Method and device for preparing synthesis gas and simultaneously recovering phosphorus from high-purity H2 through chemical-looping treatment of sludge

A synthesis gas and chemical chain technology, applied in chemical instruments and methods, inorganic chemistry, phosphate, etc., can solve problems such as high energy consumption, low gas calorific value, and large gas tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

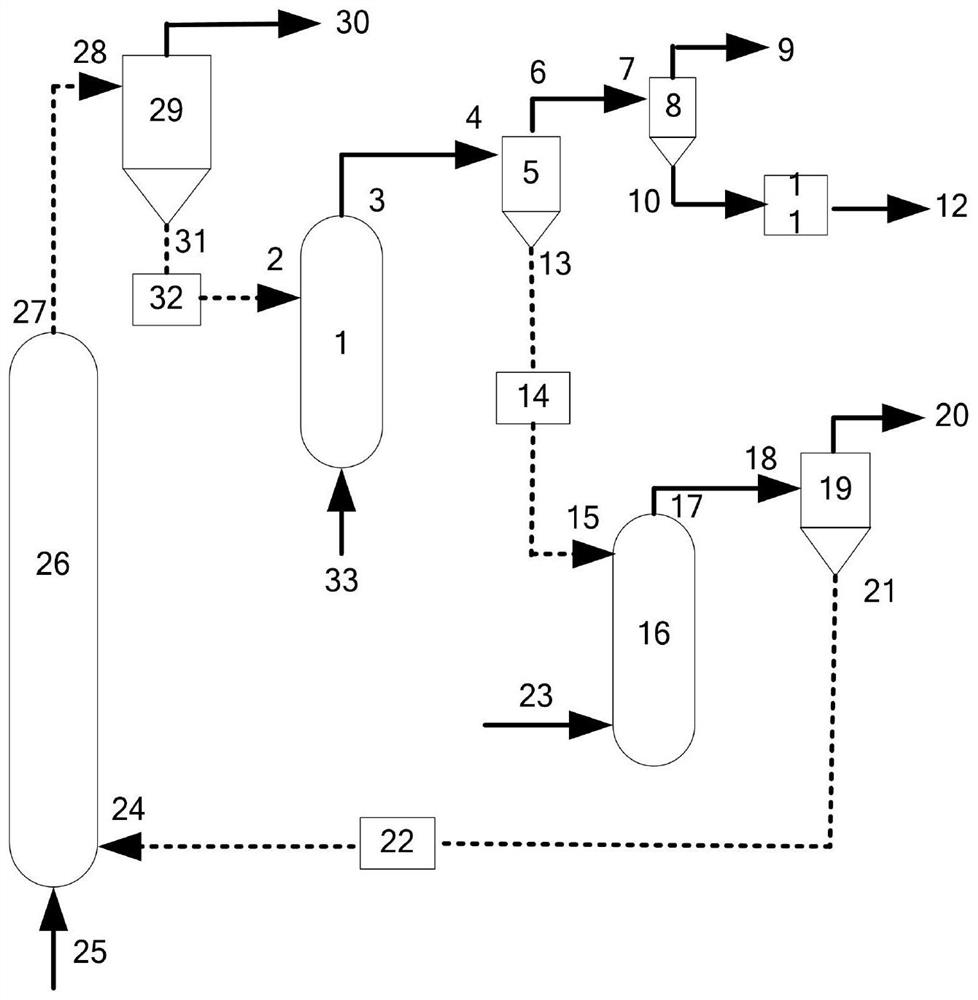

Method used

Image

Examples

Embodiment 1

[0036] This embodiment discloses a method for directional production of synthesis gas by chemical looping gasification of sludge, which is realized through the following technical solutions:

[0037] Dehydration and drying: The sludge is dried at 80°C and dehydrated to a moisture content of 5% to obtain dried sludge.

[0038] Oxygen carrier preparation: Fe 2 o 3 、Al 2 o 3 The analytical pure is mechanically mixed at a mass ratio of 7:3, shaped by a planetary molding machine, calcined at 900°C for 4 hours, crushed and sieved into 40-60 mesh particles, and used as an iron-based oxygen carrier for sludge chemical chain gasification .

[0039] Chemical chain gasification: open the screw feeder, and the dried sludge enters the sludge reactor 1 from the material inlet 33 of the sludge reactor, and the feed rate is 1kg / h; the iron-based oxygen carrier passes through the oxygen carrier inlet of the sludge reactor 2 into the circulating fluidized bed system in the sludge reactor 1...

Embodiment 2

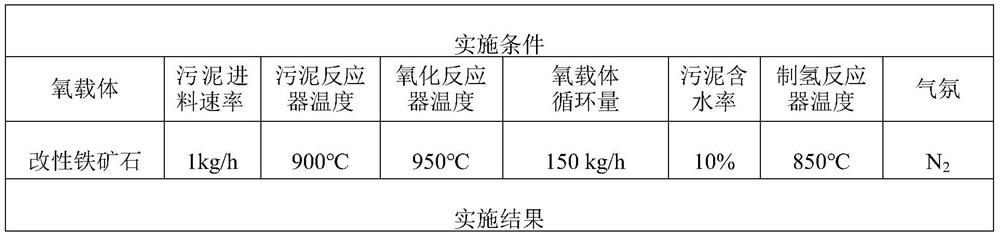

[0045] Since the method and device for directional production of synthesis gas by sludge chemical looping gasification are the same as those in Example 1, details will not be repeated here, and only the implementation conditions and implementation results are listed in Table 1, as shown in Table 1.

[0046] Table 1 Implementation conditions and results of sludge chemical chain reaction based on modified iron ore oxygen carrier

[0047]

[0048]

[0049] The preparation method of the modified iron ore in the present embodiment is: after the natural iron ore is pulverized, sieved, equal-volume impregnation of CoNi(NO 3 ) 2 , then dried at 200°C for 6 hours, and then calcined at 900°C for 3 hours to obtain modified iron ore.

Embodiment 3

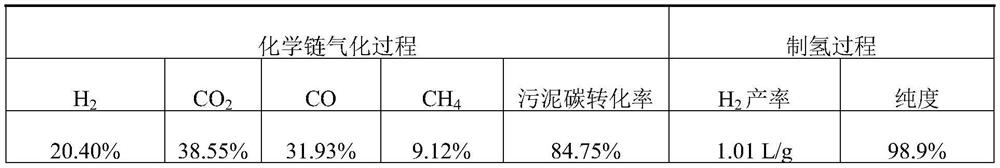

[0051] Since the method and device for directional production of synthesis gas by chemical looping gasification of sludge are the same as those in Example 1, details will not be repeated here, and only the implementation conditions and implementation results are listed in Table 2, as shown in Table 2.

[0052] Table 2 NiFe-based 2 o 4 Implementation Conditions and Results of Sludge Chemical Chain Reaction of Oxygen Carriers

[0053]

[0054] The difference between embodiment 1 and embodiment 2 is that the oxygen carrier and reaction temperature used are different. Compared with the synthetic iron-based oxygen carrier in embodiment 1, the modified iron ore in embodiment 2 has better reactivity and carbon The conversion efficiency and the synthetic calorific value obtained are also higher. Adopt synthetic NiFe in embodiment 3 2 o 4 As an oxygen carrier, it has better carbon conversion efficiency and synthesis gas calorific value, but relatively speaking, the cost is highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com