A kind of solid acid catalyzed alkylation method

A technology of solid acid catalysis and solid acid catalyst, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve the problems of complex reaction system structure, achieve good activity and selectivity, and increase and decrease the ratio of alkene to alkene. desired effect

Active Publication Date: 2018-01-05

CHINA PETROLEUM & CHEM CORP +1

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The alkene ratio of the reaction material corresponds to the number of olefins. To achieve a higher alkene ratio, the olefins need to be divided into more parts, so that the reaction system needs to have more catalyst beds or more reactors. The number of olefins usually needs to be divided into dozens of parts to achieve the ideal alkene ratio, and the structure of the reaction system will be quite complicated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

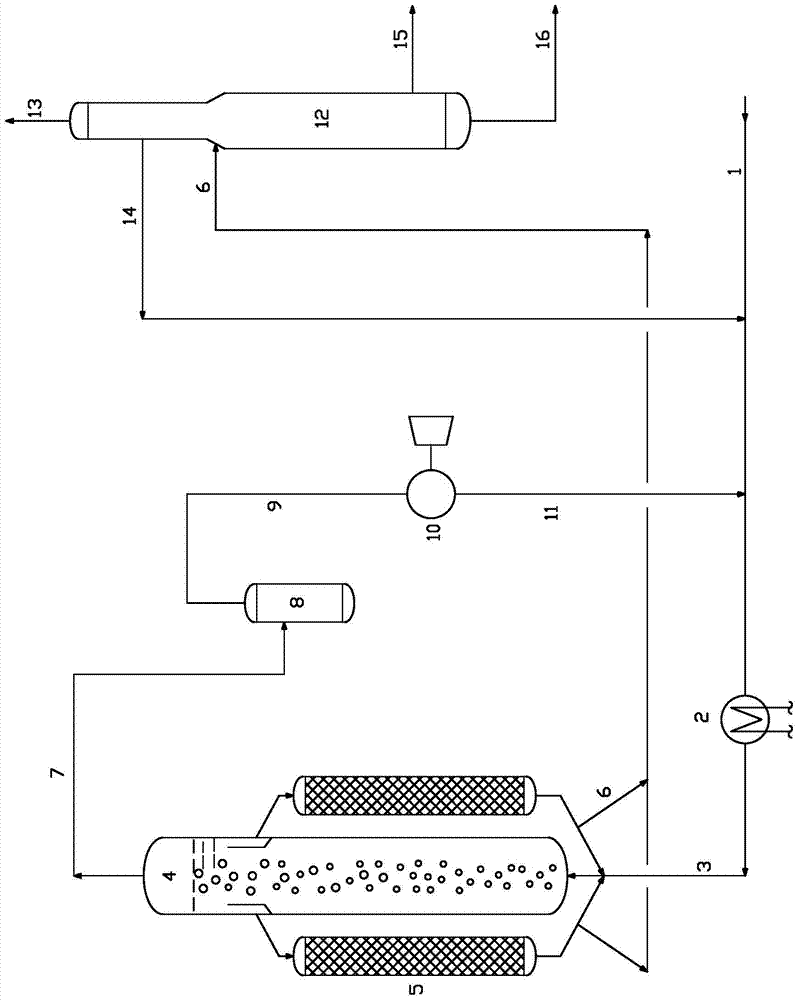

[0033] Embodiment adopts the technological process shown in accompanying drawing.

[0034] The molar composition of the raw materials for the alkylation reaction is shown in Table 1, the main process conditions of the alkylation reaction are shown in Table 2, and the main results of the alkylation reaction are shown in Table 3.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A solid acid catalyzed alkylation method, comprising: after the alkylation reaction raw material is mixed with the circulating isobutane fraction, it is contacted with a solid acid catalyst in an alkylation reactor and an alkylation reaction occurs, and the alkylation reaction The outlet stream of the device is separated in the fractionation system to obtain light fraction, isobutane fraction, n-butane fraction and alkylated gasoline respectively, wherein the isobutane fraction is circulated in the reaction system, which is characterized in that the said alkyl The reactor is a loop reactor, which provides the power of the reactant flow circulation through the circulation of the inert gas in the reaction system, and adjusts the circulation amount of the reactant flow by adjusting the circulation amount of the inert gas, so that the reactant flow in contact with the catalyst reaches the required alkane. The loop reactor is composed of an inner cylinder and no less than two side arm reaction units, and the side arm reaction units are filled with a solid acid catalyst.

Description

technical field [0001] The invention relates to an alkylation method of isoparaffins and olefins, more specifically a solid acid catalyzed alkylation method of isoparaffins and olefins. Background technique [0002] During the processing of oil products, processes such as catalytic cracking, delayed coking and thermal cracking will produce liquefied gas fractions. After recovering propylene through a gas fractionation device, the obtained C 4 C with alkanes and alkenes as the main components 4 Fraction, C 4 The isobutane and butene in the distillate can be produced by alkylation reaction to produce alkylated gasoline. Alkylated gasoline does not contain impurities such as sulfur and nitrogen, does not contain aromatics and olefins, and has a high octane number. It is an ideal clean gasoline blending component. Over the past ten years, with the continuous improvement of environmental protection requirements, my country's gasoline standards have also been continuously upgra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10G50/00C07C9/08C07C9/10C07C9/12C07C2/62

Inventor 赵志海李永祥胡合新慕旭宏

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com