Softening method of beet syrup

A beet sugar and ion exchange resin technology, applied in the purification of sugar juice, chemical instruments and methods, sucrose production, etc., to achieve the effects of reducing energy consumption, prolonging service life, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

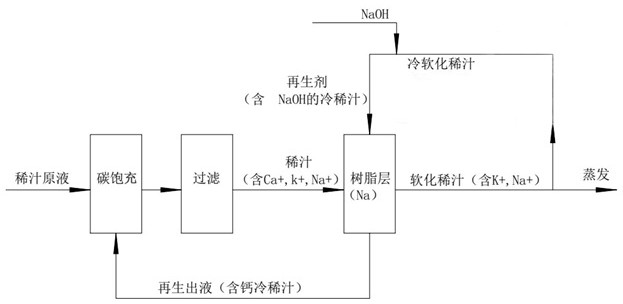

Method used

Image

Examples

Embodiment 1

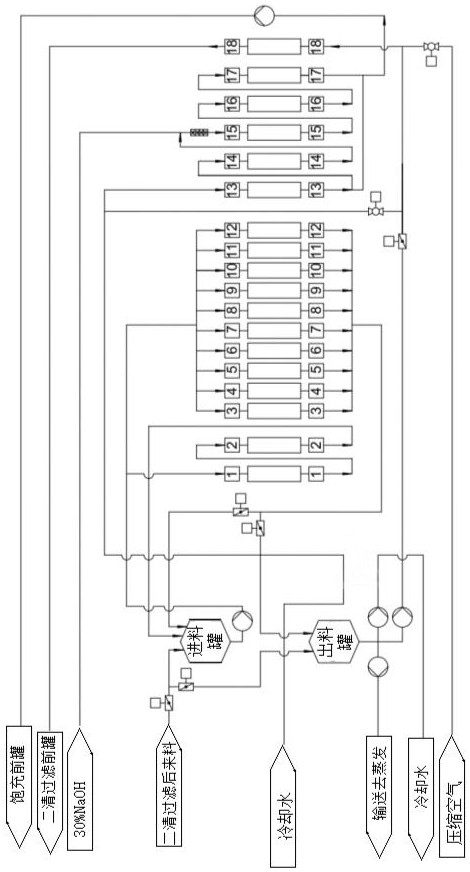

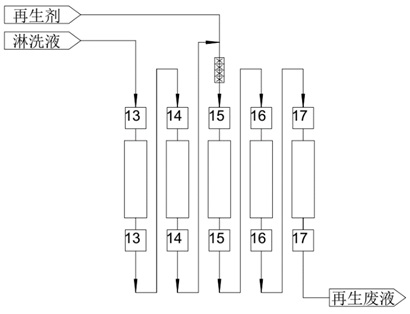

[0045] Backwashing process (16# process position): For the resin column switched out of the production process, first use 80-100 ℃ softened dilute juice for backwashing (inlet from the bottom of the column, and out from the upper part). Here, the resin is completely fluidized and washed Then use the low-temperature softening dilute juice to enter from the bottom of the column and exit from the top to cool the column, so that the temperature of the ion exchange resin is lowered to below 60 ° C, and the backwashed out material with insoluble impurities is refluxed and filtered The front tank, that is, the two-carbon retention tank, is filtered again in the clear juice filtration process. After backwashing, the resin column is switched to the regeneration process.

[0046] Regeneration process (13#—15# resin column): Use low-temperature NaOH to soften the dilute juice to regenerate the resin column, and the NaOH softened dilute juice enters the resin column, and the Na in the reg...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com