Outer heating pyrolysis reactor for high-moisture carbon-based raw material

A pyrolysis reactor and external heating technology, which is applied in the direction of pyrolysis treatment of sludge, special form of dry distillation, indirect heating dry distillation, etc., can solve the problems of low heat and mass transfer efficiency, low reaction temperature, small heat transfer area, etc. , to achieve the effect of improving heat and mass transfer efficiency, avoiding raw material accumulation, and increasing heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further introduced below in combination with specific embodiments.

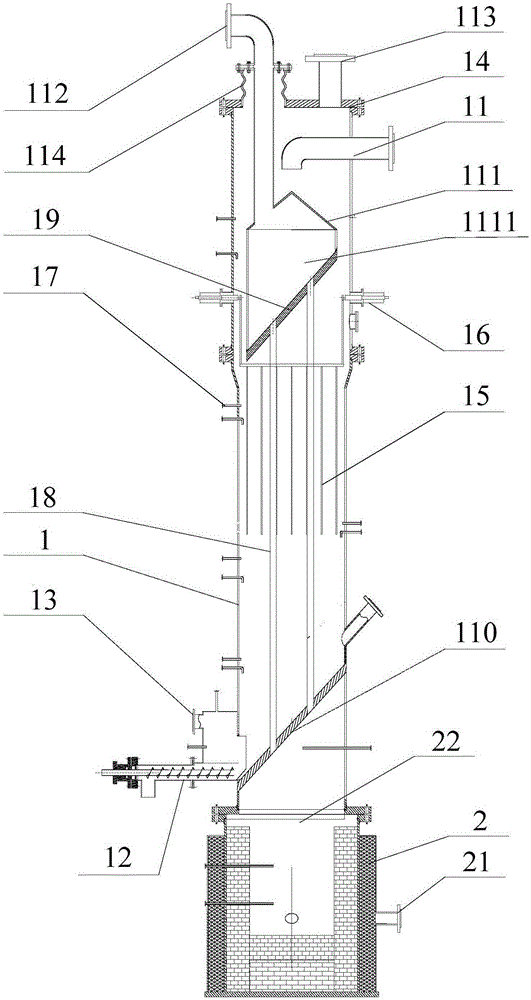

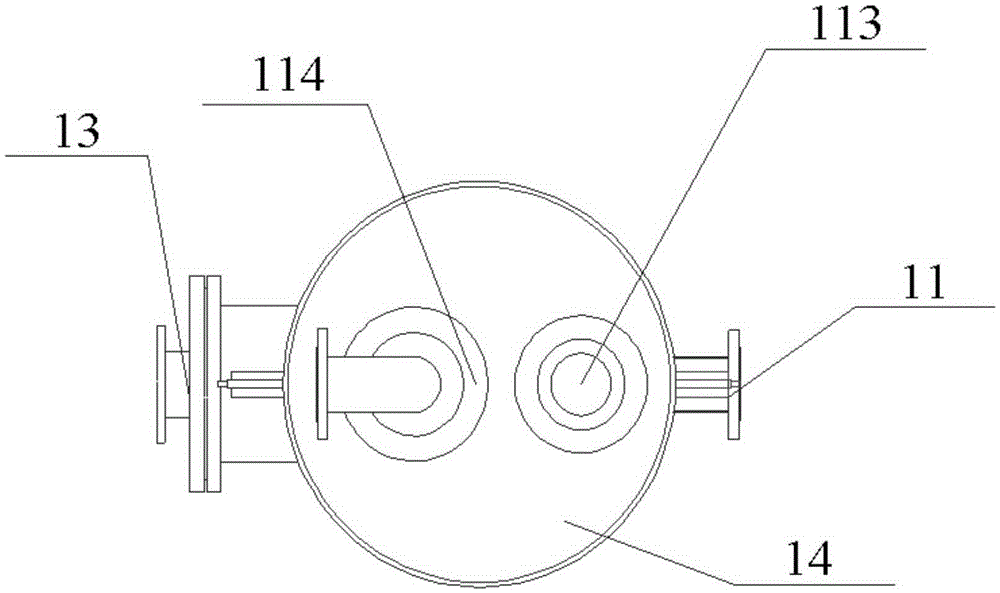

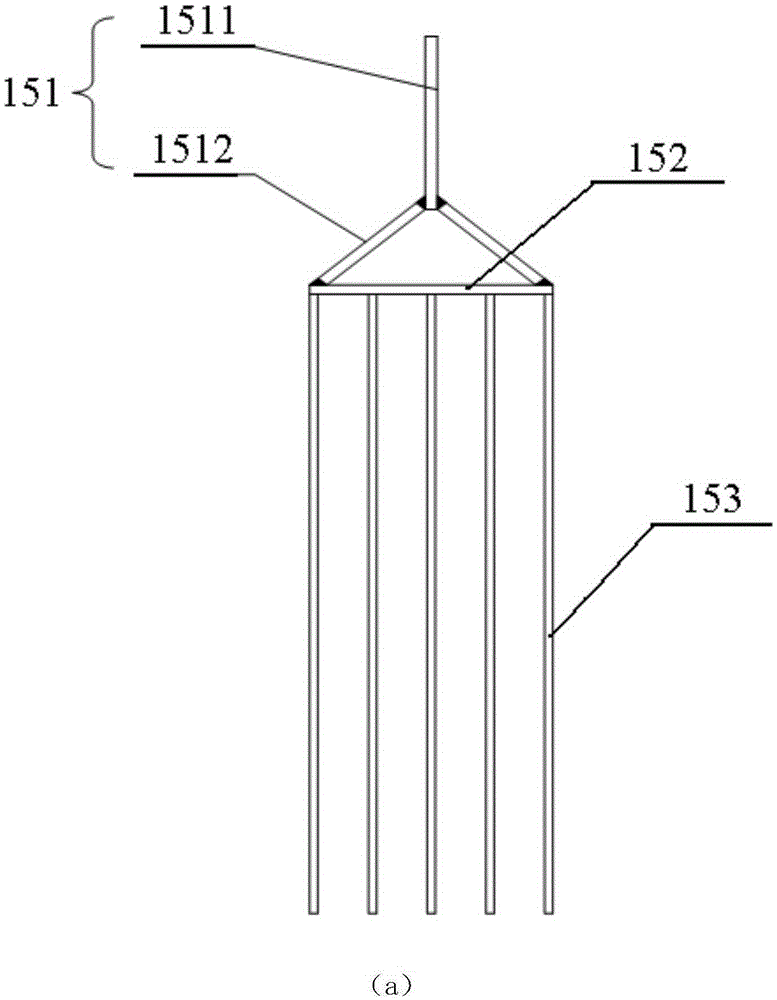

[0030] The invention provides a high-humidity carbon-based raw material external heating pyrolysis reactor, such as figure 1 and figure 2 shown. The pyrolysis reactor comprises a pyrolysis chamber 1 . The upper part of the pyrolysis chamber 1 is provided with a feed inlet 11 , the top head 14 and an explosion-proof port 113 , and the lower part of the pyrolysis chamber 1 is provided with a continuous ash discharge mechanism 12 and a gas outlet 13 . The inner wall of the pyrolysis chamber 1 is sealed with a bottom tube plate 110. The lowest point of the bottom tube plate 110 is flush with the bottom of the ash inlet 127 of the continuous ash discharge mechanism 12. The bottom tube plate 110 is connected to the lower end of the flue gas column tube 18. The upper end of the gas column tube 18 is connected with the top tube plate 19, and the top t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com