Method for preparing hydrated phospholipid from soybean oil sediment and hydrated phospholipid prepared with method

A technology for hydrating phospholipids and oily feet, which is applied in the directions of edible phospholipid compositions, chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, etc. Residues, high technical equipment requirements, and achieve the effect of being conducive to ecological sustainable development, significant environmental benefits, and no environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of hydrated phospholipid prepared by soybean oil foot, adopts following method to make:

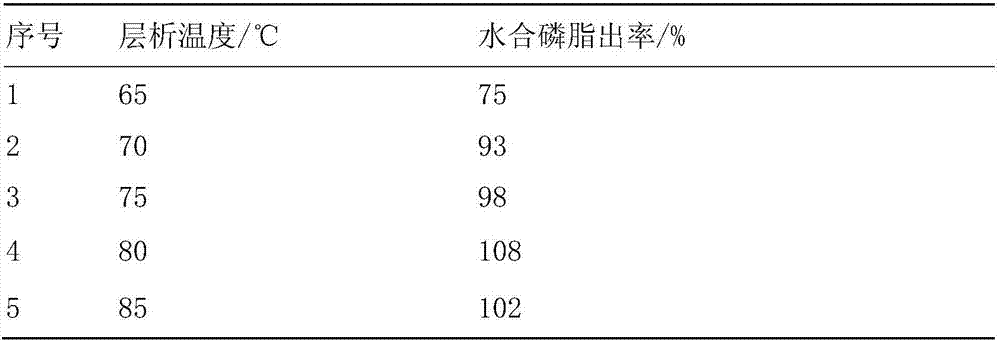

[0024] (1) Get the soybean oil bottoms produced by Shandong Zhongyang Biotechnology Co., Ltd. to process Meixi soybeans, add demineralized water and sulfuric acid and mix evenly in the reaction tank; the moisture content in the used raw material soybean oil bottoms is 32%, and the added demineralized water and The mass ratio of soybean oil bottoms is 0.69:1, and the mass of sulfuric acid added accounts for 0.3‰ of the mass of soybean oil bottoms. Heat the mixture to 85°C (the temperature difference does not exceed 1°C, and the heating rate is 2-5°C / min), keep it warm for 6 hours and perform chromatography. After the chromatography, keep the temperature of the material at 85°C, Centrifugation is carried out under certain conditions, and the obtained hydrated phospholipid enters the storage tank, and the water content in the obtained hydrated phospholipid at this time is 64%. ...

Embodiment 2

[0031] A kind of hydrated phospholipid prepared by soybean oil foot, adopts following method to make:

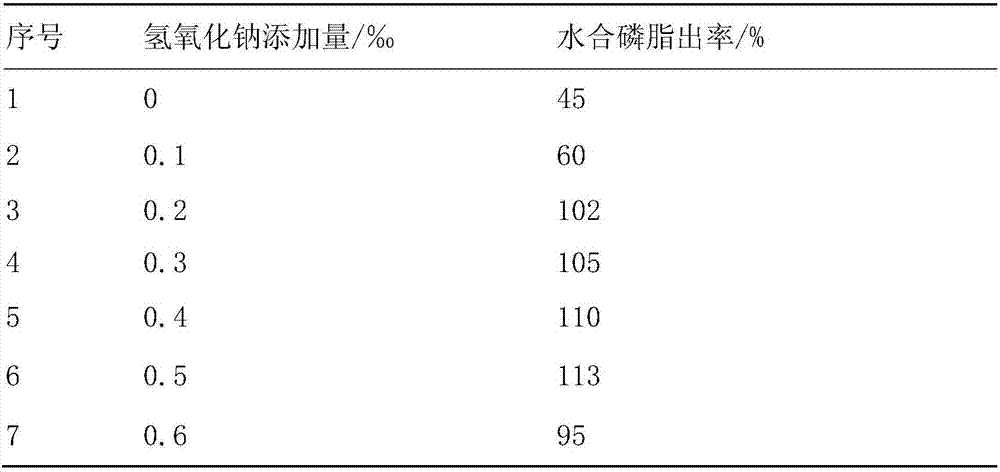

[0032] (1) Get the soybean oil bottoms produced by processing Brazilian soybeans by Shandong Zhongyang Biotechnology Co., Ltd., add demineralized water and sodium hydroxide and mix evenly in the reaction tank. The moisture content in the raw material soybean oil bottoms used is 36%, and the added demineralized water The mass ratio to soybean oil bottoms is 0.59:1, and the weight ratio of sodium hydroxide to soybean oil bottoms is 0.5‰. Heat the mixture to 75°C (the temperature difference does not exceed 1°C, and the heating rate is 2-5°C / min), keep it warm for 4 hours and perform chromatography. After the chromatography, keep the temperature of the material at 75°C. Centrifugation is performed and the resulting hydrated phospholipids enter storage tanks. The relationship between adding demulsifier sodium hydroxide and the yield of hydrated phospholipids is shown in Table 2....

Embodiment 3

[0039] A kind of hydrated phospholipid prepared by soybean oil foot, adopts following method to make:

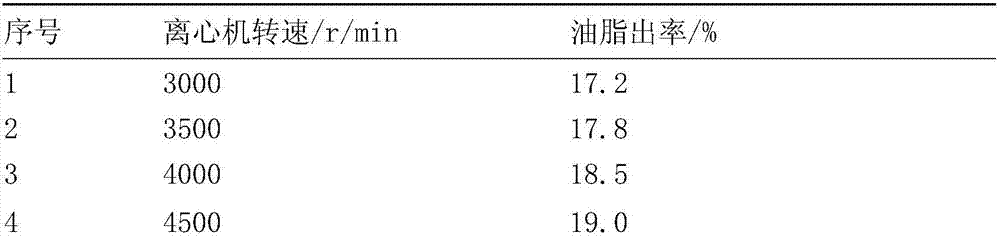

[0040] (1) Get the soybean oil bottoms produced by Shandong Sanwei Oil Co., Ltd. to process American Gulf soybeans, add demineralized water and mix them evenly in the reaction tank. The moisture content in the used raw material soybean oil bottoms is 37%. The ratio is 0.57:1, and 0.2‰ sulfuric acid is added as a demulsifier. Heat the mixture to 85°C (the temperature difference does not exceed 1°C, and the heating rate is 2-5°C / min), then keep it for 4 hours for chromatography. After the chromatography, the material is heated to 95°C (the temperature difference does not exceed 1°C). , heating rate: 2-5°C / min), and then centrifuged. The relationship between the centrifuge speed and the oil output rate is shown in Table 3.

[0041] Table 3 The relationship between the grease output rate and the centrifugal speed

[0042]

[0043]

[0044] With the increase of the speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com