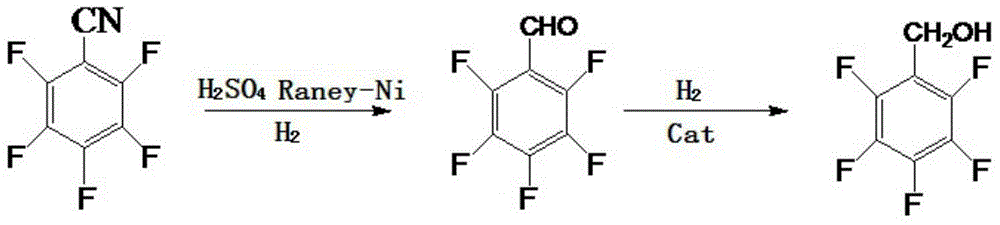

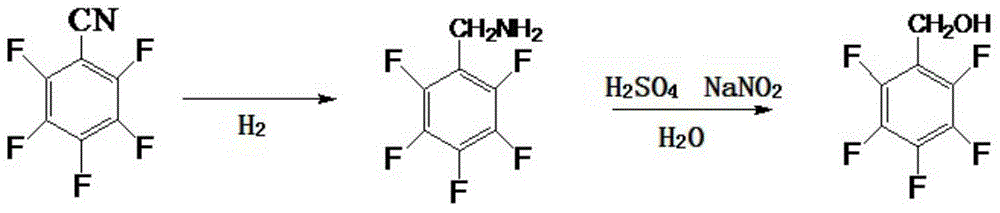

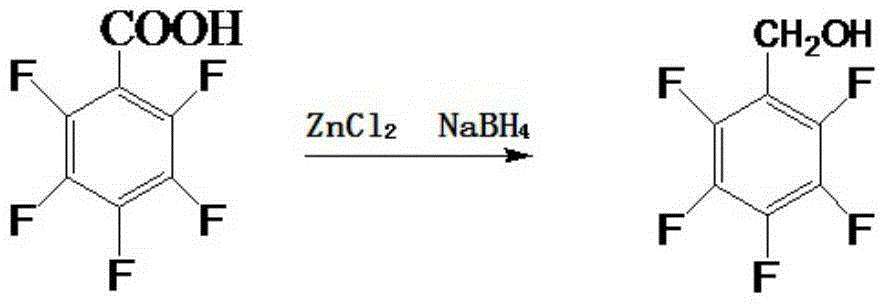

Catalyst for polyfluorinated benzoate reduction preparation of polyfluorinated benzyl alcohol and method thereof

A technology of polyfluorobenzoic acid and polyfluorobenzyl alcohol is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., and can solve the problems of low yield, difficult purification, and high cost of sodium borohydride, Achieve the effect of large output, no environmental protection pressure, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 catalyst

[0038] 10g of copper oxide, 10g of zinc oxide and 83g of aluminum oxide were mixed to obtain a catalyst, and 5g of graphite was added for use.

Embodiment 2

[0039] The preparation of embodiment 2 catalyst

[0040] Mix 50g of copper oxide, 30g of zinc oxide, 5g of cerium oxide and 420g of aluminum oxide to obtain a catalyst, which is ready for use.

Embodiment 3

[0041] The preparation of embodiment 3 catalyst

[0042] 1. Reaction

[0043] Add 235g of copper nitrate, 155g of zinc nitrate, 10g of cerium nitrate, and 65g of aluminum hydroxide to 2000g of pure water, heat to 60-70°C, add 28% ammonia water under stirring, adjust the pH to 7-8 to cause precipitation, and obtain The precipitate is a mixture of copper hydroxide, zinc hydroxide, aluminum hydroxide, and cerium hydroxide.

[0044] 2. Drying

[0045] Filter and wash the filter cake, and dry at 100-110°C for 5-8 hours to remove the precipitation and moisture brought during the filtration process;

[0046] 3. Roasting

[0047] Roast in a muffle furnace at 500-600°C for 4-6 hours to prepare the metal in the hydroxide state into an oxidized state to obtain copper oxide, zinc oxide, cerium oxide and aluminum oxide, and naturally cool down to room temperature;

[0048] 4. Tablet

[0049] 5g of graphite was added to every 100g of powder solids as a binder, and after mixing evenly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com