Esterification method for preparing biodiesel using waste oils and fats

A technology of waste oil and biodiesel, which is applied in fatty acid esterification, biofuel, petroleum industry, etc., to achieve the effects of shortened reaction time, low corrosion, and wide range of acid values of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

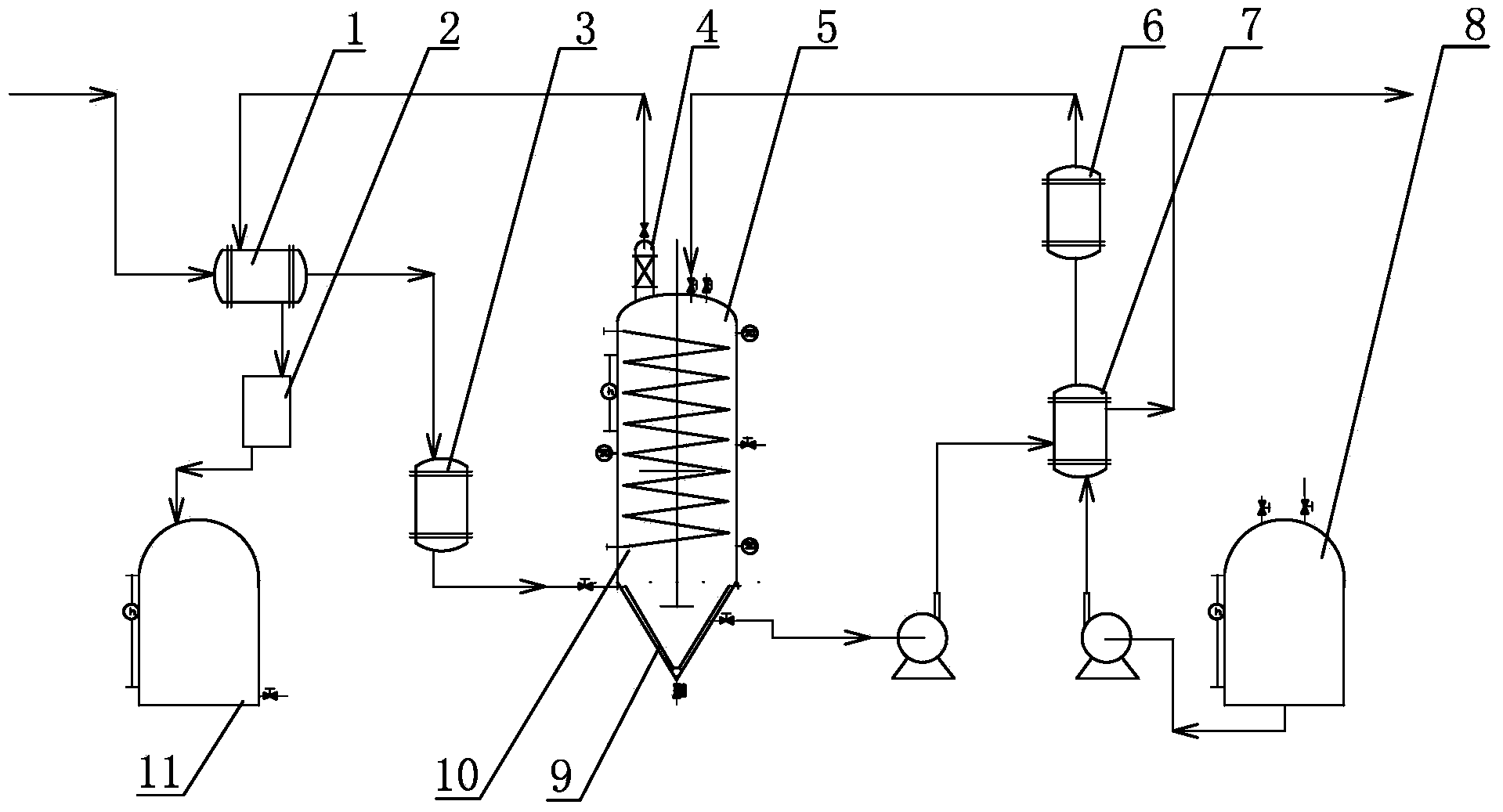

[0018] Such as figure 1 As shown, add 14 tons of waste oil with an acid value of 120 mgKOH / g after removing impurities and water into the raw oil storage tank 8, and use an oil pump to pump the waste oil into the raw oil heater 6 through the raw oil heat exchanger 7 for heating. Waste oil heated to 100°C is added into the stainless steel reactor 5 through the feed oil inlet at the top of the stainless steel reactor 5, and 52 kg of esterification catalyst is added into the stainless steel reactor 5 through the catalyst inlet at the top of the stainless steel reactor 5. The esterification catalyst is a mixture of methanesulfonic acid and phosphoric acid monoester with a mass ratio of 1:0.1. The refined methanol enters the methanol heater 3 through the methanol heat exchanger 1 to be heated and vaporized. 3 The flow rate of / h flows into the stainless steel reactor 5 from the gas phase methanol pipe 9 in the bottom of the stainless steel reactor 5, and the vaporized methanol flow...

Embodiment 2

[0022] Such as figure 1 As shown, add 14 tons of waste oil with an acid value of 120 mgKOH / g after removing impurities and water into the raw oil storage tank 8, and use an oil pump to pump the waste oil into the raw oil heater 6 through the raw oil heat exchanger 7 for heating. Waste oil heated to 110°C is added to the stainless steel reactor 5 through the feed oil inlet at the top of the stainless steel reactor 5, and 52 kg of esterification catalyst is added to the stainless steel reactor 5 through the catalyst inlet at the top of the stainless steel reactor 5. The esterification catalyst is a mixture of methanesulfonic acid and phosphoric acid monoester with a mass ratio of 1:0.05. The refined methanol enters the methanol heater 3 through the methanol heat exchanger 1 to be heated and vaporized. The vaporized methanol is heated at 0.8m 3 The flow rate of / h flows into the stainless steel reactor 5 from the gas phase methanol pipe 9 in the bottom of the stainless steel reac...

Embodiment 3

[0024] In Example 1, the esterification catalyst used is a mixture of equal mass ethanesulfonic acid and polyether acid phosphate with a mass ratio of 1:0.01, and the other steps are the same as in Example 1 to obtain an acid value of less than 1 mgKOH / g The crude methyl ester, the yield of methyl ester is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com