Preparation method of 5-methylpyrazine-2-carboxylic acid

A technology of methylpyrazine and dimethylpyrazine, which is applied in the field of bioengineering, can solve problems such as affecting production efficiency and poor bacterial growth, and achieve high comprehensive reaction yield, simple purification steps, and reduced production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

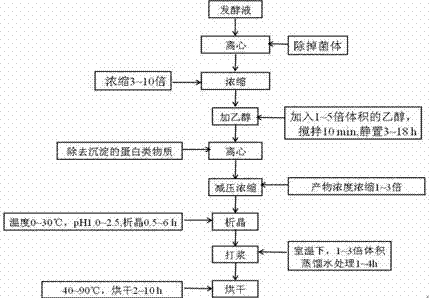

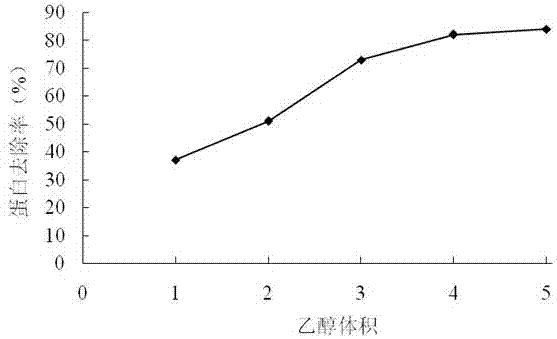

Method used

Image

Examples

Embodiment 1

[0046] Implementation Example 1: Preparation of Primary Seed Solution

[0047] Will Arthrobacter woluwensis Seeds were inoculated into LB medium at 150 r min -1 , Cultivate at 30° C. for 19 hours to obtain seed solution. The components of the LB seed medium used here are peptone 10 g / L, yeast extract 5 g / L, NaCl 10 g / L, and the solvent is water.

Embodiment 2

[0048] Implementation example 2: preparation of secondary seed solution

[0049] Will Arthrobacter woluwensis The seed liquid was transferred to 100 mL of fermentation medium with an inoculum of 2%, under the induction of p-xylene, the shaking table rotated at 150 r min -1 , pH 7.0, cultured at 30°C for 20 h, and prepared the secondary seed solution.

[0050] The fermentation medium uses p-xylene as an inducer, and other nutrients and trace elements are added. Secondary fermentation medium in the present invention consists of: yeast powder 0.6 g / L; peptone 1.2 g / L; ammonium sulfate 1.5 g / L; sodium bicarbonate 1.3 g / L; potassium dihydrogen phosphate 1.2 g / L; Sodium 0.8 g / L; Magnesium chloride 0.1 g / L; Calcium chloride 0.2 g / L; Zinc sulfate 0.02 g / L; Manganese chloride 0.05 g / L; Copper chloride 0.03 g / L; Nickel chloride 0.01 g / L ; EDTA Na 2 2H 2 O0.8 g / L; p-xylene 0.3 mL / L, the solvent is water.

Embodiment 3

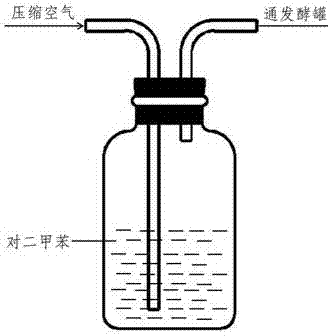

[0051] Implementation Example 3: Tank Fermentation and Biotransformation

[0052] Will Arthrobacter woluwensis The secondary seed solution was connected to a 10 L fermenter with a 6% inoculation amount, and p-xylene was injected into the fermenter in the form of steam brought by compressed air. Under the induction of p-xylene, it was cultivated at 400 rpm, 30°C, and pH 7.0 After 6 hours, when the bacterial concentration reached 1.0, 20 g of raw material 2,5-dimethylpyrazine was added into the fermenter. And according to liquid phase detection (column: C 18 Column, acetonitrile: water: trifluoroacetic acid = 12:88:0.5, flow rate 1 mL min -1 , detection wavelength 270 nm, column temperature 25°C) product concentration and substrate concentration in the fermentation broth, when the product concentration exceeds 50%, add 20 g of raw material 2,5-dimethylpyrazine to the fermentation broth in due course . The conversion process took 360 h and 15 days, and a total of 14 additiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com