Method for efficiently recovering dust sludge containing C and Fe in iron and steel industry

A technology of iron and steel industry, dust and mud, applied in the direction of petroleum industry, recycling technology, chemical instruments and methods, etc., can solve the problems of waste, low recycling rate, etc., and achieve the effect of complete combustion, efficient recovery, and high heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

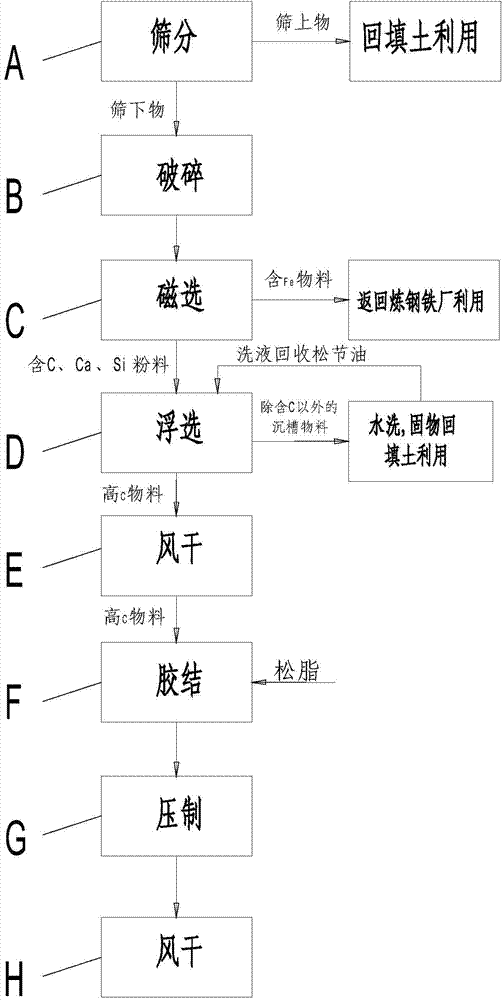

[0037] A method for efficiently reclaiming iron and steel industry dust sludge containing C and Fe, the method is to carry out magnetic separation after screening and crushing the dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel industry to obtain Ca, Si powder and Fe-containing materials, Fe-containing materials are returned to the steelmaking plant for use, C, Ca, Si powders are continuously flotation, and high-C materials are obtained by flotation. After the high-C materials are air-dried, turpentine is added for cementation , and then pressed into a spherical or rod shape, and after air-drying, the lipid coke used as a reducing agent and fuel in the smelting industry can be obtained. The method includes the following specific steps:

[0038] A. Screening:

[0039] The dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel plant is screened by a vibrating screen. In the dust sludge containing C, Fe, Ca, Si and other im...

Embodiment 2

[0055] A method for efficiently reclaiming iron and steel industry dust sludge containing C and Fe, the method is to carry out magnetic separation after screening and crushing the dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel industry to obtain Ca, Si powder and Fe-containing materials, Fe-containing materials are returned to the steelmaking plant for use, C, Ca, Si powders are continuously flotation, and high-C materials are obtained by flotation. After the high-C materials are air-dried, turpentine is added for cementation , and then pressed into a spherical or rod shape, and after air-drying, the lipid coke used as a reducing agent and fuel in the smelting industry can be obtained. The method includes the following specific steps:

[0056] A. Screening:

[0057] The dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel plant is screened by a vibrating screen. In the dust sludge containing C, Fe, Ca, Si and other impu...

Embodiment 3

[0073] A method for efficiently reclaiming iron and steel industry dust sludge containing C and Fe, the method is to carry out magnetic separation after screening and crushing the dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel industry to obtain Ca, Si powder and Fe-containing materials, Fe-containing materials are returned to the steelmaking plant for use, C, Ca, Si powders are continuously flotation, and high-C materials are obtained by flotation. After the high-C materials are air-dried, turpentine is added for cementation , and then pressed into a spherical or rod shape, and after air-drying, the lipid coke used as a reducing agent and fuel in the smelting industry can be obtained. The method includes the following specific steps:

[0074] A. Screening:

[0075] The dust sludge containing C, Fe, Ca, Si and other impurities in the iron and steel plant is screened by a vibrating screen. In the dust sludge containing C, Fe, Ca, Si and other im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com