Patents

Literature

55results about How to "No environmental pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

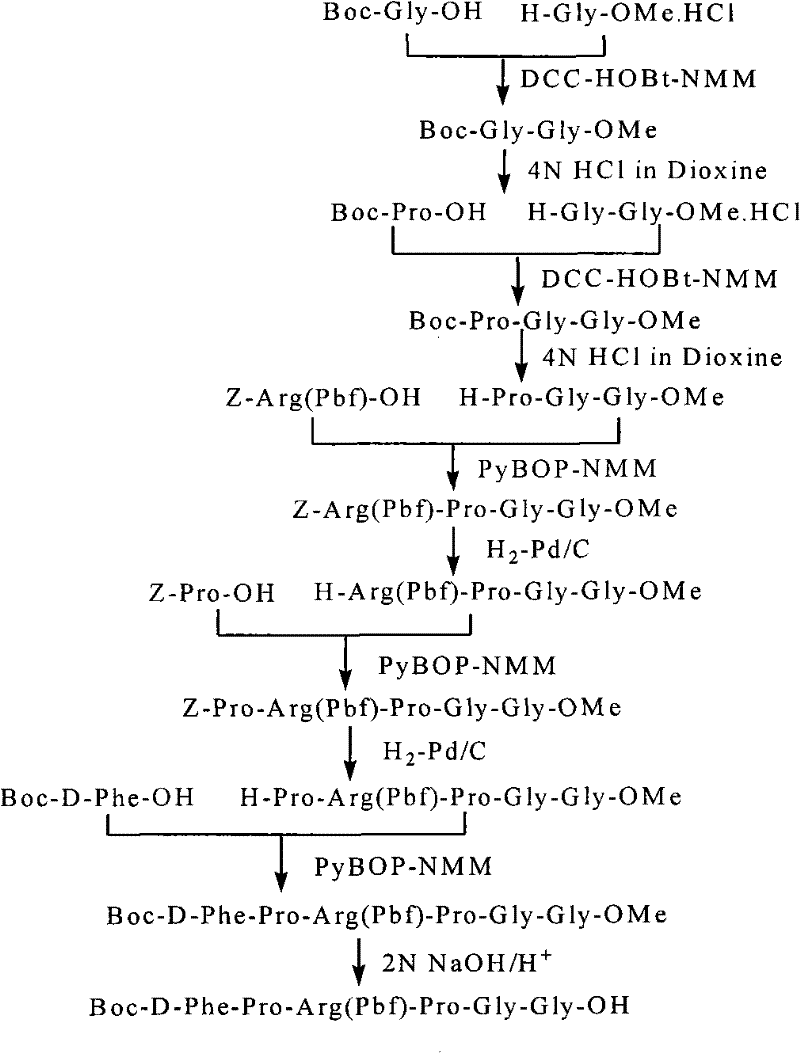

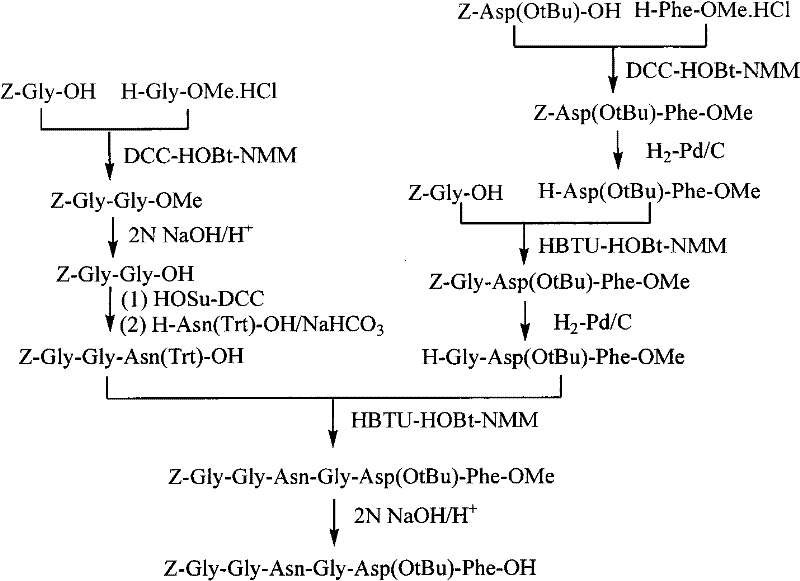

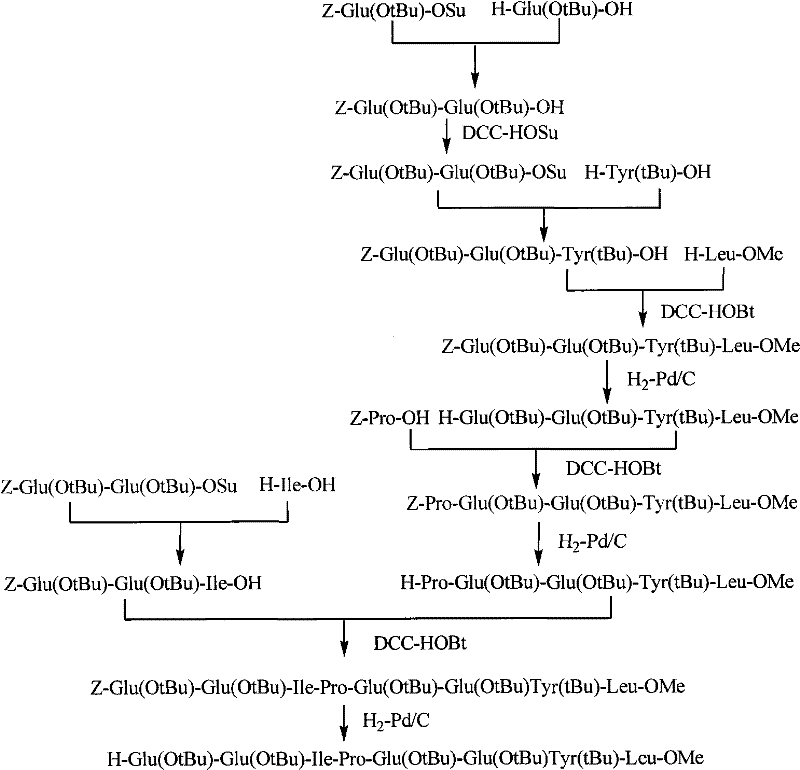

Liquid phase synthesizing method for bivalirudin

ActiveCN101475631ASimple equipmentEasy to achieve large-scale productionPeptide preparation methodsBlood disorderSynthesis methodsCombinatorial chemistry

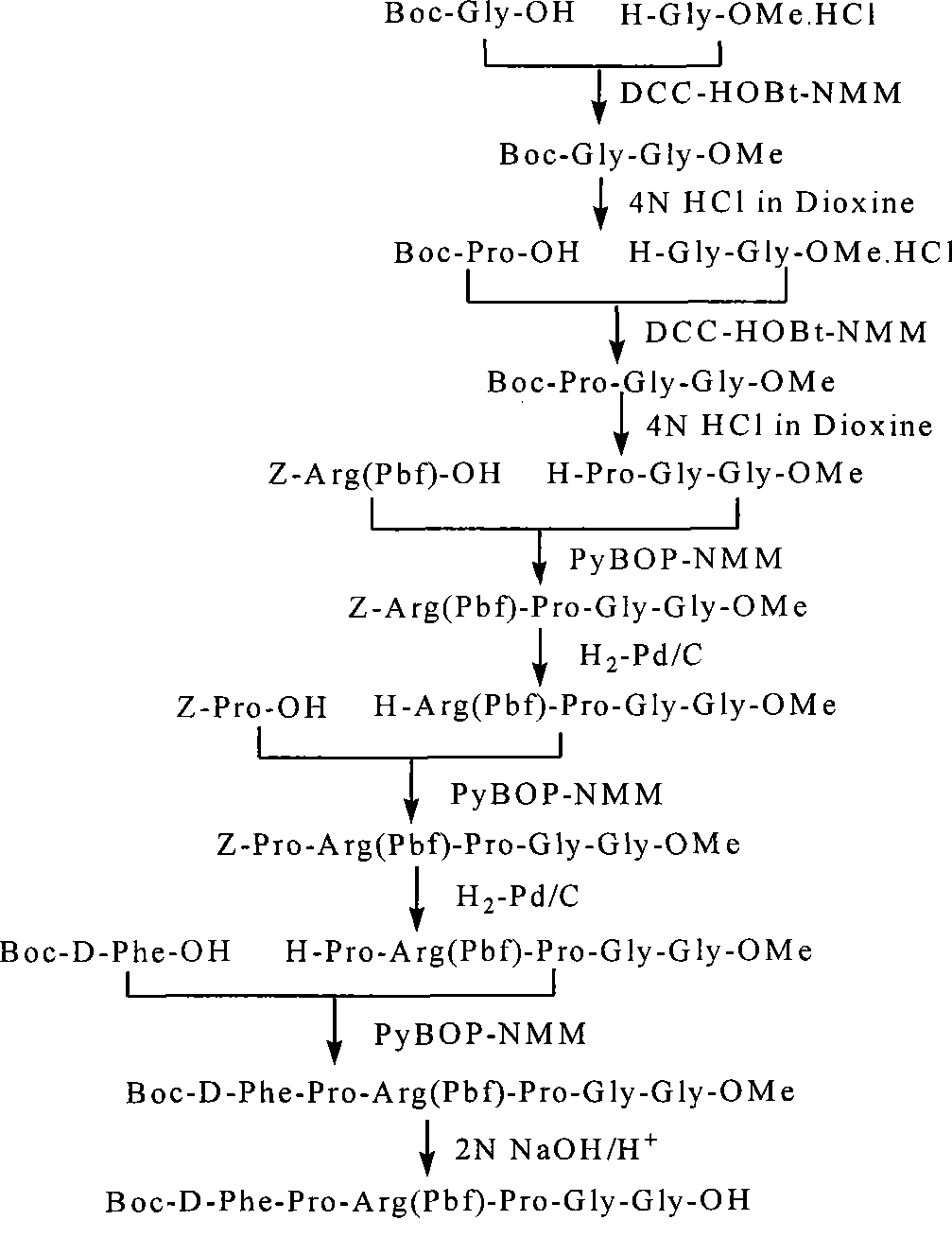

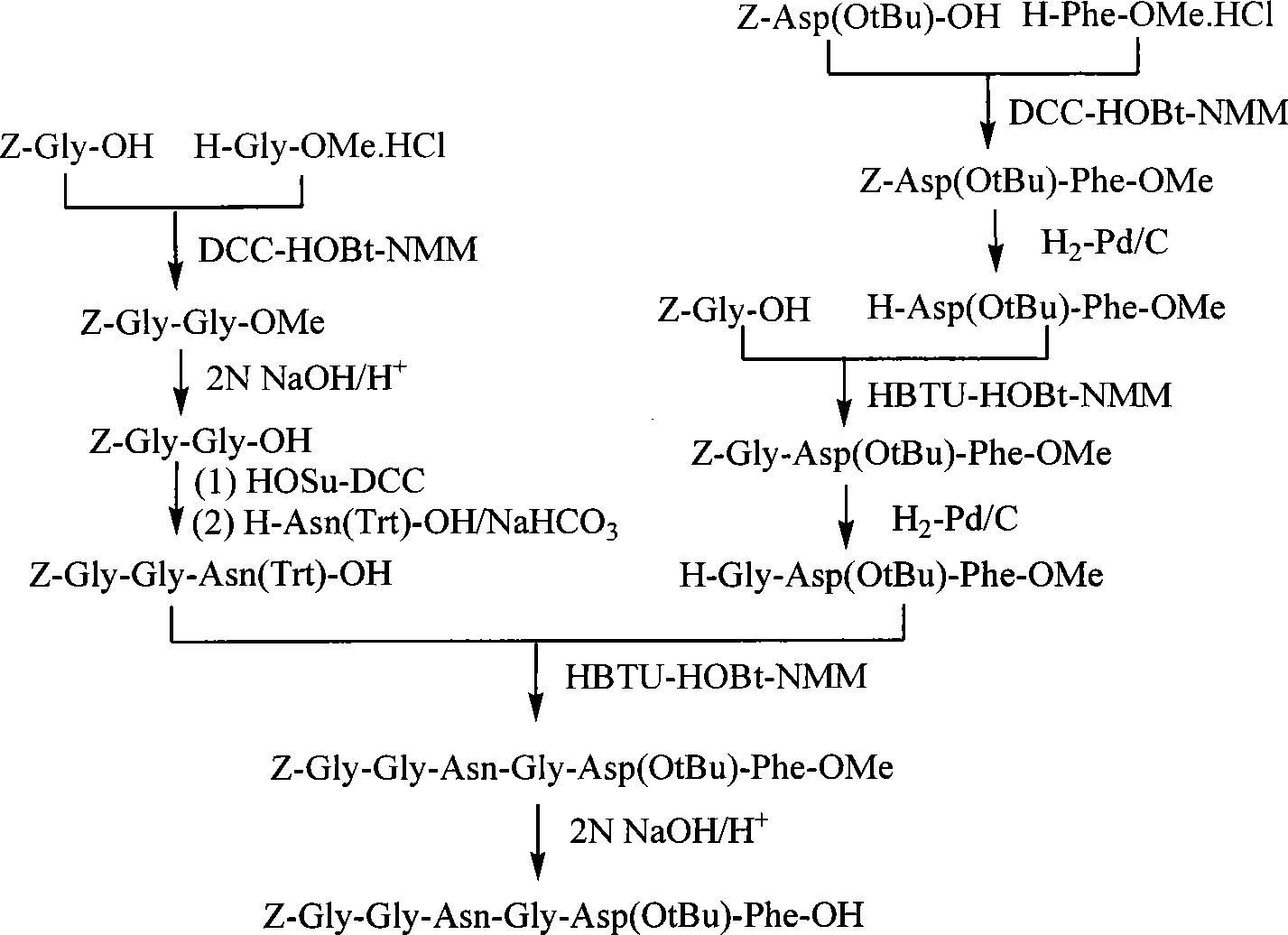

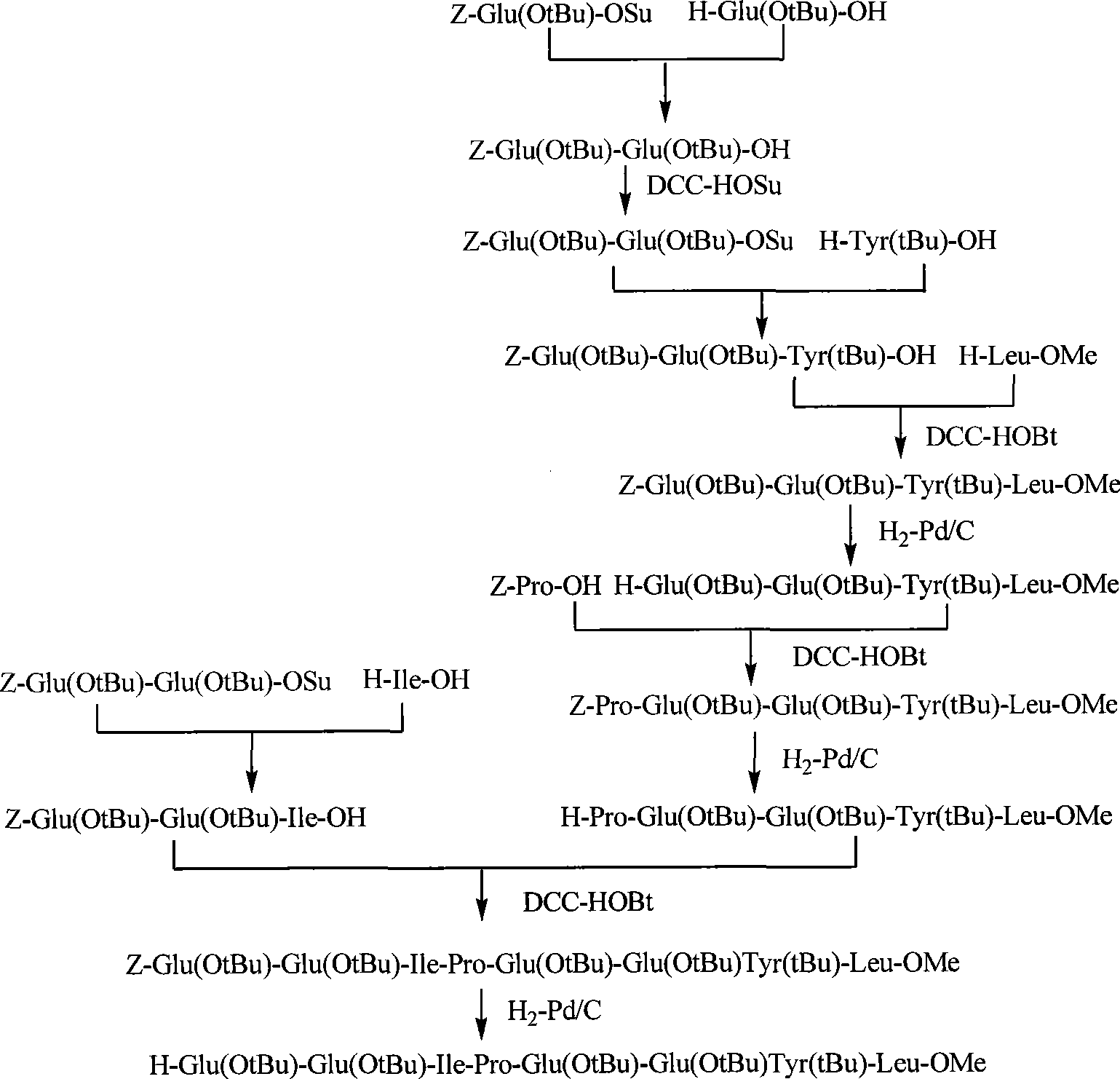

The invention provides a liquid phase synthesis method for bivalirudin. Firstly, three all-protected fragments, namely 6 peptide with an all-protected N-terminal, 6 peptide with an all-protected middle segment and 8 peptide with an all-protected C-terminal are gradually synthesized, then all-protected bivalirudin is obtained by orderly condensing the three fragments, finally all protective genes are removed to obtain a crude product of the bivalirudin, and then a pure product of the bivalirudin is obtained through high-efficiency liquid chromatography purification. The method does not need a resin, excessive protected amino acid and a condensing agent, is easy to realize mass production, and has relatively lower production cost.

Owner:苏州天马医药集团天吉生物制药有限公司

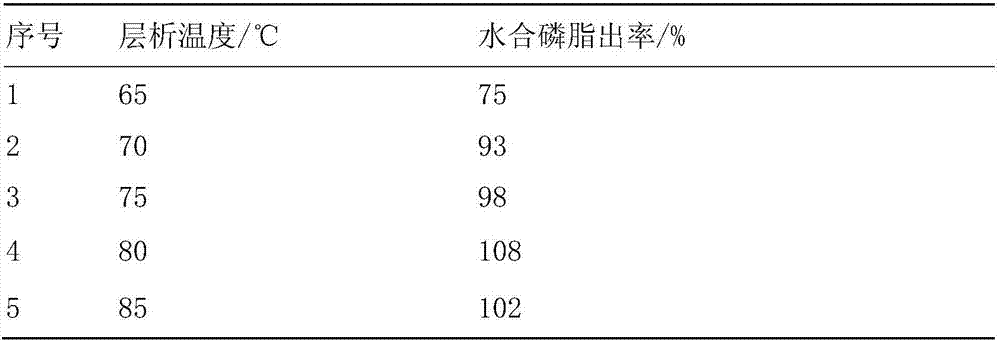

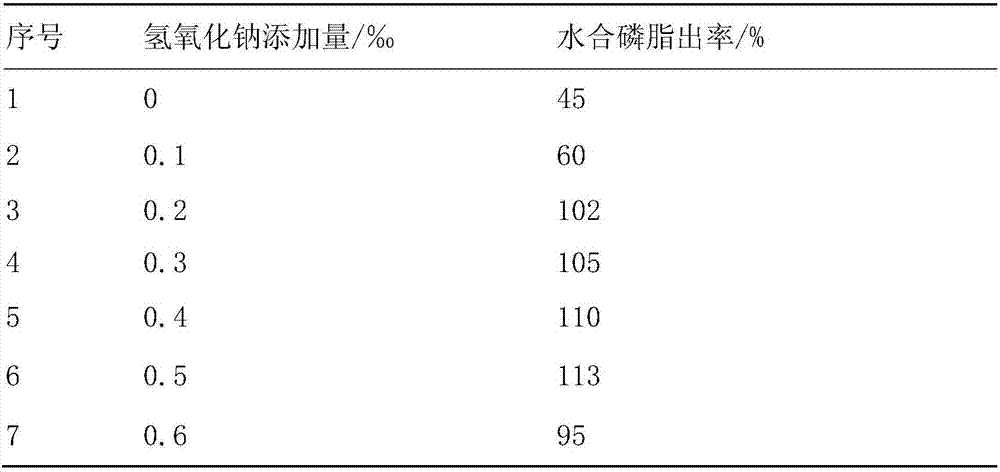

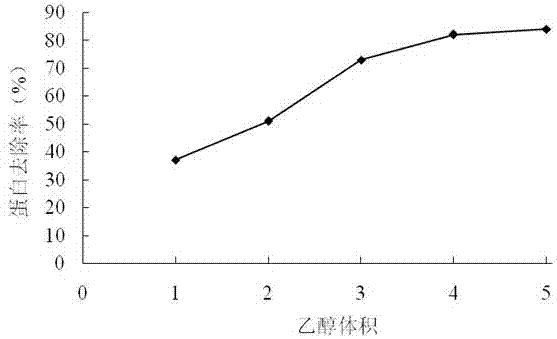

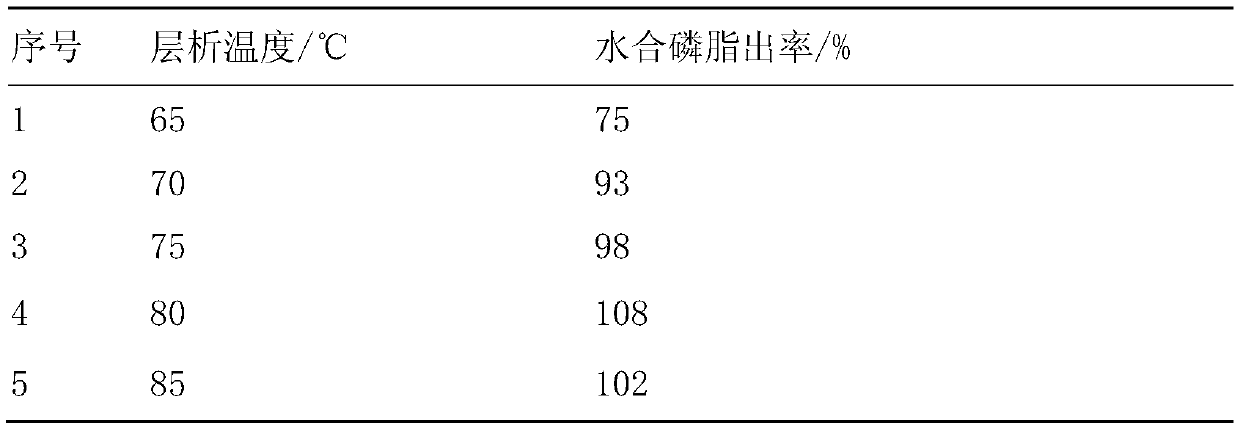

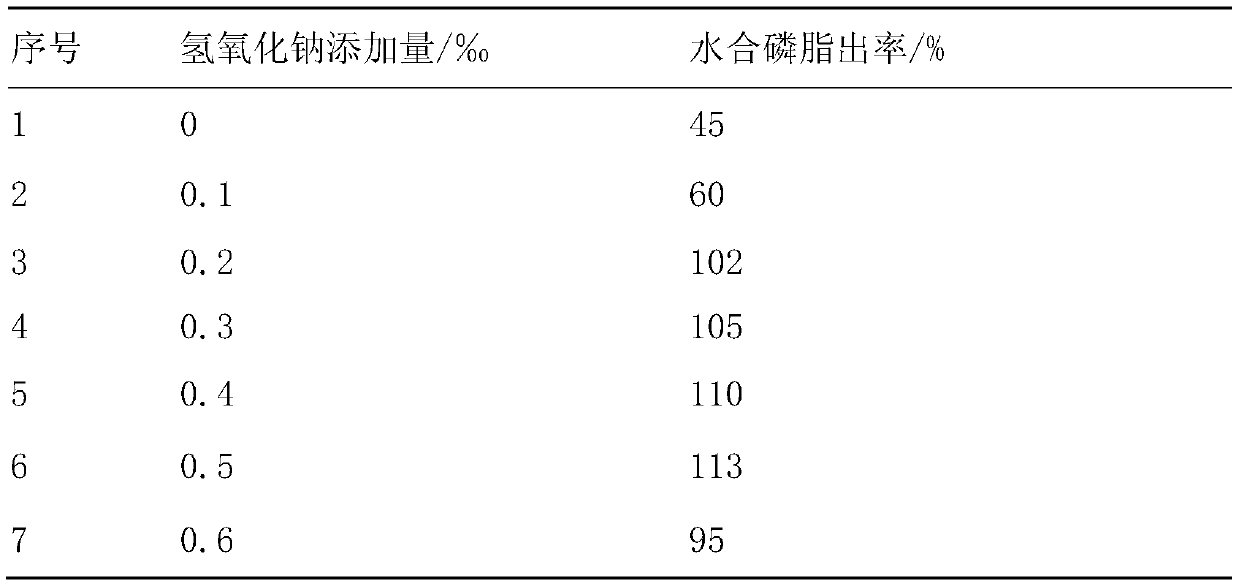

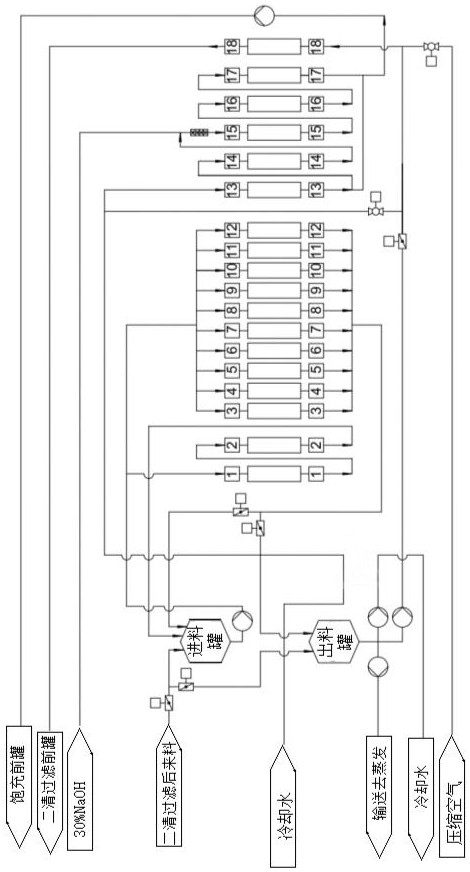

Method for preparing hydrated phospholipid from soybean oil sediment and hydrated phospholipid prepared with method

ActiveCN107325125AGood dispersionSmall degree of processingGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsOrganic solventSoftened water

The invention discloses a method for preparing hydrated phospholipid from soybean oil sediment and hydrated phospholipid prepared with the method, relates to the field of a treatment method of the soybean oil sediment and aims to solve the problems that with adoption of the conventional soybean phospholipid refining method, organic solvent consumption is high and many residues are produced and are harmful to a human body or the prepared soybean phospholipid is strong in flavor, dark in color and low in quality. According to the method, softened water is added to the soybean oil sediment, then the soybean oil sediment is left to stand for chromatography, heating is performed after chromatography for centrifugal separation, and hydrated phospholipid is obtained. Acetone insoluble substances in the prepared hydrated phospholipid can reach 90% or higher, the phospholipid content is higher, and organic matter residues are avoided.

Owner:山东中阳生物科技有限公司

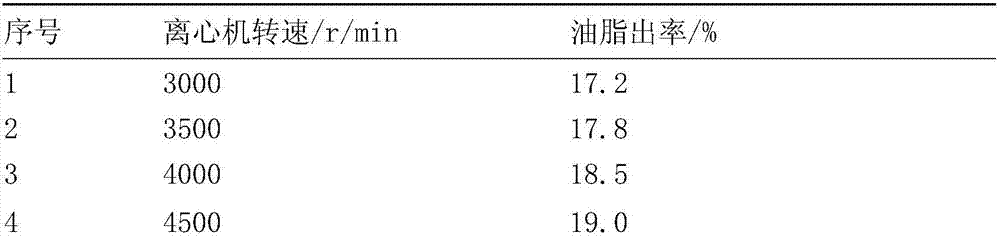

Environment-friendly molded pulp formation method and product

InactiveCN109797604ANo environmental pressureReduce dosageWater-repelling agents additionNon-woody plant/crop pulpMolded pulpShell molding

The invention discloses an environment-friendly molded pulp formation method. The method comprises the steps that raw materials are subjected to impurity removal, sterilization, soaking and boiling, and a hydrapulper is used for conducting smashing to obtain a smashed material; the treated smashed material is defibered for obtaining an even pulp; the mixed pulp is prepared; a molded pulp wet blankis made; after the wet blank is formed, before the wet blank is dried, the surface of the wet blank is sprayed with a liquid-state waterproof agent; the molded pulp wet blank is dewatered, subjectedto hot press formation and cut to a molding product. The product made through the environment-friendly molded pulp formation method is an environment-friendly degradable material, and after being wasted, the material can be directly discarded and naturally degraded into soil for planting or smashed and reduced into the soil for planting for reuse or discarding; according to the method, the application quantity of chemical products is greatly lowered, and plain boiled water can also be more clean. The surface of the product is coated with the material, no chemical product exists in the product,the production cost is reduced, and the environment-friendly performance is better.

Owner:杭州西红柿环保科技有限公司

Method for preparing PET-organic intercalated montmorillonite composite material

InactiveCN102432985AImprove barrier propertiesNo change in injection molding processCoatingsPhosphonium saltPolyethylene terephthalate glycol

The invention discloses a method for preparing a PET (Polyethylene Terephthalate)-organic intercalated montmorillonite composite material, comprising the following steps of: 1) mixing organic intercalated montmorillonite and fully dried PET according to the weight ratio of 20: 80 to 80: 20 to obtain mixed materials, and preparing the mixed materials into a PET master batch containing the organic intercalated montmorillonite, in which the organic intercalated montmorillonite is obtained by reacting a quaternary phosphonium salt or a silane coupling agent and a sodium montmorillonite intercalation; and 2) uniformly mixing the PET master batch containing the organic intercalated montmorillonite prepared in the step 1) and the PET, so that the mass percentage of the montmorillonite in the mixture is 1-10%; and moulding in an injection way by an injection moulding machine to obtain the product. By mixing the quaternary phosphonium salt or the silane coupling agent organic intercalation modified sodium montmorillonite and the PET to obtain the PET master batch containing the organic intercalated montmorillonite, and then mixing with the pure PET proportionally and moulding in the injection way to obtain the product, the method disclosed by the invention provides a new technology applied to the large-scale production, and can obtain the PET product with good water and gas barrier properties.

Owner:GUANGZHOU IMPROVE MEDICAL TECH CO LTD +1

Method for extracting hemicellulose from plant fiber

The invention aims at solving the problem of high cost of ethanol extraction of hemicellulose and provides a method for extracting the hemicellulose from plant fiber. The method is characterized by comprising the following steps of dissolving the plant fiber in an alkaline solution with the mass fraction of 5%-15%, then removing large particle impurities in the alkaline solution obtained by squeezing by adopting a conventional pre-filtration method, further enabling the alkaline solution to enter a ceramic membrane device through a pump to perform cross-flow filtration, adding an acid into an obtained concentrated solution for neutralization, collecting the precipitated hemicellulose, and drying to obtain the hemicellulose, wherein the alkaline solution after pre-filtration contains 50-100g / l of alkali and 40-60g / l of hemicellulose. The whole process basically adopts a pure physical method to extract the hemicellulose, the purity of the obtained hemicellulose is high, and the operation cost is low.

Owner:YIBIN HIEST FIBER +1

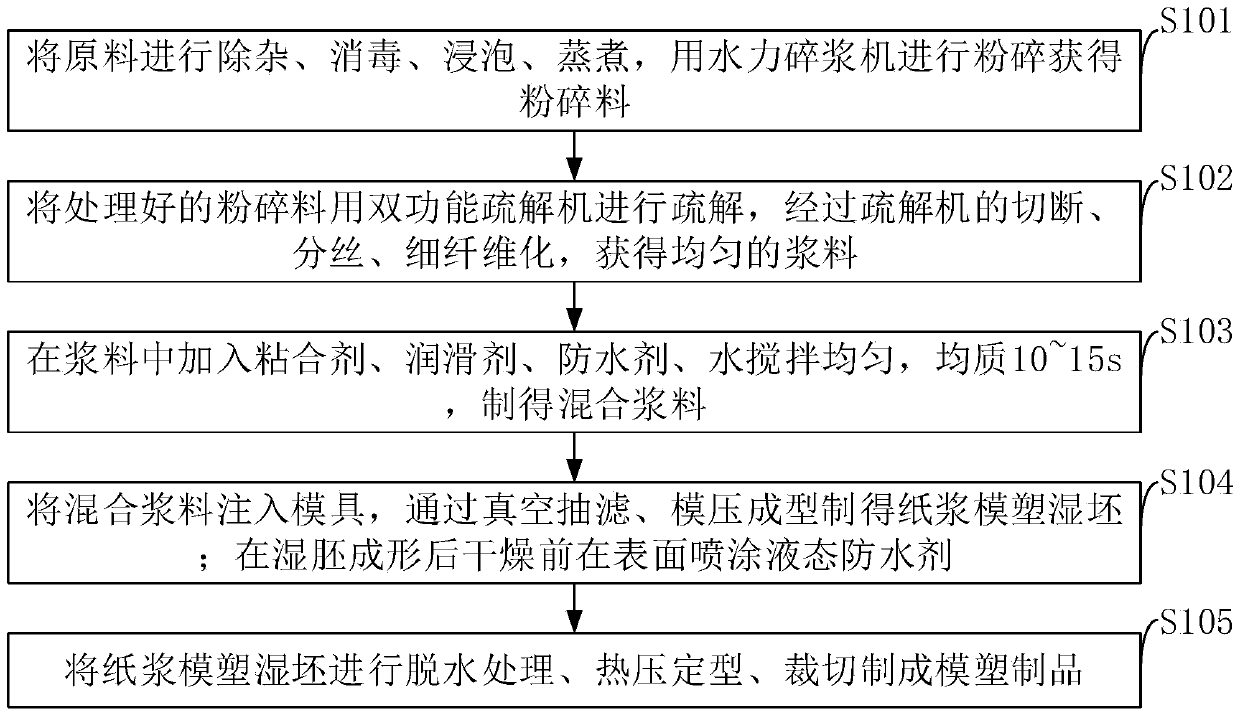

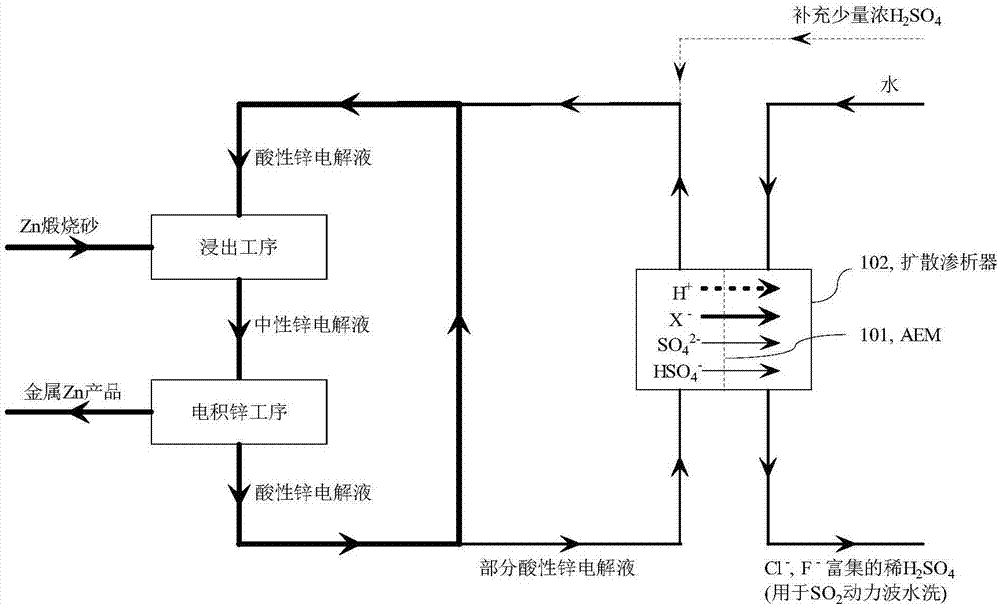

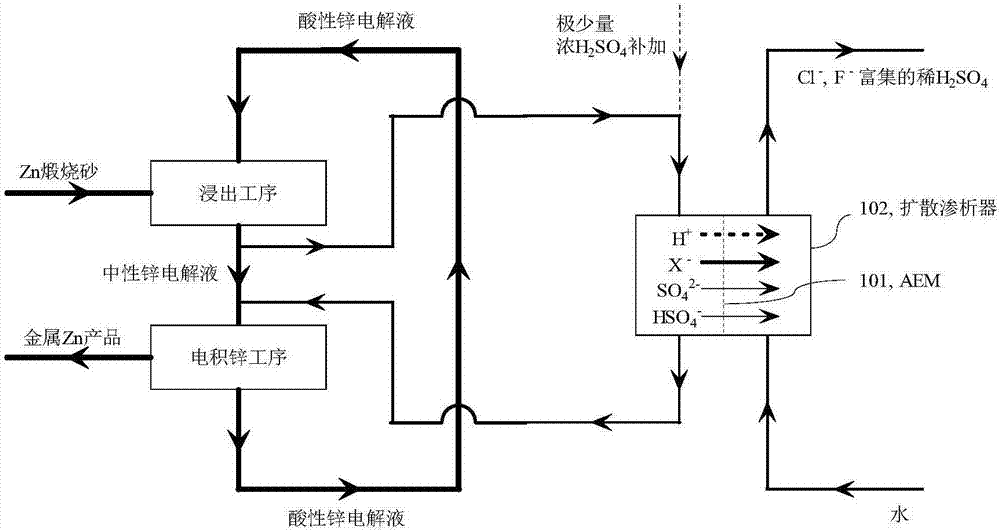

Method for selectively removing one valent anion impurities from sulfuric acid system electrolytes

ActiveCN106868544ALong processing cycleStreamlined and optimized processingPhotography auxillary processesElectrolysis componentsImpurity ionsZinc

The invention provides a method for selectively removing one valent anion impurities from sulfuric acid system electrolytes. The method is characterized in that the concentration of free H2SO4 in the electrolytes is adjusted, the electrolytes containing the free H2SO4 are led into a diffusion dialyzer waste acid chamber, water serves as receptor fluid to be led into a diffusion dialyzer recycling chamber in a reverse flow manner, the flow strength of the electrolytes in the diffusion dialyzing operation process is controlled, under drive of the concentration difference of partial free H2SO4 and the anion impurities in the electrolytes in a diffusion dialyzer, a transmission film is transmitted to the receptor fluid, and thin-H2SO4 purified electrolytes rich in anion impurities are formed. The new use manner of diffusion dialyzing is expanded, free acid recycling is changed into selective removing of the impurity ions, two existing problems of fluorine chlorine impurity removal and waste liquid disposal in the zinc electrolytes can be solved at the same time, and the new solution is provided for resource recycling of the wet metallurgy industry.

Owner:WENZHOU UNIVERSITY +1

Method for deeply purifying sodium stannate liquor

InactiveCN102674437AHigh chemical activityAvoid disadvantages such as difficulty in returning to useTin compoundsDistilled waterWater immersion

The invention discloses a method for deeply purifying sodium stannate liquor. The method includes realizing ball-milling and activation for a refining agent, then proportionally mixing materials containing tin, NaOH, NaNO3 and the activated refining agent, adding and uniformly mixing distilled water or sodium stannate crystallization mother liquor with the mixture, and curing materials uniformly mixed; adding and uniformly stirring distilled water with the materials after the materials are cured; heating the material to a certain temperature and enabling the materials to react sufficiently; and adding the reacted materials into distilled water to carry out water immersion reaction; separating liquid from solid to obtain liquor after the water immersion reaction is completed, and evaporating, concentrating and crystallizing the obtained liquor to obtain a high-purity sodium stannate product. The crystallization mother liquor can be recycled for mixed materials after the high-purity sodium stannate product is obtained. The content of sodium stannate in the sodium stannate product is higher than 99.995%, and contents of impurity elements such as As, Sb and Pb are lower than 10ppm. The method for preparing the high-purity sodium stannate product has the advantages that raw material sources are wide, cost is low, tin recovery rate is high, the quality of the product is good, and the like.

Owner:CENT SOUTH UNIV +1

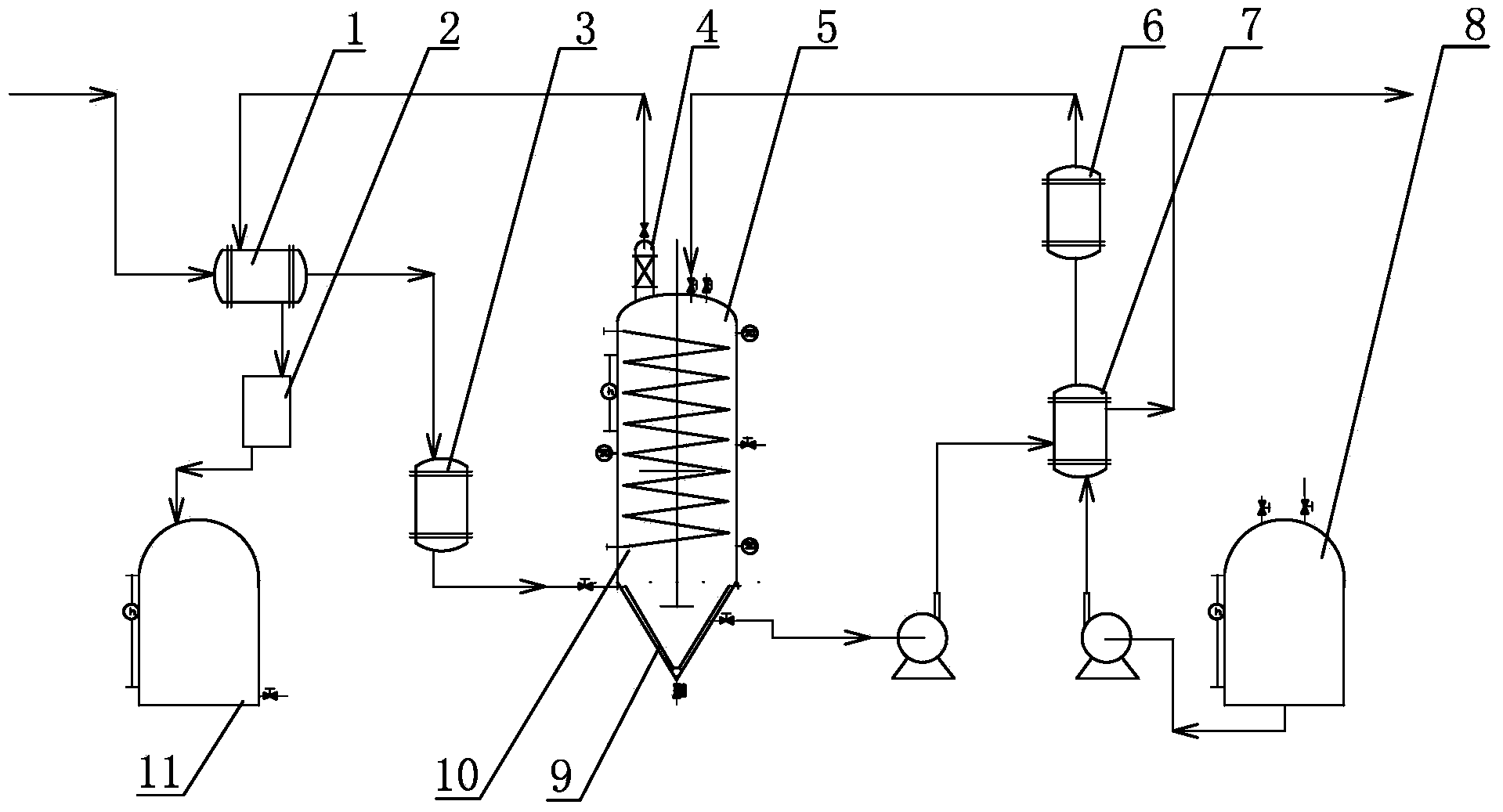

Esterification method for preparing biodiesel using waste oils and fats

ActiveCN103451027AWide range of acid values of raw materialsEquipment material requirements are lowFatty acid esterificationBiofuelsChemistryWaste oil

Provided is an esterification method for preparing biodiesel using waste oils and fats. Under the normal pressure condition, the mixture of methanesulfonic acid, ethanesulfonic acid or chlorosulfonic acid and erosion restraint agents is used as a catalyst, the using amount of the catalyst is little, the catalyst can be repeatedly used, erosion on equipment is small, through a demister arranged on the top of a reaction kettle, the utilization rate of raw oil and the yield coefficient of coarse methyl ester are improved, heat generated in the reaction process is used for preheating fine methyl alcohol and waste oils and fats, heat is circularly used, energy loss is reduced, methyl alcohol which is not reacted is recovered, and production cost is lowered. The acid value of raw materials of the esterification method is wide (15-180mgKOH / g), the reaction time is short, energy loss is little, production cost is low, the yield coefficient of coarse methyl ester is high, high-acid-value flora and fauna waste oils and fats are esterified in one time to be lower than 1mgKOH / g in acid value, the next transesterification can be directly carried out to prepare biodiesel, and the method is suitable for producing biodiesel in an industrial mode.

Owner:四川惠盛新能源有限公司

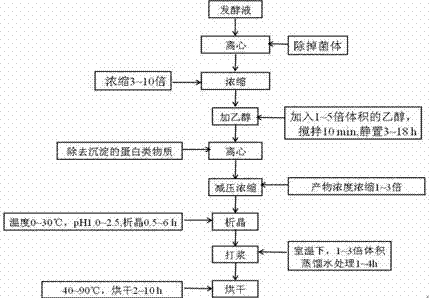

Preparation method of 5-methylpyrazine-2-carboxylic acid

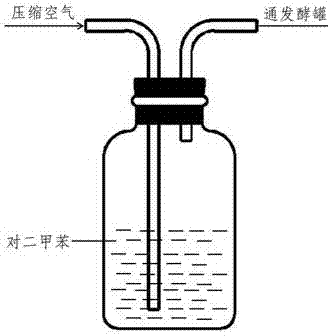

InactiveCN107541532AReduce manufacturing costReaction conditions are easy to controlMicroorganism based processesFermentationChemical synthesisXylene monooxygenase activity

The invention belongs to the technical field of bioengineering, in particular to a method for preparing and purifying 5-methylpyrazine-2-carboxylic acid by microbial fermentation. The technical scheme of the present invention uses 2,5-dimethylpyrazine as a raw material, uses Arthrobacter woluwensis HW-1 strain with xylene monooxygenase activity as a catalyst, and uses compressed air to bring in xylene vapor as a catalyst. inducer, and add raw materials in batches in due time, and ferment and transform for a period of time to obtain a fermentation broth containing 5-methylpyrazine-2-carboxylic acid. The invention makes up for the deficiencies in the process of chemically synthesizing 5-methylpyrazine-2-carboxylic acid, overcomes the defect of low conversion rate of shake flask fermentation, and provides a method for purifying 5-methylpyrazine-2-carboxylic acid in fermentation broth for the first time method.

Owner:DISHA PHARMA GRP +1

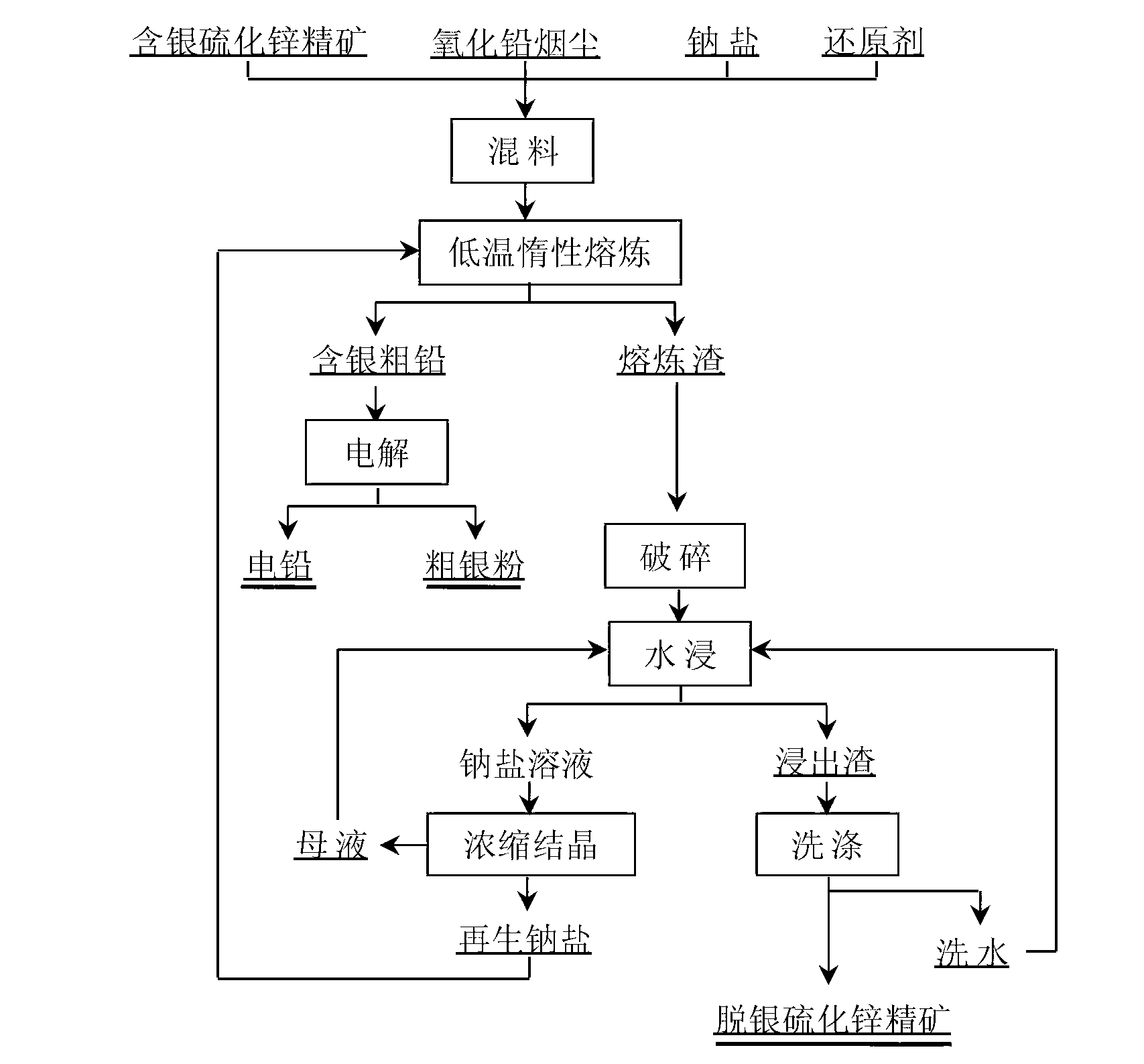

Method for extracting silver from silver-containing zinc concentrate and improving quality of zinc concentrate

ActiveCN103266226ARealize de-silveringImprove qualityPhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a method for extracting silver from a silver-containing zinc sulfide concentrate and improving quality of the zinc sulfide concentrate. The method comprises the following steps: mixing the silver-containing zinc sulfide concentrate with a proper amount of lead oxide flue dust, a sodium salt and a reducing agent and carrying out heating and a complete reaction, wherein silver-containing crude lead and smelt slag are obtained after completion of the reaction; subjecting the silver-containing crude lead to electrolysis to obtain electric lead and silver powder; subjecting the smelt slag to water leaching; and carrying out liquid-solid separation after water leaching and subjecting a filtrate to evaporative concentration and crystallization so as to obtain the sodium salt which can be returned and reused as a flux, wherein leaching slag is a desilverized zinc sulfide concentrate with higher quality. With the method provided by the invention, high efficiency desilverization, dearsenification, cadmium removal and fluorine and chlorine removal of the silver-containing zinc concentrate can be realized, the electric lead, the silver powder and the high-grade zinc sulfide concentrate product are produced, and the sodium salt used as the flux in the reaction is not consumed and can be regenerated through evaporative concentration and crystallization after the reaction, thereby realizing cyclic usage of the flux. The method has the advantages of short flow, good environment-friendliness, high economic benefits and the like and is suitable for industrial popularization and application.

Owner:德兴市益丰再生有色金属有限责任公司

Method for separating sodium chloride and sodium bromide by organic solvent

InactiveCN109437245ANothing producedSeparation equipment is simpleAlkali metal bromidesAlkali metal chloridesOrganic solventHalogen

The invention belongs to the technical field of halogen element salt separation, and particularly relates to a method for separating sodium chloride and sodium bromide by an organic solvent. The organic solvent is added into dry sodium chloride and sodium bromide mixed salt; stirring dissolution is performed at normal temperature; filtering is performed; undissolved salt is filtered out; filteringliquid is heated to be evaporated; methanol is evaporated out; the temperature is lowered for crystallization; filtering is performed; crystallized salt is filtered out; the content of sodium bromidein the salt reaches 90 weight percent or higher; the filtering liquid is continuously heated and evaporated; the rest methanol is evaporated out; the temperature is lowered for filtering; a finishedproduct sodium bromide salt is obtained; all evaporation recovered methanol is used again for next batch of dissolving salt. The method for separating sodium chloride and sodium bromide by the organicsolvent has the advantages that the separation equipment is simple; the operation cost is low; the process is reasonable; the realization is easy; the recovery rate is high; no waste water is generated; no environment pollution exists; the industrialization can be easily realized.

Owner:山东金城晖瑞环保科技有限公司

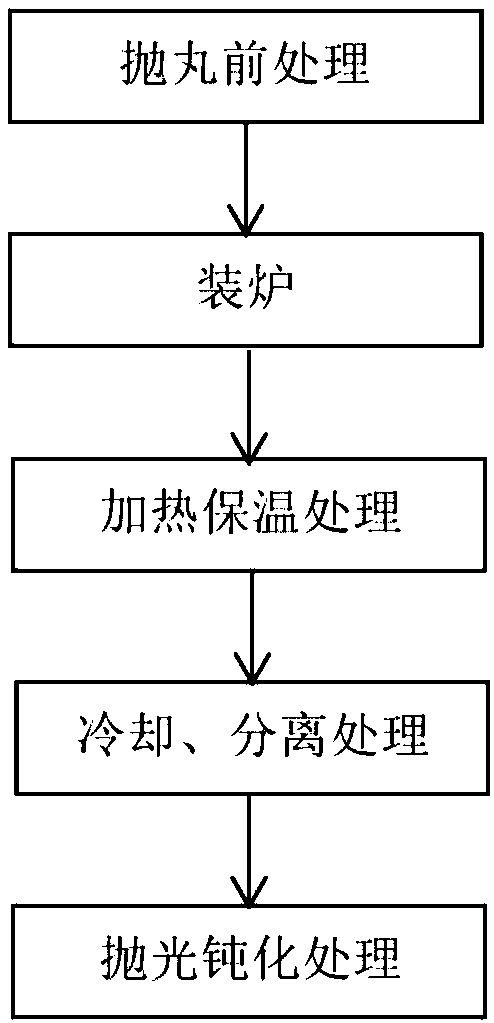

Alloy atomic infiltration surface treatment method for elastic rail clip

InactiveCN109576639AImprove corrosion resistanceFatigue has no effectSolid state diffusion coatingAlloyHigh intensity

The invention provides an alloy atomic infiltration surface treatment method for an elastic rail clip. The method comprises the following steps that a zinc-iron alloy atomic infiltration coating withthe thickness of 30-80 microns is prepared on the surface of the elastic rail clip by adopting an alloy atomic infiltration method, surface polishing and post passivation treatment are conducted on the zinc-iron alloy atomic infiltration coating, wherein the zinc-iron alloy atomic infiltration coating uses an innovatively prepared zinc-saturated compound which mainly comprises zinc powder and zincoxide zinc powder, the compound and an elastic rail clip workpiece are loaded into a heating roller with the temperature of 350-410 DEG C, and metal atom diffusion permeation is used to form the zinc-iron alloy atomic infiltration coating. According to the method, aimed at the high-strength fastener elastic rail clip, the surface of the elastic rail clip is treated through innovative introductionof an alloy atomic infiltration technology, so that the processed elastic rail clip has excellent corrosion resistance and scratch resistance, the service life of the elastic rail clip under complexand severe working conditions of various environments is prolonged, and the railway operation safety is guaranteed.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

Method for extracting copper from bound-type oxidized copper ore by wet process

The invention discloses a method for extracting copper from bound-type oxidized copper ore by a wet process. The method comprises the steps of (1) crushing the bound-type oxidized copper ore and grinding to obtain ore powder; (2) pretreating the ore powder by alkali liquid to obtain pretreated liquid and pretreated residue; (3) carrying out acid leaching treatment on the pretreated residue, and filtering to obtain copper-containing acid leachate; and (4) extracting copper from the copper-containing acid leachate to obtain copper sponge. According to the method, the ore powder of the bound-type oxidized copper ore is pretreated by the alkali liquid, the leaching of copper from the bound-type oxidized copper ore is achieved by the acid leaching treatment process, and a copper sponge product is obtained by further recovery. The method has obvious extracting effect on copper in the bound-type oxidized copper ore with a copper bound-type phase accounting for 40% or above, and the copper extraction rate can reach 80-93.5%.

Owner:西安西北有色地质研究院有限公司 +1

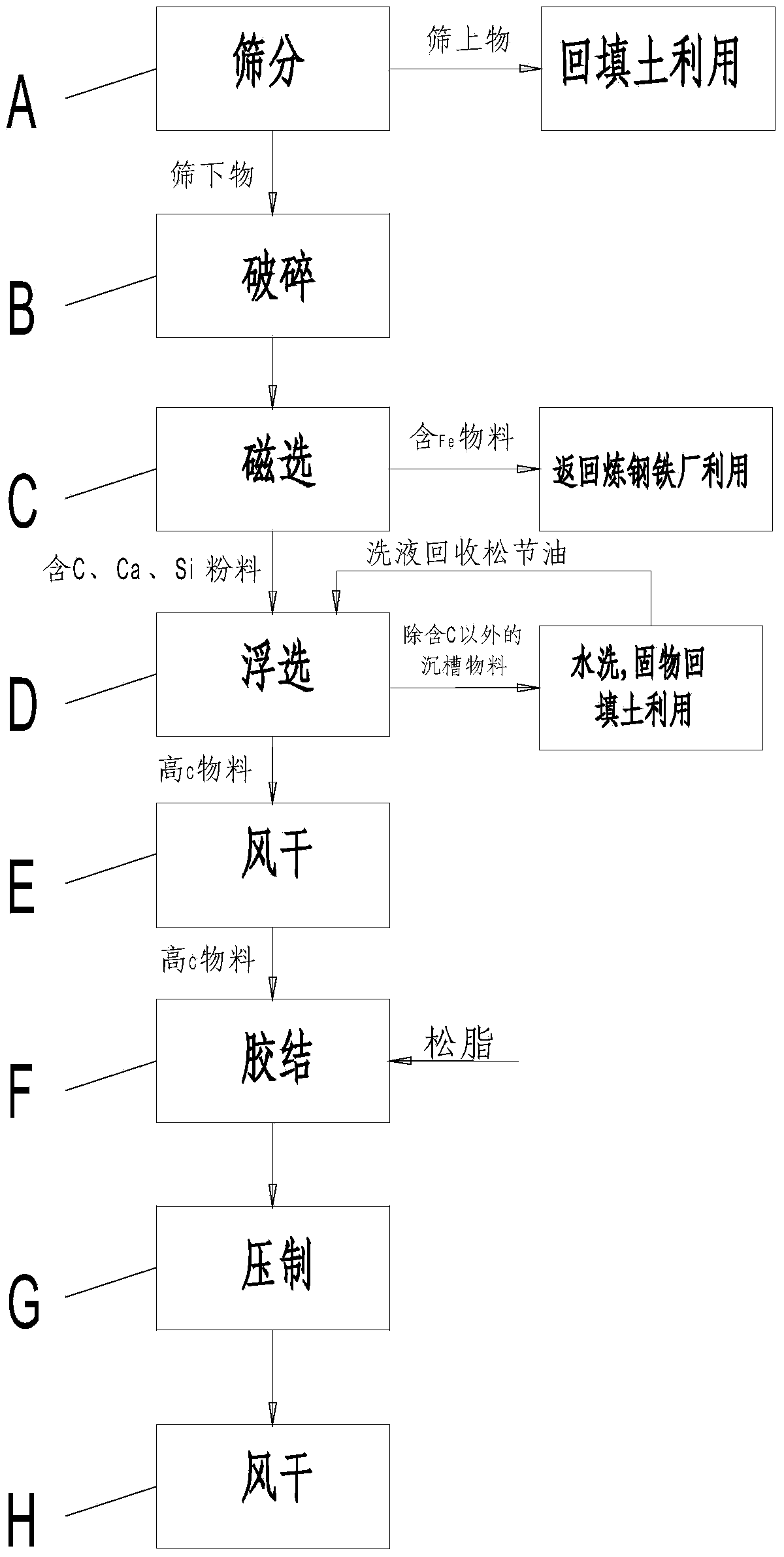

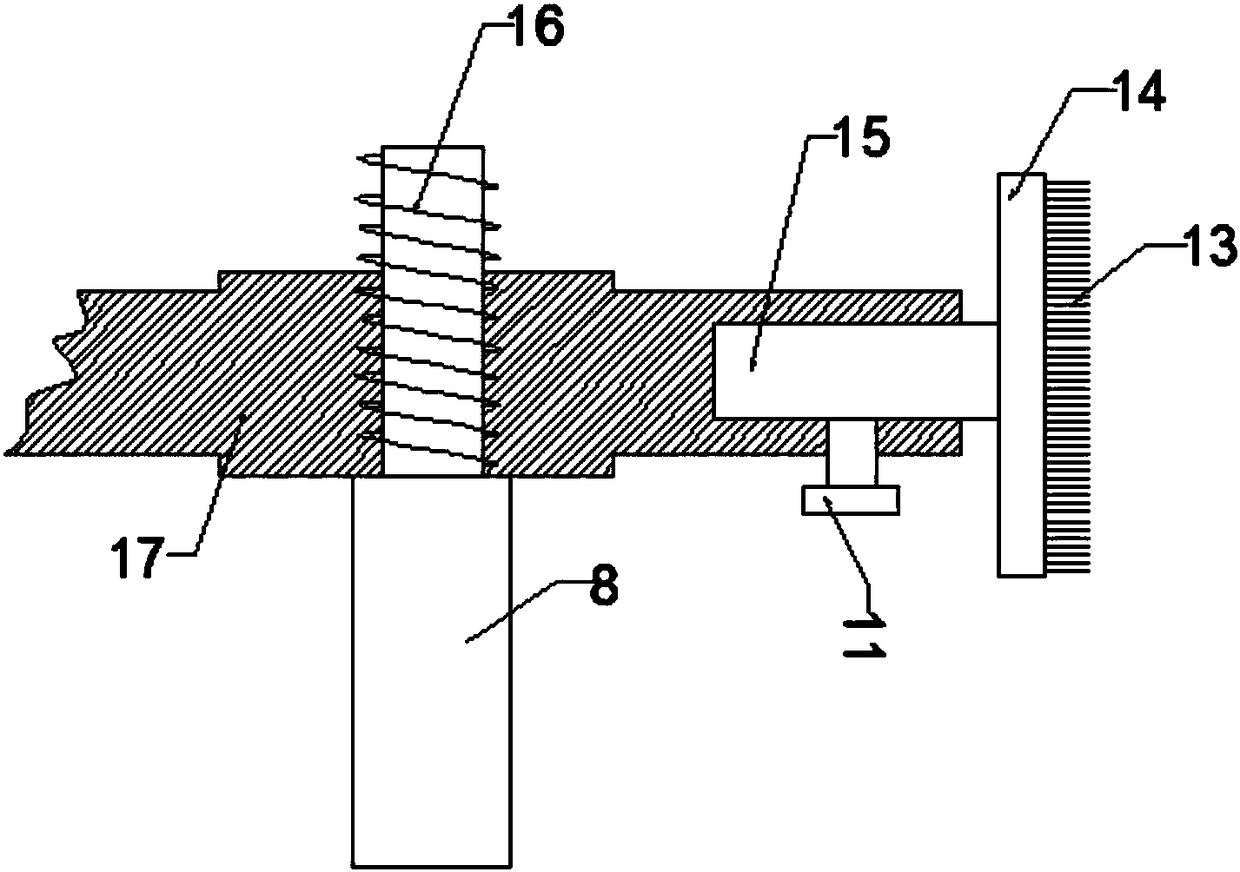

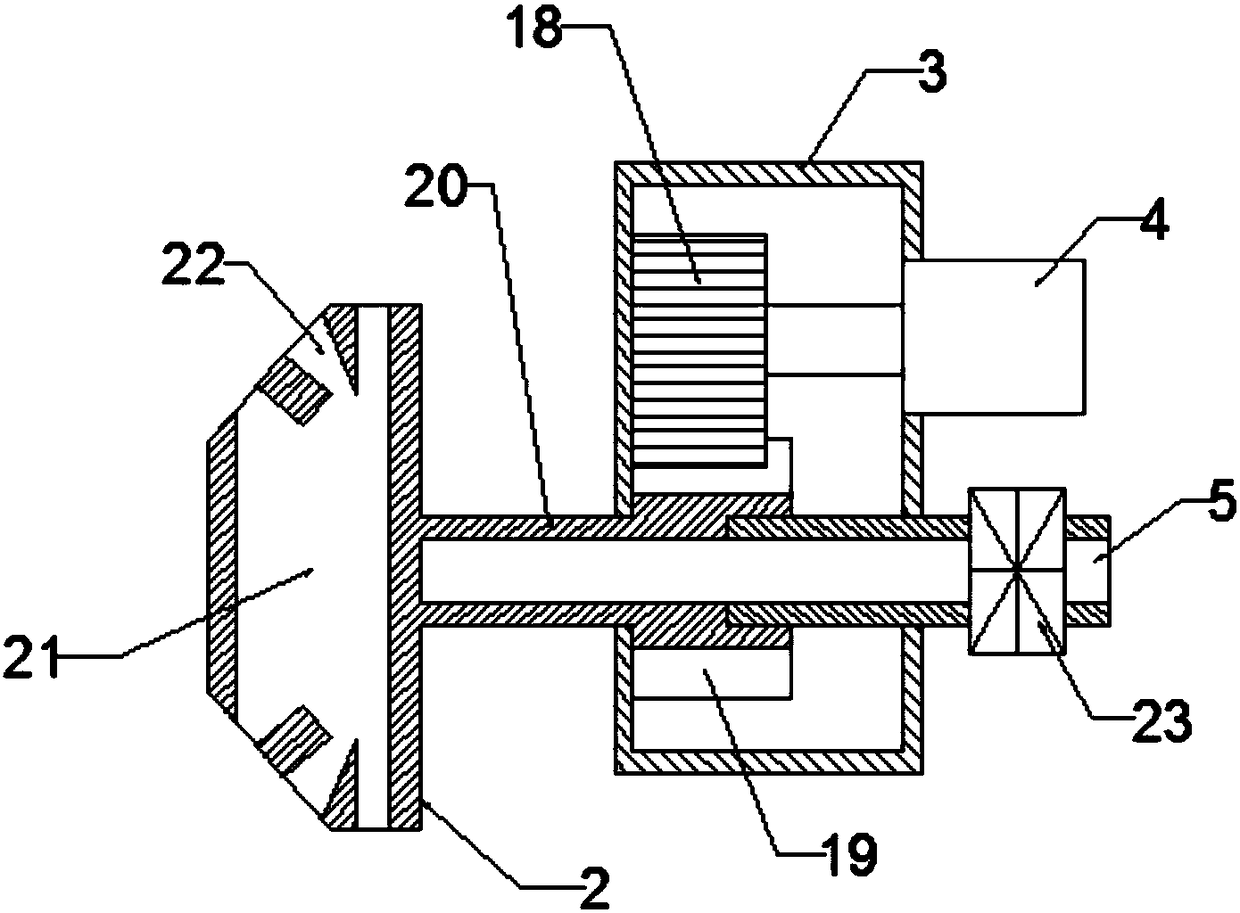

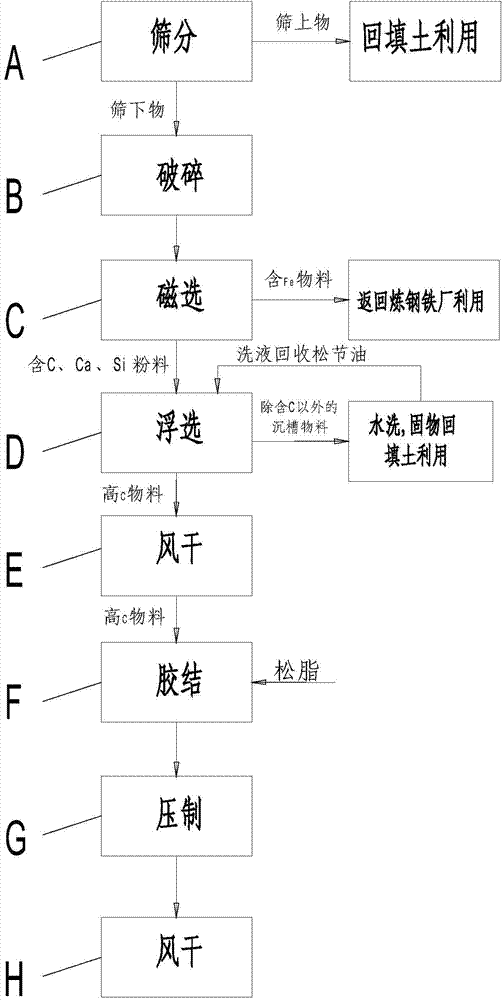

Method for efficiently recovering dust sludge containing C and Fe in iron and steel industry

InactiveCN103436644AEfficient recyclingImprove yieldSolid fuelsRecycling and recovery technologiesRecovery methodSludge

The invention provides a method for efficiently recovering dust sludge containing C and Fe in the iron and steel industry and relates to a dust sludge recovering method in the iron and steel industry. According to the method, the dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel industry is screened, crushed, magnetically separated and then selected in a flotation manner to get a high-C-content material, the high-C-content material is added with rosin for lipidation and cementation after being air-dried, then is compressed into the ball or rod shape, and is air-dried to get lipidation coke used as a reducer and fuel in the smelting industry. The method can efficiently recover C and Fe, the yield of the C-containing material is high, the burning is more thorough and sufficient, the heat efficiency is higher, and the method facilitates popularization and application.

Owner:LIUZHOU XIANMING SCI & TECH

Method for enriching carbon disulfide and hydrogen sulfide in viscose fiber waste gas

ActiveCN106693647AImprove protectionNo environmental pressureDispersed particle separationCelluloseHigh concentration

The invention discloses a method for enriching carbon disulfide and hydrogen sulfide in viscose fiber waste gas. The method comprises a step A of collecting the viscose fiber waste gas, and using absorption liquid composed of alkali liquor and alkali cellulose; a step B of adding acid wastewater into solution after spraying reaction, and performing degassing after reaction; a step C of cooling and dewatering the degassed waste gas, and obtaining waste gas with the carbon disulfide concentration content larger than or equal to 25%, the hydrogen sulfide concentration content larger than or equal to 23% and the moisture content equal to or smaller than 0.5%. Through matched processing of absorption liquid spraying and acid-containing wastewater, carbon disulfide and hydrogen sulfide in viscose production waste gas are enriched; by applying the obtained high-concentration waste gas to a follow-up separation method, the recycling rate of carbon disulfide can be improved, the treatment of the viscose fiber waste gas is facilitated, and environmental protection pressure is reduced.

Owner:四川雅丽兴科技有限公司

Liquid phase synthesizing method for bivalirudin

ActiveCN101475631BSimple equipmentEasy to achieve large-scale productionPeptide preparation methodsBlood disorderSynthesis methodsCombinatorial chemistry

The invention provides a liquid phase synthesis method for bivalirudin. Firstly, three all-protected fragments, namely 6 peptide with an all-protected N-terminal, 6 peptide with an all-protected middle segment and 8 peptide with an all-protected C-terminal are gradually synthesized, then all-protected bivalirudin is obtained by orderly condensing the three fragments, finally all protective genes are removed to obtain a crude product of the bivalirudin, and then a pure product of the bivalirudin is obtained through high-efficiency liquid chromatography purification. The method does not need a resin, excessive protected amino acid and a condensing agent, is easy to realize mass production, and has relatively lower production cost.

Owner:苏州天马医药集团天吉生物制药有限公司

Preparation method of cobalt metal particles and cobalt oxide composite graphite nanosheet powder

ActiveCN110835123AGood absorbing characteristicsThe preparation process is simpleOther chemical processesGraphiteCobalt metalPhysical chemistry

The invention relates to the technical field of preparation of graphite nanosheet composite magnetic particles, and concretely relates to a preparation method of a magnetic composite cobalt metal particle and cobalt oxide composite graphite nanosheet powder being particularly suitable for being used as a wave-absorbing material and having the sheet-core-shell microstructure of a cobalt oxide-cobalt-graphite nanosheet. Cobalt metal particle compounded graphite nanosheet composite powder is uniformly dispersed in an aqueous solution containing an oxidizing agent, stirring is performed for dispersion to ensure sufficient contact between the composite powder and the oxidizing solution in order to generate an oxidation coating layer on the surface of metallic cobalt, so the graphite nanosheet composite cobalt and cobalt oxide composite powder is obtained. The structure of the magnetic composite cobalt metal particle and cobalt oxide composite graphite nanosheet powder has the sheet-core-shell morphology, and the preparation method has the significant advantages of simple process, easiness in operation, no environmental protection pressure, and realization of large-scale mass production.

Owner:HARBIN INST OF TECH AT WEIHAI +1

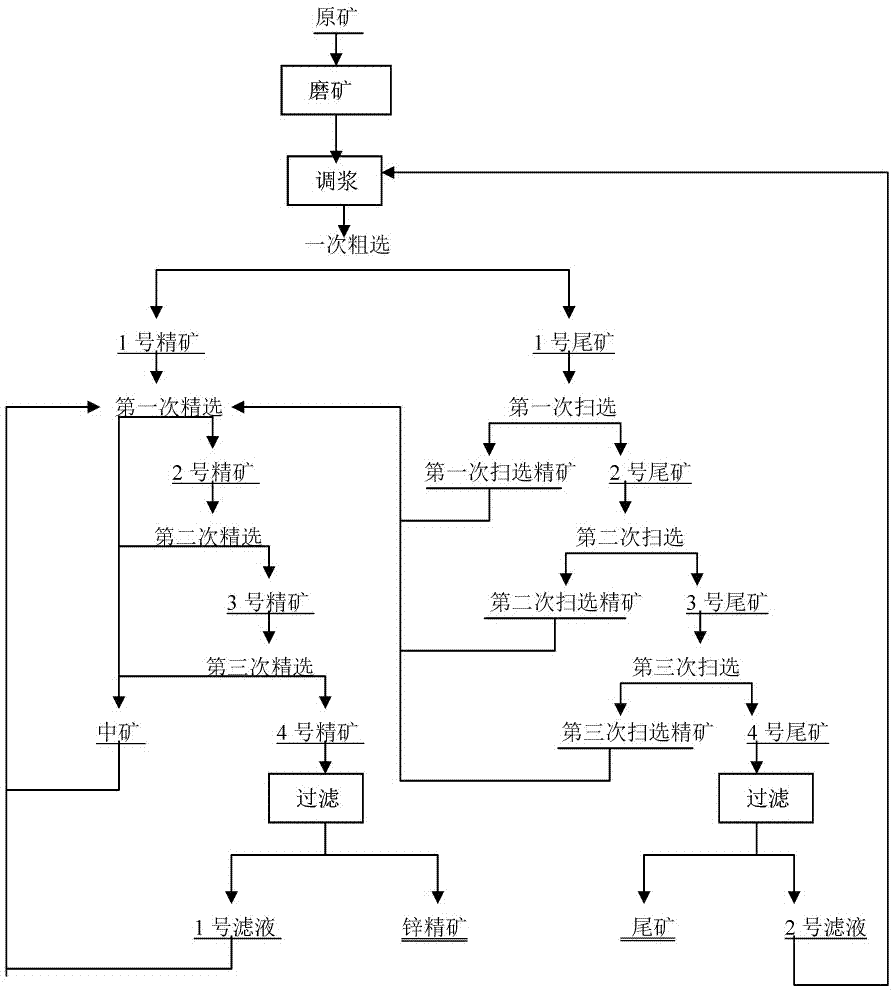

A method for inhibiting calcium and magnesium in mineral processing

The invention discloses a method for inhibiting calcium and magnesium in a mineral separation process. According to the method, zinc in zinc ores is separated by flotation in a form of zinc concentrate with a flotation process for 'roughing, scavenging and concentrating'; the method is characterized in that a combined reagent for inhibiting calcium and magnesium is added during concentration; the combined reagent is added as a calcium and magnesium inhibitor in the mineral separation process, the zinc concentrate containing relatively little calcium and magnesium is produced, inhibited calcium and magnesium are discharged along with tailings, and new slag or sewage is not generated; and the calcium and magnesium content of the zinc concentrate is greatly reduced, so that the difficult problem of calcium-magnesium open circuit in wet zinc hydrometallurgy production is solved, the zinc, germanium and sulfur grades and yields of the zinc concentrate can be all increased, and the transport cost of the zinc concentrate is reduced while the production value is increased.

Owner:YUNNAN LUOPING ZINC & ELECTRICITY

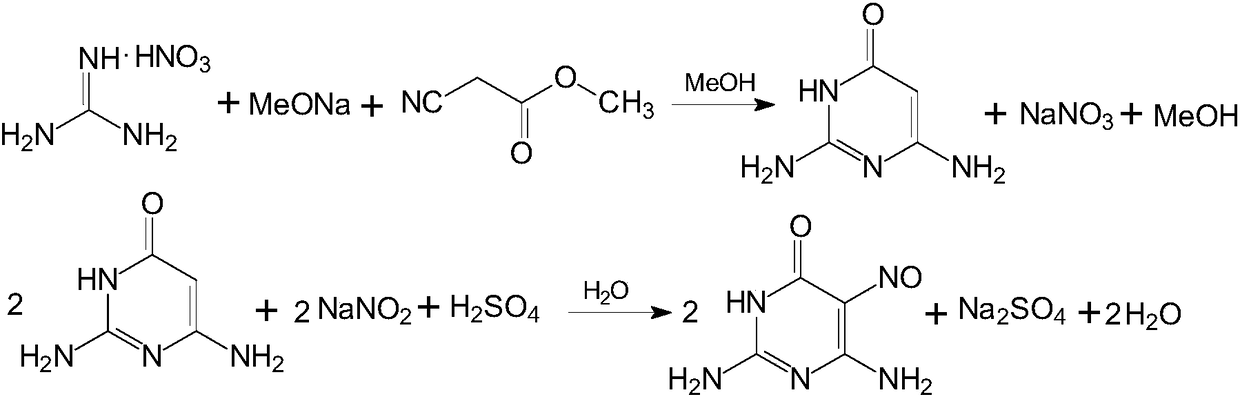

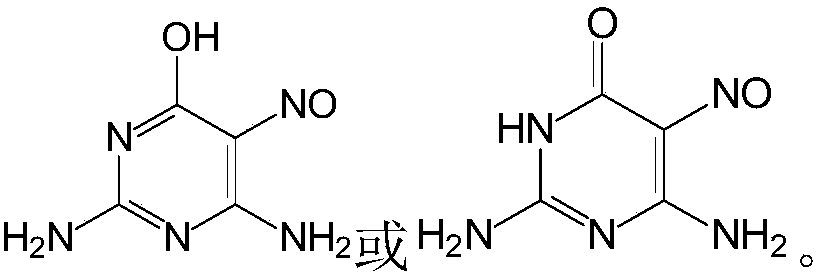

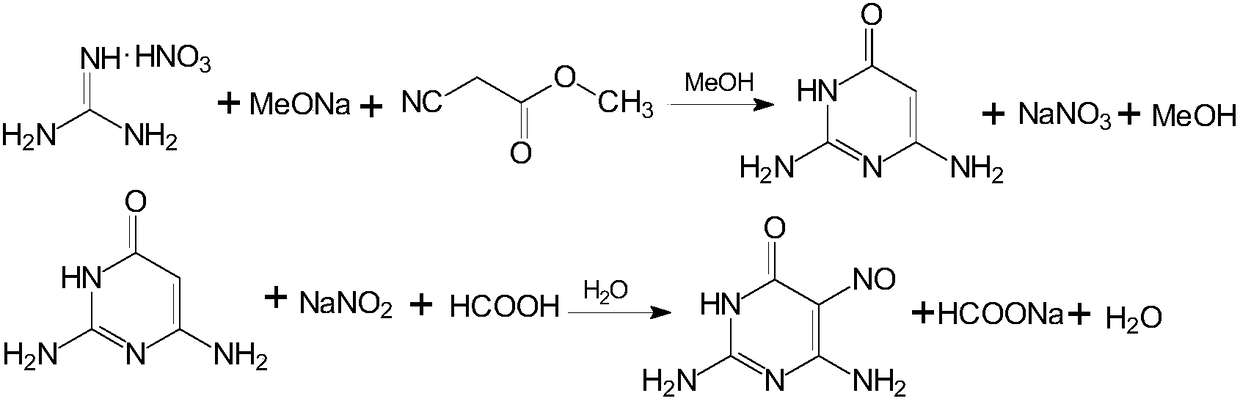

Preparation methods of 2,4-diamido-5-nitroso-6-hydroxypyridine and guanine

The invention discloses a preparation method of 2,4-diamido-5-nitroso-6-hydroxypyridine. The preparation method comprises the following steps: (1) in a sodium methoxide methanol solution, carrying outa ring-closure reaction between methyl cyanoacetate and guanidine salt; (2) adding recycled absolute methanol to be diluted, filtering and recycling byproduct sodium nitrate; (3) concentrating a filter liquor, and recycling absolute methanol; (4) adding water to destroy excessive sodium methoxide, concentrating and recycling water-containing methyl alcohol; (5) in a diluted methane acid solution,carrying out a nitrosation reaction among an obtained concentrate, sodium nitrite and a nitrosation mother liquor; (6) after the reaction ends, carrying out cooling crystallization, filtering, takinga filter liquor as the nitrosation mother liquor to be used indiscriminately, and drying an obtained filter cake to obtain the 2,4-diamido-5-nitroso-6-hydroxypyridine. According to the preparation method, indiscriminate use of the nitrosation mother liquor and recycling of sodium nitrate and methyl alcohol are realized, and simultaneously the diluted methane acid solution is used for replacing concentrated sulfuric acid used, in the prior art, to carry out the nitrosation reaction, so that the recycling of a solvent and a reagent is facilitated, and the displacement of waste water is reduced.

Owner:潍坊奥通药业有限公司

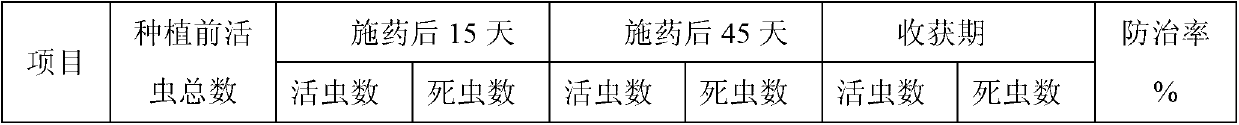

Agent for preventing and treating plant continuous cropping disease and preparation method thereof

InactiveCN103098805ABroad spectrum of prevention and treatmentReduce use costBiocideFungicidesDiseaseContinuous cropping

The invention discloses an agent for preventing and treating plant continuous cropping disease and a preparation method thereof. The preparation method comprises the following steps of uniformly mixing a carrier adsorbent with an abamectin water solution with the mass concentration of 30wt%, and then drying and granulating, wherein the mass ratio of the carrier adsorbent to the abamectin water solution is (70-80): 33; then introducing gas formed by heating and gasifying nitrochloroform into a reaction tank filled with the product of the last step to carry out adsorption reaction; and when the mass ratio of the reduced mass of the nitrochloroform to the carrier adsorbent is (10-20): (70-80), preparing a final product. According to the preventing and treating agent disclosed by the invention, the ratios and the contents of effective components of the product can be adjusted according to different preventing and treating objects and the preventing and treating spectrum is wide. The preventing and treating agent is efficient, low-toxic and medicine-saving, and has a low use cost. The application is safe and convenient and no environmental pressure exists. The preventing and treating agent has wide application range and application prospect.

Owner:伊长君 +1

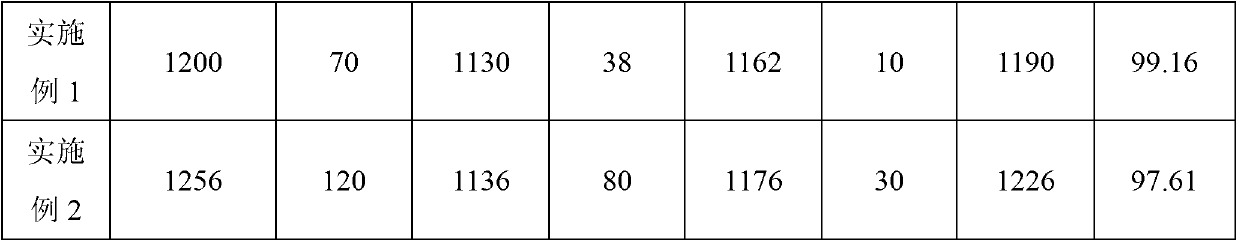

Medical equipment pipeline cleaning device

InactiveCN108160632AReduce in quantityEasy to cleanHollow article cleaningMedical equipmentEconomic benefits

The invention discloses a medical equipment pipeline cleaning device and belongs to the technical field of medical equipment maintenance. The medical equipment pipeline cleaning device comprises brushdevices, an installing disc, a spraying device and a telescopic device. The brush devices are arranged at one ends of sleeve rods. The brush devices comprise brushes and brush handles. The other endsof the sleeve rods are arranged in sleeves. The four arranged sleeves are fixedly connected with the installing disc. The sleeve rods are fixed to the sleeves through fastening screws. A bolt is arranged at one end of a fixed rod and is fixedly connected with the installing disc through mutual screwing of the bolt and a nut. A liquid inlet pipe is fixed to the side face of a transmission device and is further provided with a booster pump. According to the medical equipment pipeline cleaning device, a medical equipment pipeline is cleaned in the mode that high-rotation-speed friction cleaningand high-pressure spray cleaning are combined, the cleaning effect is good, meanwhile labor efficiency is improved, the amount of chemical cleaning fluid is reduced, cleaning cost is lowered, environmental protection pressure is avoided, and economic benefit is increased.

Owner:HUNAN HUIXUN ENTERPRISE MANAGEMENT CO LTD

Preparation method of asiaticoside

The invention belongs to the technical field of traditional Chinese medicines, and particularly relates to a preparation method of asiaticoside. An enzymolysis method of asiaticoside provided by the invention has obviously higher yield and purity than those in an acid-base hydrolysis method, has low requirements on equipment, has the advantages of small environmental pollution, no environmental pressure and the like, and provides an effective method for researching and developing active substances of traditional Chinese medicine centella asiatica.

Owner:LUNAN PHARMA GROUP CORPORATION

Efficient sterilization method of animal blood

The invention provides an efficient sterilization method of animal blood. According to the efficient sterilization method provided by the invention, by carrying out high-temperature sterilization on pork blood under the conditions that the temperature is 85 DEG C or above and the action time is 30 minutes or above to several hours and then adding a part of a biological agent, a way of completely killing viruses can be realized, and the problem of virus propagation of the pork blood can be effectively solved; meanwhile, enzyme engineering is facilitated to be developed and utilized for processing the pork blood, and more valuable products can be produced.

Owner:湖南璟荣生物科技有限公司

A method for enriching carbon disulfide and hydrogen sulfide in viscose fiber waste gas

ActiveCN106693647BImprove protectionNo environmental pressureDispersed particle separationCellulosePhysical chemistry

Owner:四川雅丽兴科技有限公司

Method for efficiently recovering dust sludge containing C and Fe in iron and steel industry

InactiveCN103436644BEfficient recyclingImprove yieldSolid fuelsRecycling and recovery technologiesRecovery methodSludge

The invention provides a method for efficiently recovering dust sludge containing C and Fe in the iron and steel industry and relates to a dust sludge recovering method in the iron and steel industry. According to the method, the dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel industry is screened, crushed, magnetically separated and then selected in a flotation manner to get a high-C-content material, the high-C-content material is added with rosin for lipidation and cementation after being air-dried, then is compressed into the ball or rod shape, and is air-dried to get lipidation coke used as a reducer and fuel in the smelting industry. The method can efficiently recover C and Fe, the yield of the C-containing material is high, the burning is more thorough and sufficient, the heat efficiency is higher, and the method facilitates popularization and application.

Owner:LIUZHOU XIANMING SCI & TECH

Method for preparing hydrated phospholipids from soybean oil bottoms and hydrated phospholipids prepared therefrom

ActiveCN107325125BGood dispersionSmall degree of processingGroup 5/15 element organic compoundsPhosphatide foodstuff compositionsOrganic solventSoftened water

The invention discloses a method for preparing hydrated phospholipid from soybean oil sediment and hydrated phospholipid prepared with the method, relates to the field of a treatment method of the soybean oil sediment and aims to solve the problems that with adoption of the conventional soybean phospholipid refining method, organic solvent consumption is high and many residues are produced and are harmful to a human body or the prepared soybean phospholipid is strong in flavor, dark in color and low in quality. According to the method, softened water is added to the soybean oil sediment, then the soybean oil sediment is left to stand for chromatography, heating is performed after chromatography for centrifugal separation, and hydrated phospholipid is obtained. Acetone insoluble substances in the prepared hydrated phospholipid can reach 90% or higher, the phospholipid content is higher, and organic matter residues are avoided.

Owner:山东中阳生物科技有限公司

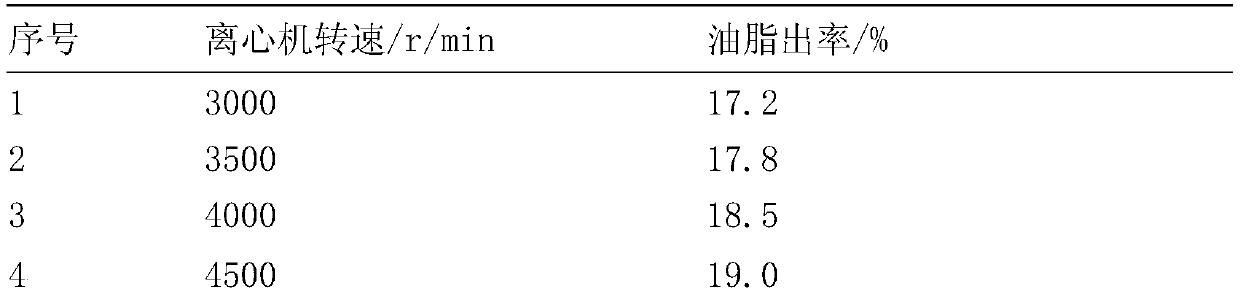

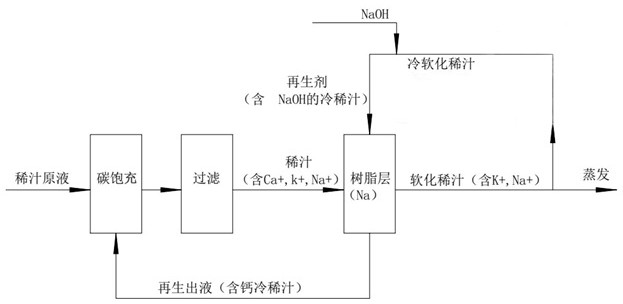

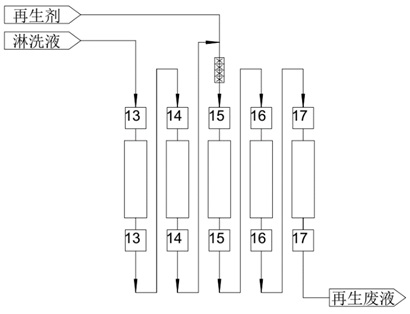

Softening method of beet syrup

PendingCN114606349ARealize continuous productionReduce foulingIon-exchange process apparatusIon-exchanger regenerationPhysical chemistryIon exchange

The invention discloses a method for softening beet syrup. The method comprises the following steps: 1) a production process: enabling beet syrup to pass through a decalcification ion exchange resin column to obtain softened syrup; (2) backwashing: backwashing the decalcified ion exchange resin column which is saturated by adsorbing calcium ions; 3) regeneration process: regenerating the decalcification ion exchange resin column saturated by adsorbing calcium ions by using NaOH softened thin juice; and 4) leaching: leaching the regenerated ion exchange resin column by using the softened thin juice. When the softened thin juice obtained through the beet sugar thin juice softening method enters a subsequent evaporator and other procedures, the scaling phenomenon of the evaporator and crystallization sugar boiling equipment is reduced, the situation that production is stopped due to descaling of the evaporator and other equipment is avoided, continuous production of beet sugar is achieved, and labor cost is saved. And meanwhile, the service lives of the evaporator and the crystallization sugar boiling equipment are prolonged.

Owner:OUSHANGYUAN PROCESS & EQUIP INTELLIGENT CO

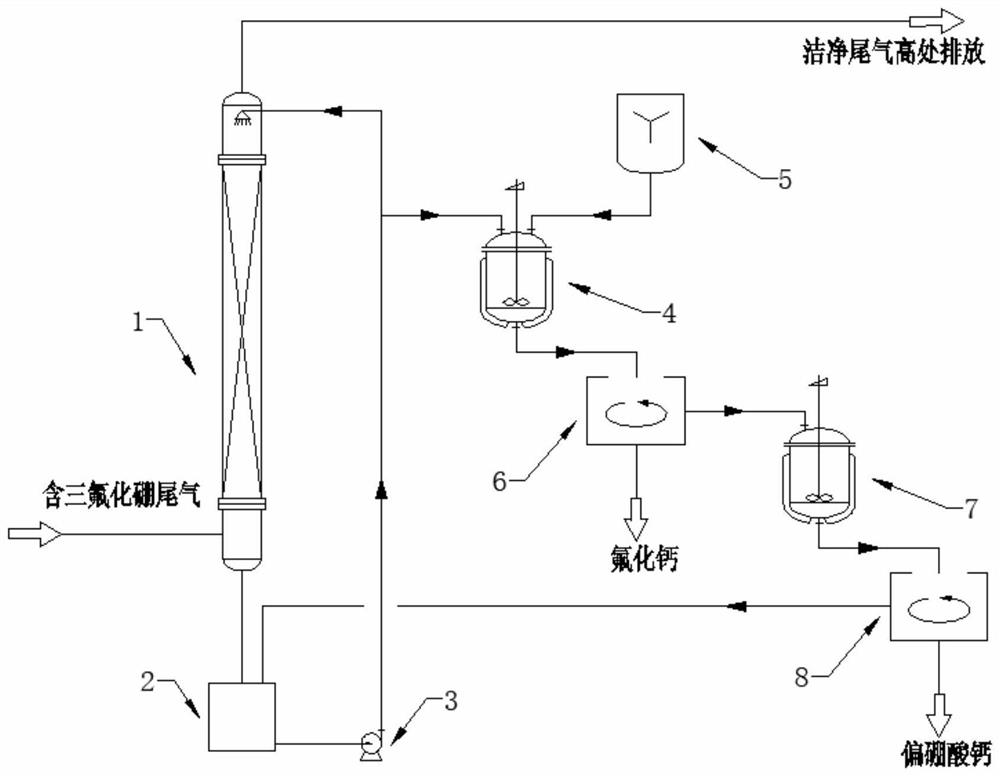

A kind of treatment method of boron trifluoride tail gas

ActiveCN112169562BEasy to operateReduce consumptionGas treatmentCalcium/strontium/barium fluoridesSodium hydroxideSodium metaborate

The invention discloses a method for treating boron trifluoride tail gas, comprising the following steps: (1) absorbing the boron trifluoride tail gas with excess sodium hydroxide solution to generate a mixed solution containing sodium fluoride and sodium metaborate (2) mixed solution and calcium hydroxide emulsion are mixed and react, generate calcium fluoride precipitation, obtain the first mother liquor containing calcium fluoride; (3) first mother liquor is centrifuged to obtain the first pair of The product calcium fluoride and the first clear liquid; (4) the first clear liquid is heated to 40~65 ℃, reacts while stirring, generates calcium metaborate precipitation, obtains the second mother liquor containing calcium metaborate; (5) will The second mother liquor is centrifuged to obtain the second by-product calcium metaborate. In the present invention, NaOH solution is used for lye absorption first, and then Ca(OH) 2 Staged treatment is carried out to obtain by-products calcium fluoride and calcium metaborate. While efficiently treating boron trifluoride in the tail gas, no fluorine-containing wastewater is produced.

Owner:SUZHOU JINHONG GAS CO LTD

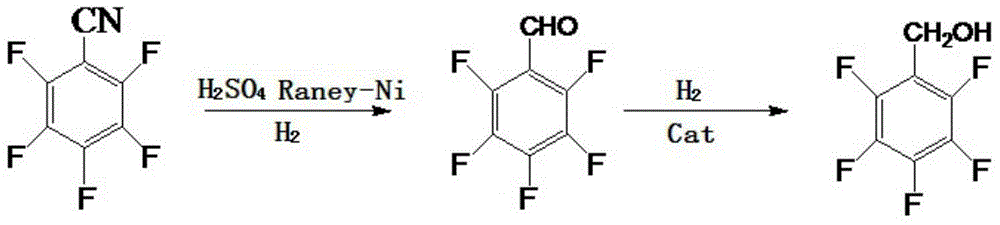

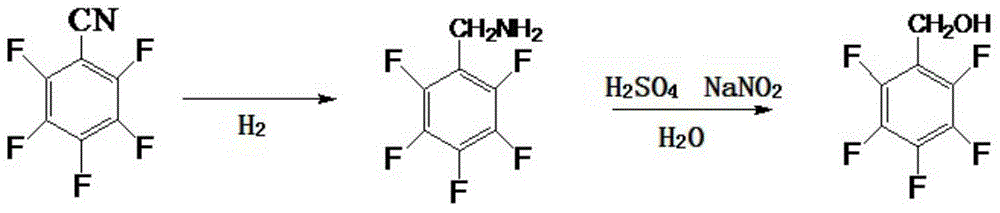

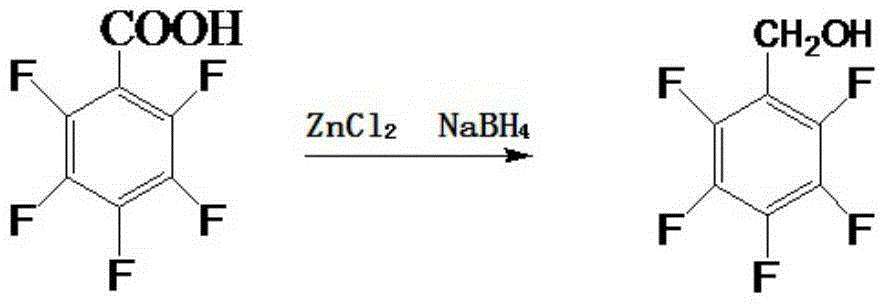

Catalyst for polyfluorinated benzoate reduction preparation of polyfluorinated benzyl alcohol and method thereof

ActiveCN104826634AIncrease productionEasy to recycleOrganic compound preparationHydroxy compound preparationHydrogen pressureFixed bed

The invention discloses a catalyst for polyfluorinated benzoate reduction preparation of polyfluorinated benzyl alcohol; the catalyst includes the components in parts by weight: 10-50 parts of copper oxide, 10-30 parts of zinc oxide, 1-5 parts of cerium oxide, and 10-40 parts of aluminum oxide; graphite is mixed and added in the catalyst, and the catalyst is treated for 20-26 h by introducing hydrogen at the temperature of 170-220 DEG C. The catalyst is used for polyfluorinated benzoate reduction preparation of polyfluorinated benzyl alcohol, and has the advantages of good reaction selectivity, high yield, and easy industrialized production. The invention also provides a method for polyfluorinated benzoate reduction preparation of polyfluorinated benzyl alcohol by using the catalyst; the catalyst is packed in a fixed bed reactor, hydrogen is introduced at the temperature of 200-210 DEG C, the hydrogen pressure is 2.0-2.5 MPa, and the hydrogen flow rate is 1-2 L / min; an alcohol solution of polyfluorinated benzoate is added by a high-pressure metering pump, continuous production can be carried out, the yield is high, a by-product only comprises alcohol and is easy to recycle, no three waste generated by other processes exists, no environmental protection pressure exists, and the polyfluorinated benzyl alcohol yield is greater than 90%.

Owner:DALIAN QIKAI MEDICAL TECH

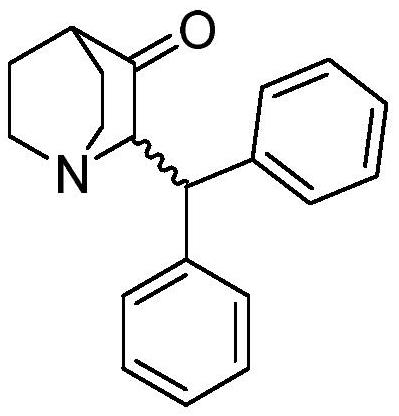

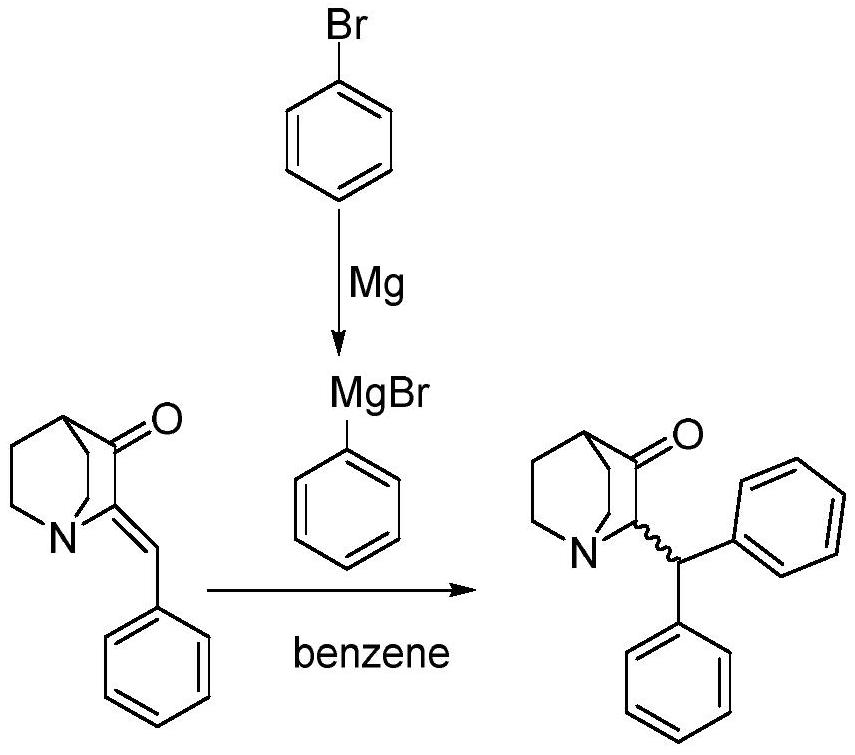

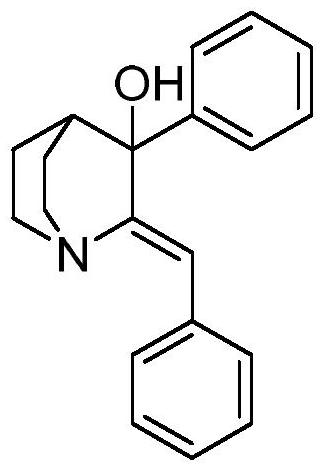

A kind of method of Michael addition synthesis benzhydryl quinuclidone

The invention discloses a method for synthesizing benzhydryl quinuclidine by Michael addition, and belongs to the field of organic synthesis. In the present invention, (Z)-2-benzylidenequinine-3-ketone is used as a raw material, and 2-(diphenylmethyl)quinuclidine-3- is obtained through Mike addition reaction in the presence of a cuprous catalyst. ketone product. Under the preferred reaction conditions, the yield can reach 85%, and the purity is higher than 99%. The preparation method of benzhydryl quinuclidine of the present invention solves the problems of low yield, low selectivity, unfriendly environment and the like existing in the prior method.

Owner:SICHUAN QINGMU PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com