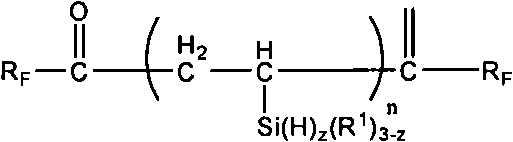

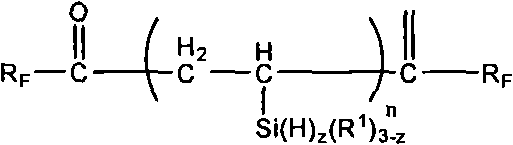

Process for preparing full-fluorine group end capping siloxane oligomer for hard surface finish and uses thereof

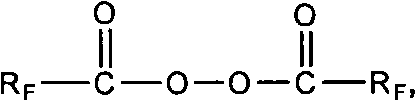

A technology of siloxane oligomer and perfluoroalkyl peroxide, applied in the production field of siloxane oligomer, can solve the problems of low yield and the like, achieve low temperature, low requirements on equipment material, and low reaction rate. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 0.0107 mol of vinyltriethoxysilane and 200 ml of perfluorobutyl ethyl ether to a 250 ml three-necked bottle, slowly add 0.0107 mol of perfluorodioctyl peroxide dropwise at 40°C under nitrogen Tetrafluoropropyl methyl ether solution, iodometric method to track the reaction of peroxide. After 5 hours, perfluorodioctyl peroxide disappeared, and the reaction ended. Perfluorobutyl ethyl ether was distilled off to obtain a perfluorooctyl-terminated triethoxysilane oligomer. Gas chromatography showed a conversion of vinyltriethoxysilane of 74%.

Embodiment 2

[0027] Add 0.0214 mol of vinyltriethoxysilane and 200 ml of tetrafluoropropyl methyl ether to a 250 ml three-necked bottle, slowly add 0.0107 mol of perfluorodioctyl peroxide dropwise at 50°C under nitrogen Tetrafluoropropyl methyl ether solution, iodometric method to track the reaction of peroxide. After 5 hours, perfluorodioctyl peroxide disappeared, and the reaction ended. Tetrafluoropropyl methyl ether was distilled off to obtain a perfluorooctyl-terminated triethoxysilane oligomer. Gas chromatography showed a conversion of vinyltriethoxysilane of 74%.

Embodiment 3

[0029] Into a 250ml three-neck flask, add 0.043mol of vinyltripropoxysilane and 200ml of tetrafluoropropyl difluoromethyl ether, and slowly add 0.0107mol of perfluoroperoxide at 60°C under argon. Dioctyl tetrafluoropropyl difluoromethyl ether solution, iodometric method to follow the reaction of peroxide. After 6 hours, perfluorodioctyl peroxide disappeared, and the reaction ended. Tetrafluoropropyl difluoromethyl ether was distilled off to obtain a perfluorooctyl-terminated tripropoxysilane oligomer. Gas chromatography showed that the conversion of vinyltripropoxysilane was 71%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com