A method for inhibiting calcium and magnesium in mineral processing

A technology for concentrates and ore, applied in the field of hydrometallurgy and mineral processing, can solve the problems of rising production costs, rising production costs, high sulfate solubility, etc., and achieve the effects of improving grade and recovery rate, increasing output value, and improving grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

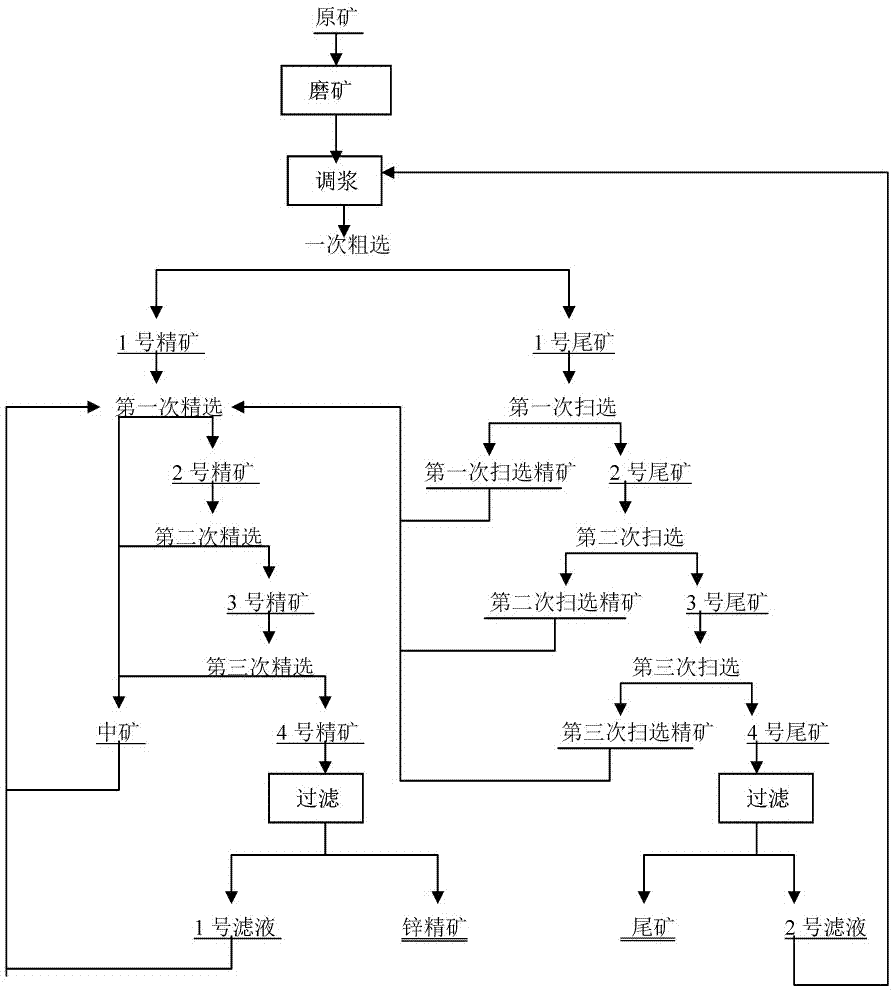

Image

Examples

Embodiment 1

[0030] Take the mine acquired by our company containing 1.52wt% zinc, 10.13wt% magnesium oxide, 0.0041wt% germanium, 0.11wt% lead, 1.25wt% sulfur, 0.52wt% iron, and 3.15wt% silicon, 20000.00 grams of zinc ore containing calcium oxide 15.48wt% are dried for use;

[0031] 1 Grinding: Grind the dried zinc ore with a dry ball mill until 100wt% of the mineral powder passes through a 160-mesh sieve;

[0032] 2 Slurry: take 15000.0 g of ground mineral powder, and use water slurry to form a slurry with a concentration of 40wt%, and perform a rough separation on it;

[0033] 3 The first roughing: add 300g / t sodium carbonate to prepare a 5wt% aqueous solution as a regulator, make the pulp pH = 6, stir for 2 minutes, add 100g / t activator copper sulfate to prepare a 5wt% aqueous solution, stir for 2 minutes, Add 150g / t of collector butyl xanthate to prepare a 5wt% aqueous solution, stir for 2 minutes, add foaming agent No. 2 oil 50g / t, stir for 1 minute, open the inflation valve, and scr...

Embodiment 2

[0045] Take the mine acquired by our company containing 2.49wt% zinc, 14.96wt% magnesium oxide, 0.0058wt% germanium, 0.19wt% lead, 1.47wt% sulfur, 0.96wt% iron, and 4.96wt% silicon, 25,000.00 g of zinc ore containing 24.96 wt% of calcium oxide was dried for use.

[0046] 1. Grinding: Grind the dried and ready-to-use zinc ore with a dry ball mill until 100wt% of the mineral powder passes through a 160-mesh sieve.

[0047] 2 Slurry: take 20,000.0 g of ground mineral powder, slurry it with water into a slurry with a concentration of 50wt%, and conduct a rough separation on it.

[0048] 3 Primary roughing: add 400g / t sodium carbonate to prepare a 10wt% aqueous solution as a regulator, make the slurry pH=7, stir for 3 minutes, add 150g / t activator copper sulfate to prepare a 10wt% aqueous solution, stir for 3 minutes, add Prepare 200g / t of dixanthate as a 10wt% aqueous solution, stir for 3 minutes, add foaming agent No. 2 oil 60g / t, stir for 2 minutes, open the inflation valve, an...

Embodiment 3

[0060] Take the mine acquired by our company containing 2.09wt% zinc, 14.16wt% magnesium oxide, 0.0048wt% germanium, 0.12wt% lead, 1.37wt% sulfur, 0.86wt% iron, and 4.86wt% silicon, 25000.00 grams of zinc ore containing calcium oxide 23.36wt% was dried for use.

[0061] 1. Grinding: Grind the dried and ready-to-use zinc ore with a dry ball mill until 100wt% of the mineral powder passes through a 160-mesh sieve.

[0062] 2 Slurry: Take 20,000.0 g of ground mineral powder, slurry it with water to form a slurry with a concentration of 45wt%, and conduct a rough separation on it.

[0063] 3 Primary roughing: add 350g / t sodium carbonate to make an 8wt% aqueous solution as a regulator, make the slurry pH=7, stir for 2.5min, add 125g / t activator copper sulfate to prepare an 8wt% aqueous solution, stir for 2.5min, Add 175g / t of collector butyl xanthate to prepare 8wt% aqueous solution, stir for 2.5min, add 55g / t of foaming agent No. 2 oil, stir for 1.5min, open the inflation valve, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com