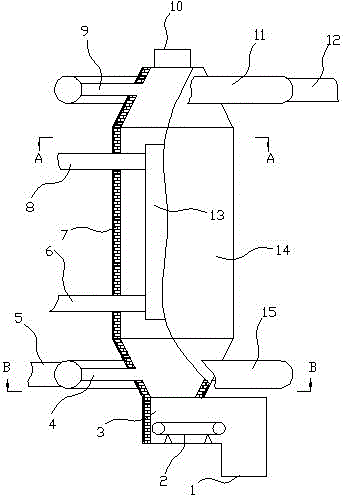

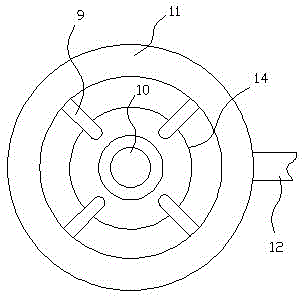

Pyrolysis furnace and treatment process for treating waste tire

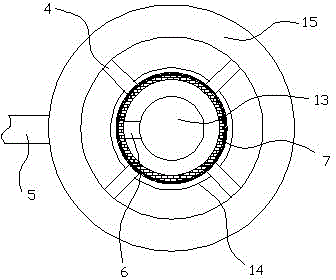

The invention provides a technical scheme of a pyrolysis furnace and a treatment process for treating waste tires. According to the technical scheme, the upper and lower parts of a furnace body take the shapes of columns of trapezoidal cones; a feeding hole is formed in the top side of the furnace body; a discharge hole is formed in the bottom side of the furnace body; an annular exhaust surrounding tube is arranged on the outer side of the upper conical part of the furnace body; a main exhaust tube is connected to the outer side wall of the exhaust surrounding tube; a plurality of branch exhaust tubes are connected to the inner side wall of the exhaust surrounding tube and are communicated with an inner cavity of the furnace body; an annular inlet surrounding tube is arranged on the outer side of the lower conical part of the furnace body; a main inlet tube is connected to the outer side wall of the inlet surrounding tube; a plurality of branch inlet tubes are connected to the inner side wall of the inlet surrounding tube and are communicated with the inner cavity of the furnace body; the furnace body is internally provided with an inner heating tube with an inner thermal gas inlet tube and an inner thermal gas exhaust tube. The treatment process of the scheme comprises the following steps: performing pyrolysis on waste tire fragments by using the pyrolysis furnace, obtaining crushed steel wires and finished carbon black product from pyrolysis slag after pyrolysis, obtaining heavy oil and a finished slag oil product from a pyrolysis gas by using a cyclone separator and a spraying tower, further obtaining a finished light oil product by using a pipe bundle condenser, heating the rest pyrolysis gas by using a combustion furnace, and subsequently feeding back to the pyrolysis furnace to provide high-temperature fume.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Method for producing fertilizer with high ammonium phosphate sulfate by adopting sulphur

InactiveCN104788161AAdding process is simpleNo risk of explosionFertilizer mixturesWater basedCombustion

The invention relates to a method for producing a fertilizer with high ammonium phosphate sulfate by adopting sulphur. The method is characterized by producing the fertilizer with high ammonium phosphate sulfate by utilizing elemental sulphur; the method comprises the following steps: adding sulphur powder in slurry, a tube reaction tank or washing liquid in the conventional production technology of the ammonium phosphate fertilizer; or / and preparing a sulphur water-based dispersion liquid from sulphur powder of 50-600 meshes, adding the prepared sulphur water-based dispersion liquid in the slurry, the tube reaction tank or the washing liquid, and obtaining the fertilizer with high ammonium phosphate sulfate. According to the method disclosed by the invention, the addition technology of the sulphur is simple, and the conventional production equipment does not need to be greatly modified; the addition is safe, the risks of the combustion and the explosion of the sulphur can be avoided; ammonium phosphate products containing different contents of sulphur can be produced according to demands for fertilizers, and the original nutrients of the ammonium phosphate fertilizers cannot be diluted too much; influence on the granulation of ammonium phosphate can be avoided.

Owner:HUBEI FORBON TECH

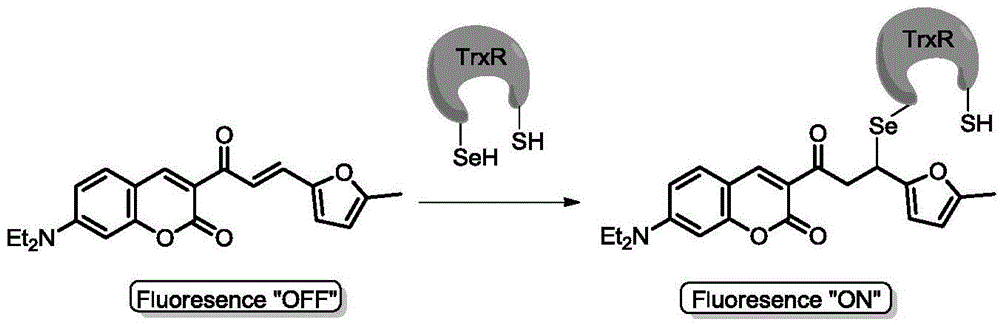

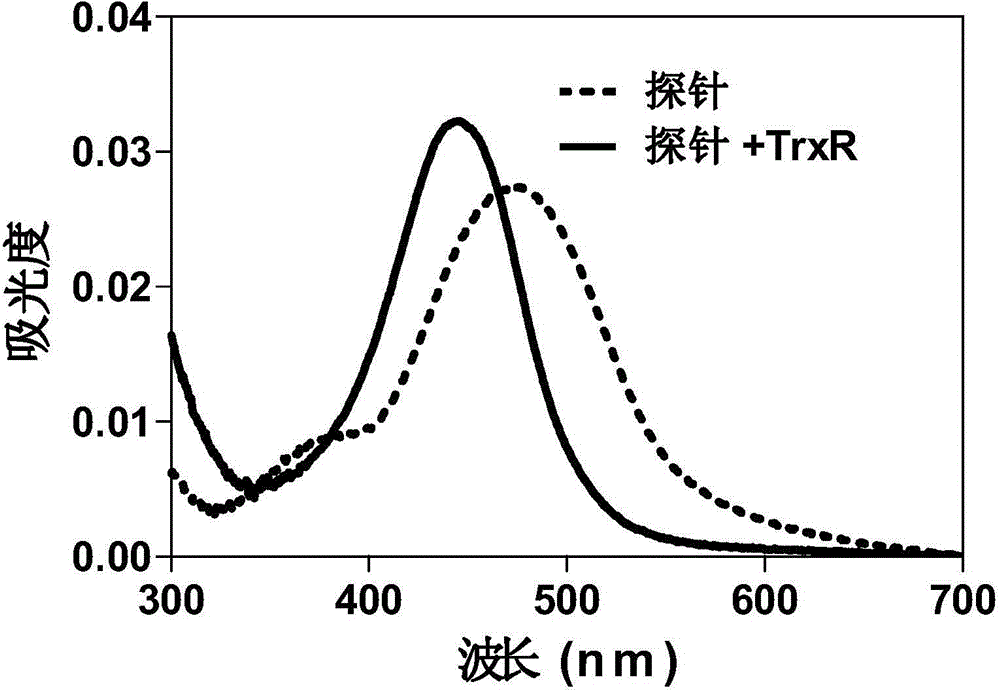

Thioredoxin reductase fluorescent probe, and preparation method and application thereof

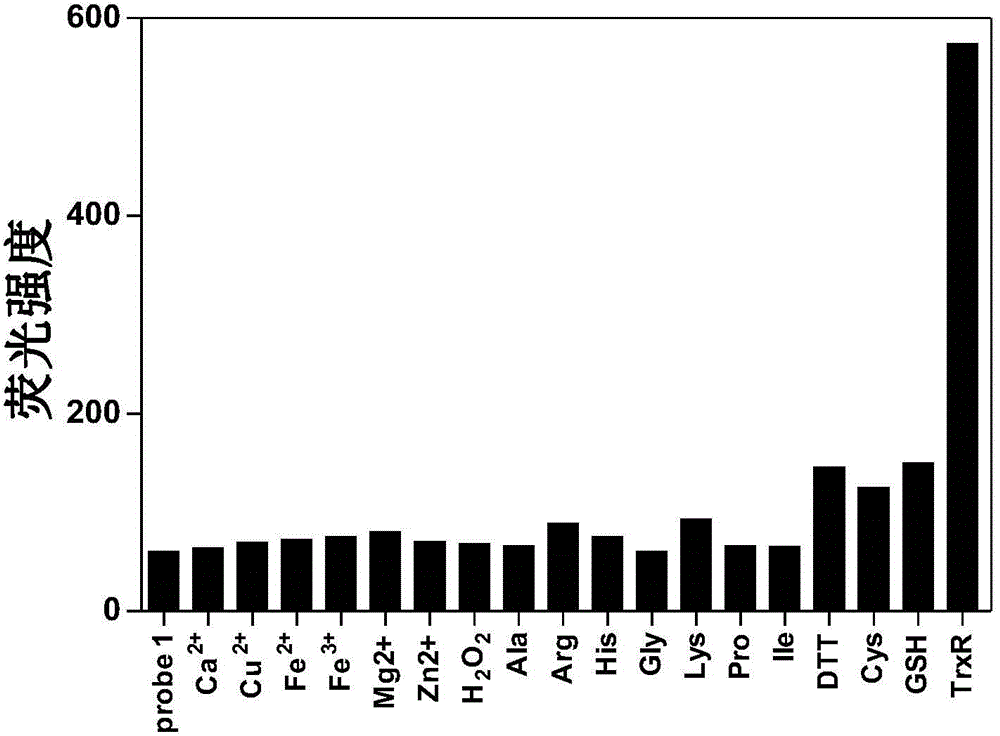

ActiveCN104974744AStrong specificityHigh detection sensitivityOrganic chemistryFluorescence/phosphorescenceChemistryFluorescent quenching

The invention discloses a thioredoxin reductase fluorescent probe, and a preparation method and application thereof. The thioredoxin reductase fluorescent probe is a compound containing a 7-diethylaminocoumarin fluorophore and a furyl acryloyl fluorescent quenching group. The fluorescent probe is covalently combined to the thioredoxin reductase through Michael addition reaction, thereby emitting fluorescence, wherein the magnitude of fluorescence intensity is directly proportional to the thioredoxin reductase content. The fluorescent probe has higher inhibition activity and selectivity for thioredoxin reductase, has very low responsiveness for other high-content mercapto small molecules in the biological system, can be widely used for detecting the thioredoxin reductase content in a sample, and is especially suitable for detecting the thioredoxin reductase content in tumor cells of a living body.

Owner:SHENZHEN HANKANG TECH CO LTD

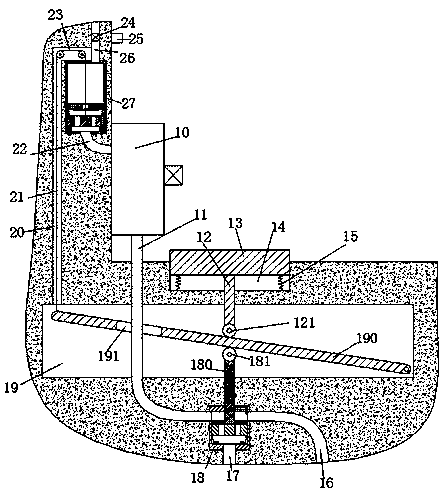

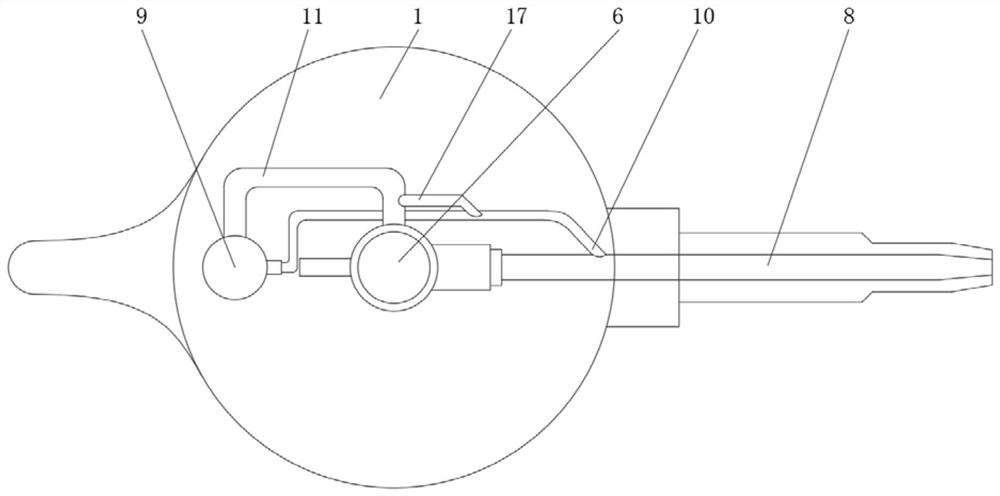

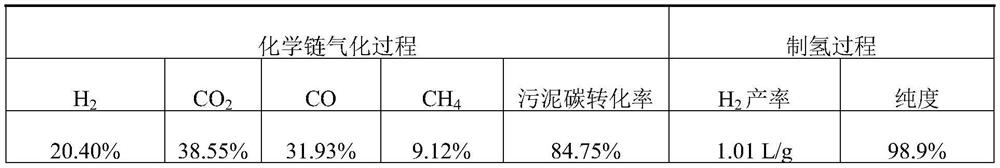

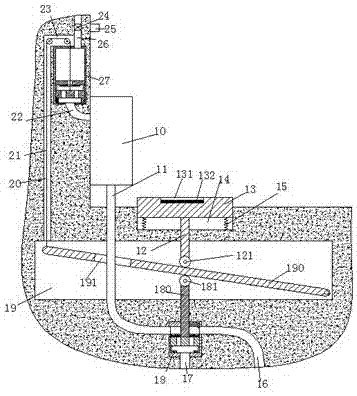

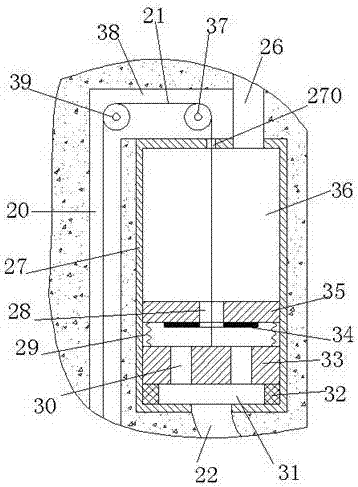

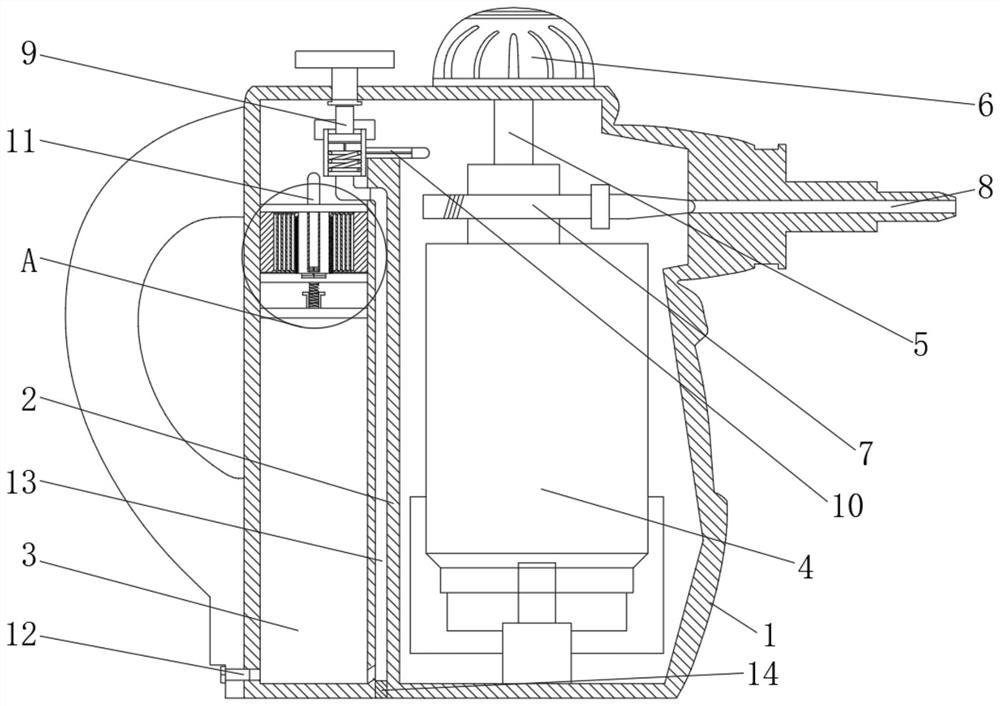

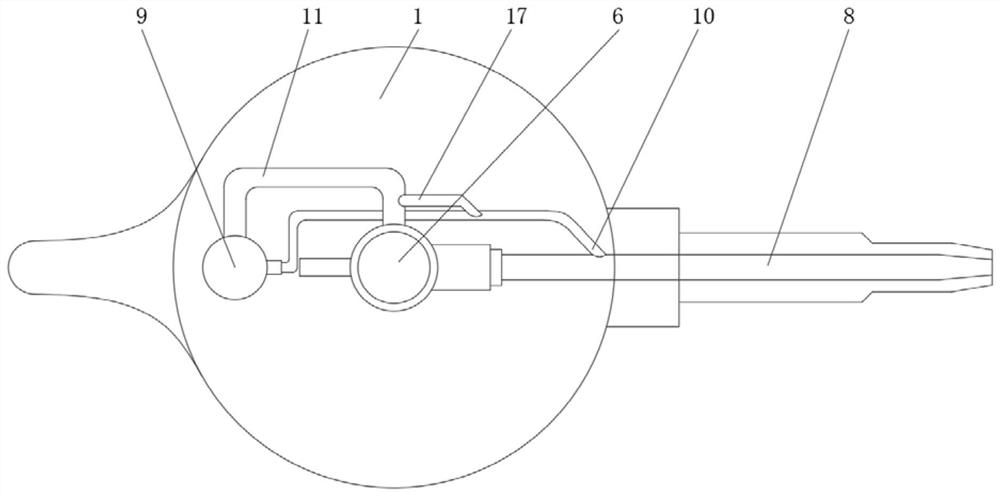

Microbubble aerator for fish and shrimp ponds

InactiveCN101816293ASimple structureLess investment in productionPisciculture and aquariaShrimpMicrometer

The invention relates to a microbubble aerator for fish and shrimp ponds, which is composed of a cabinet 12, a gas-water mixer 2, a gas-water outlet pipe 1, a sinking pump 11 and a pump-outlet pipe 10, wherein the cabinet 12 is a cylinder; the sinking pump 11 is positioned on the bottom in the cabinet 12; the pump-outlet pipe 10 is connected to the gas-water mixer 2; the gas-water mixer 2 is externally connected with the gas-water outlet pipe 1; the gas-water mixer 2 is provided with a gas inlet pipe 5; the lower end of the gas inlet pipe 5 is communicated with the inside of the gas-water mixer 2; and an internal water pipe 4 is arranged in the gas-water mixer and provided with a strong magnet 7 and a weak magnet 8. The invention has the advantages of simple structure, low production cost and energy conservation, and is a microbubble aerator for fish and shrimp ponds; the aeration quantity can be regulated according to the water quality status, and the dissolved oxygen is 8-9.2 mg / L; the bubble size can reach 20-30 micrometers, and the bubbles can not be diluted by the air in water within 20-50 seconds; and the aerator has the function of air flotation, and is convenient for removing impurities in water and keeping the water clear.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

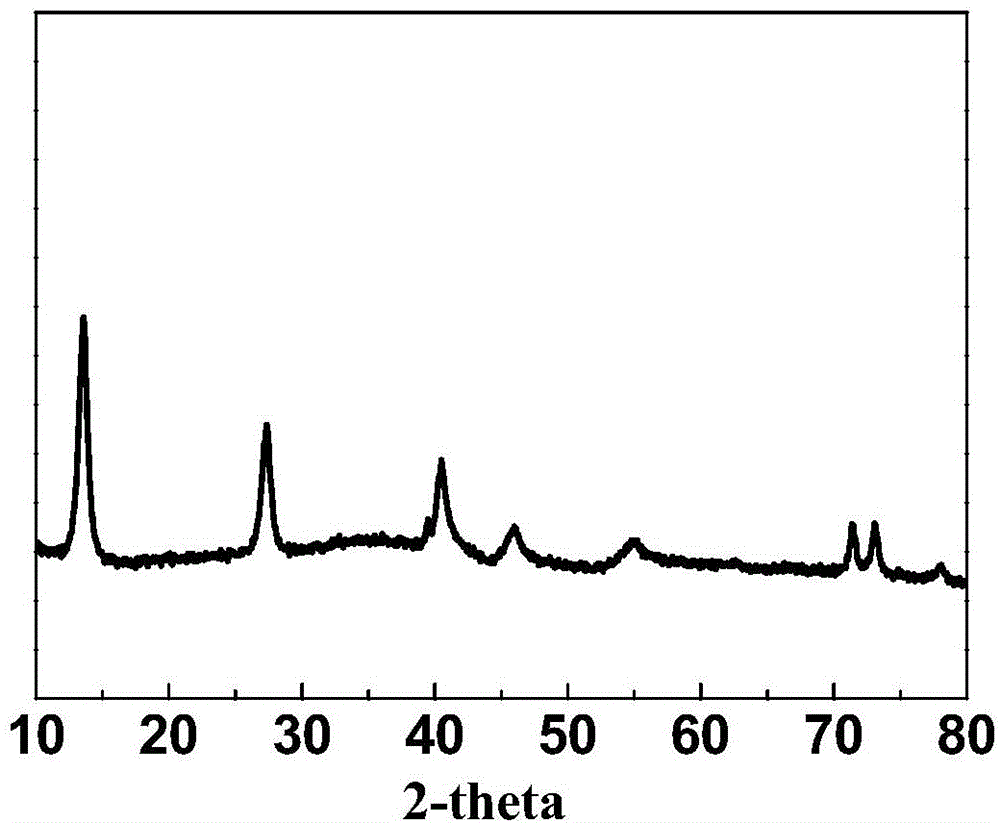

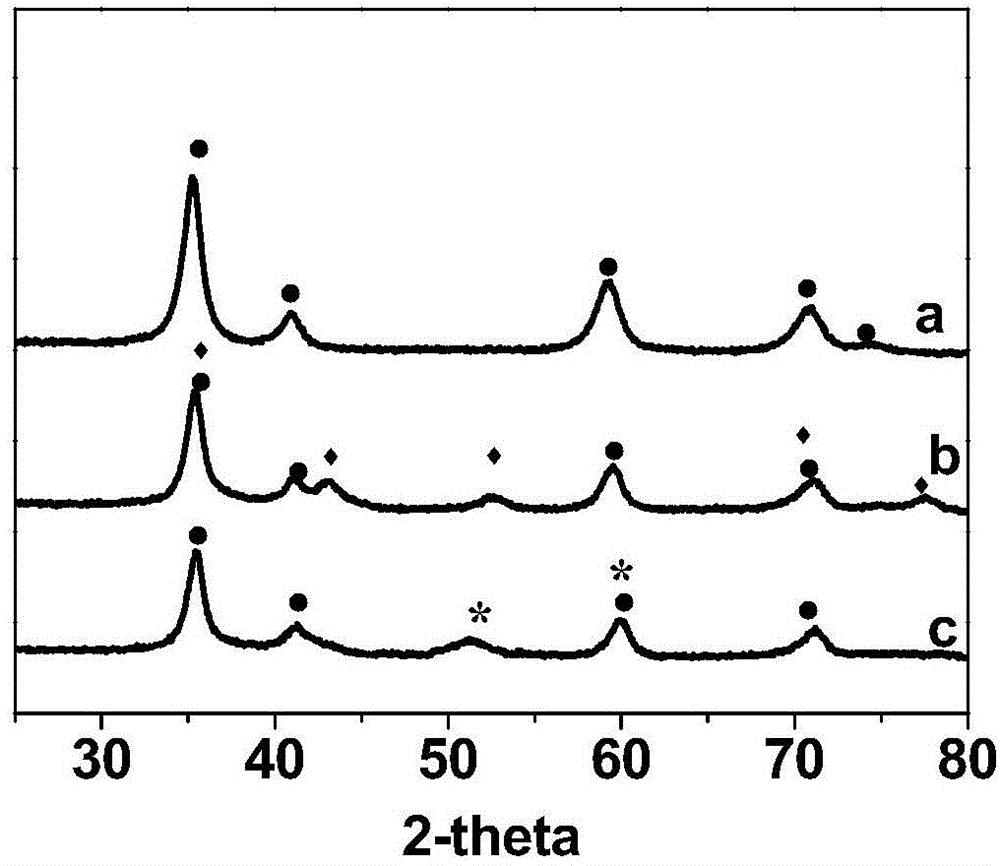

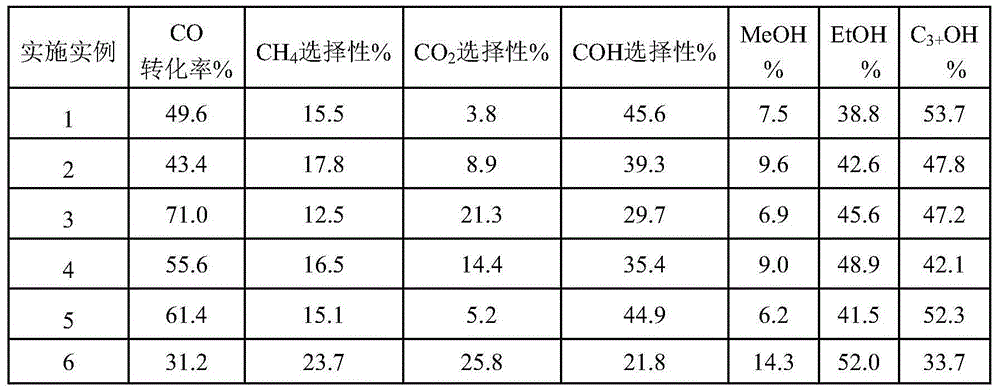

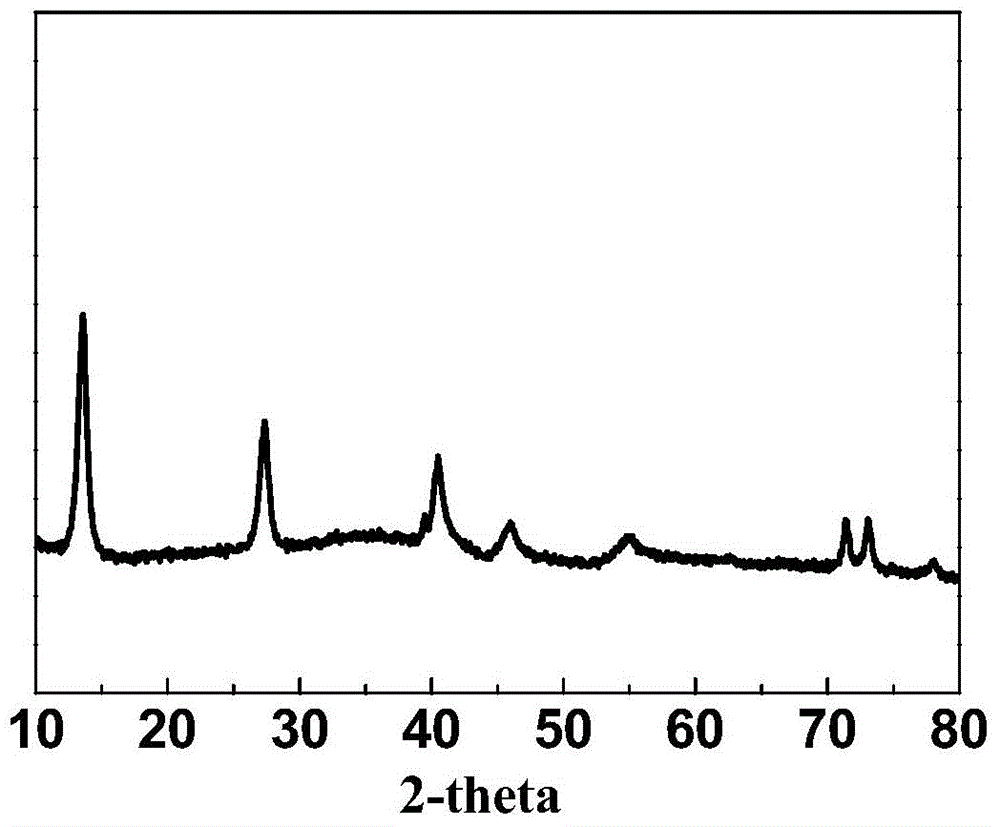

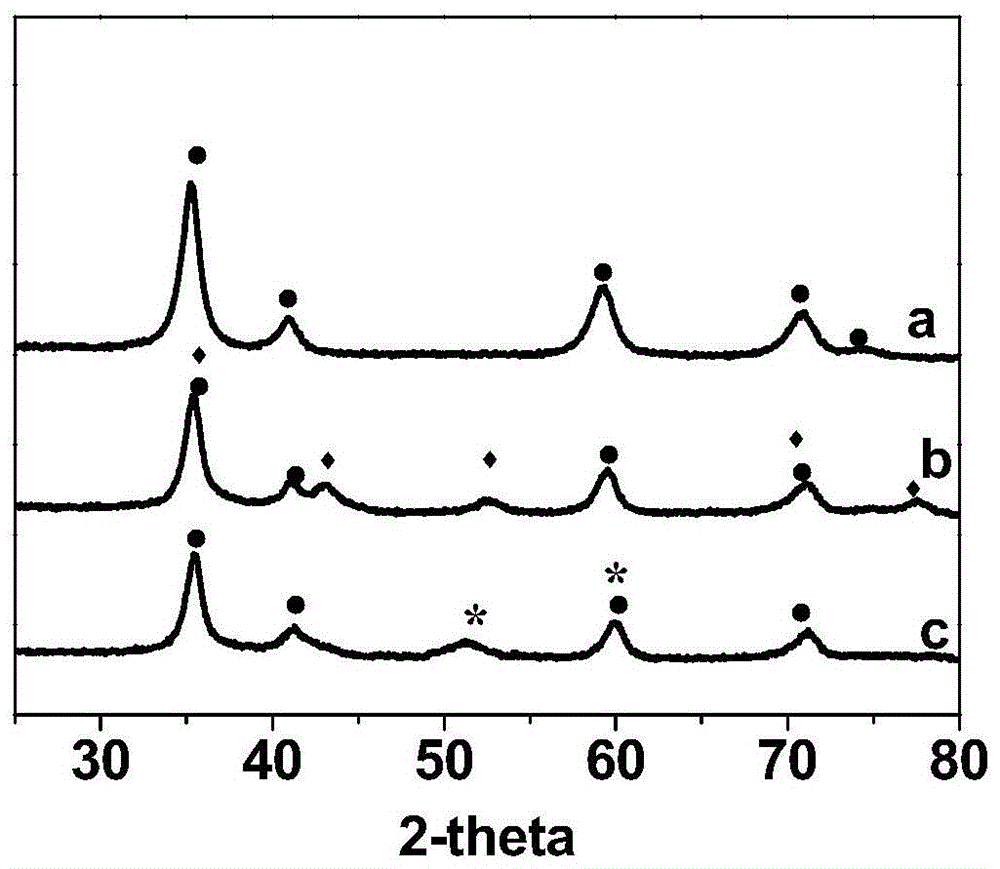

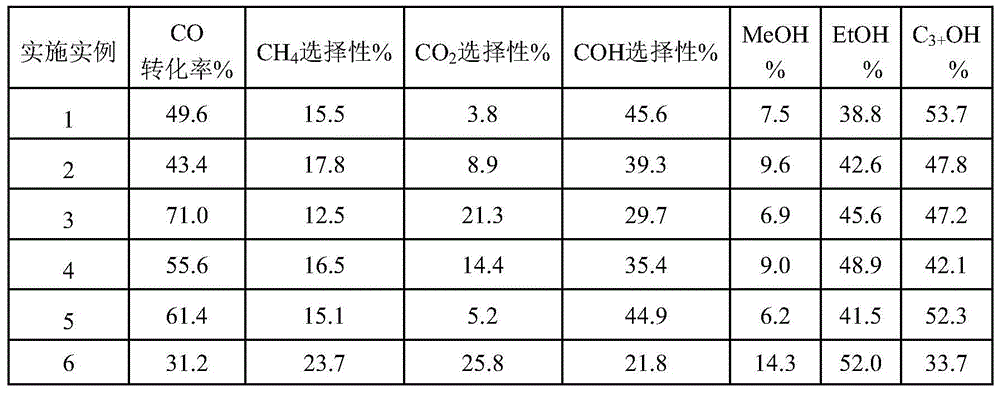

Preparation method and application of mixed oxide-doped nano copper-cobalt alloy catalyst

ActiveCN104645991AReduce contentGood dispersionOrganic compound preparationHydroxy compound preparationMixed oxideActive component

The invention relates to a preparation method and application of a mixed oxide-doped nano copper-cobalt alloy catalyst. According to the catalyst, CuCo serves as an active component and mixed oxide serves as a carrier, wherein Cu accounts for 5-25% in the catalyst in percentage by mass, Co accounts for 5-25% in the catalyst in percentage by mass, Al2O3 accounts for 13-25% in the catalyst in percentage by mass, and one of SiO2, ZrO2, CeO2 or TiO2 accounts for the balance. The mixed oxide-doped nano copper-cobalt alloy catalyst is obtained by calcinating and reducing a hydroxide-doped hydrotalcite-like precursor. Since silicon, zirconium, cerium and titanium ions cannot enter a hydrotalcite-like laminate, the dispersion of copper and cobalt on the surface is improved, the dispersion degree of active components is increased, and the formation of a hotspot in a reaction process of synthesizing low-carbon alcohol is relieved. The catalyst is relatively high in low-carbon alcohol selectivity and low-temperature activity, easy to operate, and low in cost and is applicable to industrial production.

Owner:TIANJIN UNIV

Method for enhancing acid pickling efficiency of stainless steel tubes

The invention discloses a method for enhancing the acid pickling efficiency of stainless steel tubes. The method comprises the following steps of (1) acid pickling tank equipment modification, wherein the bottom of each acid pickling tank is arranged to be in an arc shape, and movable supporting devices are adopted on the two sides of an acid tank; and (2) an acid pickling process, wherein the procedures of carrying out feeding and acidification in sequence and carrying out acid discharge and uncovering in sequence are adopted, the acid mist discharge amount is greatly reduced, movement of the two ends of a crown block track is controlled in the acid pickling process, the two ends alternately move up and down, the process is repeated, acid liquor is disturbed by the steel tubes to form a turbulent flow state, the flow of an acid liquor circulation system is increased, the turbulent flow effect is enhanced, sludge accumulation in the acid tank is reduced, the acid liquor is cyclically heated through a heat exchanger, the temperature is automatically controlled, and the acid pickling efficiency is improved. According to the method, the acid pickling effect of the steel tubes is enhanced; the acid pickling efficiency is improved; and by means of an empty tank feeding and automatic acid discharge system, the acid mist discharge amount is greatly reduced, and environment benefits are enhanced.

Owner:TAIYUAN IRON & STEEL GROUP

Furfural preparation process

PendingCN111848557ALower reaction yieldEnhanced dehydration selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsProcess engineeringAldehyde

The invention discloses a furfural preparation process. The furfural preparation method adopts a two-step method. The method comprises the following specific steps: firstly, catalyzing hydrolysis of hemicellulose in corncobs by adopting an SO4 < 2-> / Fe2O3-alpha-Al2O3 supported solid acid catalyst; then catalyzing corncob hydrolysis reaction liquid to prepare furfural by using a novel catalyst instead of sulfuric acid, stripping crude aldehyde in the reaction system by using nitrogen instead of water vapor, performing alkali washing and refining on the stripped crude aldehyde by using a continuous centrifugal extraction refining method, introducing the crude aldehyde into a rectifying tower, and rectifying to obtain furfural with the purity of over 99%. According to the method, the furfuralis prepared through the two-step method, lignin and cellulose in the corncob residues can be reserved for reuse, the concentration of the crude aldehyde is increased through nitrogen steam stripping,the furfural production yield is increased, and the wastewater yield is reduced.

Owner:QINGDAO UNIV OF SCI & TECH

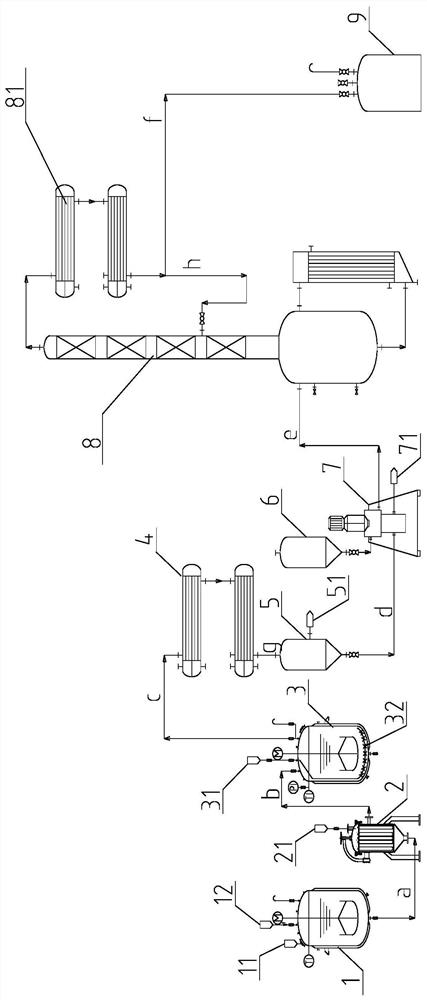

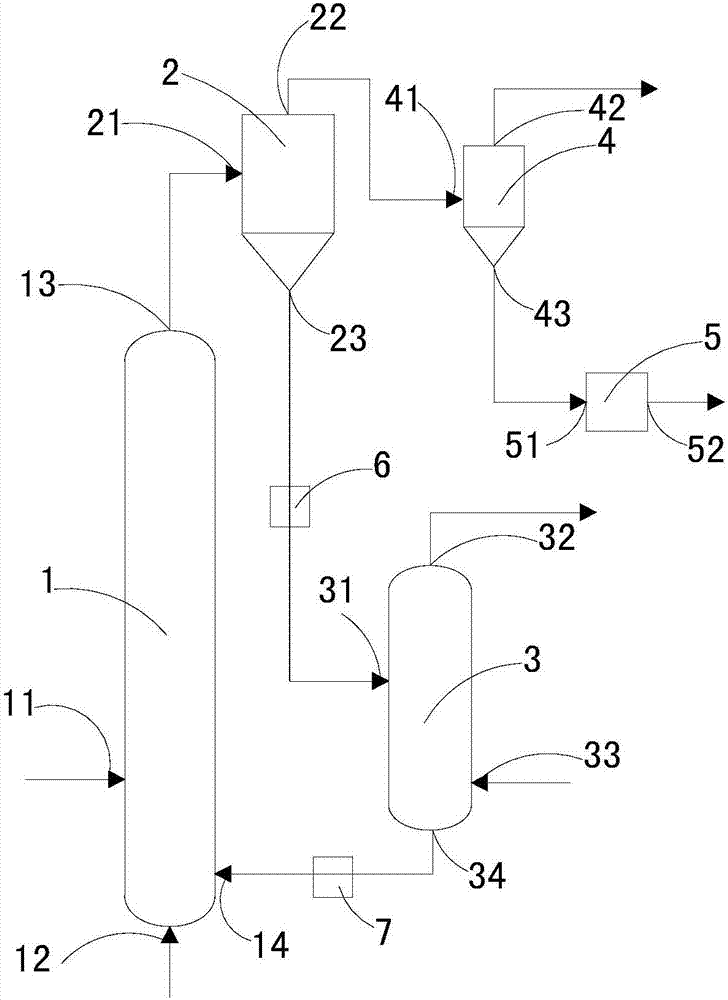

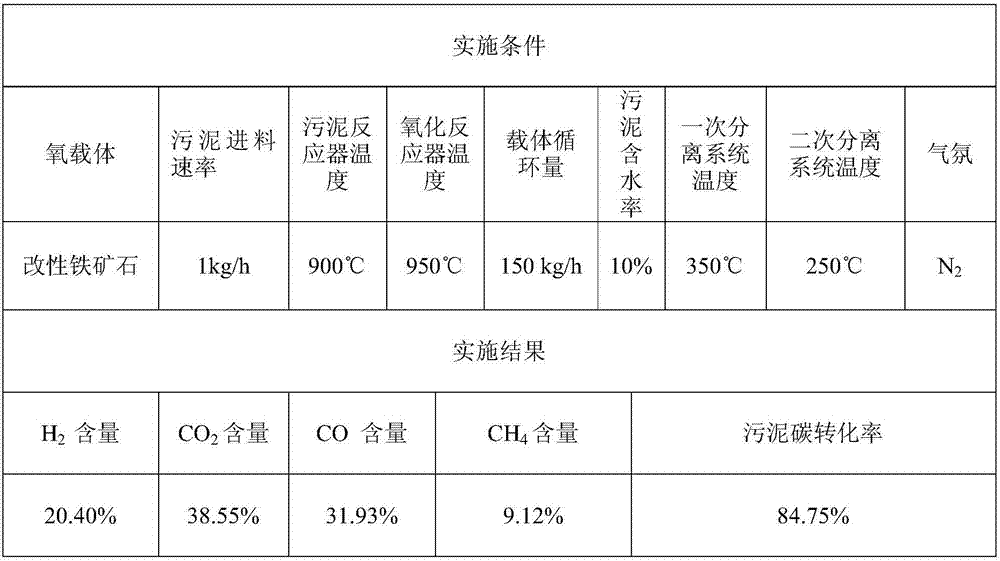

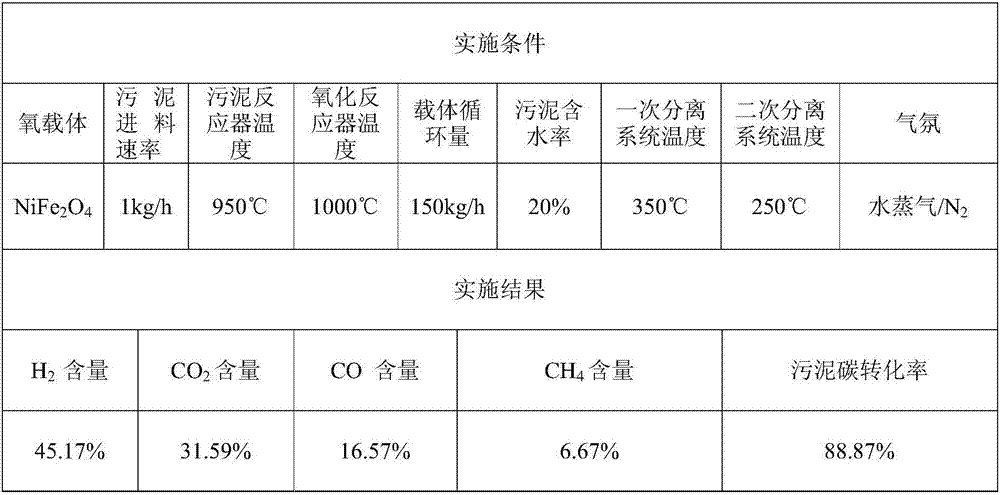

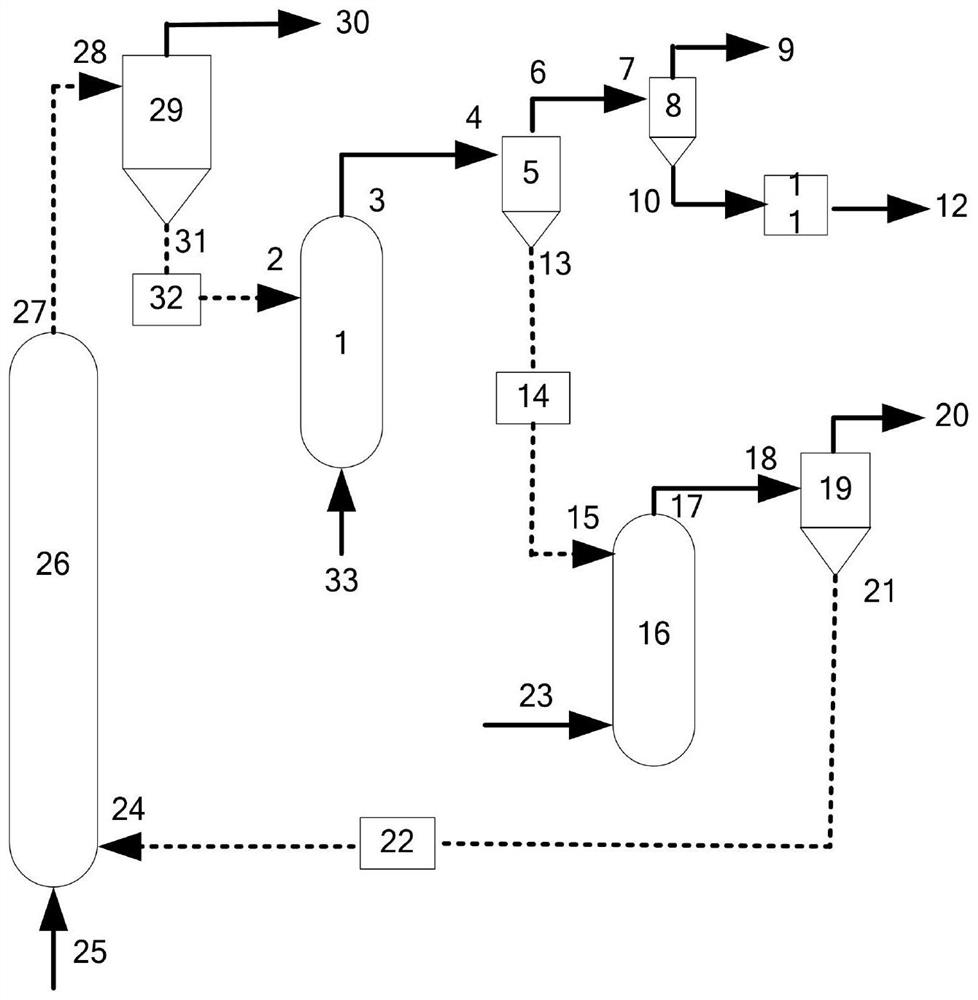

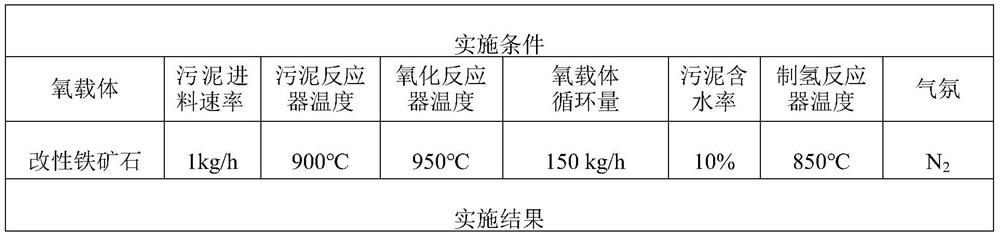

Method for directionally producing syngas by chemical chain gasification of sludge

InactiveCN107142125AEasy to operateEase of mass productionGasification processes detailsCombustible gas productionSyngasCatalytic pyrolysis

The invention discloses a method for directionally producing syngas by chemical chain gasification of sludge. The method comprise the steps of 1, inputting an oxygen carrier, carrier gas and sludge into a sludge reactor to perform a chemical chain gasification reaction, wherein reaction temperature is 850-950 DEG C, and an oxygen carrier reaction time is 4-15s to acquire the syngas, sludge ash and the reduction state oxygen carrier; 2, inputting the acquired syngas, sludge ash and reduction oxygen carrier into a primary separation system to separate the reduction state oxygen carrier to acquire a mixture of the syngas and the sludge ash, wherein separation temperature is 350-500 DEG C, and cutting diameters are 2-4mm. According to the method for directionally producing syngas by chemical chain gasification of sludge provided by the invention, chemical chain gasification is used for directionally converting organics in the sludge into the high-quality syngas, gas proportion in the syngas can be directionally adjusted via the different reactions, and the oxygen carrier has a catalytic pyrolysis effect on tar generated by the reactions; the syngas is relatively low in tar content, and applicable to gas power generation, FT synthesis or fuel cells.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

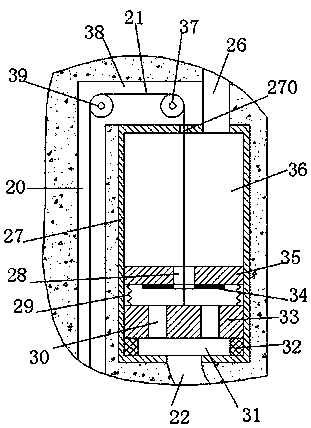

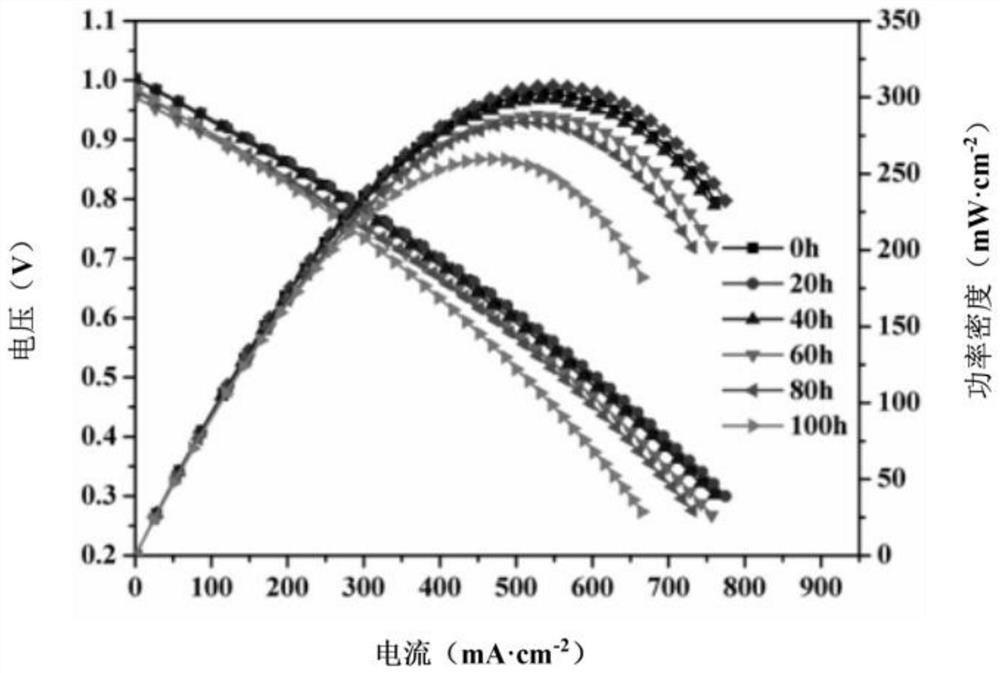

Low temperature electrolyte membrane of H-SOFC (high temperature solid oxide fuel cell) and preparation method

InactiveCN108306032ALower working temperatureWill not diluteFinal product manufactureFuel cellsWorking temperatureNormal electrolytes

The invention relates to the field of fuel cells and discloses a low temperature electrolyte membrane of an H-SOFC (high temperature solid oxide fuel cell) and a preparation method. The method comprises the following steps of: (1) mixing a raw material A and a raw material B, adding a doping oxide to prepare a doped compound in an A2B2O7 solid solution fluorite structure, (2) adding the doped compound into concentrated nitric acid, di-ethyl alcohol and citric acid to prepare doped nano gel, and (3) performing drying, pressing, sintering, annealing and cold treatment on the doped nano gel to form a doped nano ceramic membrane material. Compared with the common electrolyte, since a reaction occurs at a cathode, the electrolyte membrane of the fuel cell is good in structural stability and durability and high in mechanical strength; output power of a cell is stable for a long time; the cell is low in working temperature and high in electrical efficiency; and the fuel cell electrolyte membrane is simple in preparation process and low in production cost and has better economic advantages and application prospects.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

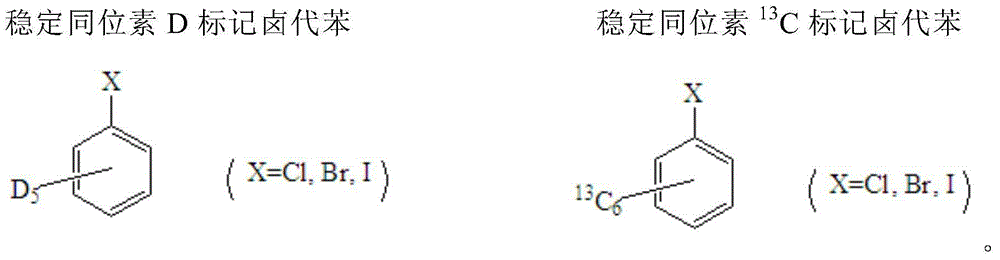

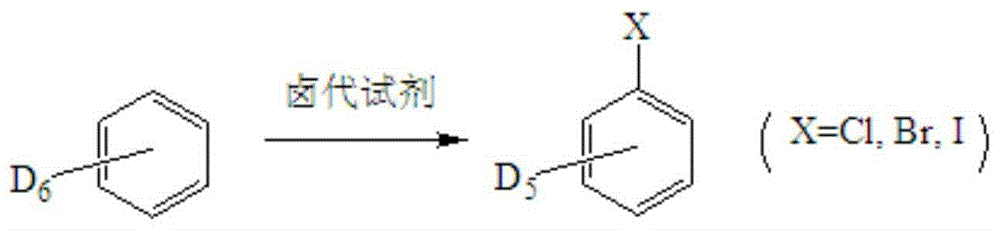

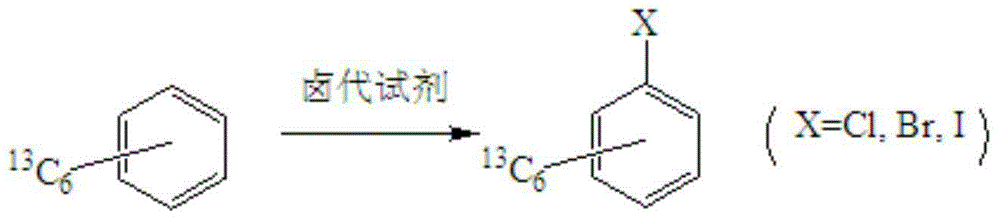

Synthetic method for stable isotope labeled halobenzene

ActiveCN104610012ACheap and easy to getSimple processHalogenated hydrocarbon preparationChemical purityBenzene

The invention relates to a synthetic method for stable isotope labeled halobenzene, in particular to a synthetic method for stable isotope D labeled halobenzene-D5 or stable isotope 13C labeled halobenzene-13C6. The organic synthetic method is utilized to enable the stable isotope D labeled benzene-D6 or benzene-13C6 to be reacted with a halogenating reagent, so as to obtain the stable isotope labeled halobenzene-D5 or halobenzene-13C6. Compared with the prior art, the method for preparing the stable isotope labeled halobenzene-D5 or halobenzene-13C6 is simple, safe and reliable; after separation and purification, the chemical purity of the product is up to more than 99.0%, and the isotope abundance is up to more than 99.0% atoms.

Owner:SHANGHAI RES INST OF CHEM IND

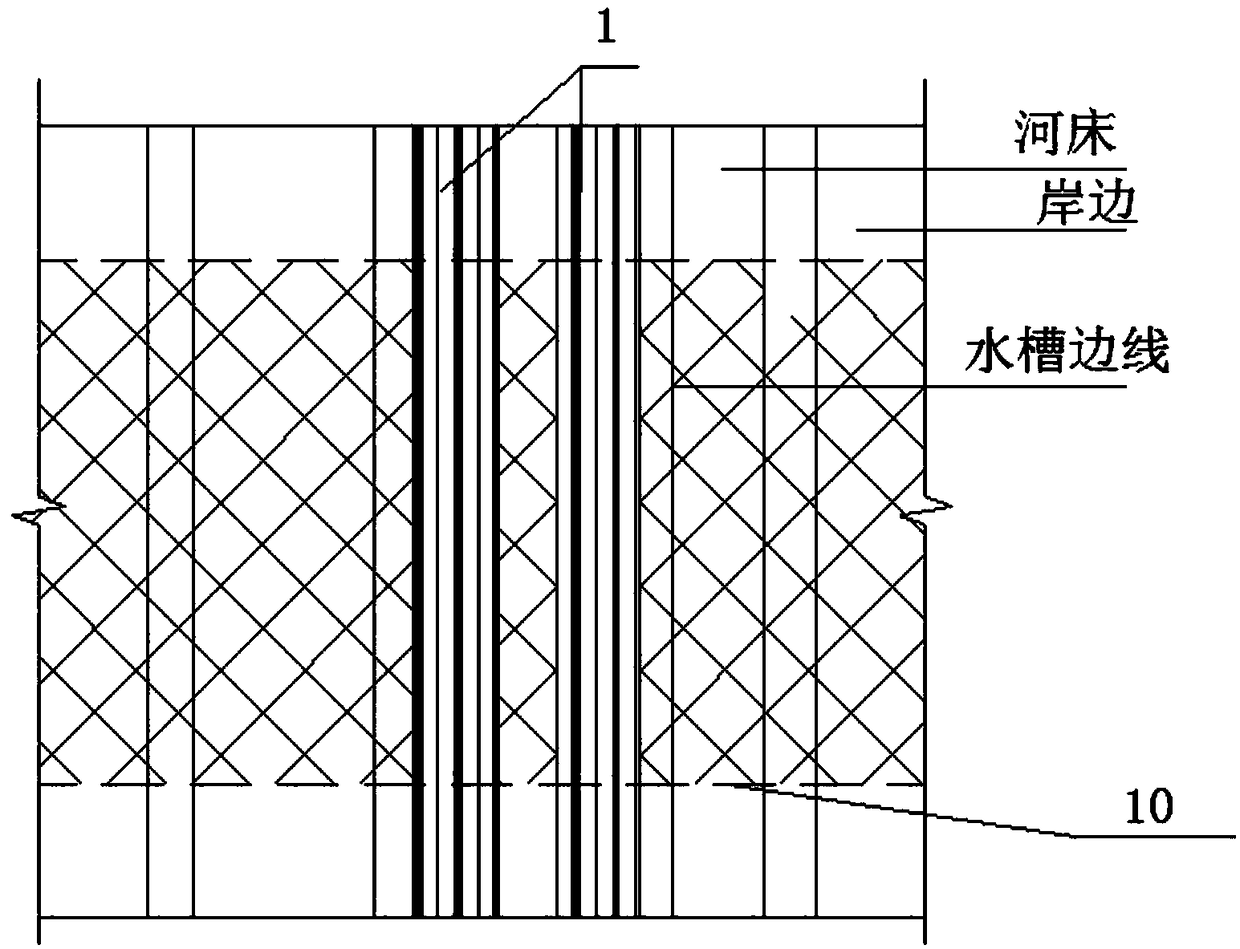

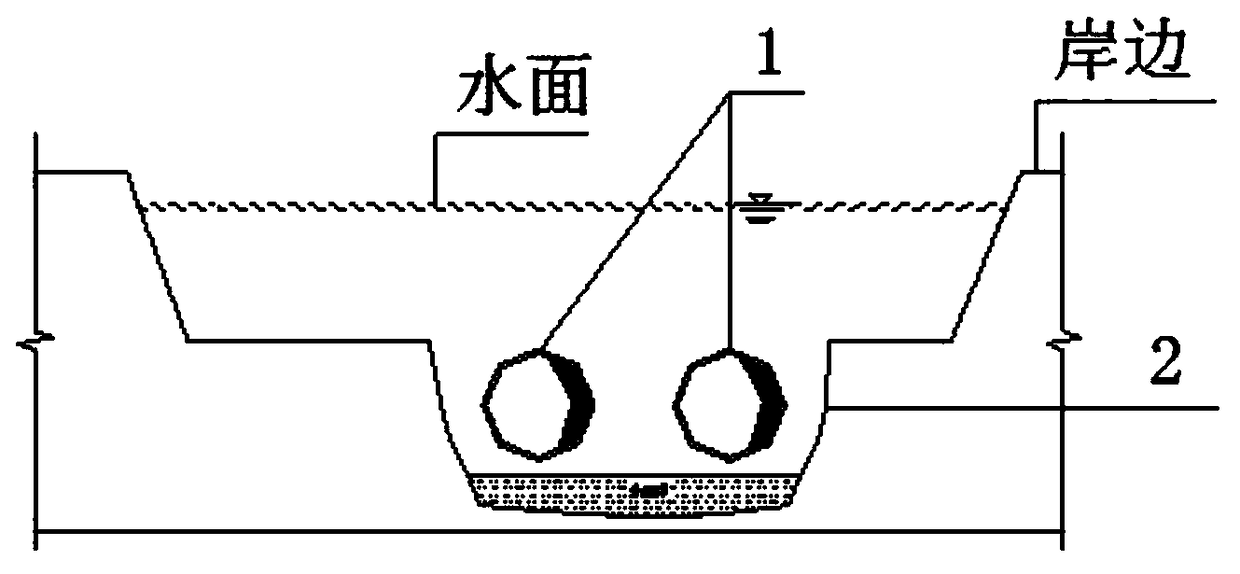

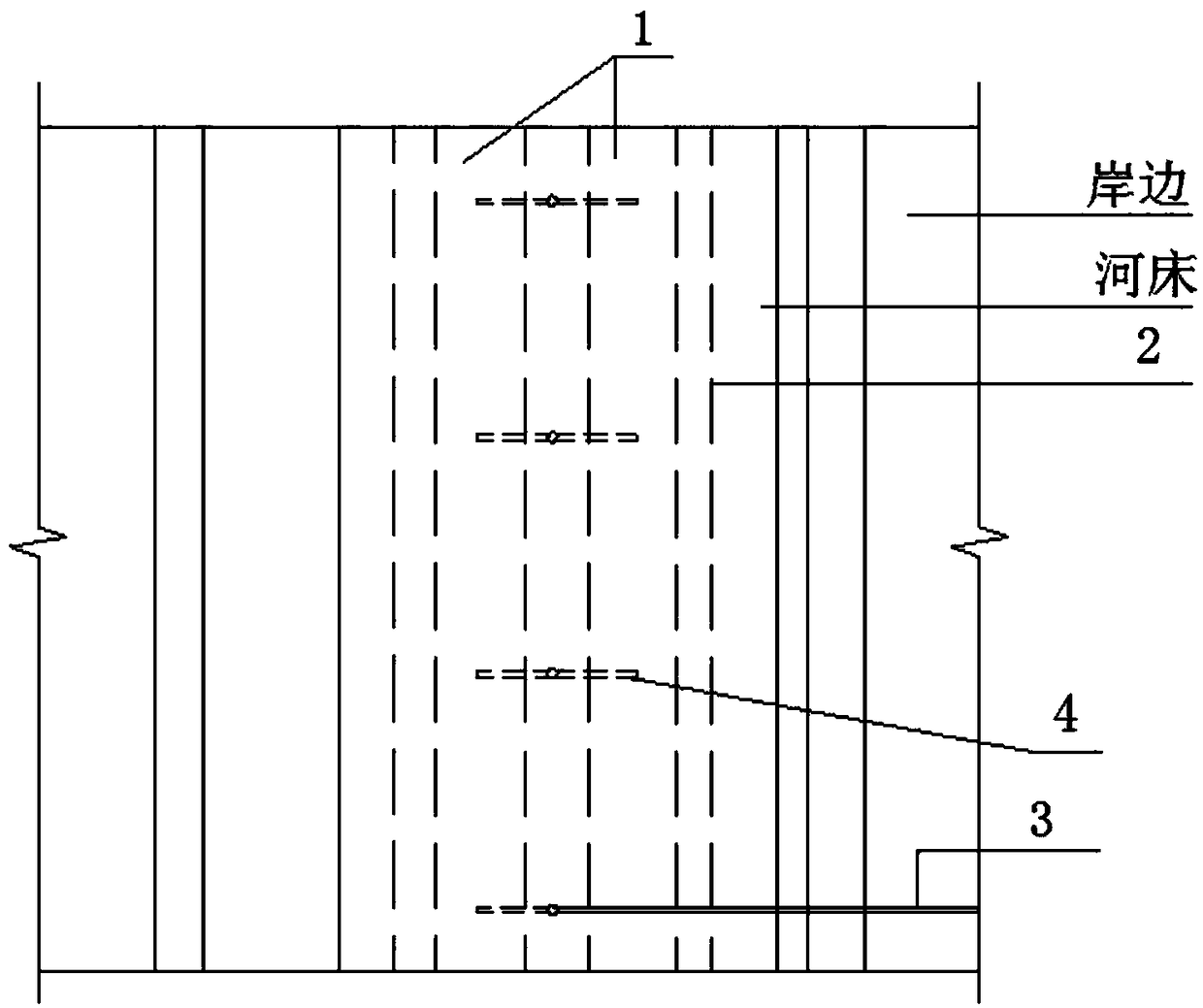

Underwater stone throwing and grouting reinforcing method for hanging soft foundation at lower part of immersed tube

ActiveCN108797759AMeet the design requirementsPerformance is not affectedSewer pipelinesUnderwaterWater channel

The invention discloses an underwater stone throwing and grouting reinforcing method for a hanging soft foundation at the lower part of an immersed tube. The method comprises the following steps: first, finding out the position of a pipeline, and excavating a water channel; throwing stone to the water channel, thus forming a stone-throwing silt squeezing layer; pre-burying a plurality of groutingpipelines at the position, close to the bottom, of the stone-throwing silt squeezing layer; then still throwing stone to the water channel, thus forming a stone-piled layer; then carrying out backfilling on the part around the pipeline by adopting stone chips till the water channel is level, thus forming a buffer layer; then covering the surface of the buffer layer with seepage-proofing geotechnical cloth, and carrying out backfilling on the seepage-proofing geotechnical cloth with gravel; then carrying out grouting and mud pumping simultaneously, thus forming a compact stone piled concrete structure; and finally, carrying out road pavement construction through layered paving and pressing according to the roadbed reequipments of road design. With the technical scheme, the purpose that whenthe waterway after construction adopting the immersed tube method encounters the construction road, the reinforcing for the foundation of the hanging part at the lower part of the immersed tube achieves the design bearing capacity requirements of the road is achieved, the method is simple and feasible, and the construction cost is low.

Owner:CHINA FIRST METALLURGICAL GROUP

Multifunctional environment-friendly coating device

The invention discloses a multifunctional environment-friendly coating device which comprises an environment-friendly box fixedly mounted on a base body, a discharge pipe connected to a coating filling box and a connecting pipe connected to a pollution discharging system. A mounting and connecting cavity is formed in the ground; an adapting plate is rotatably mounted at the left bottom end of themounting and connecting cavity through an adapting shaft; a first through slot is formed in the left end of the adapting plate; a flow guide device is fixedly mounted at the lower end of the mountingand connecting cavity; the flow guide device comprises a first sleeve, a first accommodating groove is formed in the first sleeve, a first partition plate is fixedly mounted in the first accommodatinggroove to cut the first accommodating groove into a first upper accommodating groove and a first lower accommodating groove; a first sliding connecting block is mounted in the first lower accommodating groove in a sliding manner up and down; a first ejecting shaft is fixedly mounted in the middle of the upper end surface of the first sliding connecting block; the upper end of the first ejecting shaft penetrates through the first partition plate and the first sleeve and penetrates into the mounting and connecting cavity; and second through slots communicating to the first upper and lower accommodating grooves are symmetrically arranged on the left and right sides of the first partition plate.

Owner:乐绪春

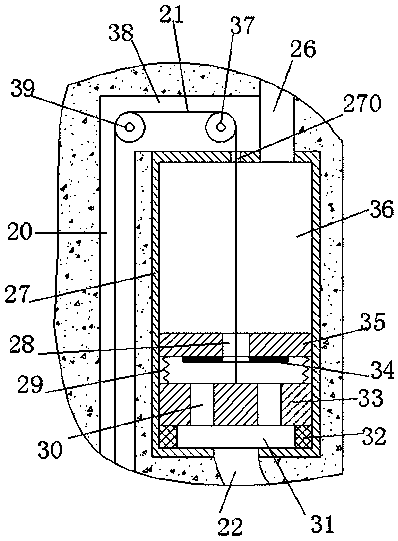

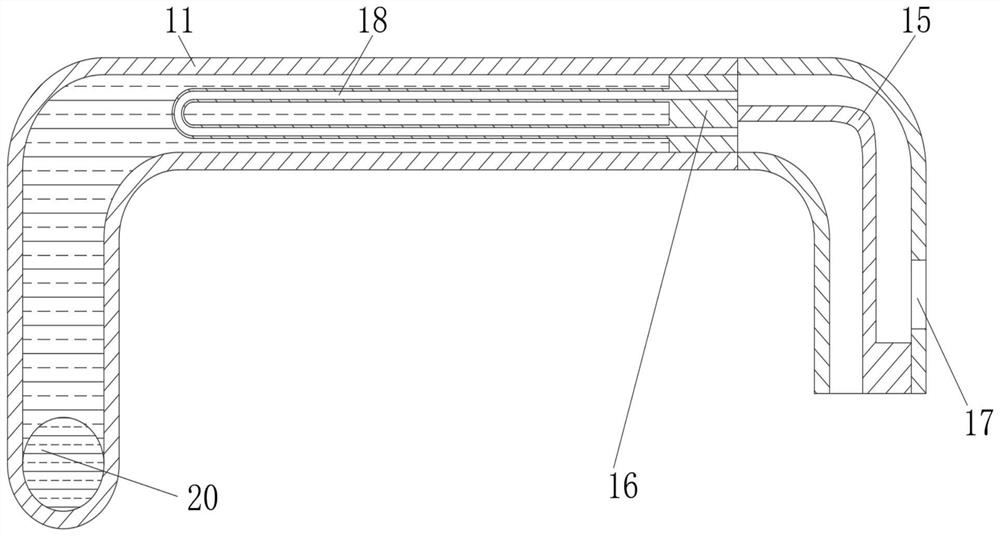

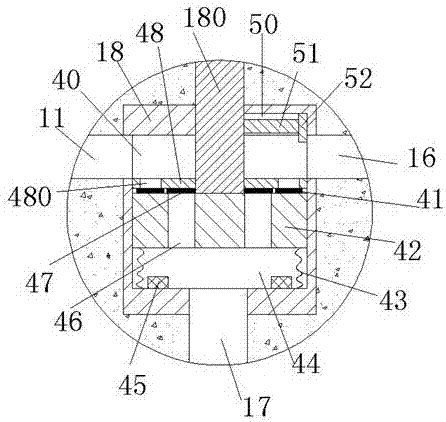

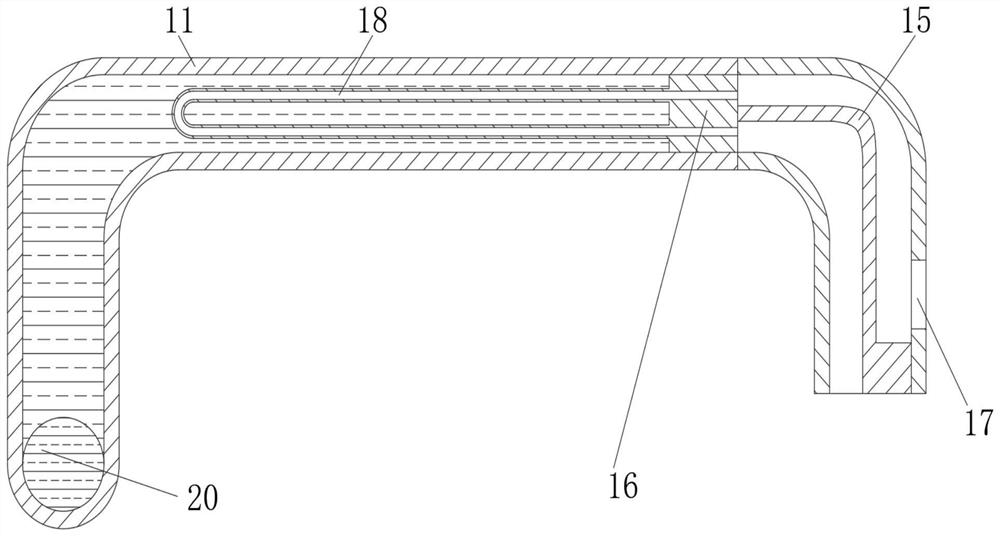

Detergent spray-out pressure application structure for household steam cleaner

ActiveCN111672656AWill not divertWill not diluteLiquid spraying apparatusCleaning using liquidsThermodynamicsEngineering

The invention relates to the technical field of cleaning equipment and discloses a detergent spray-out pressure application structure for a household steam cleaner. The structure comprises a box. A vertical plate is integrally formed on one side of the middle of the box, and a solvent cavity sleeves the side, of the vertical plate, in the box. According to the detergent spray-out pressure application structure for the household steam cleaner, a gas inlet pipe cooperates with a mounted circulation pipe and injected compressed air, under the combined action of a partition board, a baffle and a heat exchange pipe, high-temperature steam generated in a generator circularly flows in the air inlet pipe and is discharged into a solvent discharging pipe through a circulation pipe, the steam is mixed with a detergent, then the mixture is discharged into a spray pipe and discharged out, and the compressed air absorbs heat and expands, thereby pushing a pressure plate to apply pressure downward.The high-temperature steam is prevented from being directly discharged into the solvent cavity and contacting the detergent, it is guaranteed that the detergent cannot be diluted and the generated steam cannot be distributed, and the spray-out speed of the steam of the equipment is guaranteed, thereby guaranteeing the effect of deep cleaning.

Owner:重庆啄木鸟网络科技有限公司

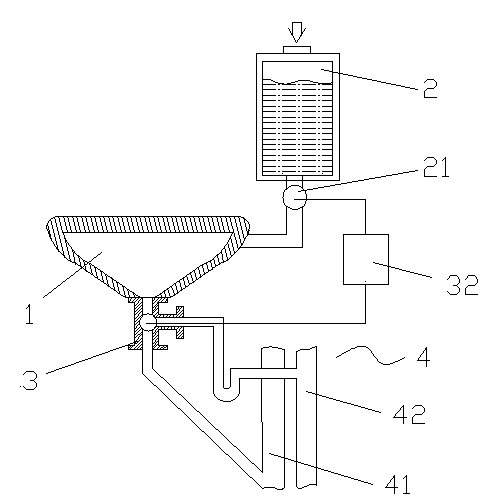

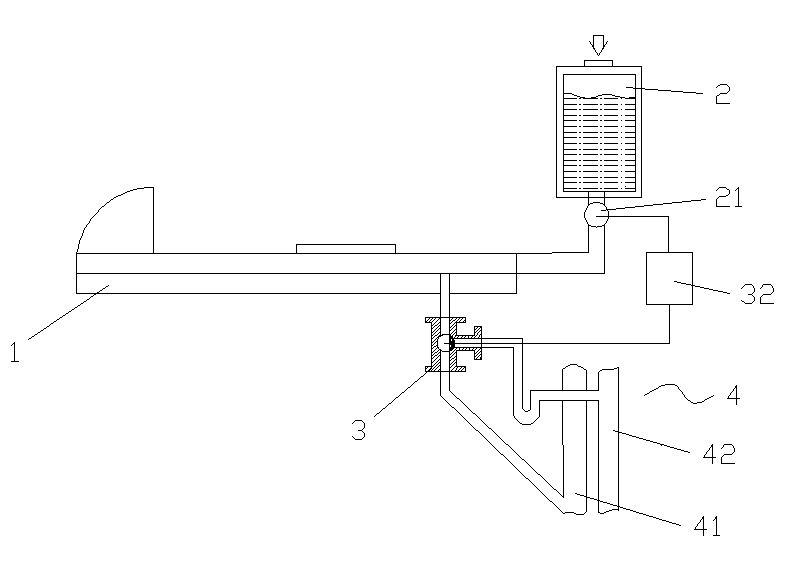

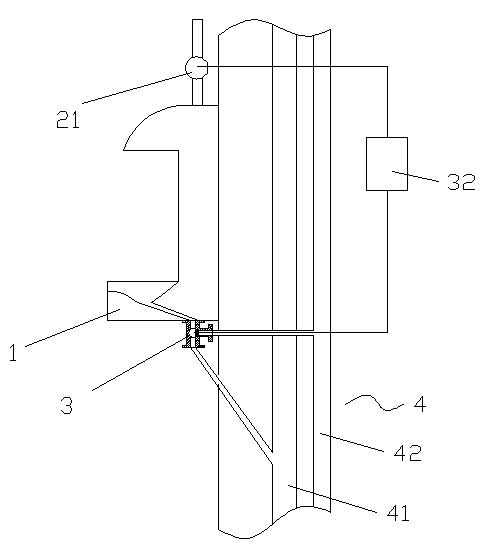

Environment-friendly system for excrement-water/urine-water separation and collection

The invention relates to the technical field of excrement-water separation, in particular to an environment-friendly toilet apparatus for excrement-water / urine-water separation and collection. The environment-friendly toilet apparatus comprises a water tank and a body. A three-way valve is connected to the bottom of the body and is connected with two connecting pipes which are independent; one connecting pipe is a blow-down pipe communicated with an excrement collection tank; the other connecting pipe is a drain pipe communicated with the blow-down pipe. The environment-friendly toilet apparatus has the advantages that excrement and water are separated for convenience of collection, active components are never diluted by the water, and organic fertilizer can be greatly collected for free; the organic fertilizer can be transported for farmland irrigation and restoration of the natural circulation of materials; methane gas, deep-processed fertilizer and proteins can be produced; fouling odor can be isolated effectively, a trap is omitted, flushing water is little, and water resources are saved; excrement and flushing water are separated and are discharged to urban sewers, low pollution is caused to rivers and lakes, underground water and soil are protected, cleaning work of septic tanks is reduced, and urban sanitation cost is reduced; the environment-friendly toilet apparatus is good in operation stability, simple in structure, low in cost and easy to maintain.

Owner:洪果平

Method and device for preparing synthesis gas and simultaneously recovering phosphorus from high-purity H2 through chemical-looping treatment of sludge

PendingCN112322355AEasy to condenseNo dilution issuesPhosphatesGasification processes detailsSyngasSludge

The invention discloses a method and device for preparing synthesis gas and simultaneously recovering phosphorus from high-purity H2 through chemical-looping treatment of sludge. The method comprisesthe following steps: (1) introducing an oxygen carrier, carrier gas and sludge into a sludge reactor for reaction to obtain a mixture of synthesis gas, sludge ash and a reduction-state oxygen carrier,(2) introducing the mixture into a first separation system, separating the reduction-state oxygen carrier to obtain a mixture of synthesis gas and sludge ash, and introducing the mixture of synthesisgas and sludge ash into a second separation system for separation, (3) inputting the reduction-state oxygen carrier into a hydrogen production reactor, introducing an oxidant for reaction, and carrying out gas-solid separation on the reaction product through a third separation system to obtain H2 and an oxygen carrier, and (4) introducing the oxygen carrier into an oxidation reactor for oxidationreaction, and introducing the oxygen carrier after oxidation reaction into a sludge reactor for reaction. According to the method, the phosphorus element in the sludge is converted into soluble phosphate by adopting a chemical-looping reductive reaction atmosphere, so that high-purity H2 co-production is realized, and higher resource utilization efficiency is achieved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Etching agent as well as preparation method and application thereof

ActiveCN103013523AEasy to operateWill not dilutePhotomechanical apparatusSemiconductor/solid-state device manufacturingAmmonium sulfateHydrogen peroxide

The invention provides an etching agent consisting of sulfuric acid and ammonium persulphate, wherein the mass concentration of ammonium persulphate is 1%-25%. The mass concentration of sulfuric acid is 98%. The invention further provides a method for preparing the etching agent, and the method comprises a step of adding ammonium persulphate in sulfuric acid at 100-200 degrees centigrade. In the invention, the oxidant hydrogen peroxide is replaced by ammonium persulphate. Ammonium persulphate is powder, which makes the operation be simpler. When being used for processing a wafer or an optical mask, the etching agent disclosed by the invention is still not diluted after being washed for many times because sulfuric acid is a by-product of a reaction with an organism instead of water, so that the production cost is lowered.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

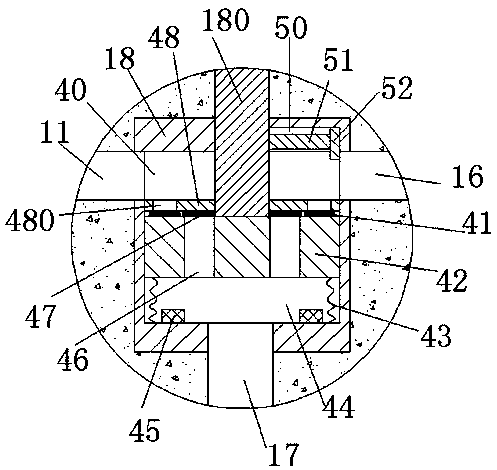

An organic fertilizer collecting device

The invention discloses an organic fertilizer collecting device. The organic fertilizer collecting device comprises a urine pool fixedly arranged on a wall body, a urethra tube connected with a urine collecting cylinder and a connecting tube connected with a dirt discharge system; a placing cavity is arranged in the ground surface; a rotating frame is rotatably arranged at the right lower end of the placing cavity by using a rotating pin shaft; a first through connecting hole is formed in the left end of the rotating frame; a collecting device is fixedly arranged at the lower end of the placing cavity; the collecting device comprises a first sleeve shell; a first cavity is formed in the first sleeve shell; a first barrier plate is fixedly arranged in the first cavity; the first barrier plate separates the first cavity into a first upper cavity and a first lower cavity; a first sliding block is arranged in the first lower cavity in an up-and-down sliding mode; a first top arm is fixedly arranged at the middle end of the upper end surface of the first sliding block; the upper end of the first top arm penetrates through the first barrier plate and the first sleeve shell and penetrates into the placing cavity; a second through connecting hole for connecting the first upper cavity and the first lower cavity is formed in the first barrier plate in a bilateral symmetry mode.

Owner:河北跃洋生物科技有限公司

Disinfection method for livestock breeding

The invention discloses a disinfection method for livestock breeding. The disinfection method has technical scheme key points that after basic cleaning is finished and before a disinfectant is sprinkled, a dry heat blower is used for blowing hot wind of which the temperature is 65 DEG C and the humidity is 5% or below into a livestock shed, and after the disinfectant finishes being sprinkled and being subjected to sealed disinfection, the dry heat blower is used for assisting in ventilation. The disinfection method has the advantages that the hot wind of which the temperature is 65 DEG C and the humidity is 5% or below is blown into the livestock shed under a working state of the dry heat blower, on one hand, the high-temperature dry hot wind can effectively kill darkness and moisture loving microorganisms in an environment, on the other hand, a dry floor and wall environment is provided for subsequent disinfectant sprinkling, so that the disinfectant can not be diluted, and a disinfection effect is better.

Owner:太湖县华中农业发展有限公司

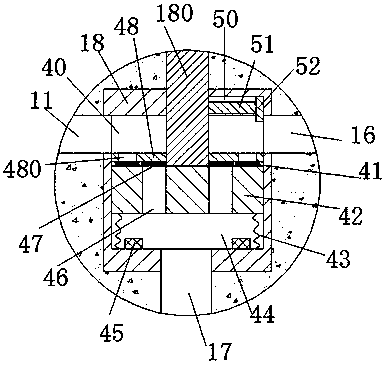

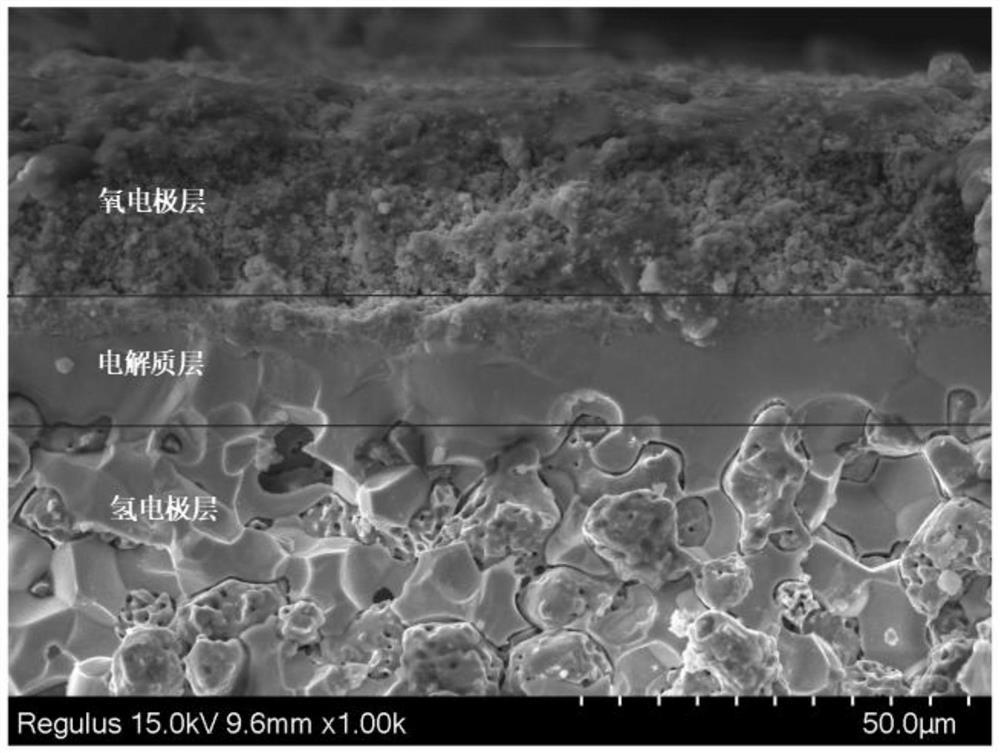

Method for preparing ceramic composite membrane of proton conduction type solid oxide pool through water-based tape casting

PendingCN114044673AWill not diluteLower activation energyFinal product manufactureFuel cellsCeramic compositeElectrical conductor

The invention discloses a method for preparing a ceramic composite membrane of a proton conduction type solid oxide pool through water-based tape casting, and belongs to the field of preparation of high-temperature fuel cells and electrolytic pools. A water-based tape casting method is used, a proton conductor material is used as an electrolyte, a dispersing agent, a binding agent, a plasticizer and the like are added into ceramic powder, then ball milling is performed to obtain uniform tape casting slurry, a hydrogen electrode layer and an electrolyte layer are subjected to composite tape casting to form a biscuit, and after drying, the co-sintering is performed to obtain the ceramic composite membrane of the proton conduction type solid oxide pool, wherein the area of the ceramic composite membrane is 80 * 80 mm. The electrolyte layer is compact and free of pores, and has a thickness of about 12 [mu]m. A water-based tape casting method is adopted, the preparation method is harmless to the environment and human bodies, the preparation cost is reduced, and the proton conduction type solid oxide pool preparation method which is stable, environmentally friendly, reliable and easy to operate is formed.

Owner:NANJING UNIV OF SCI & TECH

Preparation and application of mixed oxide-doped nano-copper-cobalt alloy catalyst

ActiveCN104645991BReduce contentGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystMixed oxide

Owner:TIANJIN UNIV

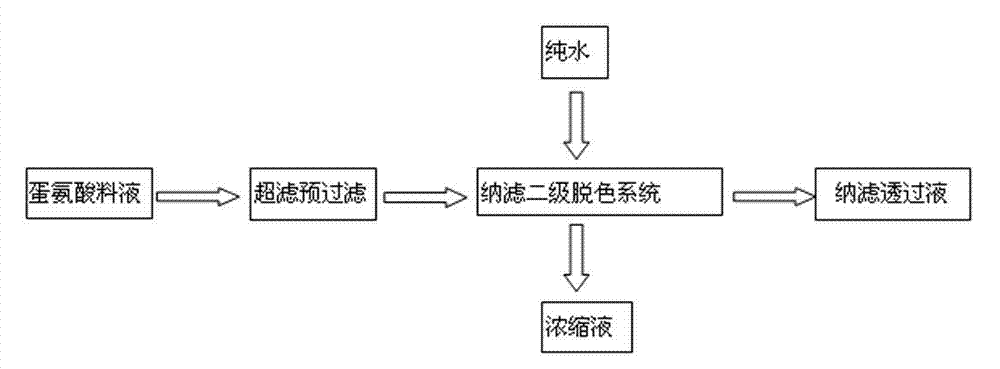

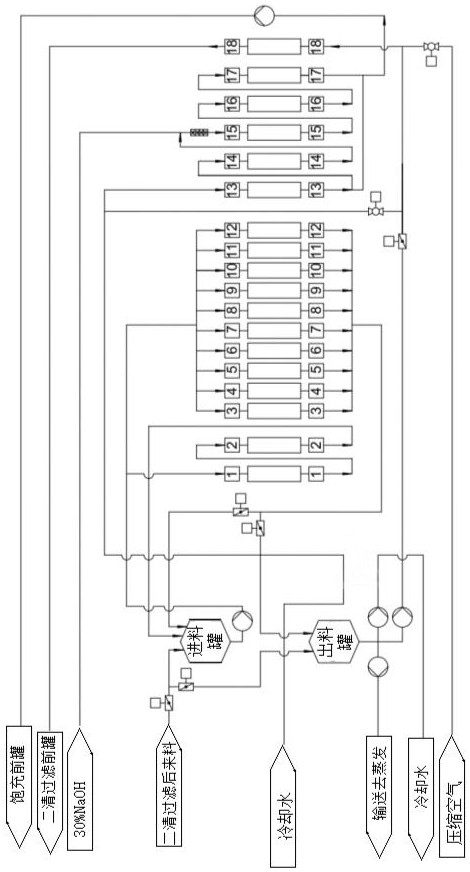

Method for decoloring methionine crystallization mother liquor by adopting membrane integration technology

InactiveCN104844487AReduce turbidityPurify and refineOrganic chemistryOrganic compound preparationHigh concentrationUltrafiltration

The invention provides a method for decoloring a methionine crystallization mother liquor by adopting a membrane integration technology. The method comprises the following steps: 1, carrying out ultrafiltration (UF) system treatment on methionine; and 2, carrying out nanofiltration (NF) membrane decoloring purification system treatment, adding pure water to the obtained nanofiltration concentrate, carrying out filter washing, directly conveying the obtained substance to a burning device, burning, and allowing an NF permeation liquid to directly enter a subsequent process. The clean production membrane integration decoloring technology is adopted to substitute active carbon decoloring in order to remove colloids and other pigments in the methionine crystallization mother liquor, so the generation of solid wastes of an enterprise is reduced, and the working environment of a decoloring workshop is improved; and high concentration multiple of the membrane technology is used, so the emission amount of wastewater is reduced, and the running pressure of the wastewater treatment station of the enterprise is reduced.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

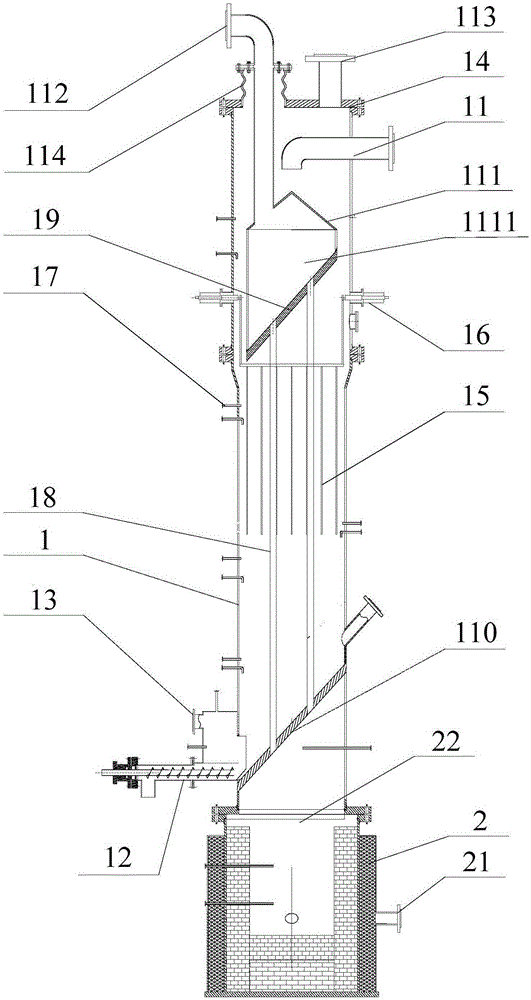

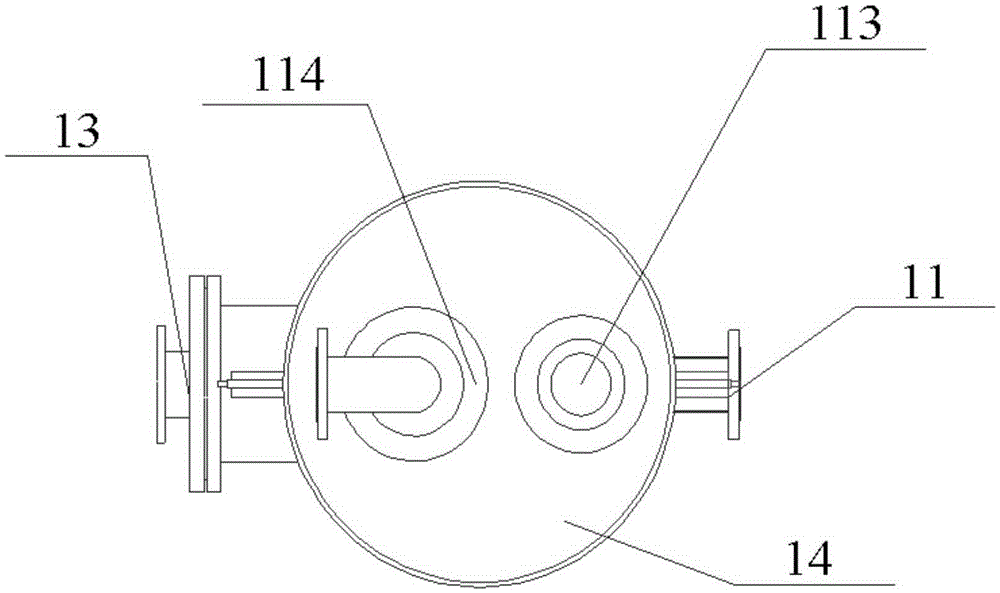

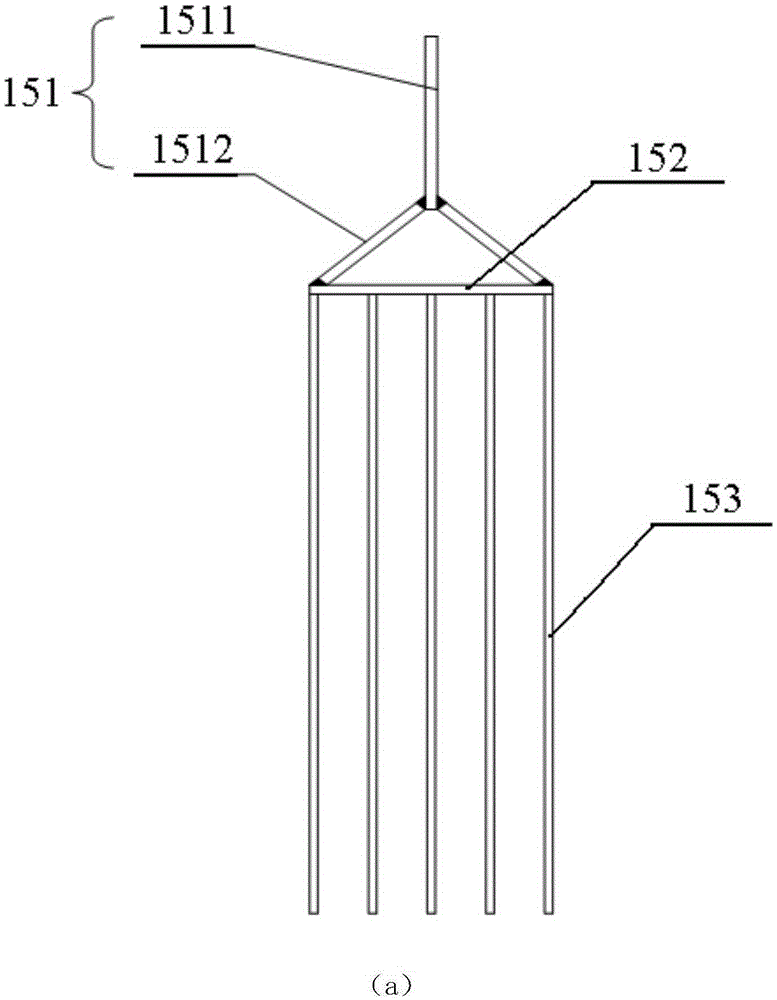

Outer heating pyrolysis reactor for high-moisture carbon-based raw material

ActiveCN105295967AIncrease heat transfer areaHigh heat and mass transfer efficiencySludge treatment by pyrolysisByproduct vaporizationFlue gasProcess engineering

The invention discloses an outer heating pyrolysis reactor for a high-moisture carbon-based raw material. The outer heating pyrolysis reactor comprises a pyrolysis chamber; the upper part of the pyrolysis chamber is provided with a feed inlet; the lower part of the pyrolysis chamber is provided with a continuous ash discharging mechanism and a combustion gas outlet; the inner wall of the pyrolysis chamber is plugged with a bottom tube plate; the lowest point of the bottom tube plate is aligned with the bottom of an ash inlet of the continuous ash discharging mechanism; the bottom tube plate is connected with the lower ends of vertical flue gas tubes, and the upper ends of the vertical flue gas tubes are connected with a top tube plate; a flue gas chamber sealing head covers over the top tube plate; the top tube plate and the flue gas chamber sealing head define a flue gas chamber; and a flue gas discharging tube connected with the flue gas chamber sealing head extends out from the pyrolysis chamber. Flue gas produced after combustion enters from the bottom of the pyrolysis chamber, is sent to the flue gas chamber through the vertical flue gas tubes and is then discharged out via the flue gas discharging tube. The outer heating pyrolysis reactor has an increased heat transfer area and improved heat and mass transfer efficiency.

Owner:YANCHENG INST OF TECH

Method for preventing liquor from being diluted and protecting surface of silicon wafer

ActiveCN102108556BImprove surface qualityNot easy to corrodeAfter-treatment detailsRenewable energy productsSiliconCorrosion

The invention relates to a method for preventing liquor from being diluted and protecting the surface of a silicon wafer, which comprises the following steps: before a silicon wafer is moved into a cleaning tank, jetting de-ionized water onto the surface of the silicon wafer; then, passing the silicon wafer of which the surface is provided with the de-ionized water through a clearance formed between two rollers; and finally, using a scraper to scrape the de-ionized water on the surface of the silicon wafer, which is to be immersed in liquor. By using the method provided by the invention, the surface of the silicon wafer can be better protected from corrosion in the silicon wafer cleaning process, the liquor is prevented from being diluted, and the consumption of the liquor is reduced.

Owner:盐城天合国能光伏科技有限公司

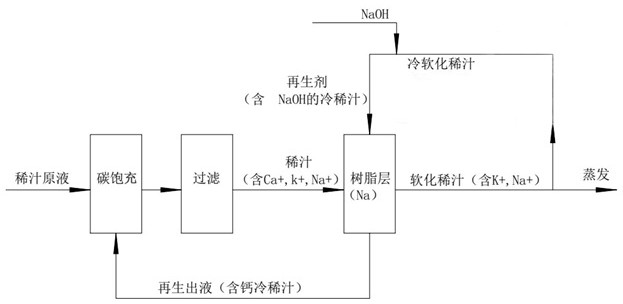

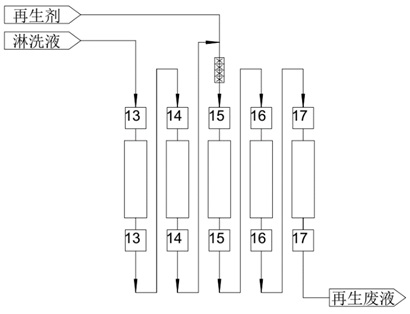

Softening method of beet syrup

PendingCN114606349ARealize continuous productionReduce foulingIon-exchange process apparatusIon-exchanger regenerationPhysical chemistryIon exchange

The invention discloses a method for softening beet syrup. The method comprises the following steps: 1) a production process: enabling beet syrup to pass through a decalcification ion exchange resin column to obtain softened syrup; (2) backwashing: backwashing the decalcified ion exchange resin column which is saturated by adsorbing calcium ions; 3) regeneration process: regenerating the decalcification ion exchange resin column saturated by adsorbing calcium ions by using NaOH softened thin juice; and 4) leaching: leaching the regenerated ion exchange resin column by using the softened thin juice. When the softened thin juice obtained through the beet sugar thin juice softening method enters a subsequent evaporator and other procedures, the scaling phenomenon of the evaporator and crystallization sugar boiling equipment is reduced, the situation that production is stopped due to descaling of the evaporator and other equipment is avoided, continuous production of beet sugar is achieved, and labor cost is saved. And meanwhile, the service lives of the evaporator and the crystallization sugar boiling equipment are prolonged.

Owner:OUSHANGYUAN PROCESS & EQUIP INTELLIGENT CO

Improved type organic fertilizer collecting and taking device

InactiveCN107989146AWill not diluteRealize centralized recyclingUrinalsLavatory sanitoryEngineeringOrganic fertilizer

The invention discloses an improved type organic fertilizer collecting and taking device. The device comprises a urine pool fixedly installed on a wall body, a urethra pipe connected with a urine collecting tube, and a connecting pipe connected with a sewage discharging system; a placing cavity is formed in the ground, a rotating frame is rotatably mounted on the lower right end of the placing cavity through a rotation pin shaft, a first through connection hole is formed in the left end of the rotating frame, and the collecting and taking device is fixedly installed at the lower end of the placing cavity; the collecting and taking device includes a first casing shell, a first cavity body is formed in the first casing shell, a first baffle plate is fixedly installed in the first cavity body, the first baffle plate divides the first cavity body into a first upper cavity body and a first lower cavity body through obstruction, a first sliding block capable of sliding up and down is installed in the first lower cavity body, a first top arm is fixedly installed in the middle of the upper end surface of the first sliding block, the first top arm is in through connection with the first baffle plate and the first casing shell and penetrates into the first placing cavity, and second through connection holes communicated with the first upper cavity body and the first lower cavity body areformed in the first baffle plate in a bilateral symmetry mode.

Owner:广州正顺机械技术开发有限公司

Method and apparatus for application of chemicals to insect, and use for selecting medicine in large scale therewith

A method for applying method to insect in order to screen the medicine features that its medicine applicator is composed of a container for raising insect and a medicine-feeding tube with medicine-loading inlet and medicine-feeding outlet, and said medicine feeding tube is inserted in said container for applying the medicine to the insects raised in it through sucking by themselves.

Owner:SUZHOU JOEKAI BIOTECH

Ejecting method of feed liquid in exchange column in mortar recovery deionization process

InactiveCN102352280AWill not diluteLight weightSolid sorbent liquid separationLubricant compositionIonSpecific gravity

The invention relates to an ejecting method of a feed liquid in an exchange column in a mortar recovery deionization process. The method comprises steps of: adding a certain amount of decolorized feed liquid into an exchange column for a deionization treatment; after adding the feed liquid, blowing and ejecting the feed liquid in the exchange column by utilizing compressed air until all feed liquid in the exchange column is ejected out; and implanting water for soaking. Because the compressed air does not mix with the feed liquid and has a small specific gravity, the invention can substantially increase blowing and ejecting speed and will not dilute the feed liquid to avoid adding burden on a sequent dewatering operation, so as to save energy.

Owner:浙江优立环境科技有限公司

A housekeeping steam cleaning machine cleaning agent spray pressure structure

ActiveCN111672656BWill not divertWill not diluteLiquid spraying apparatusCleaning using liquidsProcess engineeringCleansing Agents

The invention relates to the technical field of cleaning equipment, and discloses a housekeeping steam cleaning machine cleaning agent spraying pressure structure, including a box body, one side of the middle part of the box body is integrally formed with a vertical plate, the inside of the box body And a solvent chamber is set on one side of the vertical plate. The cleaning agent of the housekeeping steam cleaning machine is sprayed out of the pressure-applying structure, through the air intake pipe to cooperate with the installed circulation pipe, and the injected compressed air, as well as under the joint action of the partition plate, baffle plate, and heat exchange tube, the generator will generate The high-temperature steam circulates in the inlet pipe, and is discharged into the agent outlet pipe through the circulation pipe. After being mixed with the cleaning agent, it is discharged into the nozzle pipe. The compressed air absorbs heat and expands, thereby pushing the pressure plate downward to apply pressure, which prevents the high-temperature steam from being discharged directly. Contact the cleaning agent in the solvent chamber to ensure that the cleaning agent will not be diluted, and the generated steam will not be diverted, so as to ensure the ejection speed of the steam from the equipment, thereby ensuring a deep cleaning effect.

Owner:重庆啄木鸟网络科技有限公司

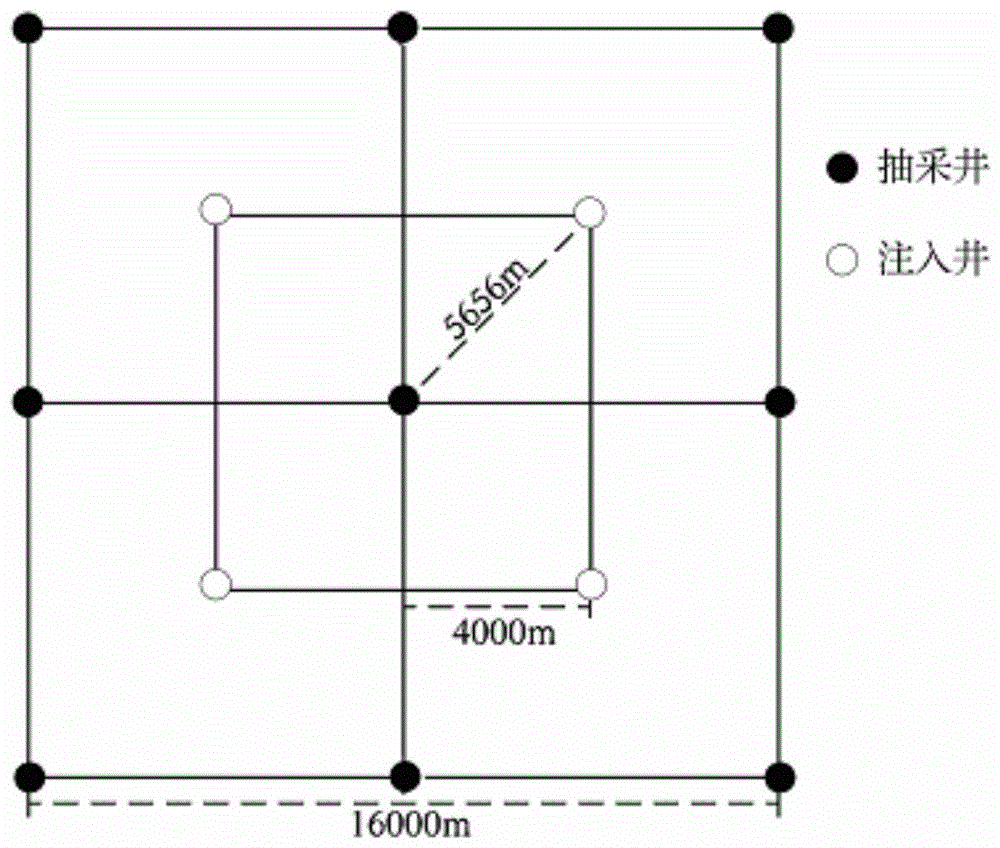

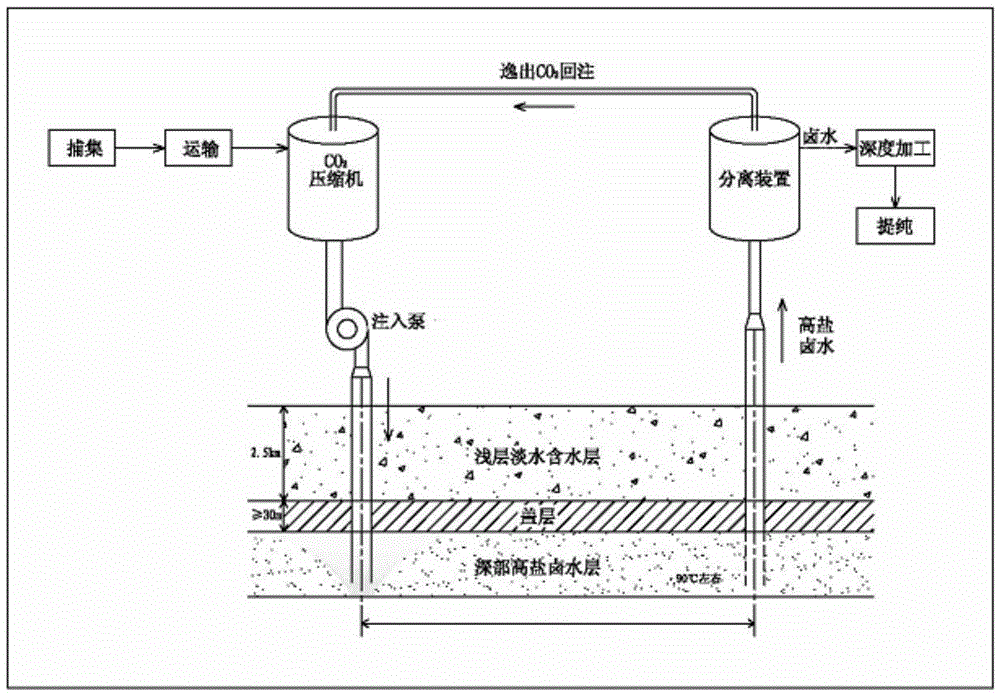

a co 2 Method for displacing high-salt brine in deep formation

ActiveCN103603642BRelief Cleansing ExtractMaximize utilizationFluid removalInjection pressureCo2 flooding

The present invention provides a CO 2 A method for displacing deep hypersaline brine in formations, comprising the following steps: converting captured CO 2 Transport to mining site via CO 2 The compressor will CO 2 Compress to supercritical state and inject supercritical CO 2 The injection well is pumped into the high-salt brine layer deep in the formation. At the same time, the high-salt brine is extracted in the extraction well, and the brine in the extracted high-salt brine is separated from the CO by a separation device. 2 Separation, deep processing and purification of the separated brine, and the separation of CO 2 by CO 2 The reinjection device repeatedly injects into the CO 2 into the compressor, and further pumped into the high-salt brine layer deep in the formation to circulate and displace the high-salt brine. This method can effectively alleviate the CO 2 Due to the serious pressure accumulation and salt rock precipitation problem during the simple injection process, the escaped CO 2 The reinjection realizes zero emission and reaps double benefits of economy and environmental protection.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com