Alloy atomic infiltration surface treatment method for elastic rail clip

A surface treatment, zinc-iron alloy technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as poor adhesion, loss of anti-corrosion ability of elastic strips, cracking of coating substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] A specific embodiment of the present invention is given below.

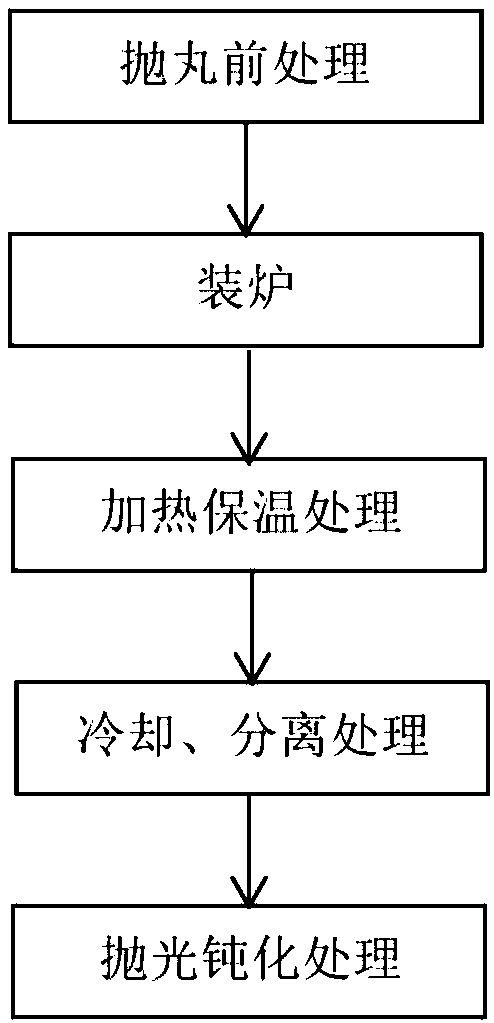

[0052] In this embodiment, the surface treatment is carried out for the elastic fasteners in the high-speed railway rail fastener system, which specifically includes the following processes:

[0053] (1) Use steel shot with a particle size of 0.3~0.8mm to blast the surface of the elastic bar for 15~20min;

[0054] (2) Put the shot blasted spring bars and a certain amount of zinc saturated compound into the heating drum of the heat treatment furnace; the zinc saturated compound consists of 72% zinc powder, 23% zinc oxide powder and 5% other auxiliary materials Composition, the other auxiliary materials include 1.5% titanium dioxide, 0.8% silicon dioxide, 1.2% calcium carbonate and 1.5% aluminum phosphate, and the added amount of zinc saturated compound is 1 / 60 of the weight of the elastic bar.

[0055] (3) Rotate the heating drum at a speed of 6rad / min, heat the part to 380~400°C, and keep it warm for 2 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com