Patents

Literature

118results about How to "No risk of explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A method for low-temperature integrated recycle of waste lithium ion batteries

InactiveCN108933307AEfficient separationFully strippedWaste accumulators reclaimingBattery recyclingEngineeringPre treatment

A method for low-temperature integrated recycle of waste lithium ion batteries is disclosed. The method includes (1) subjecting the waste lithium ion batteries to be recycled to discharging and air drying; (2) pre-freezing the pretreated batteries; (3) subjecting the pre-frozen batteries to freezing and cutting for coarse crushing; (4) subjecting the coarsely crushed batteries to freezing and impacting for fine crushing; and (5) sieving the sample after fine crushing, with an oversize product being battery shells and current collector materials and an undersize product being powder containingpositive and negative electrode materials. Through freeze crushing and sieving separation, electrode materials are efficiently separated from the shell material and current collector materials of thelithium ion batteries, low-temperature crushing does not generate heat accumulation so as to avoid the risk of explosion, and does not generate toxic or harmful gas so that the method is energy-saving, environmentally friendly and high in efficiency. Recovered products are good in quality, can be conveniently recycled, and have promotion value.

Owner:CHINA UNIV OF MINING & TECH

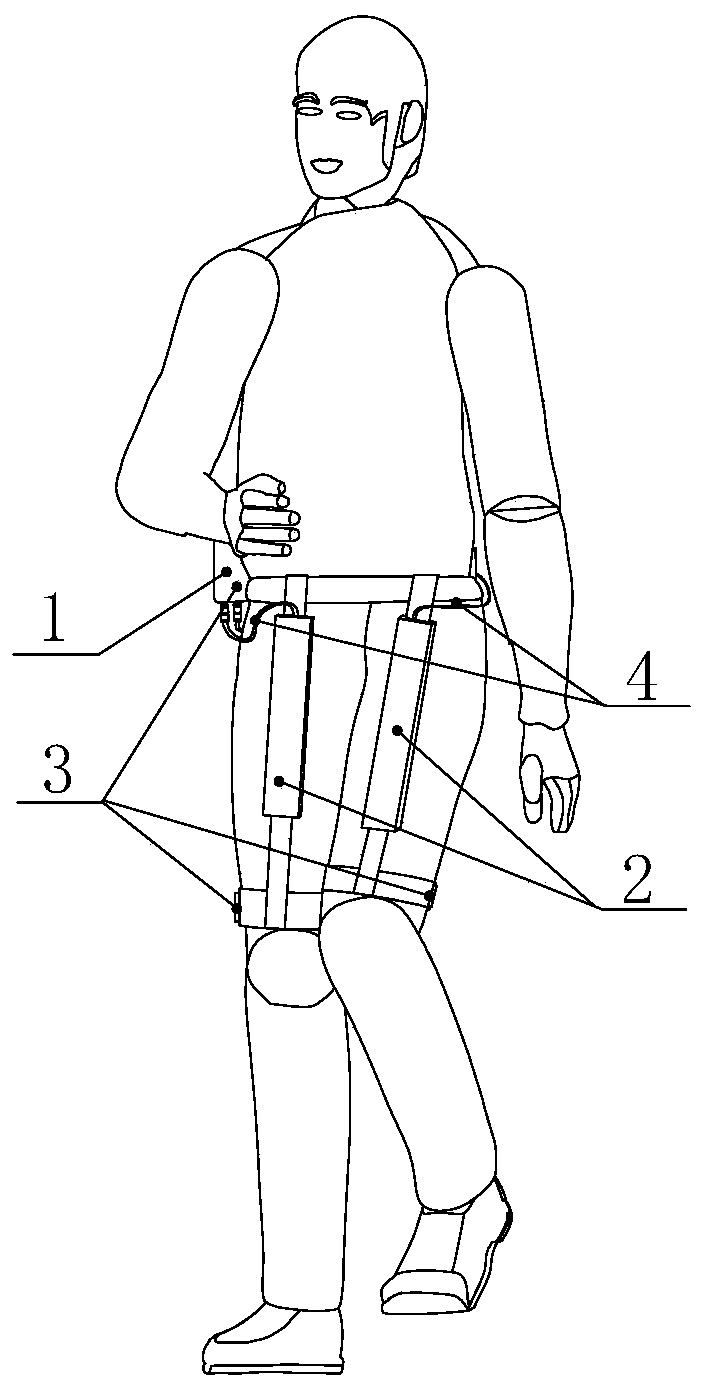

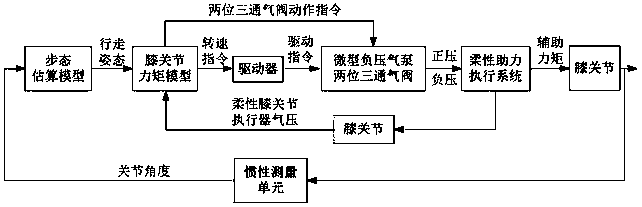

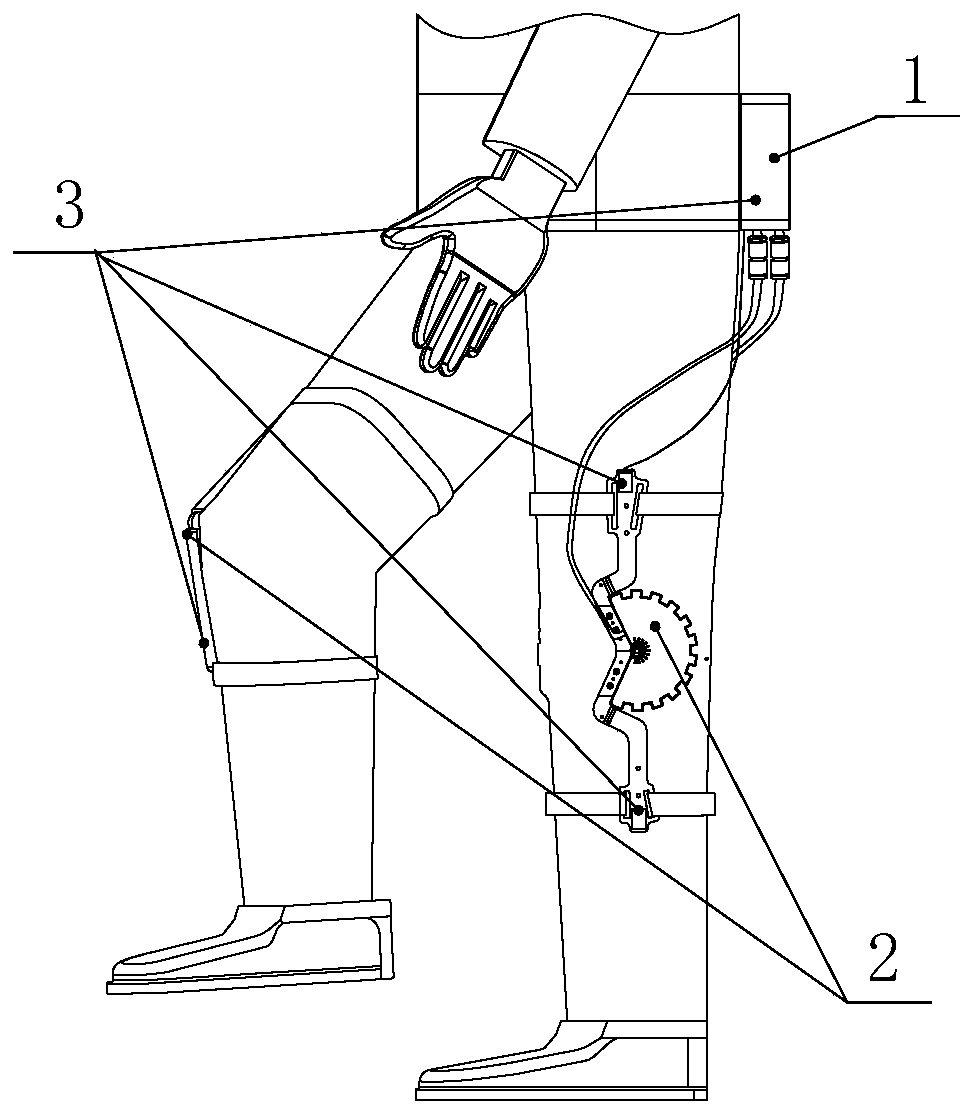

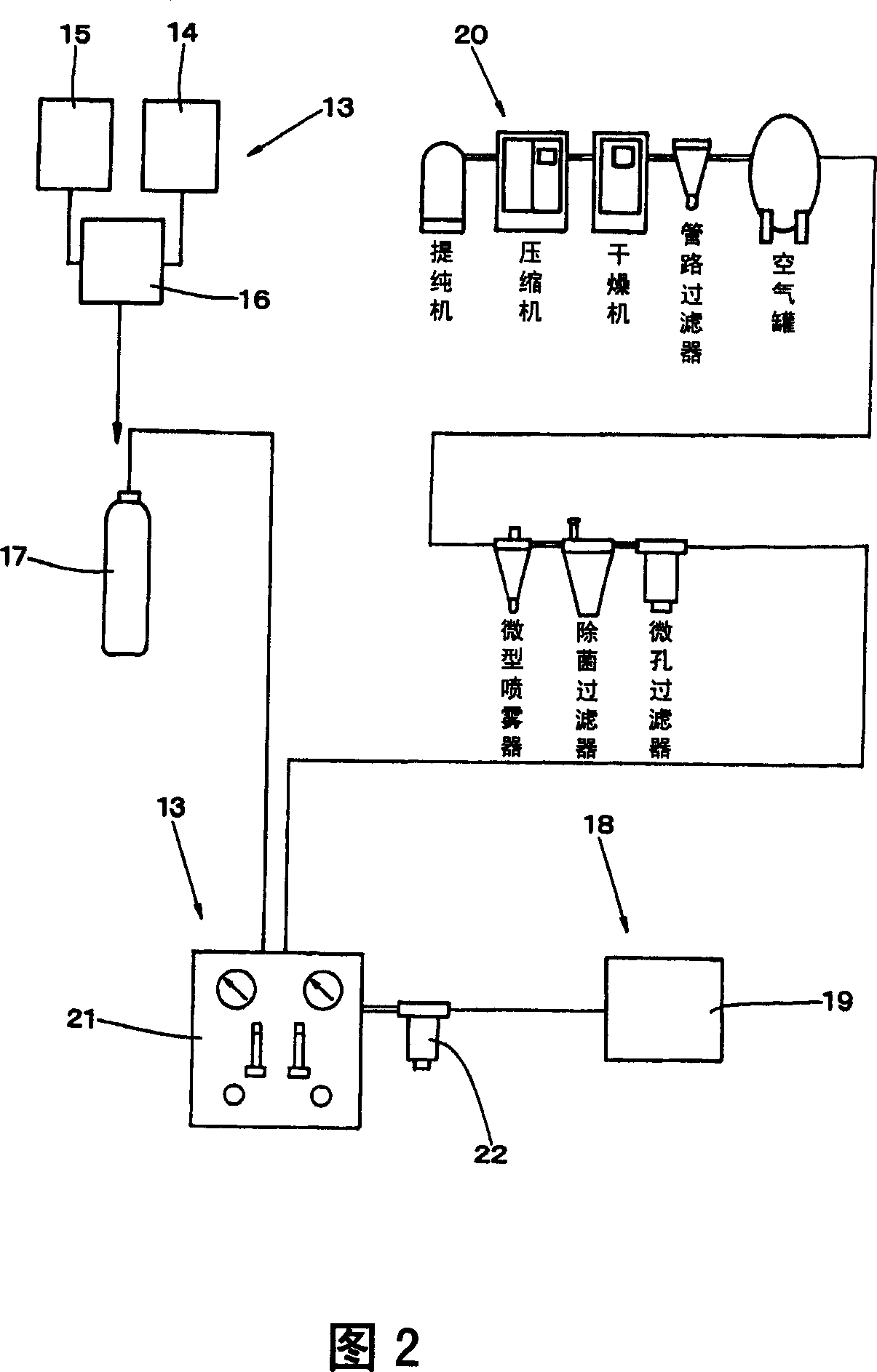

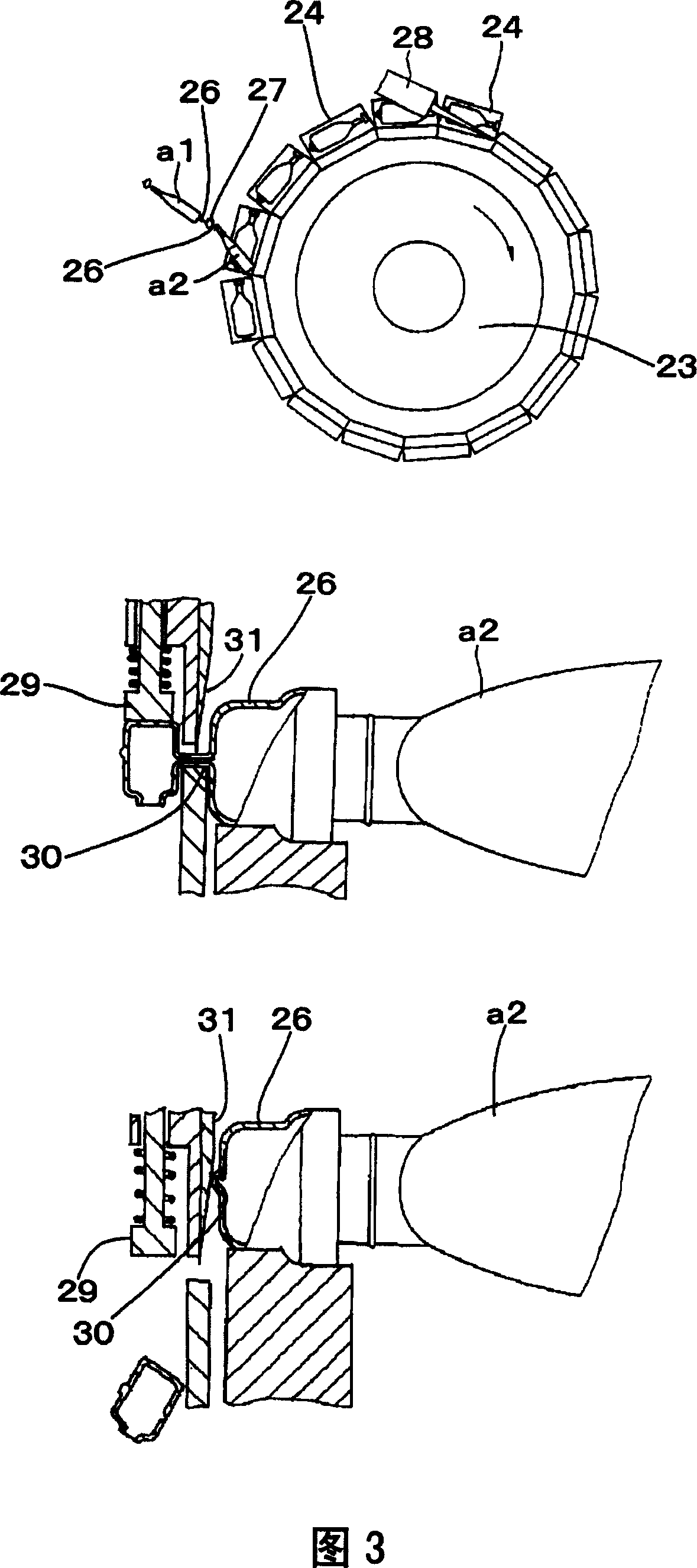

Walking assisting flexible exoskeleton and control method thereof

ActiveCN110303478AOvercome securityOvercome comfortProgramme-controlled manipulatorControl systemControl engineering

The invention discloses walking assisting flexible exoskeleton and a control method thereof. The flexible exoskeleton is mainly composed of a control system, a detection system, a pneumatic flexible execution system and an air pipe assembly. The control system analyzes user movement information and pressure information of the flexible assistance execution system acquired by the detection system, and realizes identifying and understanding of movement intention of lower limbs on the basis of a gait estimation model; and calculating is conducted to obtain corresponding instructions of aerodynamicforce opening and closing, pressure, flow rate and the like based on a hip joint moment model, corresponding actions are executed, real-time control is conducted on the negative pressure input and unloading processes of the pneumatic flexible execution system, the pneumatic flexible execution system can convert air pressure provided by the control system into mechanical energy capable of realizing linear movement in real time, assisting moment required by buckling and stretching of a hip joint is provided in real time according to the walking posture of a user, and the purpose of walking assisting is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

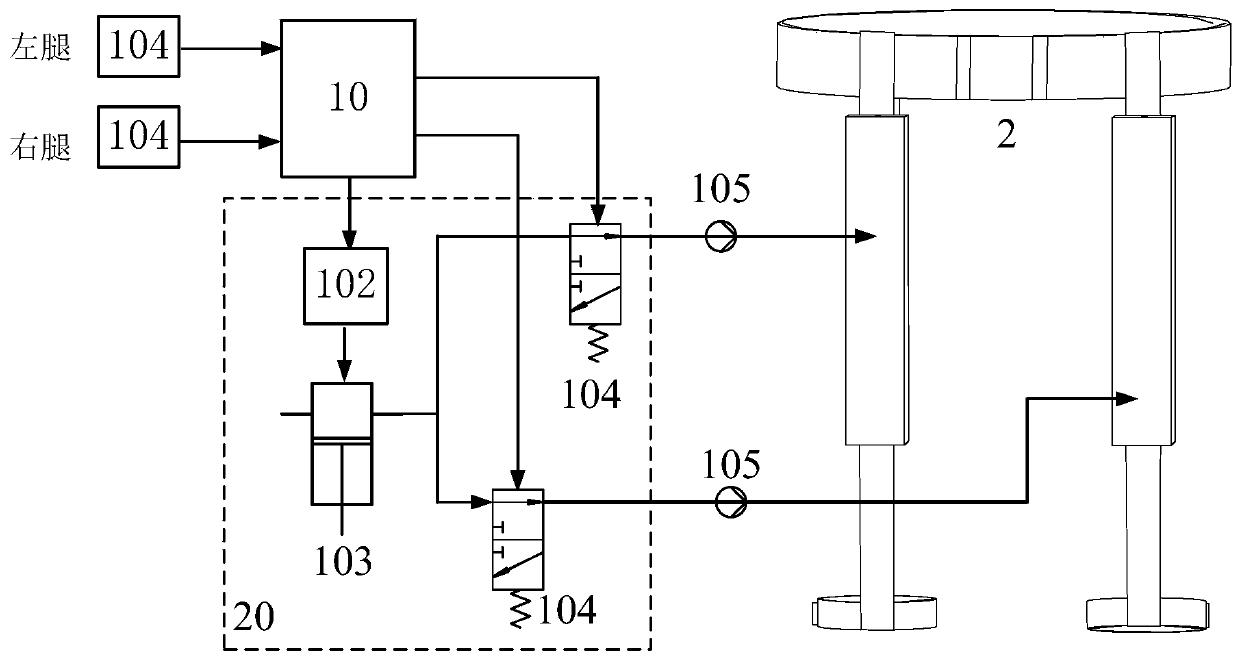

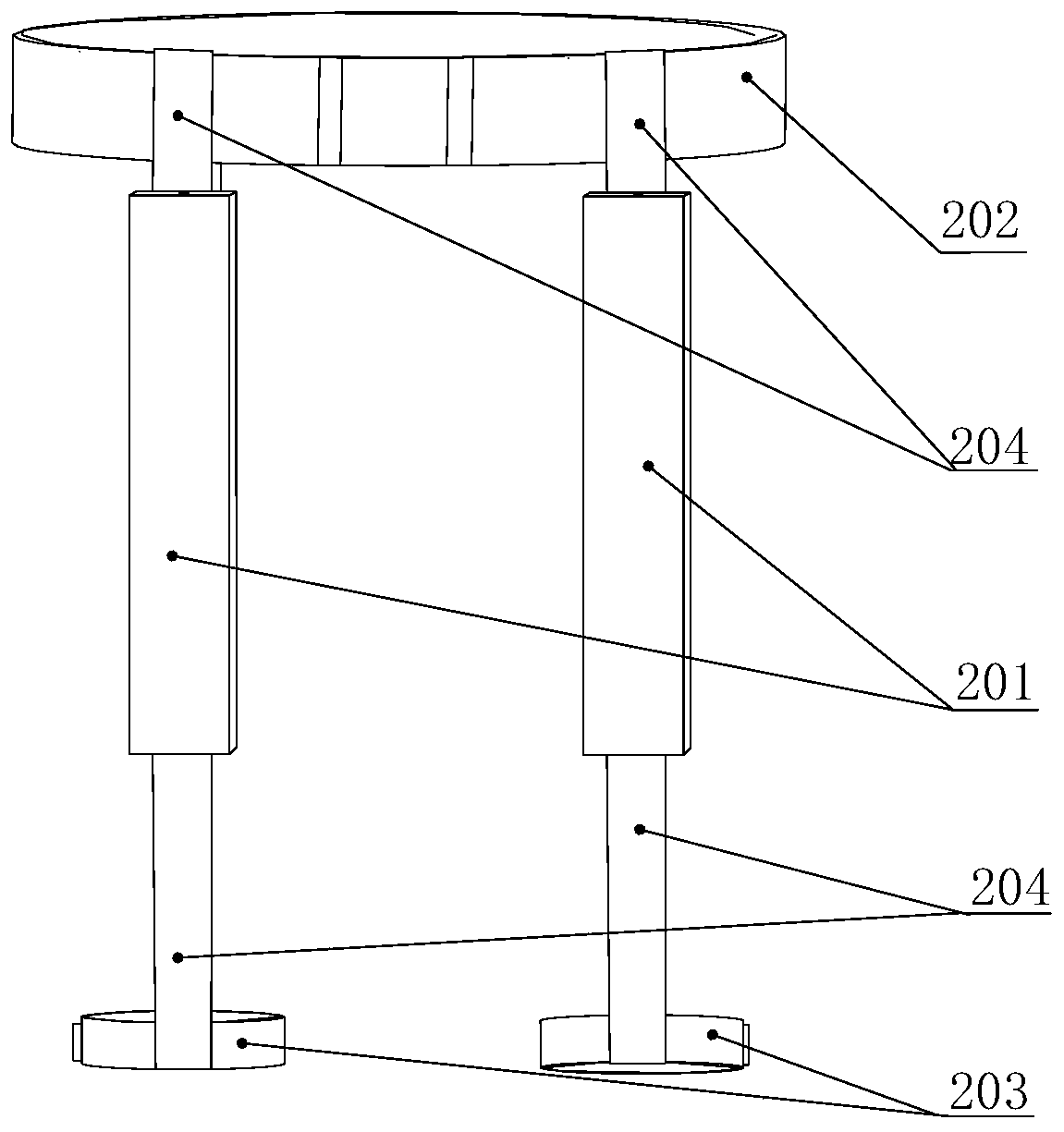

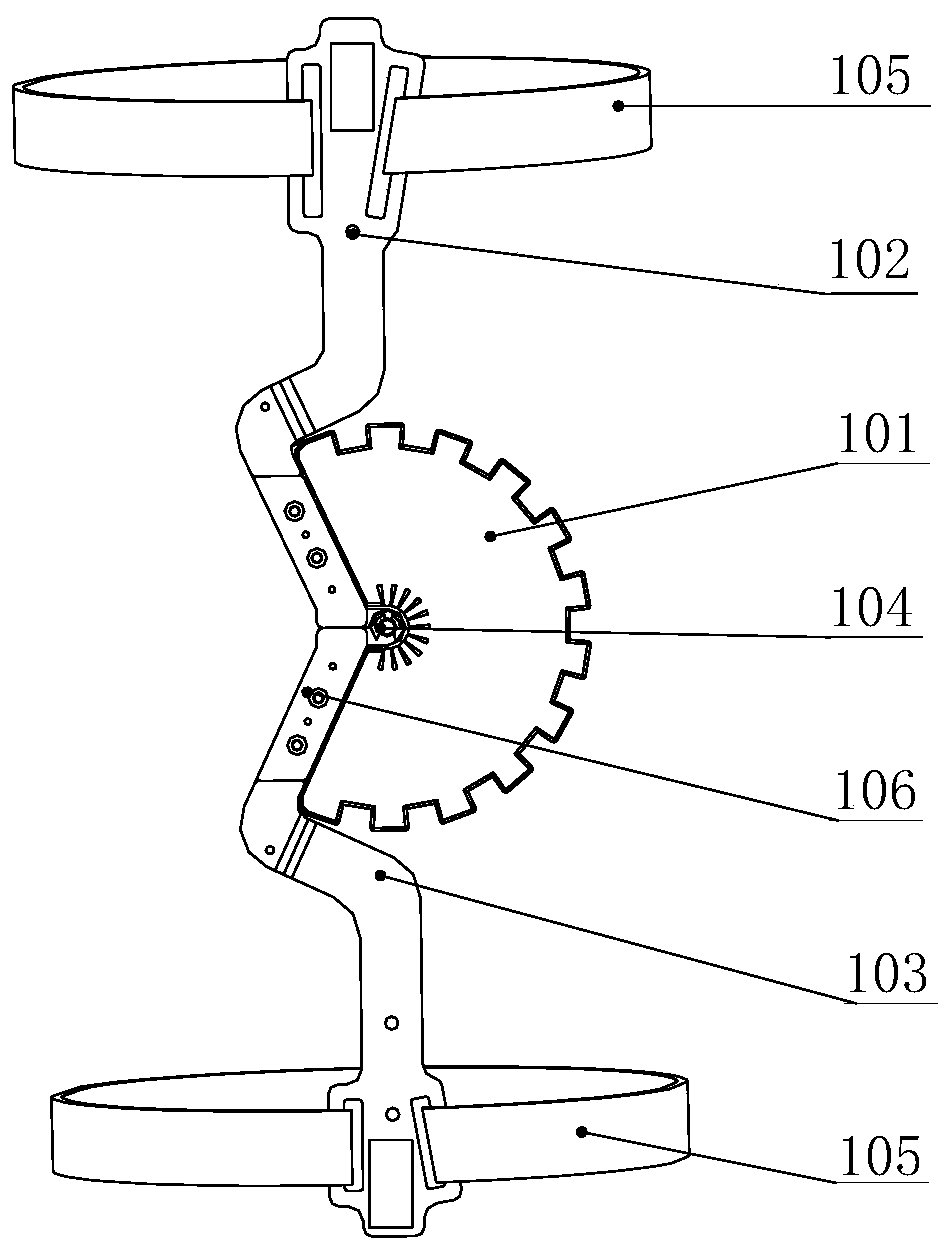

Wearable flexible knee joint exoskeleton and control method thereof

ActiveCN110303479AOvercome securityOvercome comfortProgramme-controlled manipulatorThighPositive pressure

The invention discloses a wearable flexible knee joint exoskeleton and a control method thereof. The wearable flexible knee joint exoskeleton is mainly composed of a control and air pressure output system, a sensing system and a flexible power-assisted execution system, wherein the control and air pressure output system are used for analyzing the user motion information collected by the sensing system and the pressure information of the flexible power-assisted execution system, algorithms such as a gait estimation model and a knee joint torque model are adopted to calculate corresponding instructions such as an aerodynamic force switch, a pressure and a flow speed, corresponding actions are executed, quantitative positive pressure or negative pressure is provided for the flexible power-assisted execution system, the flexible power-assisted execution system transmits the positive-pressure or negative-pressure aerodynamic force provided by the control and air pressure output system to thighs and legs of the left leg and right leg of an user, when the negative pressure is input, the flexible power-assisted execution system generates auxiliary bending torque to assist knee joints to bebent, when the negative pressure is switched to positive pressure input, the flexible power-assisted execution system generates torque which is changed into stretching by bending, the knee joints areassisted to be expanded, and the purpose of auxiliary walking is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

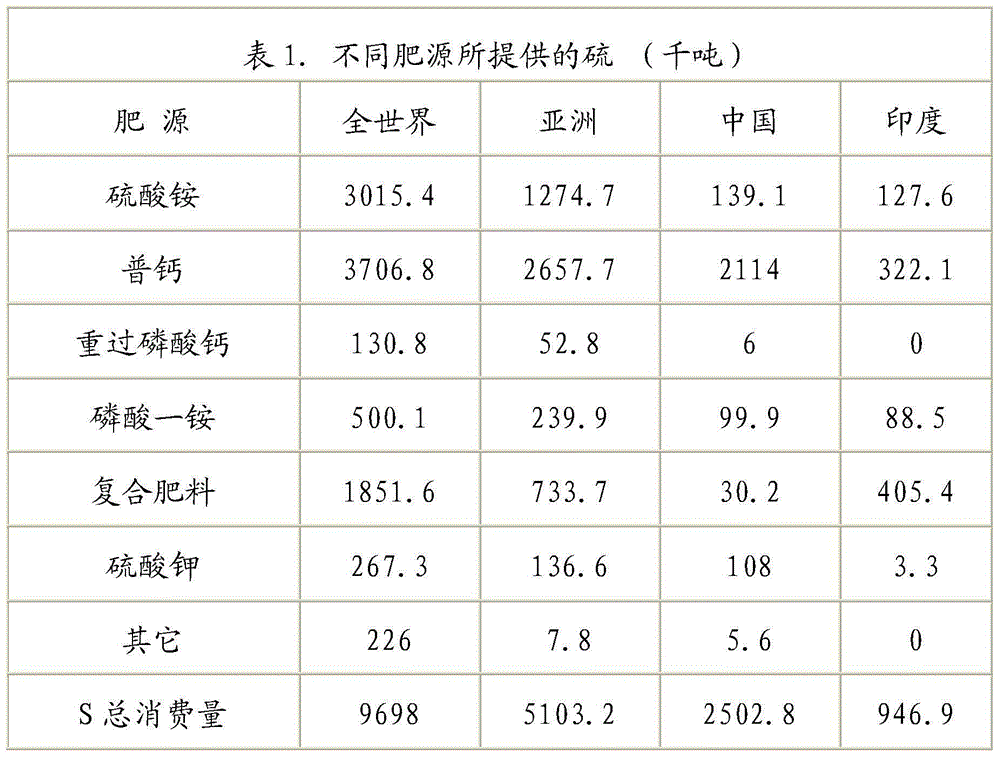

Method for producing fertilizer with high ammonium phosphate sulfate by adopting sulphur

InactiveCN104788161AAdding process is simpleNo risk of explosionFertilizer mixturesWater basedCombustion

The invention relates to a method for producing a fertilizer with high ammonium phosphate sulfate by adopting sulphur. The method is characterized by producing the fertilizer with high ammonium phosphate sulfate by utilizing elemental sulphur; the method comprises the following steps: adding sulphur powder in slurry, a tube reaction tank or washing liquid in the conventional production technology of the ammonium phosphate fertilizer; or / and preparing a sulphur water-based dispersion liquid from sulphur powder of 50-600 meshes, adding the prepared sulphur water-based dispersion liquid in the slurry, the tube reaction tank or the washing liquid, and obtaining the fertilizer with high ammonium phosphate sulfate. According to the method disclosed by the invention, the addition technology of the sulphur is simple, and the conventional production equipment does not need to be greatly modified; the addition is safe, the risks of the combustion and the explosion of the sulphur can be avoided; ammonium phosphate products containing different contents of sulphur can be produced according to demands for fertilizers, and the original nutrients of the ammonium phosphate fertilizers cannot be diluted too much; influence on the granulation of ammonium phosphate can be avoided.

Owner:HUBEI FORBON TECH

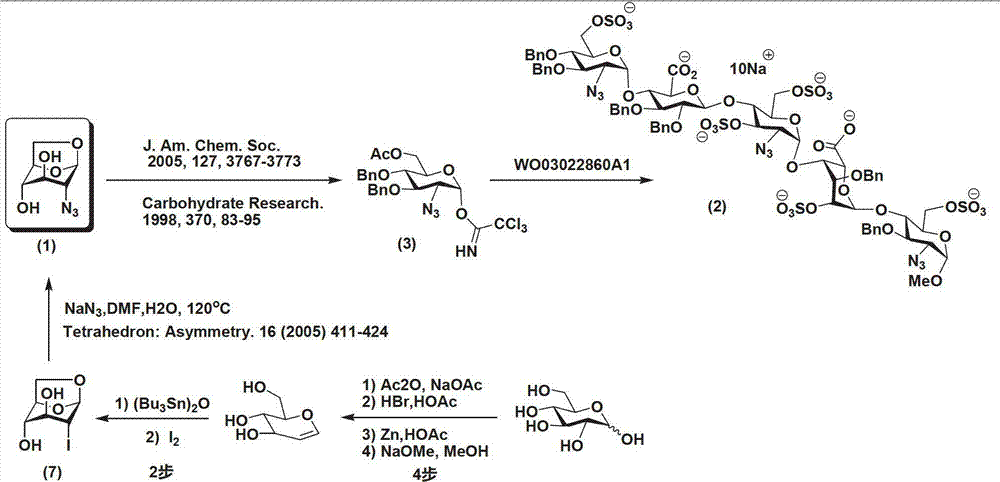

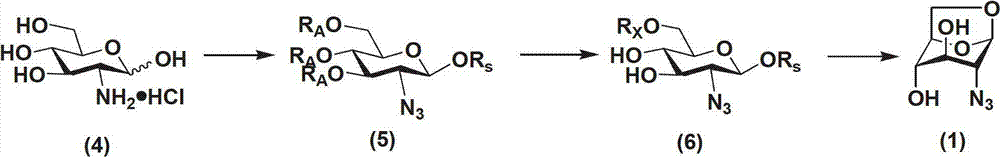

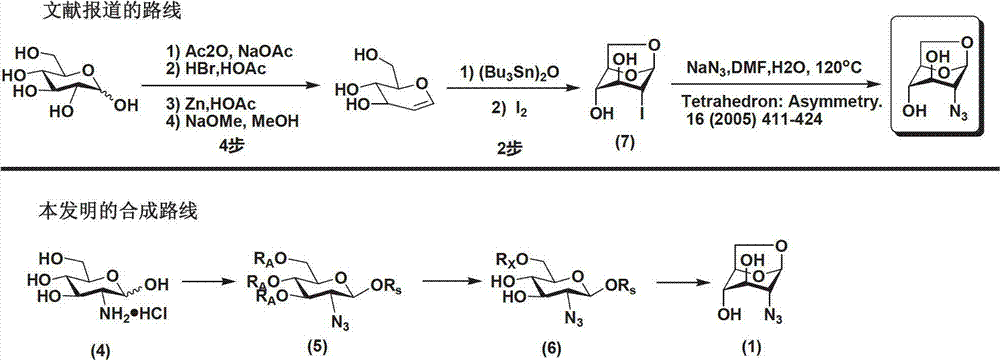

Method for preparing 1,6-Anhydro-2-azido-2-deoxy-beta-D-glucopyranose

ActiveCN102775450AEasy to operateNo risk of explosionSugar derivativesSugar derivatives preparationD-GlucopyranoseImidazole-1-sulfonyl azide hydrochloride

The invention provides a method for preparing the 1,6-Anhydro-2-azido-2-deoxy-beta-D-glucopyranose. At a room temperature, 2-Amido-2-deoxy-D-glucopyranose hydrochloride serves as a raw material, imidazole-1-sulfonyl azide hydrochloride serves as a nitrine reagent, a dowex1X8 resin serves as a acid-binding agent for acylation, silylation and sulfonylation, 1,8-Diazabicyclo-(5,4,0) undec-7-ene or the dowex1X8 resin serves as an alkali reagent for ring closing reaction, and the 1,6-Anhydro-2-azido-2-deoxy-beta-D-glucopyranose is synthesized through nitrine introduction, acylation reaction, silylation reaction, sulfonylation reaction and ring closing reaction in sequence; and the reaction process is represented as formula (I). The 1,-Anhydro-2-azido-2-deoxy-beta-D-glucopyranose can serve as an intermediate for synthesizing anticoagulant drug fondaparinux sodium. The method for preparing the 1,6-Anhydro-2-azido-2-deoxy-beta-D-glucopyranose has the advantages of being mild in reaction, simple in synthetic route, low in cost, safe and reliable, and suitable for large scale production.

Owner:EAST CHINA NORMAL UNIV +2

Method for recycling noble metal from iron alloy

InactiveCN108728645AImprove acid solubility activityImprove acid solubilityProcess efficiency improvementEquipment useOxide

The invention discloses a technology method for noble metal containing iron alloy acid dissolution and activation. The technology method comprises the following steps that firstly, the iron alloy is melted into molten iron, and the temperature of the molten iron ranges from 1,200 DEG C to 1,500 DEG C; secondly, oxide is added in the molten iron in the first step, generated reactant residues are constantly separated from the molten iron, and after the reaction is complete, the molten iron is poured out after the temperature of the molten iron is increased to 1,500 DEG C, and cooling is conducted to the room temperature; thirdly, an acid solution is added in a product of the second step, and after dissolving, the liquid part is filtered out, and a noble metal enriched product is obtained; and fourthly, the noble metal enriched product obtained in the third step is dissolved in aqua regia, filter residues are filtered out, and a noble metal solution is obtained. According to the technology method for noble metal containing iron alloy acid dissolution and activation, the one-time acid dissolution rate of the noble metal is higher than 95%, the total recycling rate of the noble metal can reach 99.9% or above, localization of all technology equipment used in the recycling process can be achieved, and the one-time investment is reduced.

Owner:上海御盾新材料科技有限公司

Harmless treatment method and harmless treatment system for metal lithium waste residue

The invention discloses a harmless treatment method and a harmless treatment system for metal lithium waste residue. The method comprises: providing a liquid phase system, wherein the liquid phase system comprises an oil phase and an aqueous phase, the oil phase and the aqueous phase are layered, and the oil phase is distributed above the aqueous phase, and does not react with metal lithium wasteresidue; adding the metal lithium waste residue to the liquid phase system, and distributing metal lithium waste residue in the oil phase; and pressing the metal lithium waste residue into the aqueousphase, and making the metal lithium react with water while continuously removing the hydrogen generated by the reaction so as to achieve the harmless treatment of the metal lithium waste residue. According to the present invention, the whole reaction of the harmless treatment method is performed on the bottom of the water, such that oxygen can be isolated, the reaction rate of metal lithium and water can be ensured, the treatment efficiency can be improved, and the demands of industrial production can be ensured; and the method is safe and controllable, and cannot cause lithium residue firingand explosion.

Owner:天齐锂业(江苏)有限公司

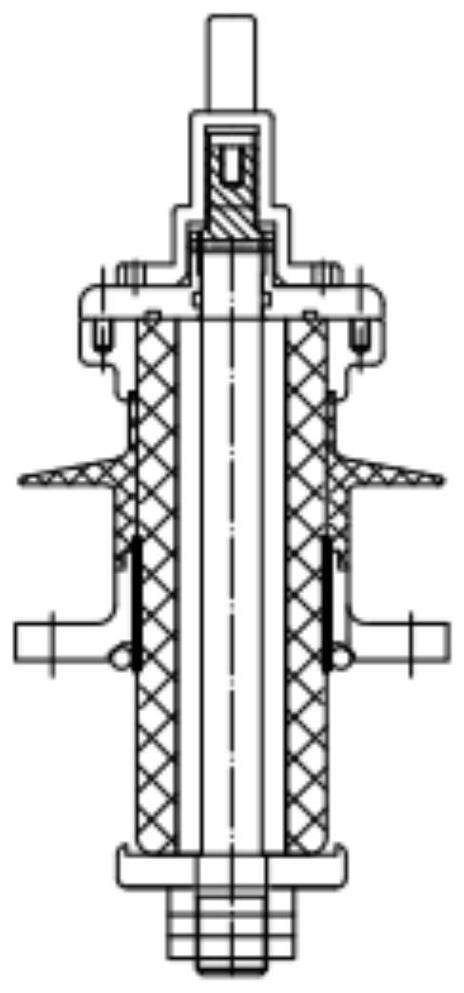

Novel dry-type bush for electric power system

PendingCN112863786AReduce manufacturing costImprove electrical performanceTransformers/inductances coils/windings/connectionsInsulating bodiesEpoxyGlass fiber

The invention discloses a novel dry-type bush for an electric power system. According to the invention, a main insulation core is made of an insulation pipe formed by dipping glass fiber yarns in epoxy resin and conducting pultrude moulding; a semiconductor material is sprayed on the inner cavity wall of the main insulation core, and an equipotential surface is formed on the inner cavity wall of the main insulation core; a current-carrying conducting rod is arranged in the main insulation core in a penetrating manner and is connected with the equipotential surface; a groove is formed in the outer wall of the main insulation core; carbon fibers impregnated with epoxy resin are wound in the groove; a mounting flange is glued on the grounding electrode; a silicon rubber umbrella cover is arranged on the main insulation core; an air end electrode of the grounding electrode is wrapped in the silicon rubber umbrella cover; and a conductive joint and a voltage-sharing ball are respectively installed on two sides of the main insulation core. A wide variety range of bushes can be made in the invention; the voltage levels of the bushes may be in a range of 380V-550kV or higher; the current levels of the bushes may be from several amperes to tens of thousands of amperes; the bushes can be used for an alternating-current power system and a direct-current power system; manufacturing cost is low; and explosion risks are avoided.

Owner:安徽智达电气科技有限公司

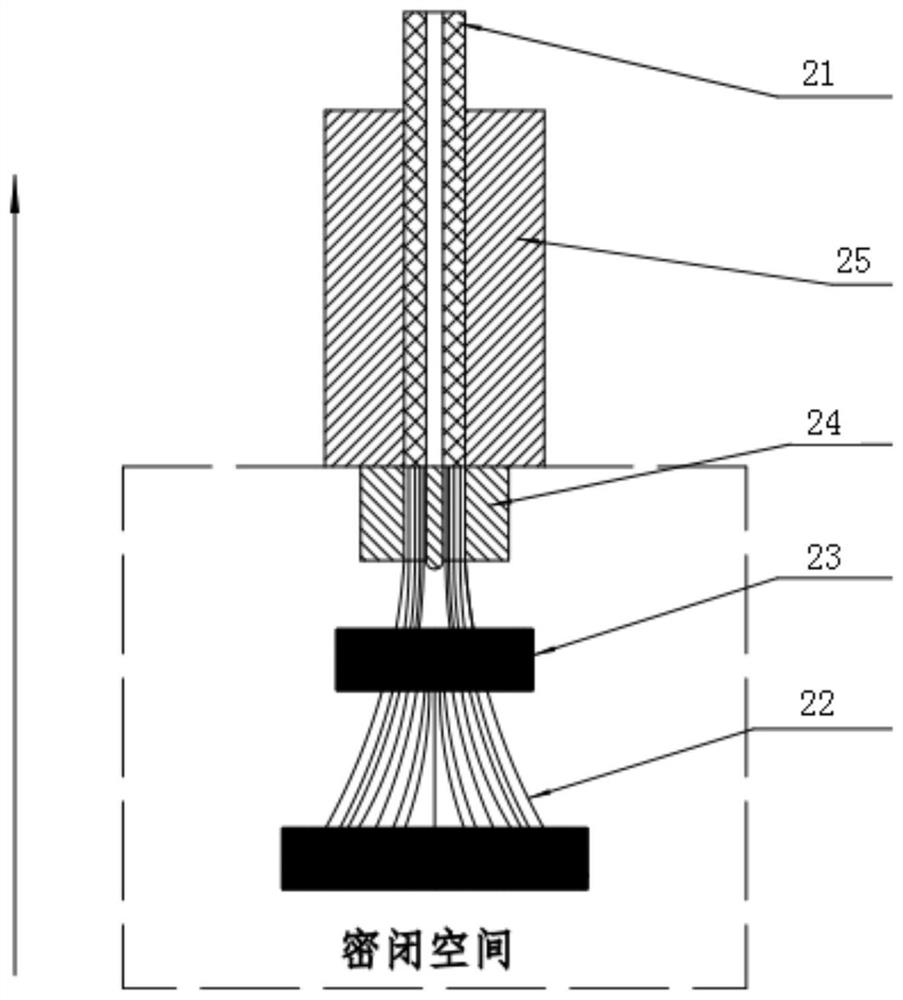

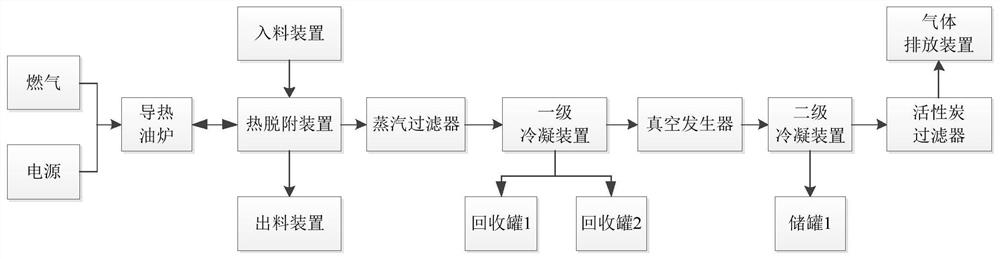

Contaminated soil thermal desorption remediation system and method

PendingCN111644454AEmission complianceEffective barrierDispersed particle filtrationHollow article cleaningActivated carbonEnvironmental engineering

The invention discloses a contaminated soil thermal desorption remediation system and method. The contaminated soil thermal desorption remediation system comprises a contaminated soil thermal desorption device and a tail gas treatment system, wherein the tail gas treatment system is connected with a tail gas exhaust port of the contaminated soil thermal desorption device. The tail gas treatment system comprises a steam filter, a primary condensing device, a vacuum generator, a secondary condensing device, an activated carbon filter and a gas exhaust device which are connected in sequence. Thesystem and the method can significantly reduce the operation energy consumption and repair cost of the system, significantly reduce the maintenance frequency of the system, maintain the safe and stable continuous operation of the system, and improve the thermal desorption effect of the contaminated soil.

Owner:浙江一龙环保科技有限公司

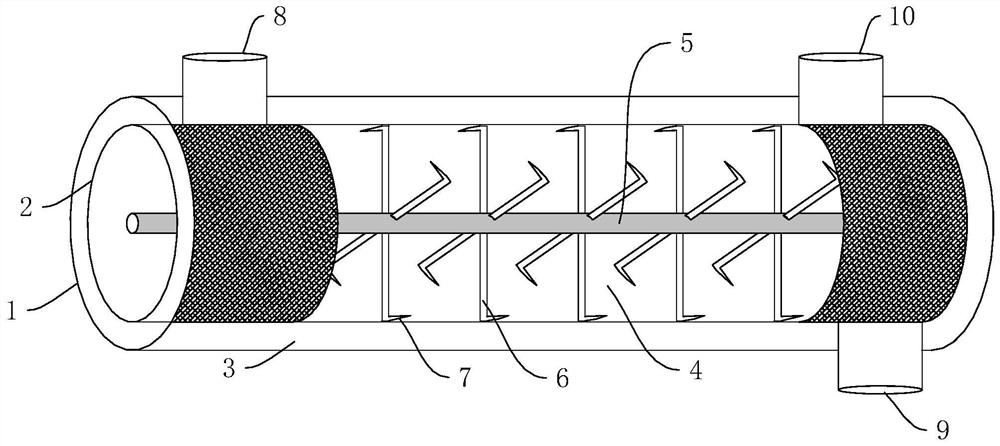

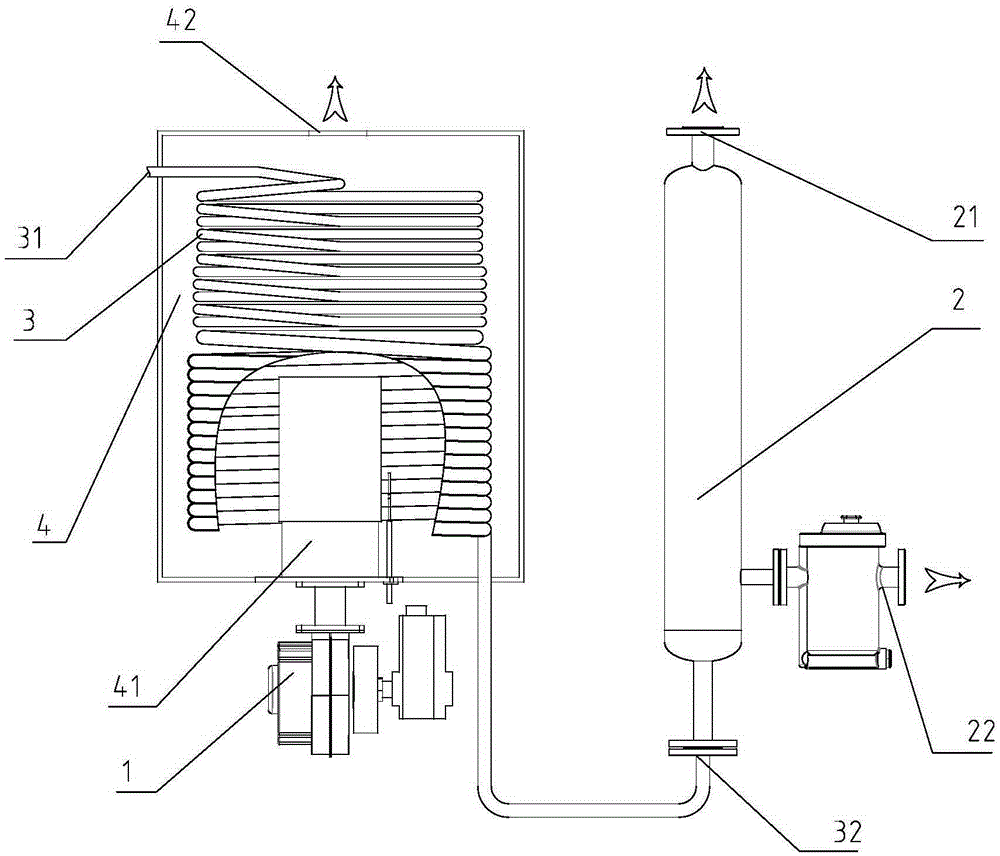

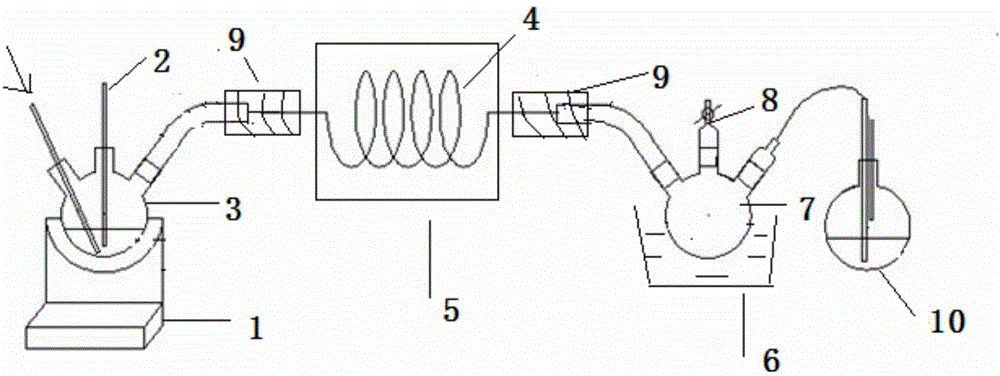

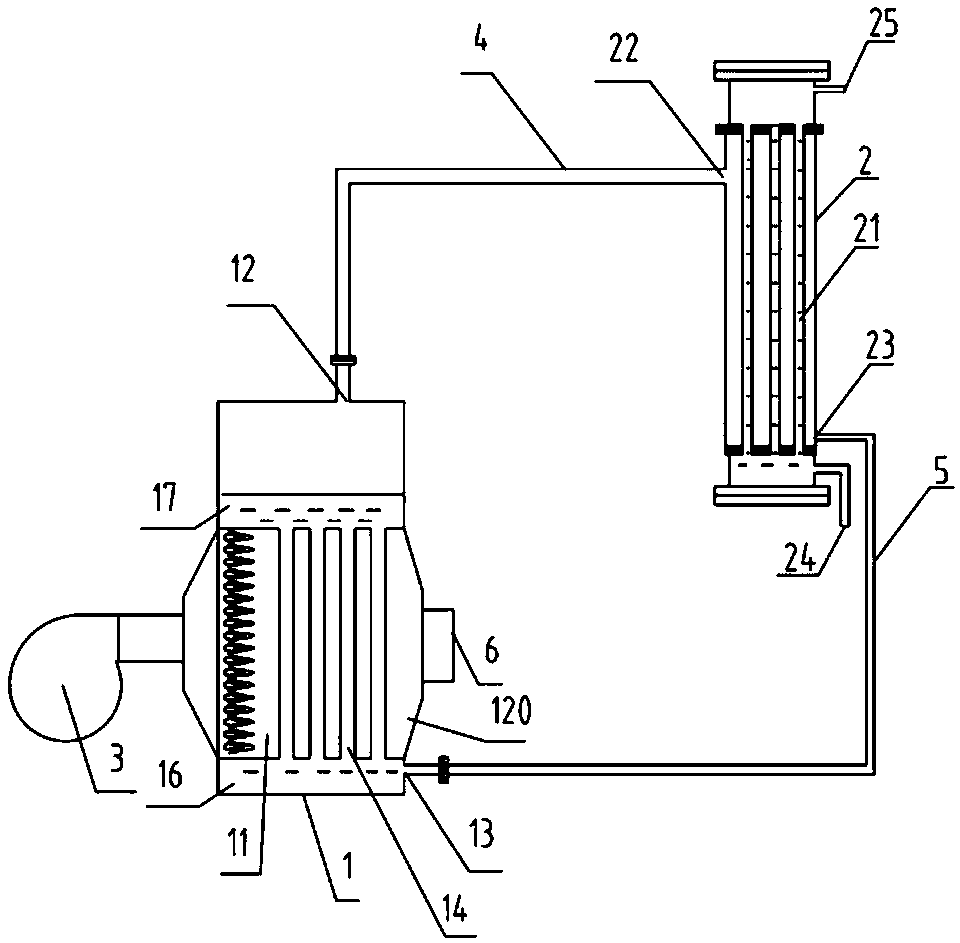

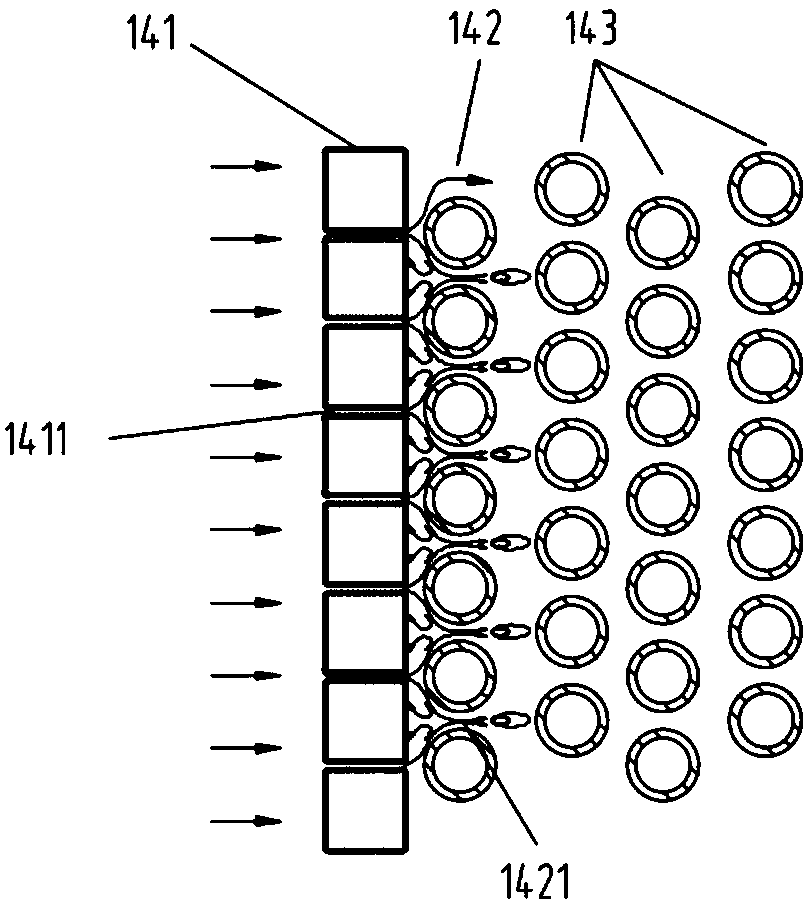

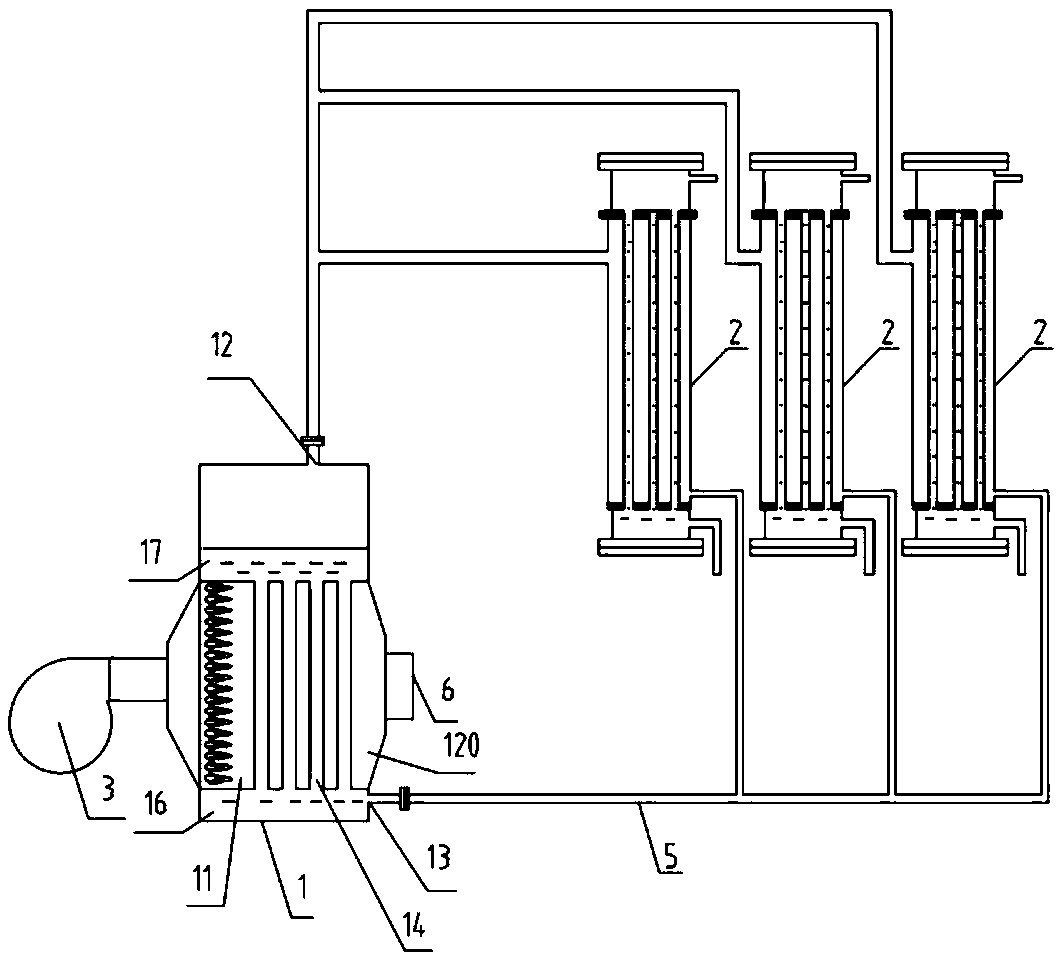

a steam generator

ActiveCN103512018BReduce volumeSmall water capacityLiquid degasificationSteam generation using hot heat carriersCombustorCombustion chamber

The invention discloses a steam generator, and relates to the field of steam equipment. The technical problems that in the prior art, a drum type boiler is started slowly when producing steam, is large in heat waste and has explosion risks are solved. The steam generator comprises a coil pipe, a combustor, a steam separator and a feed water source, wherein the coil pipe is connected between the steam separator and the feed water source, a combustion chamber is formed in the combustor, the coil pipe is arranged in the combustion chamber, and a smoke inlet pipe is arranged on the combustion chamber and extends into the coil pipe. The air-fuel ratio can be accurately controlled through the combustor, and after radiation heat transfer, smoke gas flows through the outer side of the coil pipe in the combustion chamber to exchange heat with fluid in the coil pipe; in comparison with boiler heating, the coil pipe is small in size and water capacity and free of the explosion risks, the coefficient of heat transfer of the coil pipe is high, heating loads per unit are large, steam generating speed is high, smoke exhaust temperature is low, and the use ratio of energy is high.

Owner:ZHEJIANG UNIPOWER BOILER CO LTD

High concentration organic waste gas treatment method and high concentration organic waste gas treatment apparatus

ActiveCN106362552AWill not interfere with normal operationAvoid wastingDispersed particle separationIncinerator apparatusExhaust gas emissionsEmission standard

The invention discloses a high concentration organic waste gas treatment method, which comprises that (1) high concentration organic waste gas enters a diesel oil absorption device, such that the organic matter concentration in the waste gas is stabilized at 5000-35000 mg / m<3> after treatment; (2) by examining and calculating the waste gas emission amount and the organic matter concentration in the step (1), the existing heating furnace having an appropriate wind distribution amount is selected, such that the organic matter concentration is less than 200 mg / m<3> and the oxygen consumption amount of the oxidation pollutant is less than 0.05% after the waste gas and the heating furnace wind distribution air are mixed; (3) under the premise of the step (2), the absorbed waste gas in the step (1) is introduced into a gas mixer according to a certain ratio, and is mixed with the heating furnace wind distribution air; and (4) the mixed gas is conveyed into the heating furnace to burn, and the purified gas achieves the emission standard. According to the present invention, the diesel oil is used to absorb the organic matter in the waste gas and stabilize the organic matter concentration, and the existing suitable heating furnace is selected according to the concentration, such that the normal running of the heating furnace and the wind distribution fan cannot be interfered, and the explosion risk and the insecurity hidden danger do not exist.

Owner:CHINA PETROLEUM & CHEM CORP +1

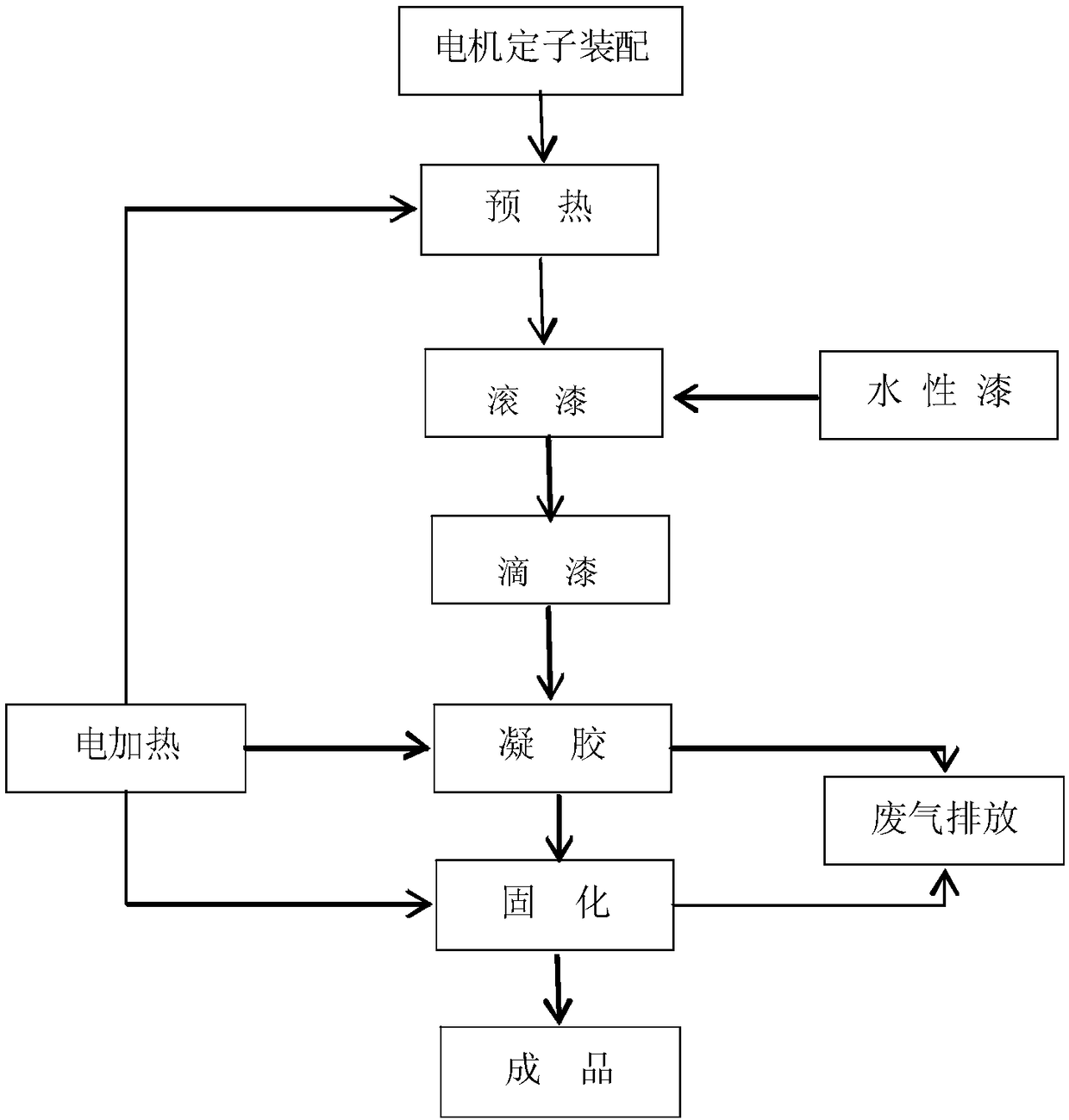

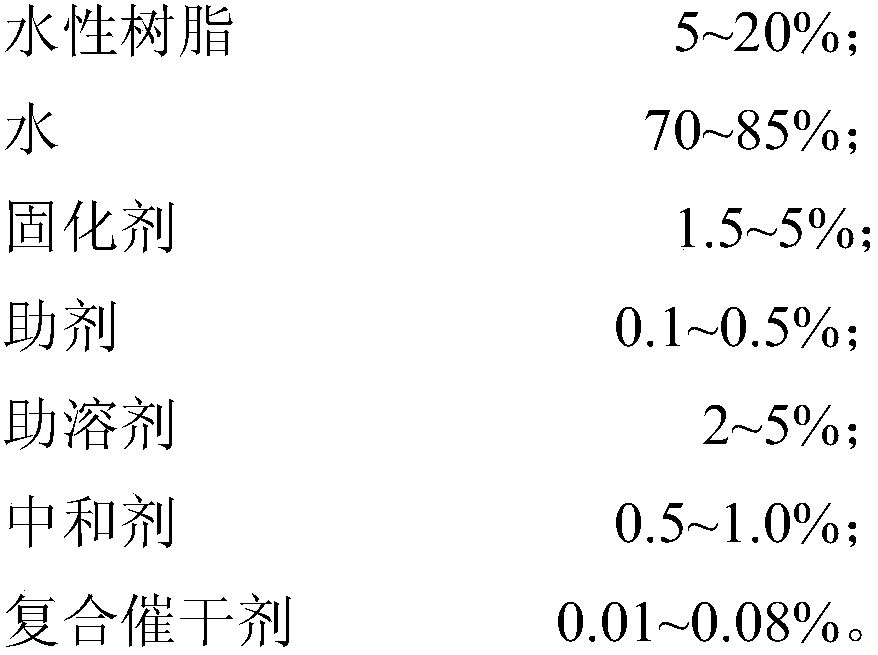

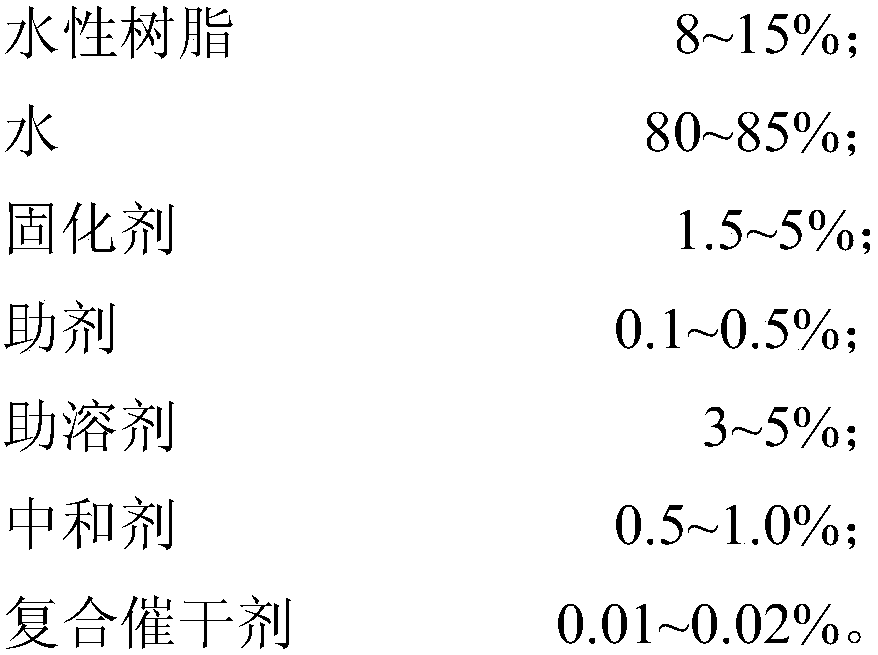

Aqueous dipping insulating paint for insulation treatment of motor of electromobile and roll dipping process for motor of electromobile

ActiveCN108441089AHigh bonding strengthImprove insulation performanceSiccativesInsulatorsLacquerZinc

The invention discloses aqueous dipping insulating paint for insulation treatment of a motor of an electromobile. The aqueous dipping insulating paint comprises aqueous resin, a curing agent, auxiliaries, water and a composite drier, wherein the composite drier comprises a zinc drier, a calcium drier and a cobalt drier. According to the aqueous dipping insulating paint for the insulation treatmentof the motor of the electromobile, provided by the invention, under the condition of high paint coating amount, the aqueous dipping insulating paint is high in drying rate, moisture cannot be remained inside paint films, and cured paint films have excellent bonding strength and insulation resistance, so that the aqueous dipping insulating paint is particularly applicable to a roll dipping processfor the motor of the electromobile.

Owner:浙江博菲电气股份有限公司

Technology method for extracting precious metal from homogeneous phase waste liquid

The invention discloses a technology method for extracting precious metal from homogeneous phase waste liquid. The technology method includes the steps that firstly, the homogeneous phase waste liquidis heated to 80 DEG C-300 DEG C, then an adsorbing agent is added in the heated homogeneous phase waste liquid, stirring and adsorbing are conducted continuously, an adsorption solid phase containingprecious metal and lean phase waste liquid are obtained through filtering separation, and the adsorption solid phase and the lean phase waste liquid are cooled to the room temperature respectively; the obtained lean phase waste liquid is subjected to proper distillation separation, triphenylphosphine and a light organic phase are obtained; the obtained adsorption solid phase containing the precious metal is subjected to high-temperature firing treatment so that organic matter can be removed, and solid slag containing precious metal is obtained; and the obtained solid slag containing the precious metal is subjected to acid liquid dissolving, then purification is conducted, and pure precious metal is obtained. The technology method for extracting the precious metal from the homogeneous phase waste liquid has the beneficial effects of being low in cost, high in recovery rate, easy and convenient to operate, environment-friendly and the like.

Owner:上海御盾新材料科技有限公司

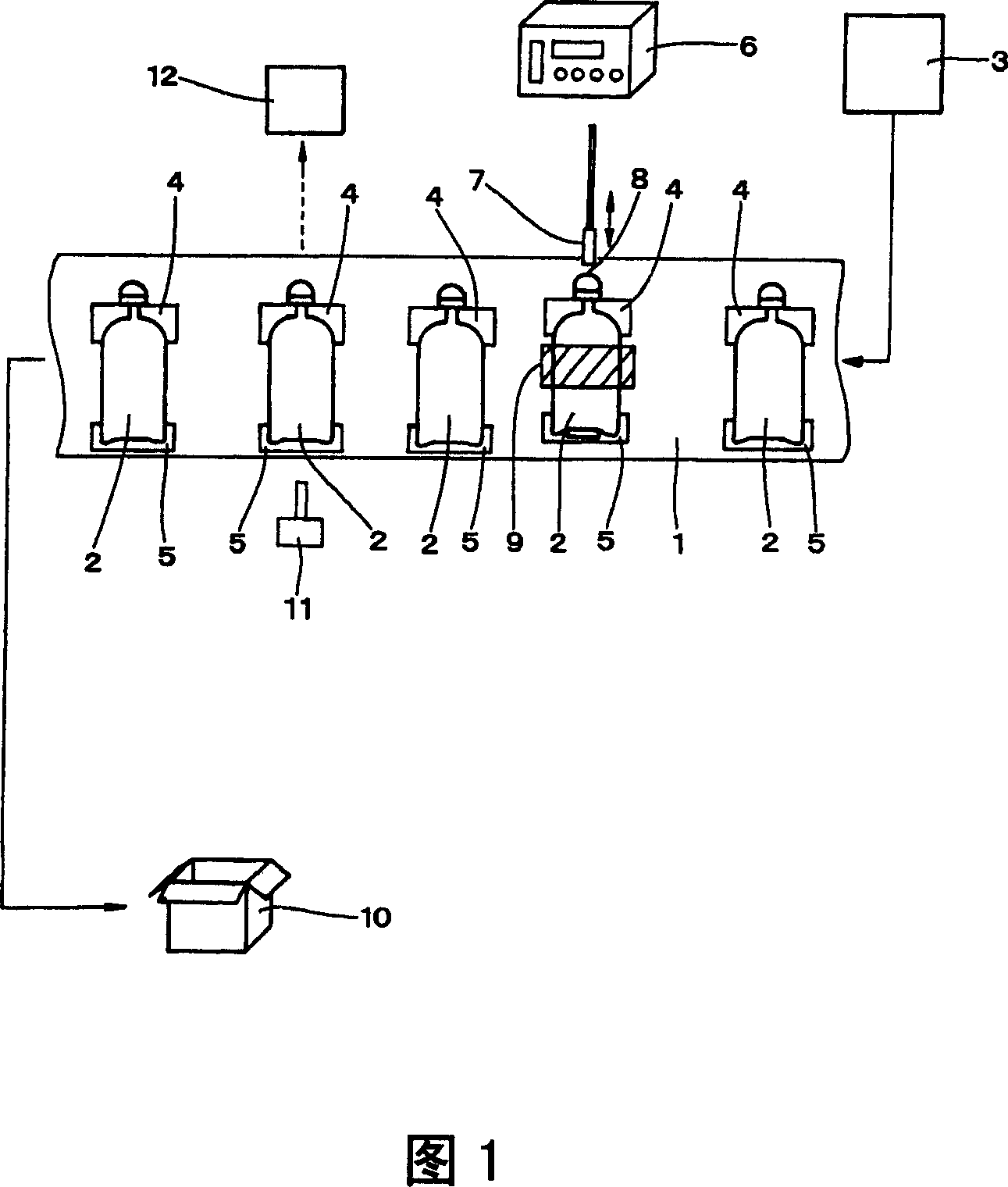

Hole checking method of blow molding article or other plastic hollow body

InactiveCN1975414AAccurate detectionLess quantityMeasurement of fluid loss/gain rateMaterial analysisBlow moldingHydrogen

The present invention provides a small hole inspection method of blow molded products, which is suitable for automatic blow molding process and can accurately detect the small holes of blow molded products with a very small amount of hydrogen in a very short time. This method is a method of sealing a blow-molded product blow-molded with a pressure fluid containing hydrogen, detecting hydrogen leaking to the outside when the sealed blow-molded product is squeezed from the outside, and determining whether the blow-molded product has pinholes. Melt and knead the synthetic resin and extrude the cylindrical parison from the extruder, then blow mold the parison in the mold with the pressure fluid containing hydrogen, take out the blow molded product from the mold, and seal the blow molding The pressurized fluid inlet hole at the time, by detecting the hydrogen leaking to the outside when the blow molded article with the pressure fluid inlet hole closed is squeezed from the outside, it is determined whether the blow molded article has small holes.

Owner:KYORAKU CO LTD

Molecular sieve composite material used for VOCs rotating wheel adsorption, and preparation method thereof

ActiveCN109173589ALow costImprove adsorption capacityGas treatmentOther chemical processesSodium BentoniteAbsorption capacity

The invention provides a molecular sieve composite material used for VOCs rotating wheel adsorption, and a preparation method thereof. The molecular sieve composite material used for VOCs rotating wheel adsorption is prepared from, by weight, 20 to 35 parts of high silicon ZSM-5 molecular sieve, 65 to 80 parts of bentonite, 2 to 6 parts of ammonium fluosilicate, 10 to 15 parts of silica sol, and 50 to 150 parts of deionized water. According to the preparation method, cheap porous natural clay-bentonite is used for replacing expensive artificially synthesized molecular sieve at a large ratio, and chemical modification method is adopted further so as to reduce material cost and satisfy absorption performance requirements. Compared with the prior art, the advantages are that: no organic solvent is adopted, the preparation method is safe, cost is low, product performance is excellent, inlet gas xylene concentration ranges from 550 to 750mg / m3, gas inlet air speed ranges from 20000 to 120000h<-1>, absorption capacity reaches 40 to 60mg / g, and the performance is better than that of commercially available Y-type and common ZSM-5 molecular sieve.

Owner:芜湖格丰环保科技研究院有限公司

Device and method for synthesizing carbonyl fluoride

The invention belongs to the fields of fluorine chemical engineering and electronic industrial gases, and particularly relates to a method and a device for synthesizing carbonyl fluoride. The method comprises the following steps of using perfluoroalkyl iodide as a raw material, and making the perfluoroalkyl iodide be in an oxygen atmosphere to obtain the carbonyl fluoride in a heating condition. The heating condition is that the heating temperature is 250 DEG C to 650 DEG C; the concentration of oxygen is 20 to 100 percent; the speed at which the oxygen is introduced is 100ml / min to 500ml / min. According to the method and the device for synthesizing the carbonyl fluoride, the perfluoroalkyl iodide is adopted as a reactant; a brand-new method is provided for producing the carbonyl fluoride; the use of strong-corrosion and high-toxicity gases of fluorine, phosgene and the like is avoided; the use of such a greenhouse gas of trifluoromethane is also avoided; a reaction process is relatively mild; a too high temperature is not needed; further, risks of explosions do not exist; crucially, gas-phase by-products of carbon dioxide or hydrogen fluoride and the like are not generated in a reaction product; the obtaining of high-purity carbonyl fluoride is facilitated.

Owner:天津长芦新材料研究院有限公司

Application of hydrogen saturated saline

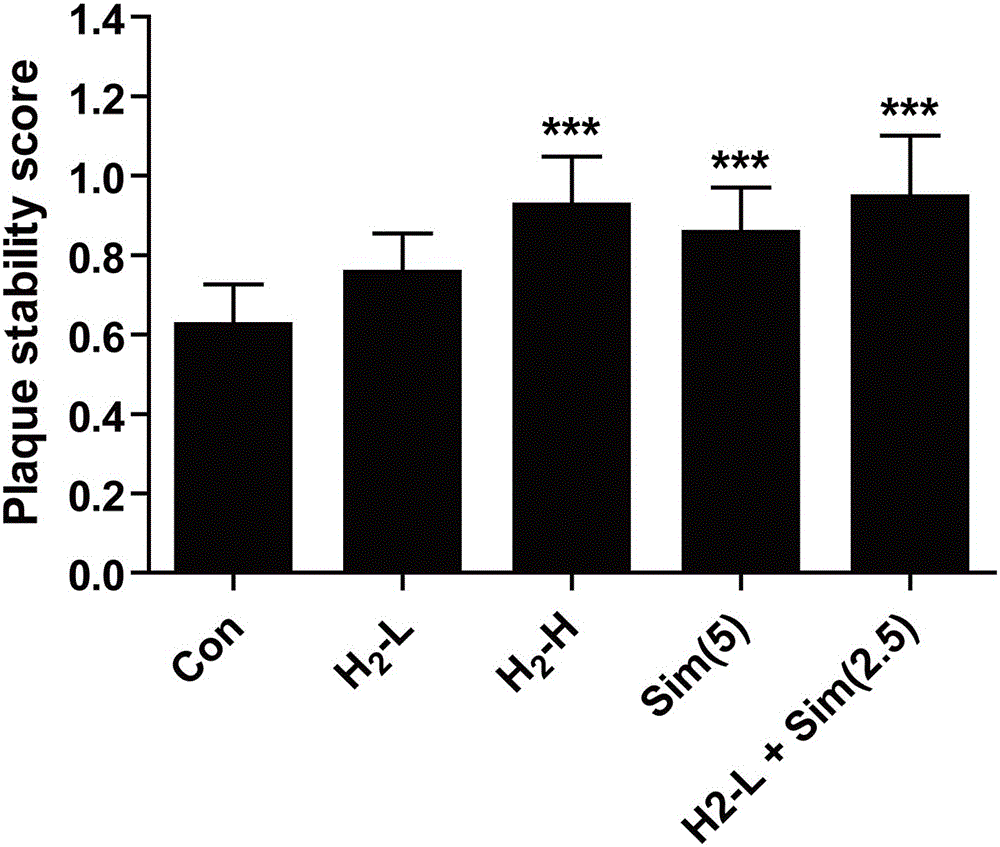

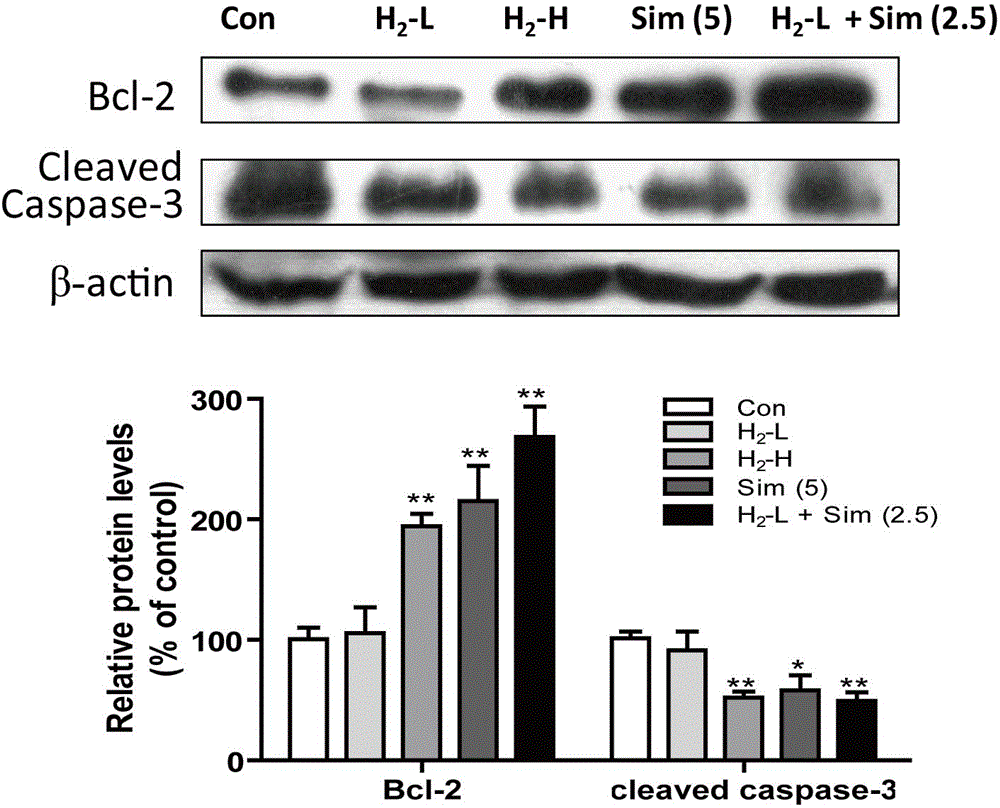

ActiveCN105079025AEasy to makeHigh injection concentrationInorganic active ingredientsCardiovascular disorderSide effectVulnerable plaque

The invention relates to application of hydrogen saturated saline in preparation of drugs for stabilizing atherosclerotic plaques. The application has the advantages that a novel use of the hydrogen saturated saline is provided, and besides a function of inhibiting formation of atherosclerotic plaques, other functions of the hydrogen saturated saline such as stabilizing the atherosclerotic plaques and enabling the atherosclerotic plaques to be rarely vulnerable are disclosed for the first time; the hydrogen saturated saline is simple to prepare, high in injection concentration, convenient to use, free of explosion risk, low in cost and free of side effects; animal experiment results show that the hydrogen saturated saline has great therapeutic advantages, the risk of patients with vulnerable plaques to suffer drug side effects is greatly decreased, and the medical cost is greatly lowered.

Owner:TAISHAN MEDICAL UNIV

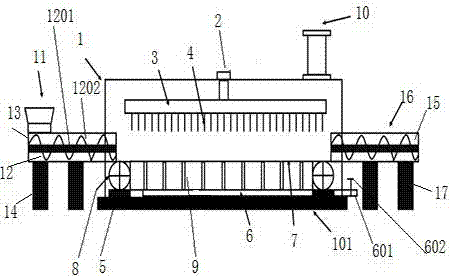

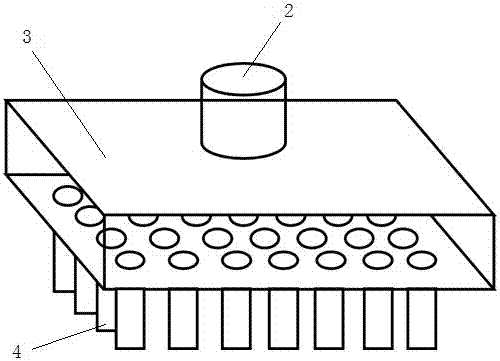

Rubbish heat drying device and method

PendingCN107116089AEfficient use ofHigh degree of automation controlTransportation and packagingSolid waste disposalProcess engineering

The invention relates to a rubbish heat drying device and method. The rubbish heat drying device comprises a feeding system, a drying box and a discharging system; the drying box comprises a purging system, a conveying system, a collecting system, a smoke discharging system and a drying box base, and the purging system comprises an air inlet, a smoke chamber, a purging device and a control device; the purging device comprises a plurality of purging needles and a plurality of purging baffles, the multiple purging needles arranged in an array manner are located below the smoke chamber and are communicated with the smoke chamber; and a base of the conveying system is connected with the drying box base to form a middle cavity, and the collecting device is located in the middle cavity. High temperature flue gas generated by a rubbish heat treatment system in the prior art is used and reused to the rubbish pre-treatment drying stage, and a contact type heating manner is adopted for deeply drying rubbish; and the device is simple in structure and high in automatic control degree.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

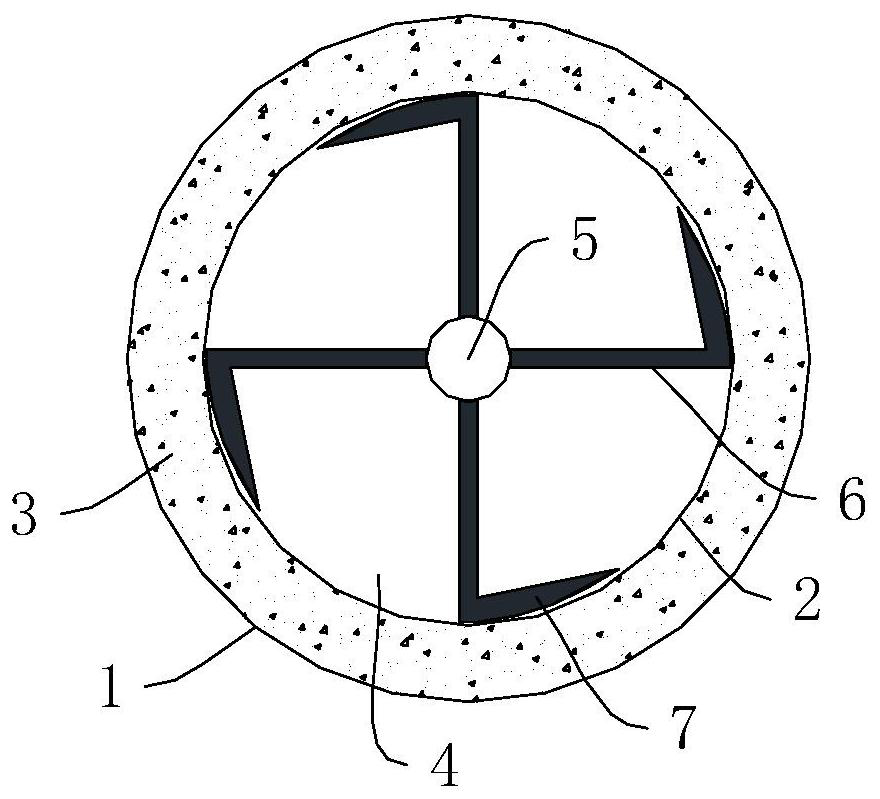

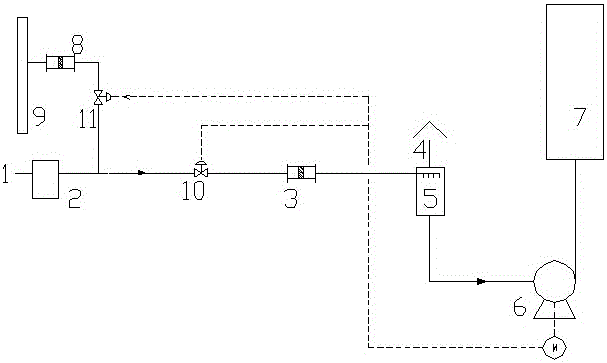

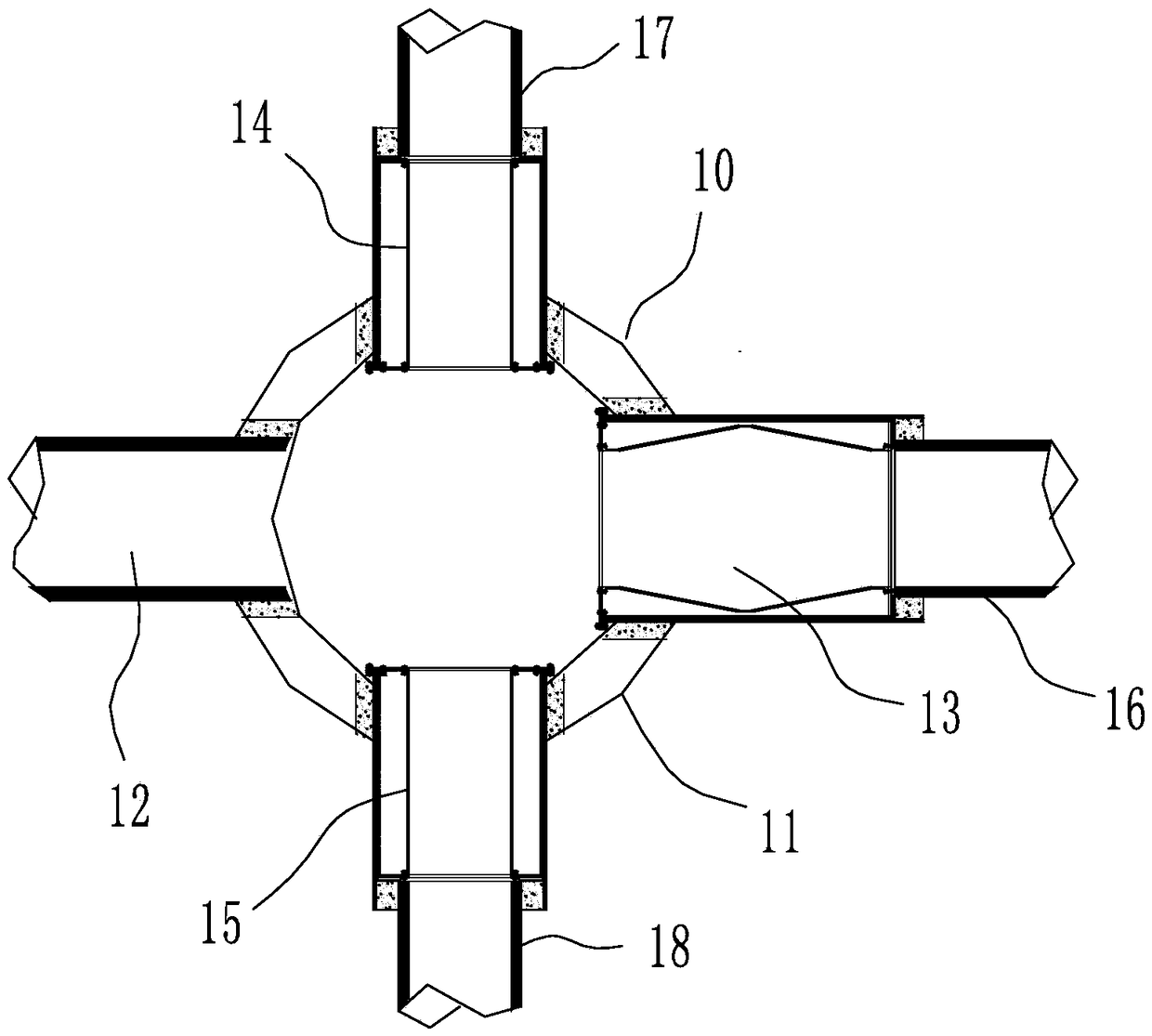

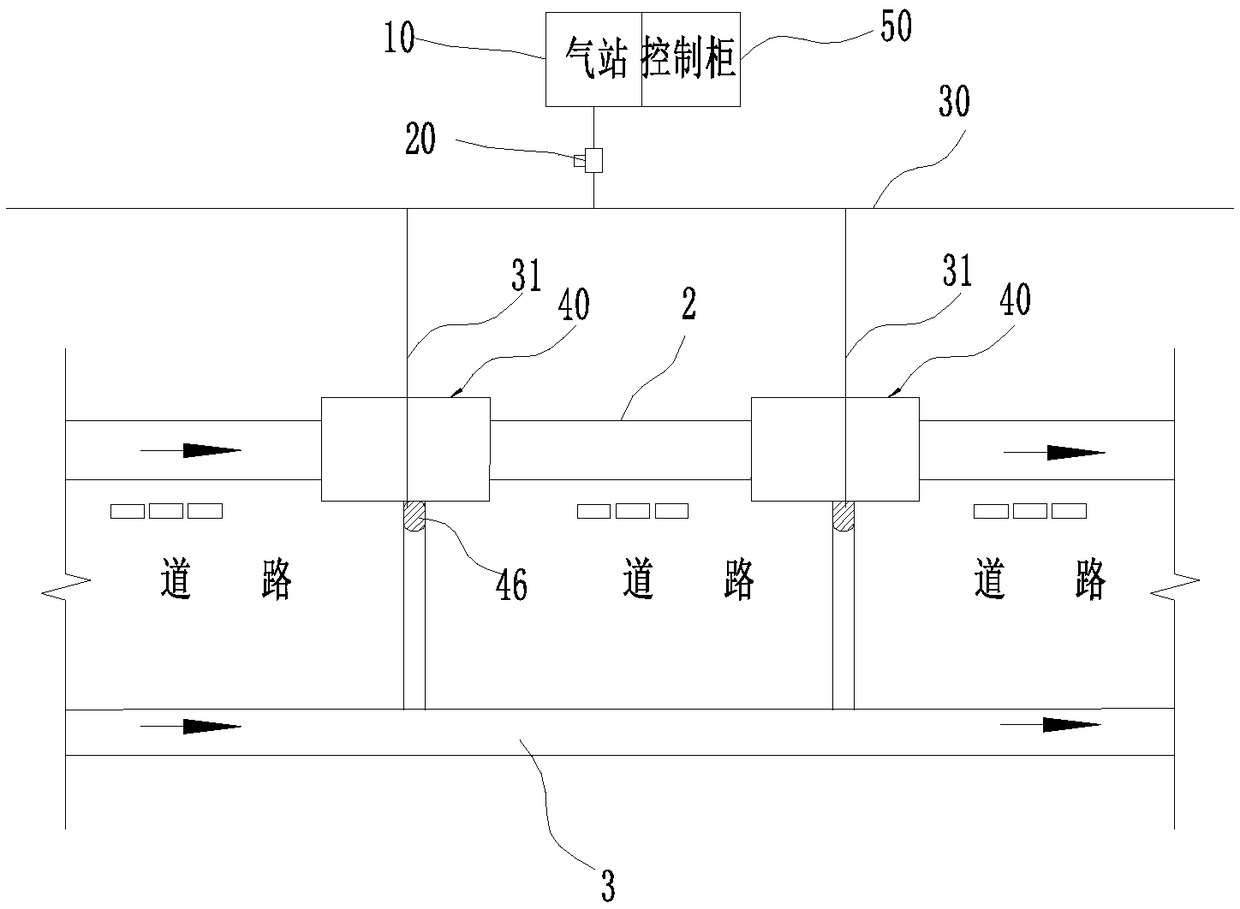

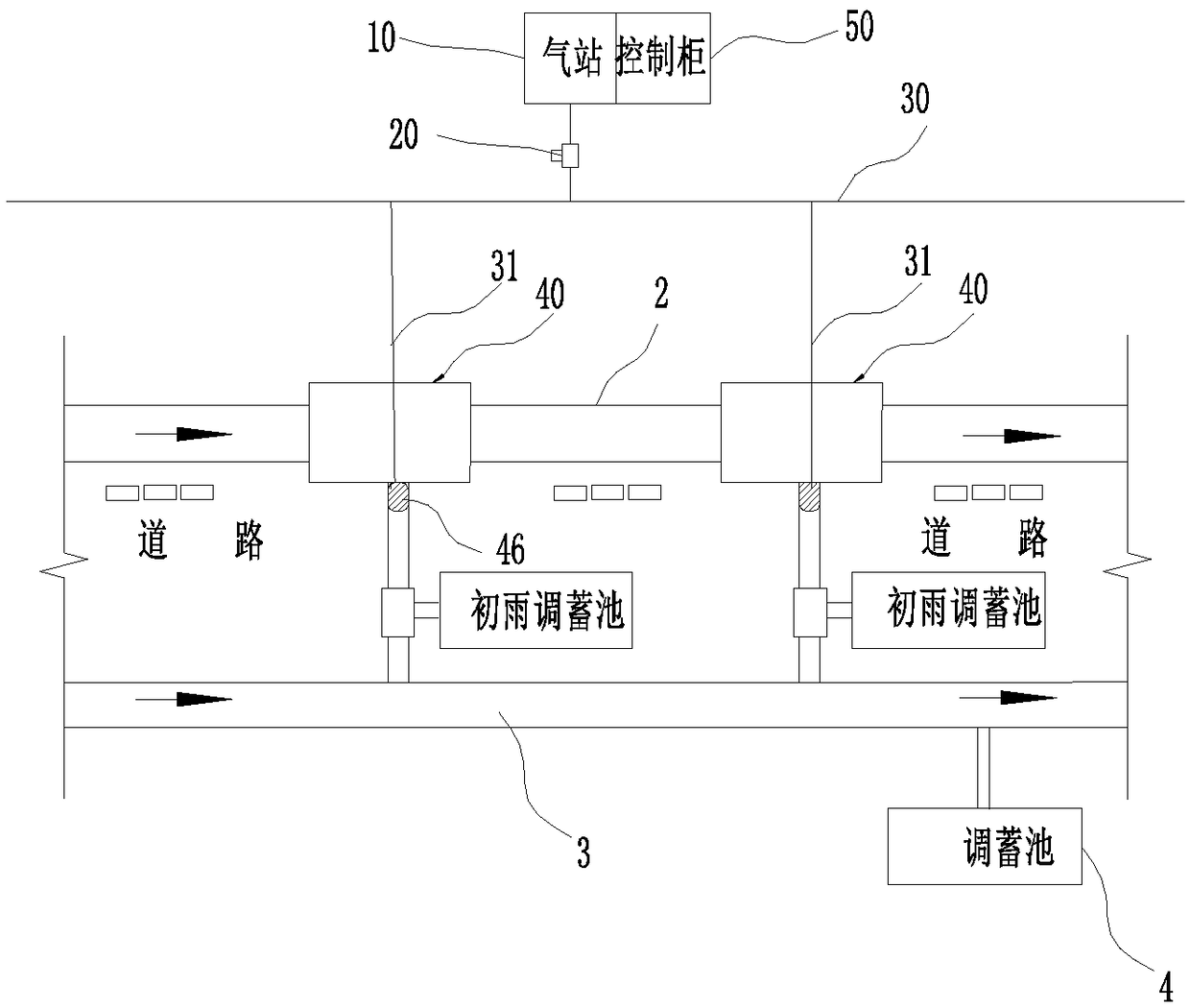

Flow control method and system for diversion shaft

PendingCN109372078ALow costReduce work stressSewerage structuresSewage drainingControl systemControl signal

The invention discloses a flow control method for a diversion shaft. A predetermined flow value is set, a flow value of a second water outlet pipe is measured as a real-time measured value, and the real-time measured value is compared with the predetermined flow value. When the real-time measured value is greater than the predetermined flow value, a controller issues a control signal to drive a control valve to actuate a pneumatic shut-off device to inflate, the second water outlet pipe tends to be closed until the measured value is equal to the predetermined flow value, and then the pneumaticshut-off device stops inflation. When the real-time measured value is smaller than the predetermined flow value, the controller issues a control signal to drive the control valve to actuate the pneumatic shut-off device to deflate, the second water outlet pipe tends to be opened until the measured value is equal to the predetermined flow value, and then the pneumatic shut-off device stops deflation.

Owner:WUHAN SHENGYU DRAINING SYST

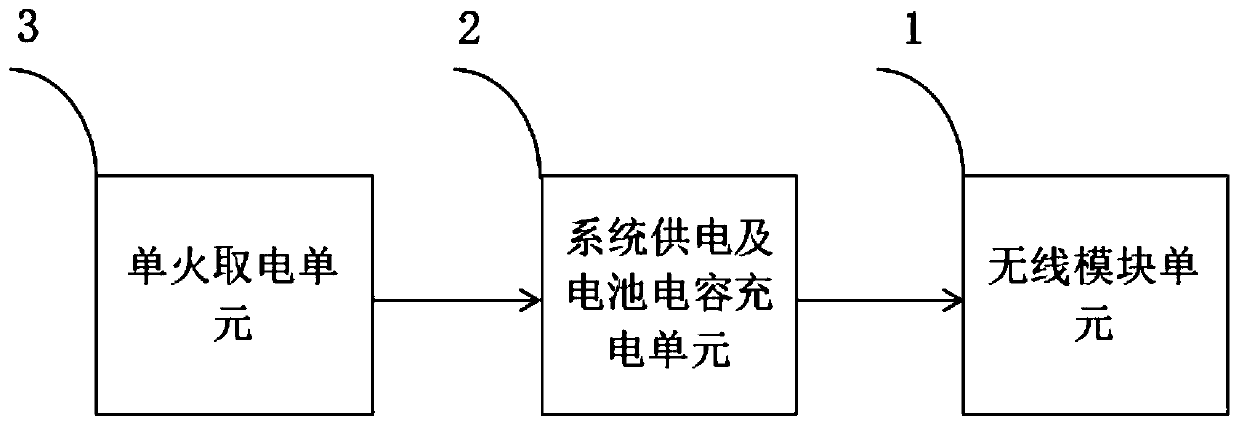

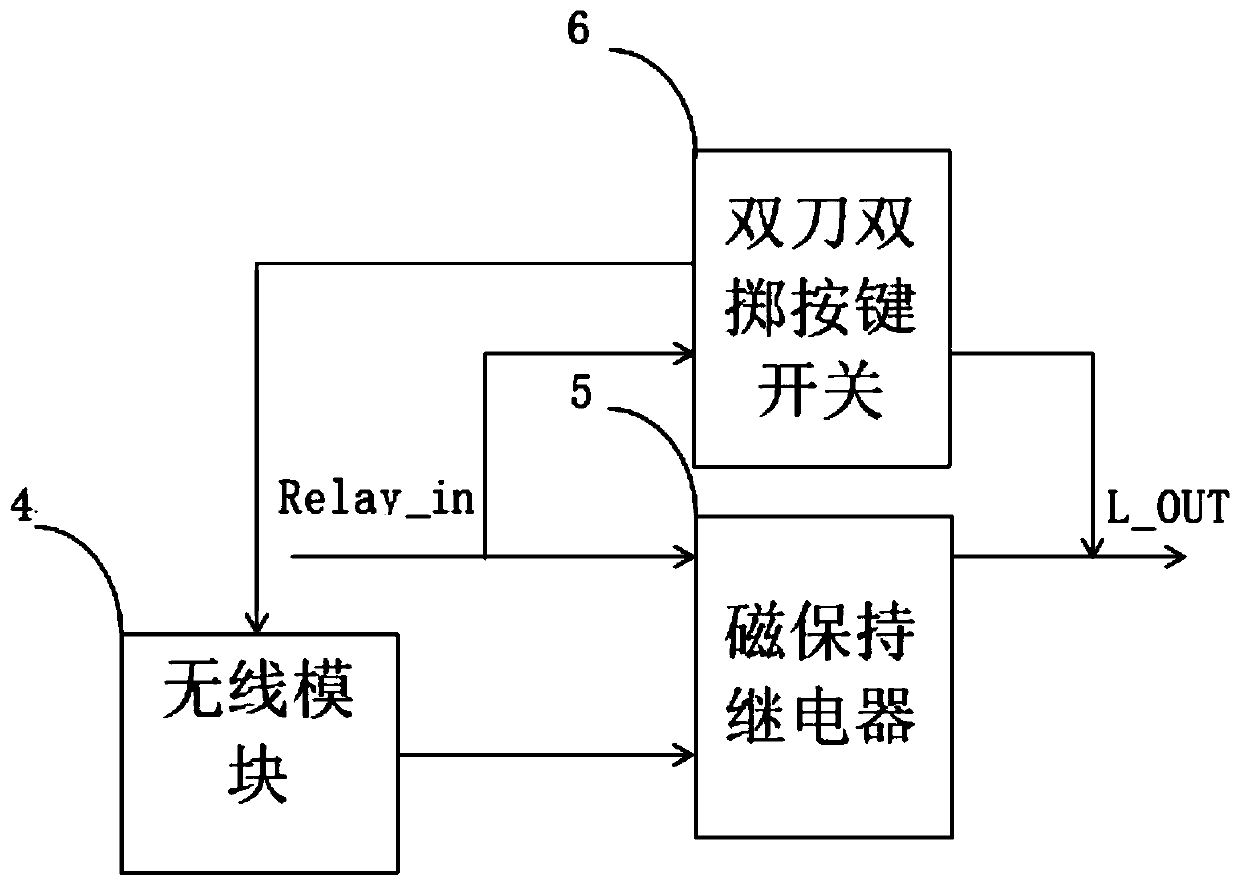

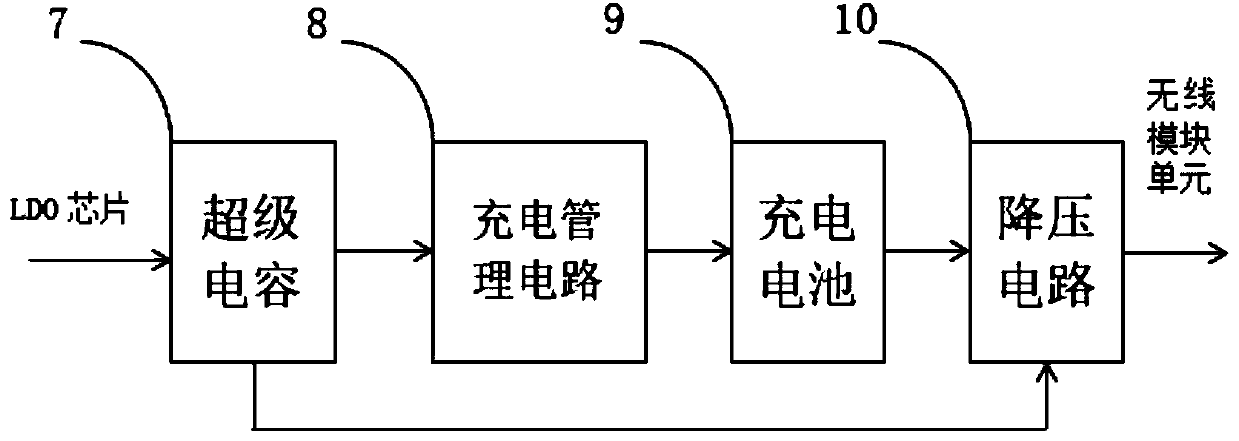

Wireless intelligent wall switch based on super capacitor and rechargeable battery

PendingCN110536519AEliminate will-o'-the-wispsExtend battery lifeBatteries circuit arrangementsElectroluminescent light sourcesCapacitanceElectricity

The invention provides a wireless intelligent wall switch based on a super capacitor and a rechargeable battery. The switch comprises a wireless module unit which comprises a wireless module and a relay module. The wireless module is used to control the relay module to turn on or off after receiving a switch control instruction from a user to control on and off of a lamp. The switch further comprises a system power supply and battery capacitor charging unit which comprises a super capacitor, a charge management circuit, a rechargeable battery and a step-down circuit, and a single fire power unit which comprises a MOS tube switch unit, an operational amplifier unit and a voltage conversion unit. According to the invention, the wireless module is used to communicate with the user's APP; bidirectional communication, real-time control of the lamp switch and update of the lamp status are realized; and when the lamp is turned off, the system power is provided by the rechargeable battery anddoes not steal current from a hot wire, thereby effectively eliminating the phenomenon of ghost fire.

Owner:TIANJIN HUALAI TECH CO LTD

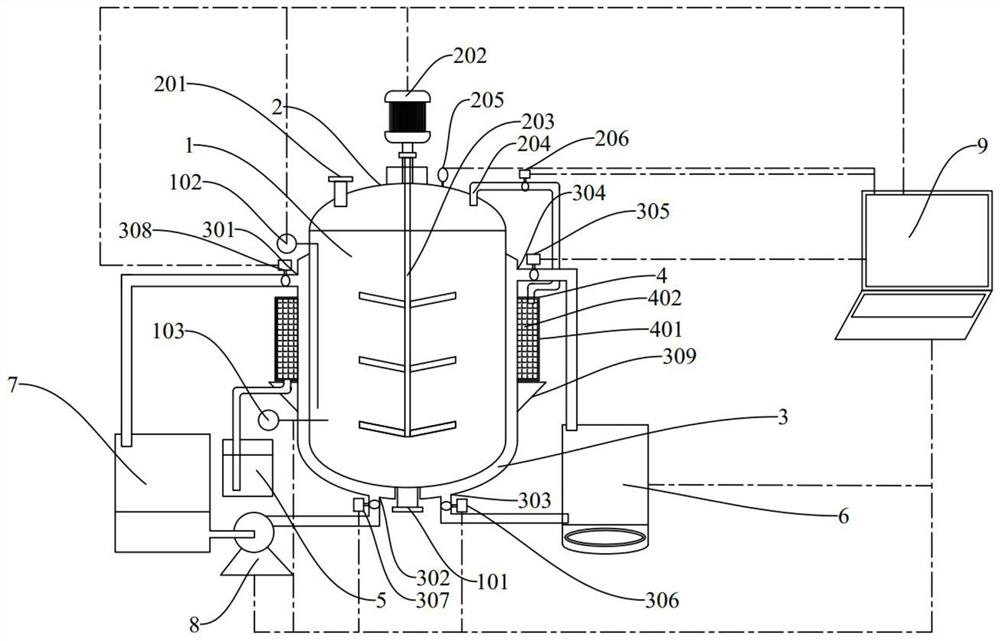

Oxidation reaction system for preparing 3-amino-4-methoxybenzanilide and control method of oxidation reaction system

ActiveCN111604021AReduce complexityReduce the temperatureProcess control/regulationOrganic compound preparationCatalytic decompositionWaste treatment

The invention discloses an oxidation reaction system for preparing 3-amino-4-methoxybenzanilide, which can realize steam heating and condensation cooling in the same jacket, greatly reduce the complexity of heating and cooling equipment of a reaction kettle and reduce the occupied area of the equipment. Nitrogen oxide treatment equipment is tightly attached to the outer side of the reaction kettle, so that the structural integration degree is high; the equipment is close to an exhaust port, long-distance conveying is not needed during waste treatment, gas temperature reduction is avoided, heat energy dissipated out of the reaction kettle can be fully utilized, the catalytic decomposition effect of a nitrogen oxide catalytic decomposition module is improved, and the tail gas safety is improved. The system is further provided with an alkali liquor absorption tank which can absorb nitrogen dioxide and hydrogen chloride gas which are not treated completely, and the tail gas safety is further improved. A controller automatically controls all valves and equipment to automatically complete control and treatment of the whole reaction process and the emergency process, manual operation isnot needed, the efficiency is improved, and meanwhile operators are protected against threats of waste gas, high temperature and explosion hidden dangers.

Owner:舟山欧莱克新材料科技有限公司

Coating agent, preparation method thereof, packaging box adopting coating agent and manufacturing method of packaging box

ActiveCN107760198AImprove breathabilityRealize the preservation effectWax coatingsPaper coatingMicrocrystalline waxIsoprene

The invention discloses a coating agent. The coating agent is characterized by being prepared from food grade paraffin, food grade microcrystalline wax, ethylene-vinyl acetate copolymer and a polyethylene and styrene-isoprene-styrene segmented copolymer. The coating agent is used for coating a packaging box, and the packaging box achieves the effects of resisting water, achieving breathability andretaining freshness.

Owner:SHANGHAI VENUS PACKAGE MATERIALS

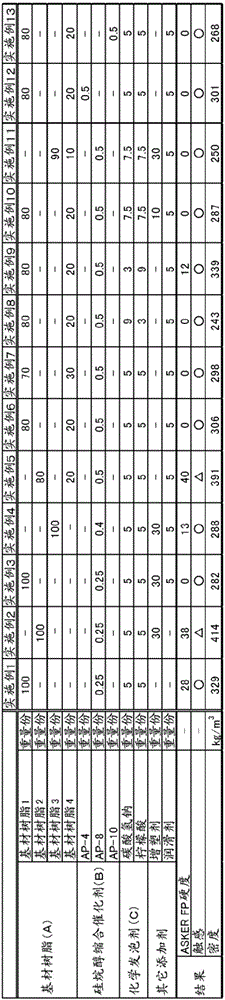

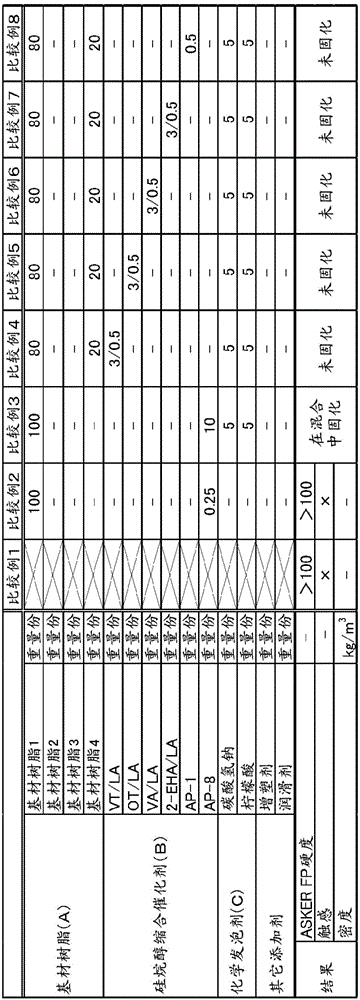

Modified silicone resin foamed body

The purpose of the present invention is to provide a modified silicone resin foamed body which, while maintaining an excellent tactile sensation and excellent flexibility, can be foam moulded without generating hydrogen as a by-product. This modified silicone resin foamed body is obtained by curing a foamable liquid resin composition including 100 parts by weight of a base material resin (A), 0.1-5 parts by weight of a silanol condensation catalyst (B), and 2-40 parts by weight of a chemical foaming agent (C). The modified silicone resin foamed body is characterized in that: the base material resin (A) comprises a polymer which has hydrolysable groups bonded to silicon atoms, has, in the molecular chain thereof, at least one silicon group capable of being crosslinked as a result of forming a siloxane bond, and has a main chain formed from oxyalkylene-based units; and the foamed body has an ASKER FP hardness of 60 or less under a 25 DEG C atmosphere.

Owner:KANEKA CORP

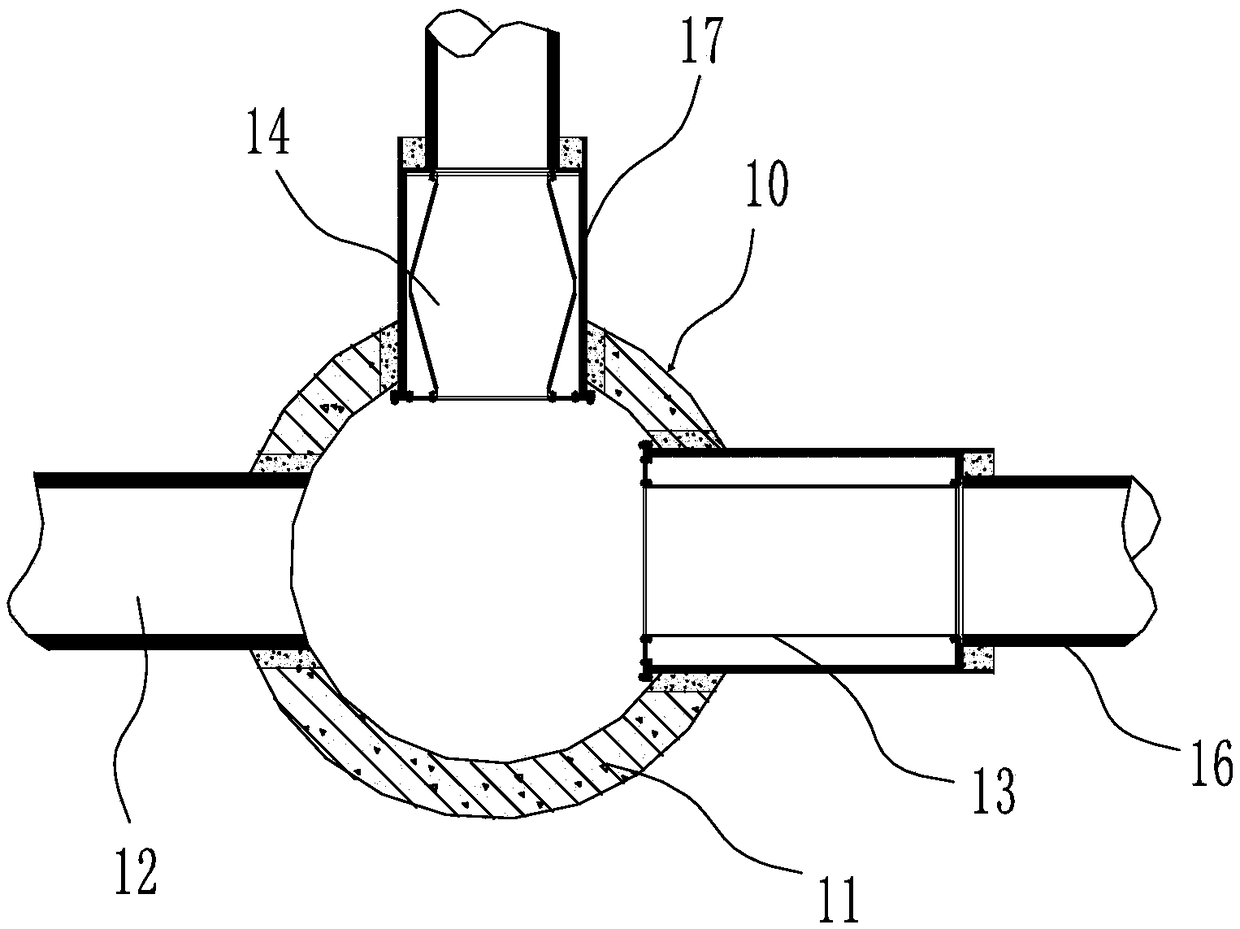

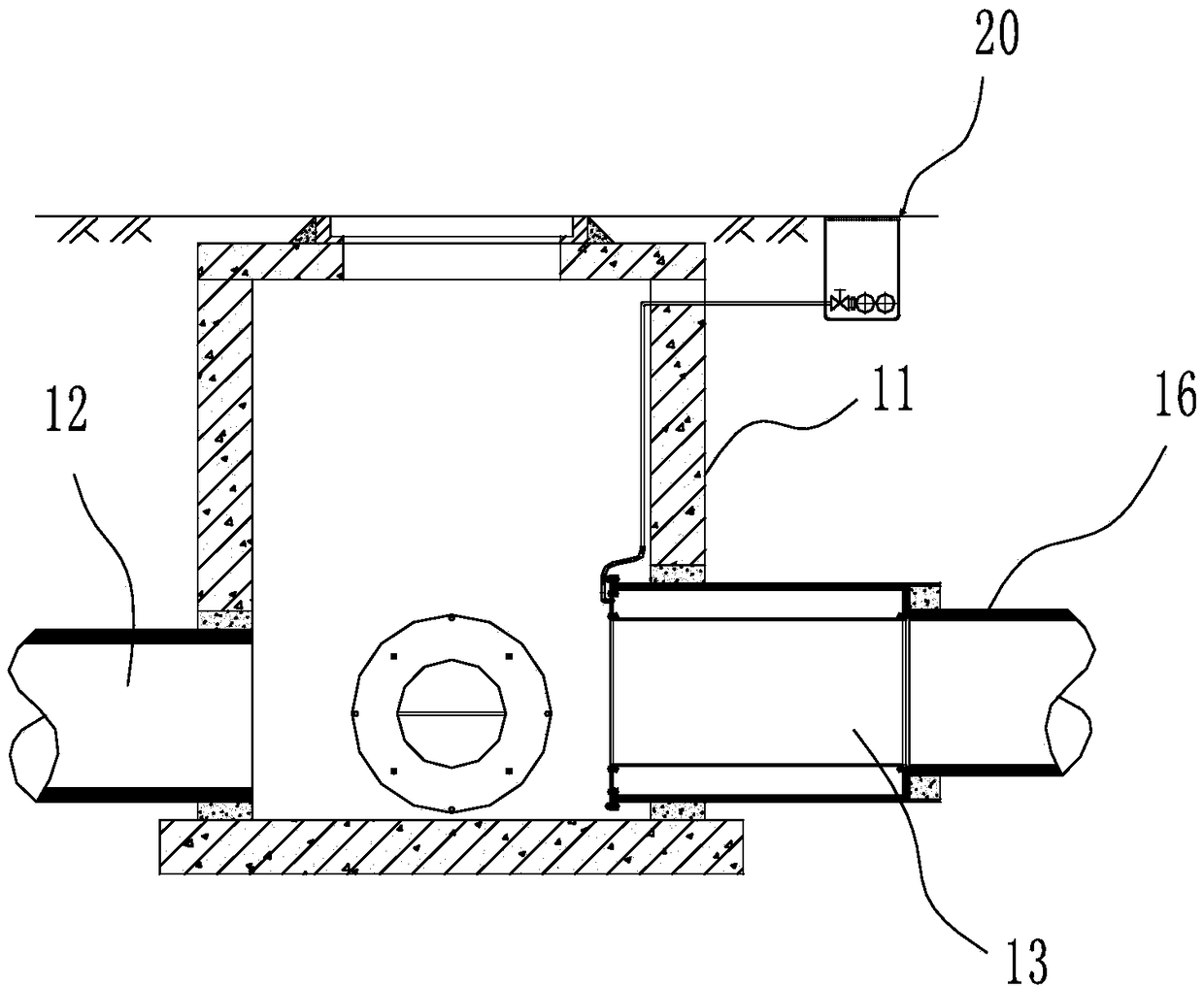

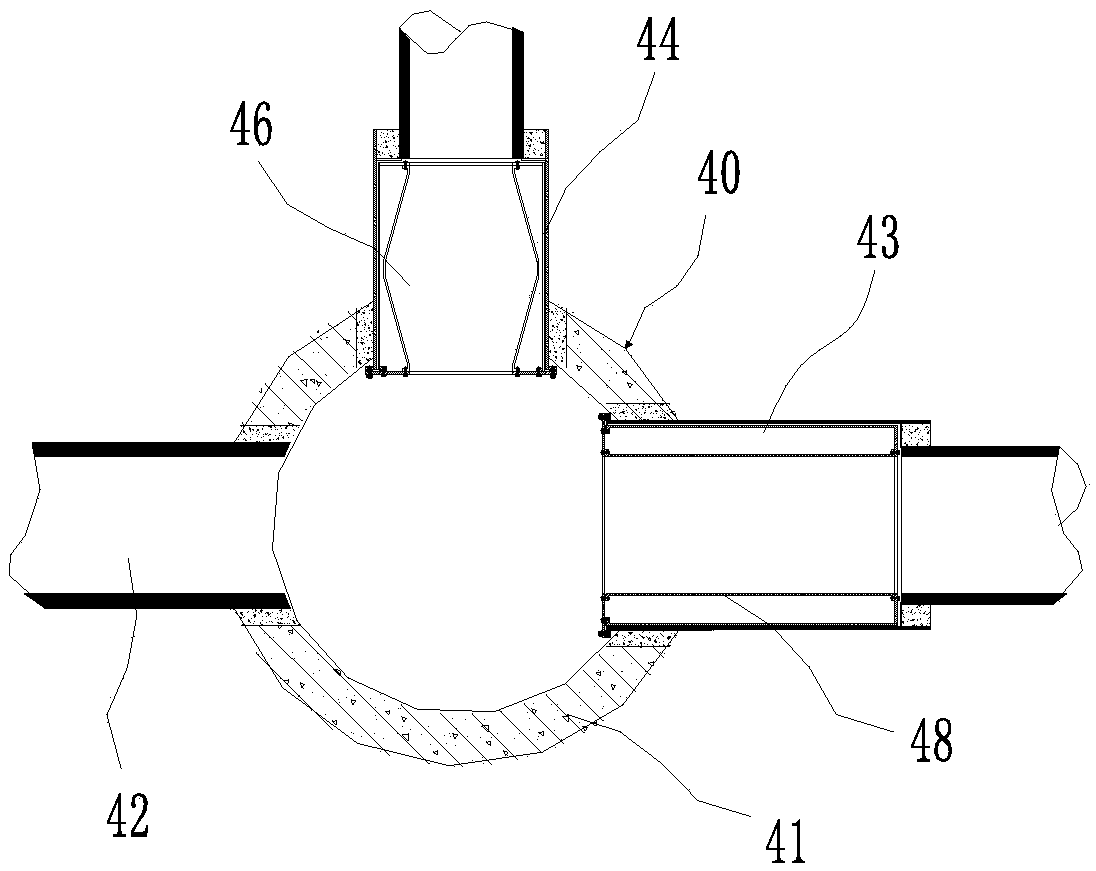

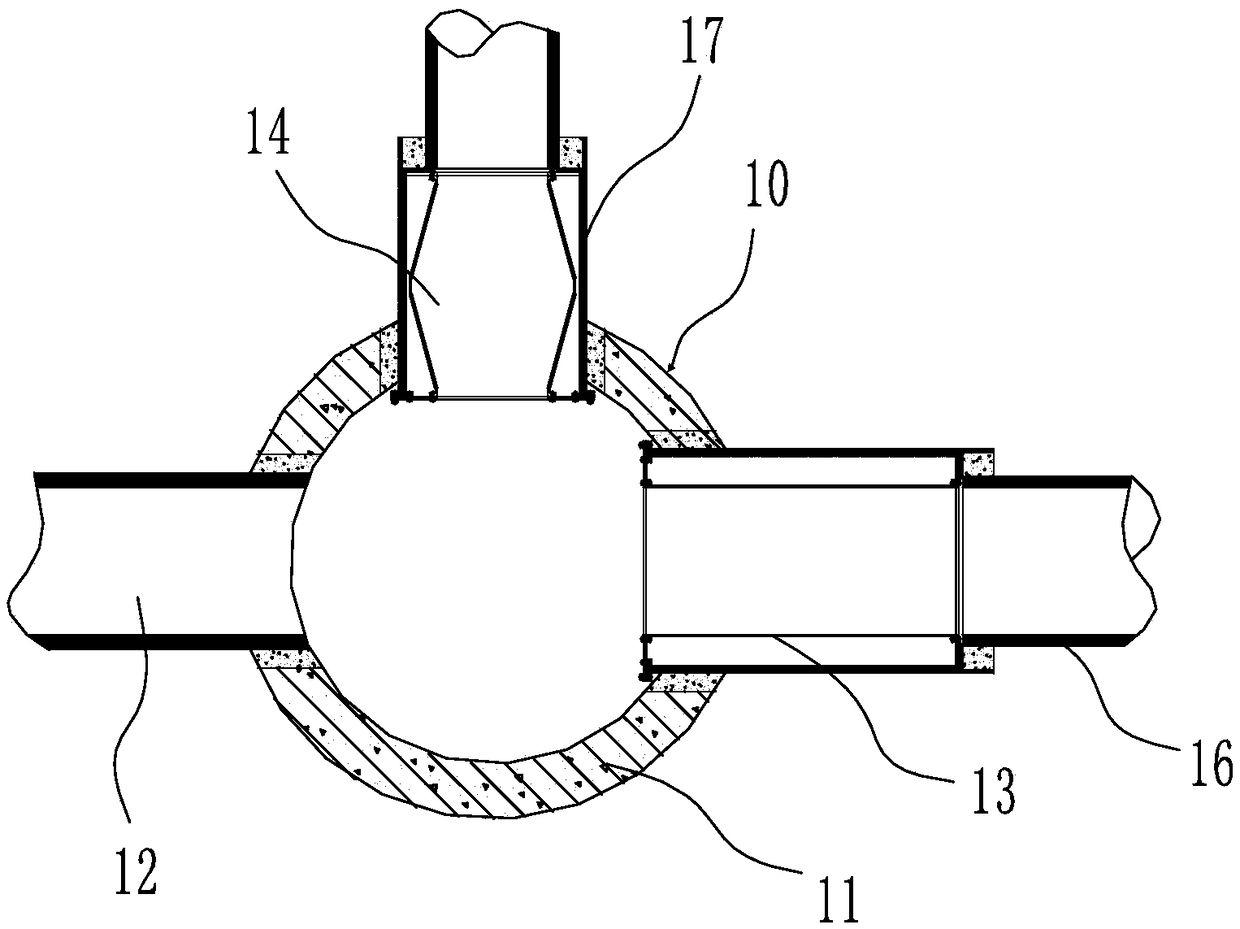

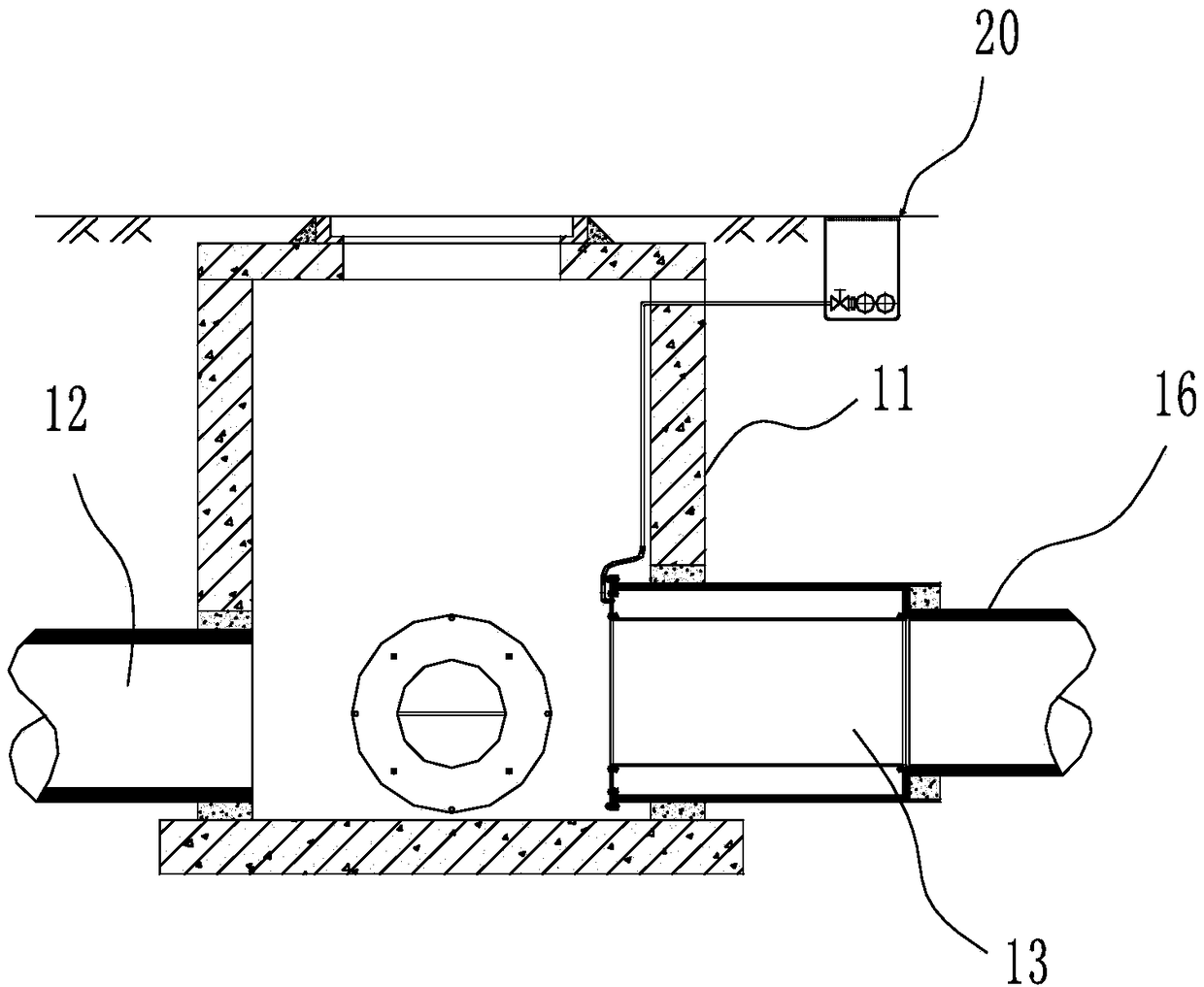

Road rainwater pneumatic diversion treatment system and control method thereof

PendingCN109339191ALow costReduce work stressSewerage structuresSewage drainingMunicipal sewageEngineering

The invention discloses a road rainwater pneumatic diversion treatment system. The system comprises a compressed air source, a gas delivery pipe, a diversion well arranged on a municipal rainwater pipe and a control valve; the diversion well comprises a well body structure, an inlet, a first water outlet pipe, a second water outlet pipe and a pneumatic cut-off device arranged on the second water outlet pipe, the well body structure is provided with the inlet, the first water outlet pipe and the second water outlet pipe, the pneumatic cut-off device is the second pneumatic cut-off device, the inlet is communicated with the municipal rainwater pipe on the upper stream of the diversion well, the first water outlet pipe is communicated with the municipal rainwater pipe on the lower stream of the diversion well or a natural water body, the second water outlet pipe is communicated with a municipal sewage pipe or sewage treatment facilities, and a third outlet is communicated with a first rain pipe or initial rainwater treatment facilities; the control valve comprises the second control valve which is arranged on the gas delivery pipe, and the second control valve controls charging and discharging of the second pneumatic cut-off device separately, and is used for controlling cut off and conducting of the corresponding second water outlet pipe.

Owner:WUHAN SHENGYU DRAINING SYST

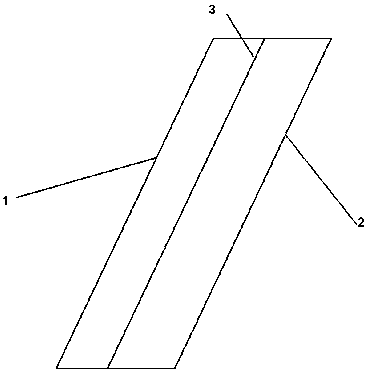

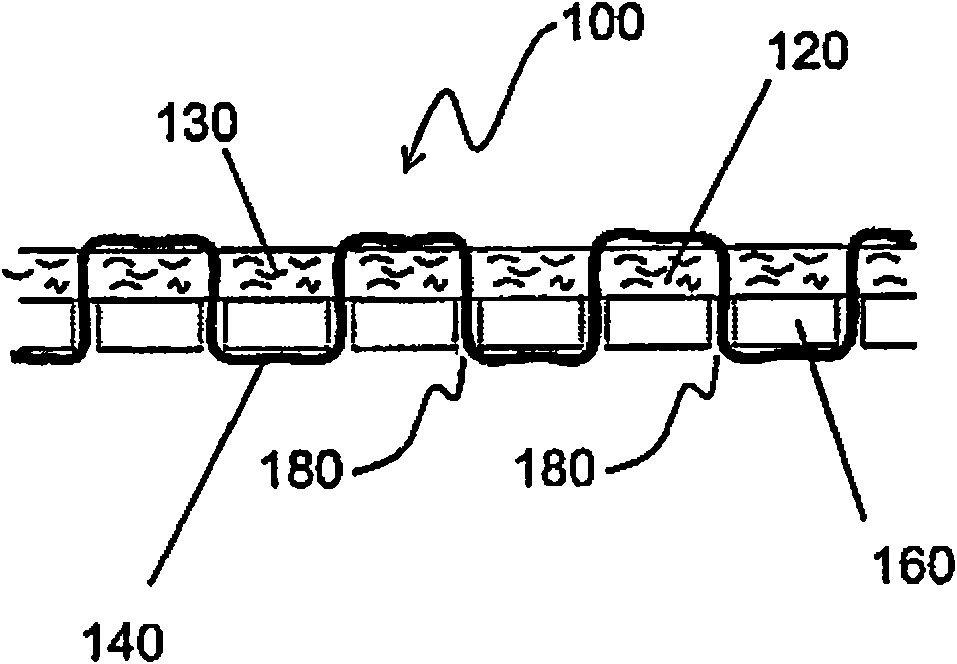

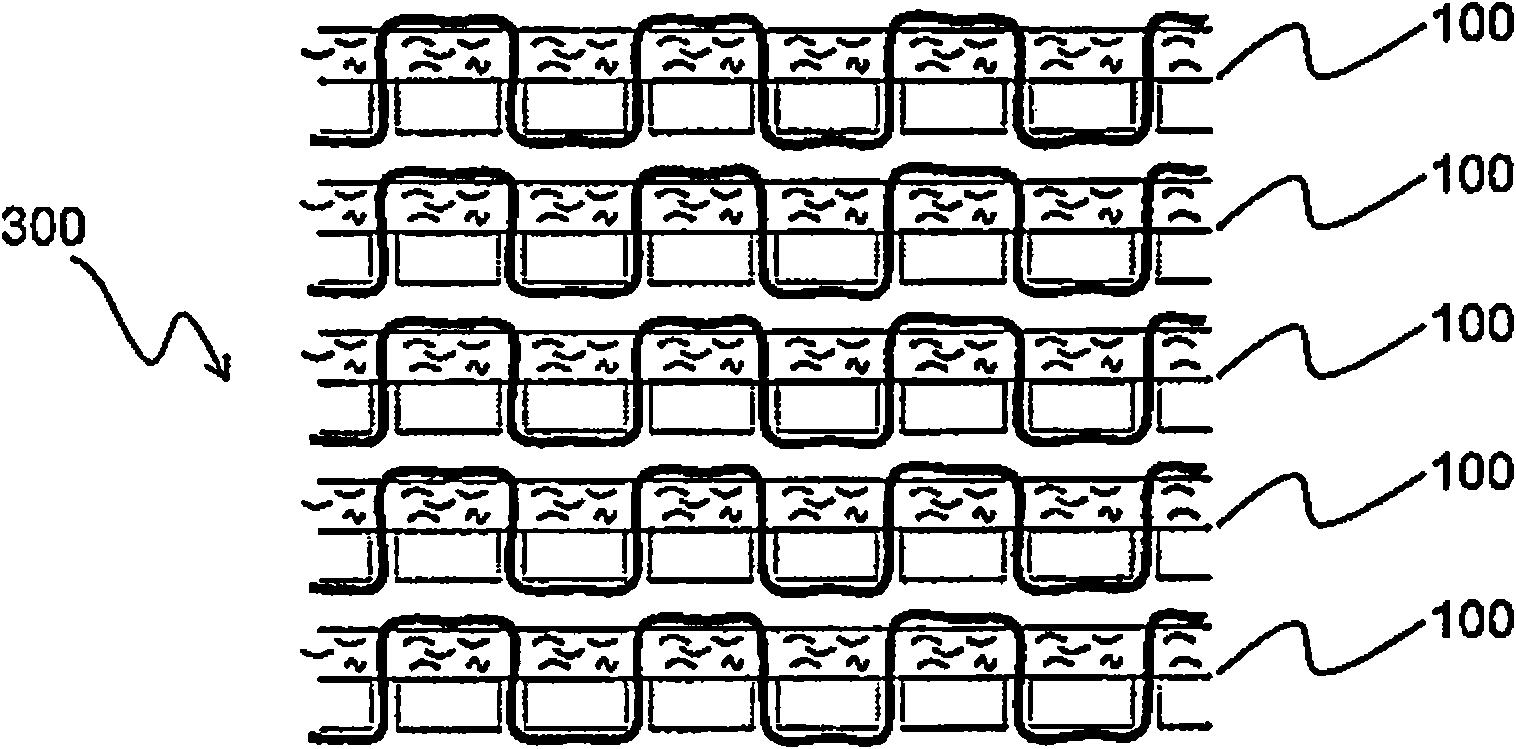

Insulation layer for use in thermal insulation, insulation and method of manufacturing such

InactiveCN101652600AFirmly connectedFriendly connectionThermal insulationVessel wallsInsulation layerThermal insulation

The present invention relates to an insulating layer (100) for use in thermal insulation, comprising a radiation shield (160) for reflecting thermal radiation and a spacer material (120) which is attached to the radiation shield (160) by means of a fastening material (140), from which insulating layer (100) the air has been evacuated. The insulating layer (100) is characterised in that said radiation shield (160) comprises a plurality of through holes (180). The present invention also relates to an insulation for thermal insulation of an object as well as a method of manufacturing such an insulation.

Owner:FIDENS HLDG

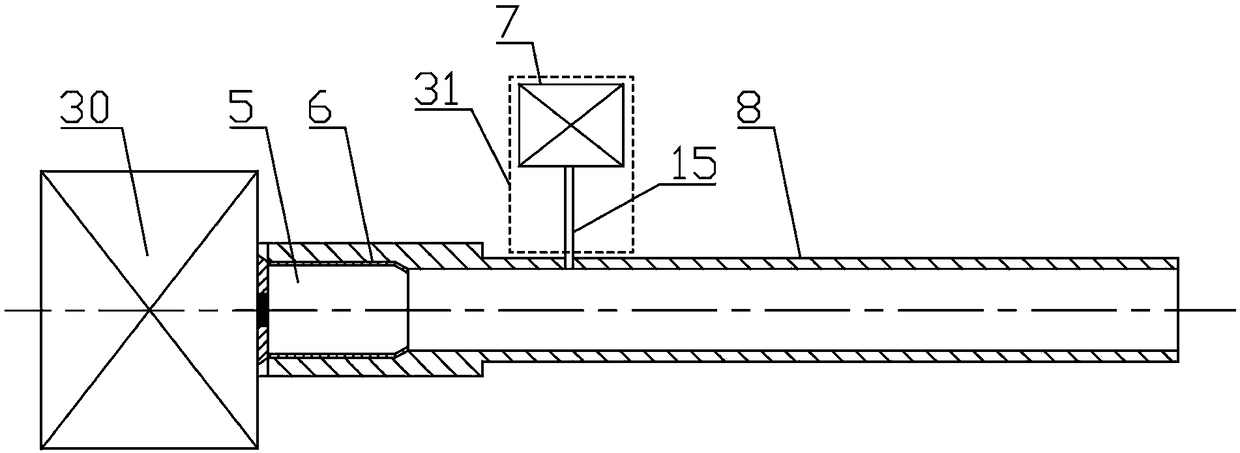

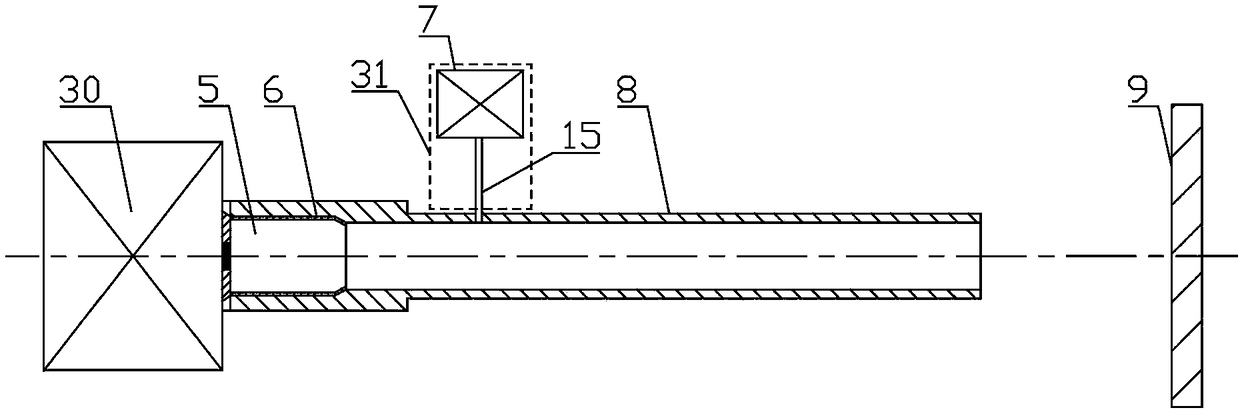

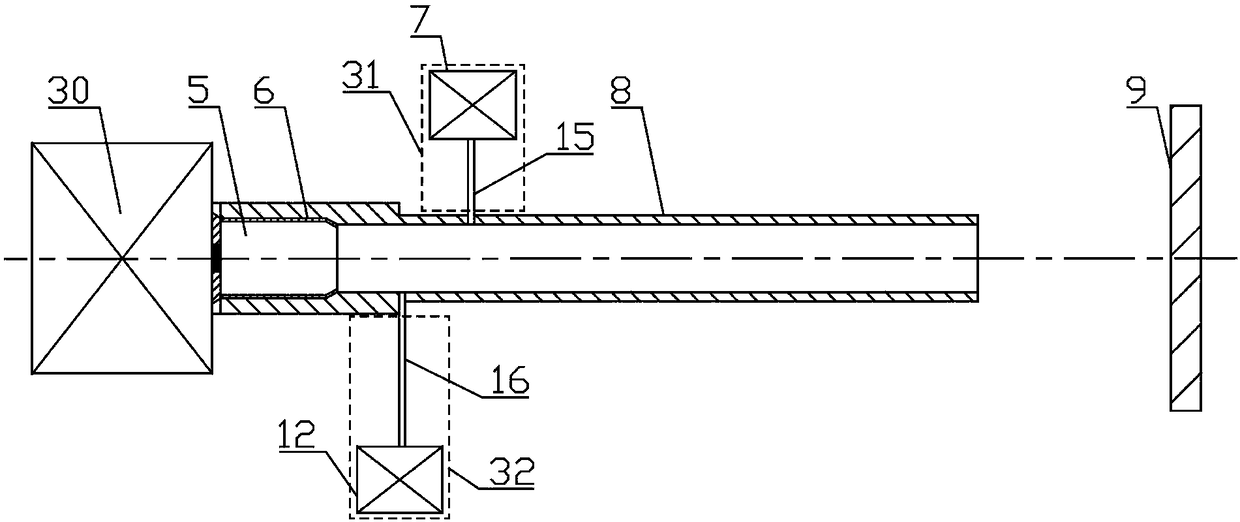

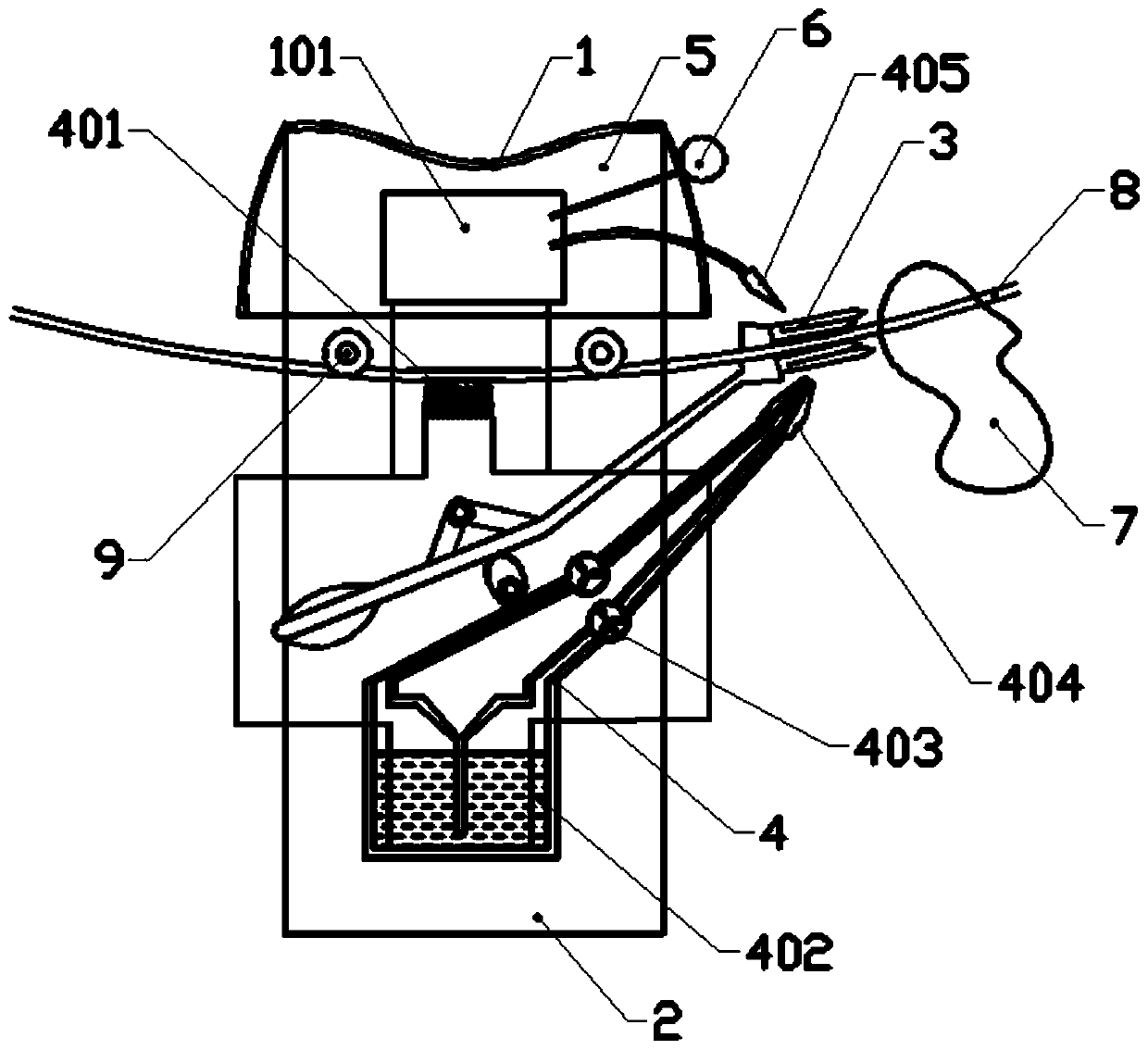

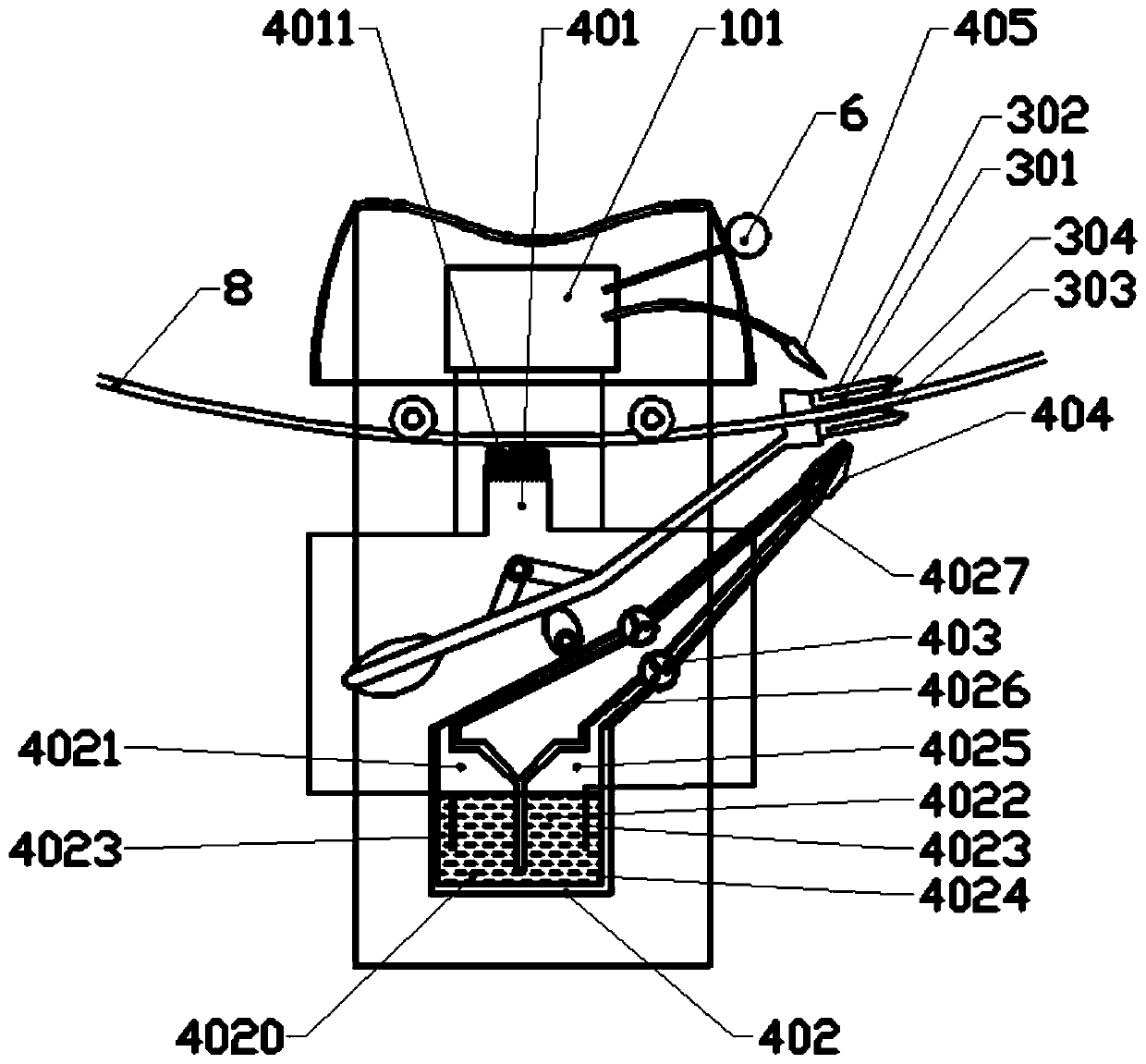

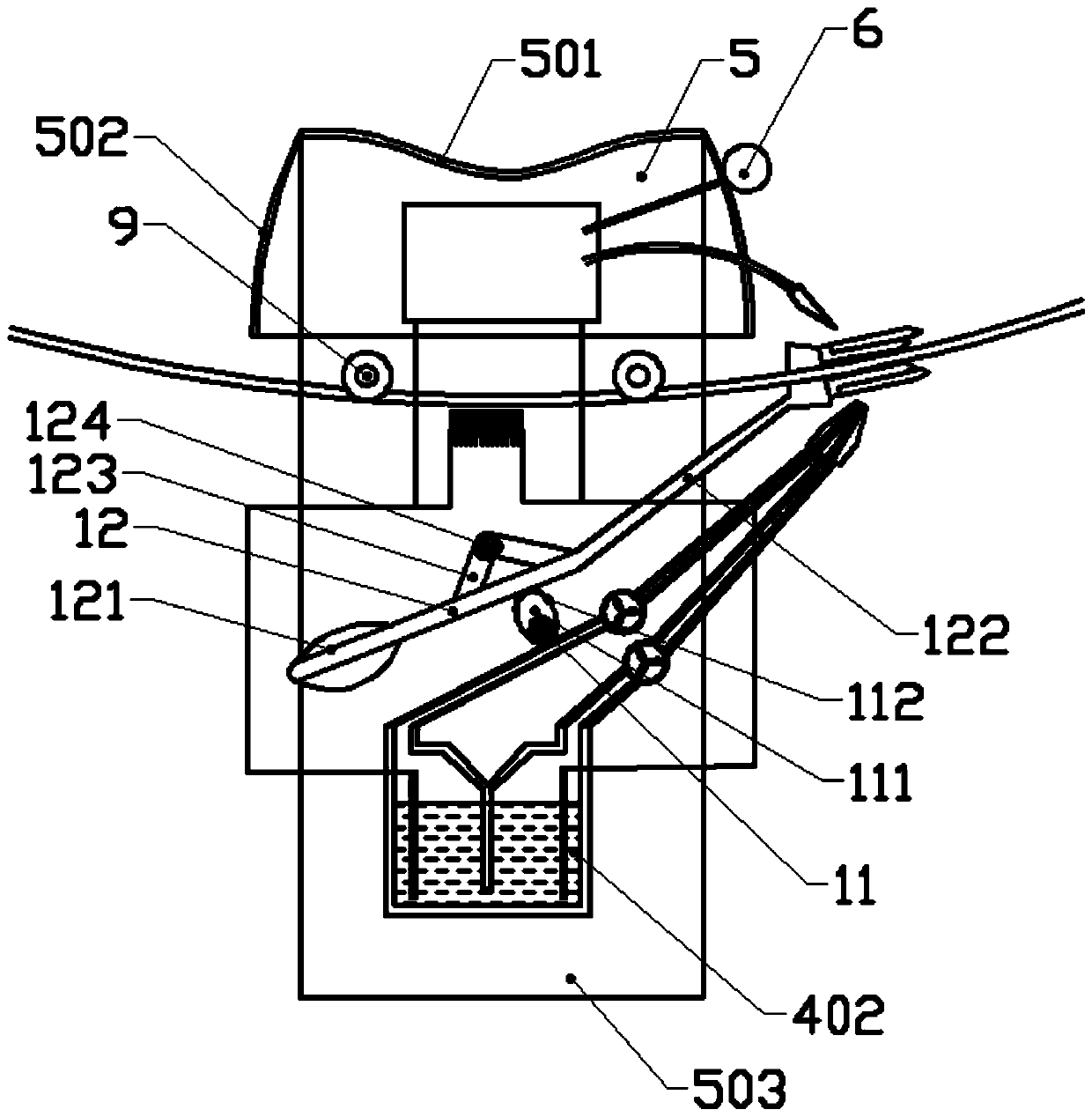

Detonation gun spraying device and detonation gun spraying technology

The invention relates to a detonation gun spraying device and a detonation gun spraying technology. The detonation gun spraying device comprises a launching unit, a jet pipe and a projectile body; thejet pipe is connected to the launching unit; a power supply unit is connected to the jet pipe and is used for conveying spraying powder into the jet pipe; the launching unit is used for detonating the projectile body; and a blast wave generated by detonation of the projectile body pushes and heats the spraying powder to jet toward a workpiece to form a coating in the jet pipe. The detonation gunspraying device provided by the invention is simple in structure, can utilize detonation of a solid propellant or a propellant in a powder load or a bullet to push and heat a powder material, replacesthe traditional technological device for pushing and heating the powder material with detonation of hybrid gas, is more light, handy and portable and can realize filed construction operation to ultra-large type parts. The detonation gun spraying technology provided by the invention does not involve combustible gas and detonation gas, is high in safety, is suitable for spraying technological needsfor various heat spraying powders and realizes accurate control on the detonation gun spraying process.

Owner:王东曦

Anti-environmental-interference method for 500KV power transmission line high-altitude line patrol robot

ActiveCN110932175AReduced risk of corroding power linesClean up thoroughlyCleaning processes and apparatusApparatus for overhead lines/cablesForeign matterAir pump

The invention discloses an anti-environmental-interference method for a 500KV power transmission line high-altitude line patrol robot. An anti-environmental-interference device is arranged and comprises a shielding device, a flamethrower and a windproof cover, the flamethrower comprises an induction power supply, an electrolytic cell, an air pump, an oxyhydrogen gas jet nozzle and an electronic igniter, and the shielding device comprises heat insulation ceramic and a metal sleeve. A high-altitude line patrol robot can be prevented from being influenced by environmental sundries during line patrol, abnormal high-temperature flames are provided, it is ensured that the environmental sundries are burnt out, no residue is left, meanwhile, high-temperature flames have no direct influence on thepower transmission line, and the functions of solving faults, defects and hidden dangers of the power transmission line and reliably treating foreign matter on the surface of the power transmission line are achieved.

Owner:YUNNAN POWER GRID CO LTD KUNMING POWER SUPPLY BUREAU

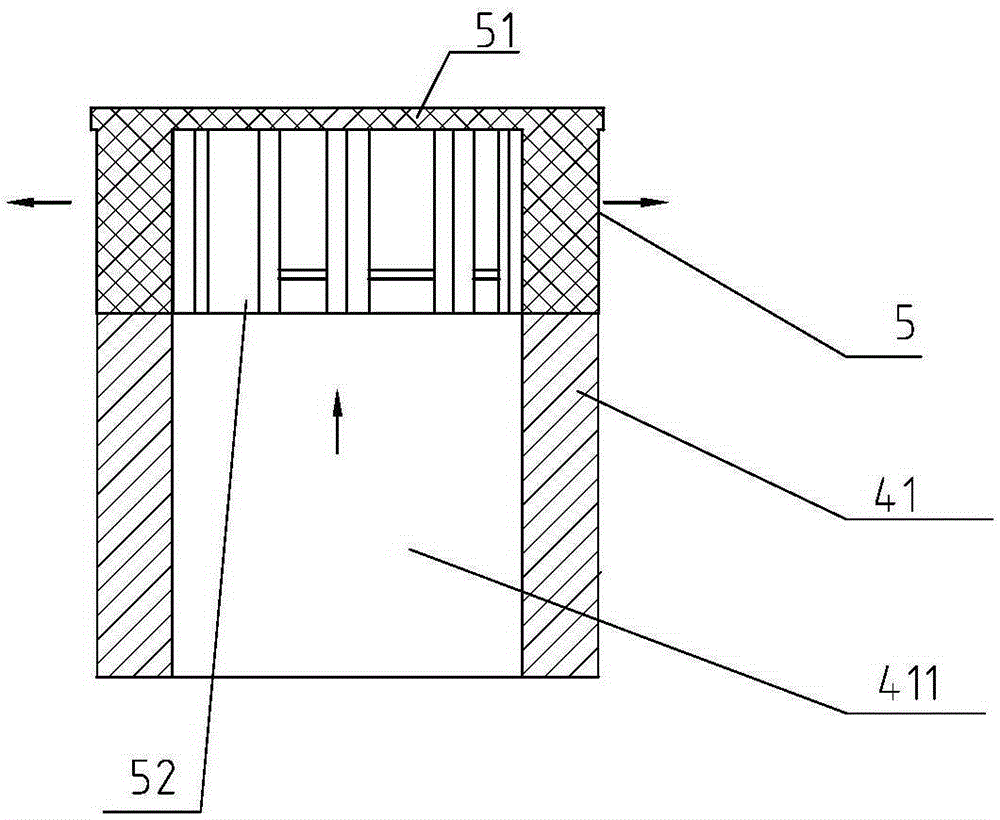

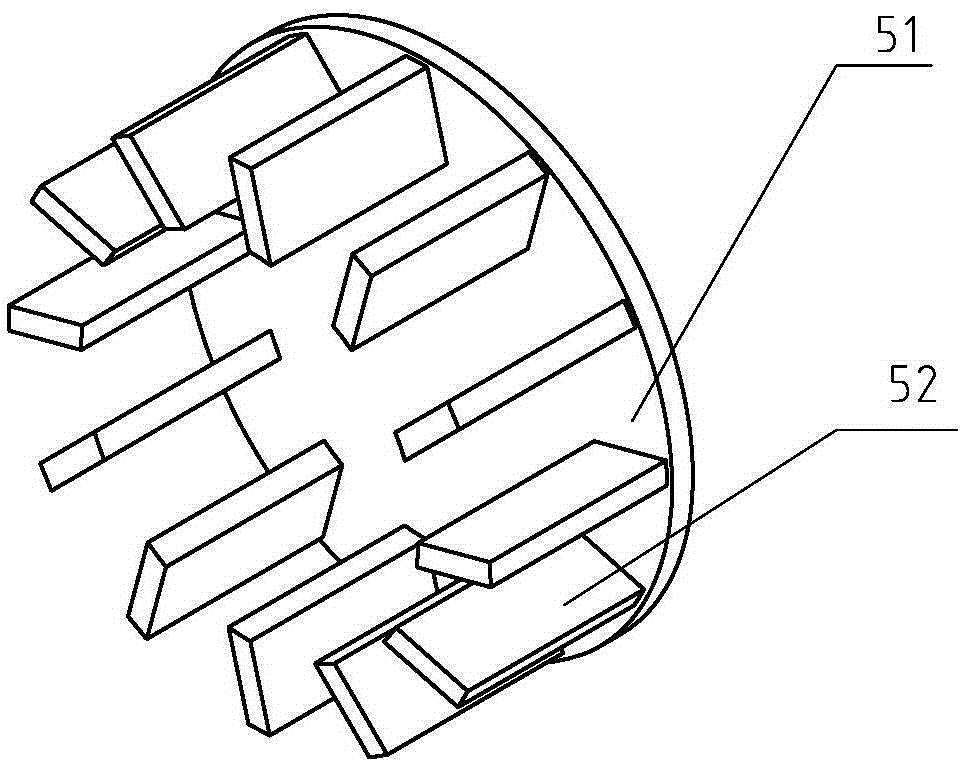

Heat pipe type steam generator

PendingCN109578966AExtended service lifeAvoid inhalationCombustion technology mitigationSteam boilersCombustorHeight difference

The invention relates to a steam generation device, in particular to a heat pipe type steam generator. The heat pipe type steam generator comprises a boiler, a generator body and a combustor. The combustion end of the combustor stretches into a hearth of the boiler. The boiler is connected with the generator body. A heat pipe is arranged in the generator body. A primary side channel is formed outside the heat pipe. A secondary side channel is formed in the heat pipe. Media in the primary side channel exchange heat with media in the secondary side channel. The boiler is connected with the primary side channel of the generator body so that a primary side cycle loop can be formed, and the primary side cycle loop is vacuum and is closed. The height of the lowest liquid level of the primary side channel is larger than the height of the highest liquid level of the boiler. By utilization of the height difference between the liquid level in the primary side channel and the liquid level of theboiler, it is guaranteed that in the primary side cycle loop, the water solution in the generator body can still return into the boiler under the situation that no water pump supplies power, accordingly, outside oxidized gas is prevented from being sucked into the primary side water cycle loop, and the service life of the boiler is prolonged.

Owner:杭州联赫节能环保科技有限公司

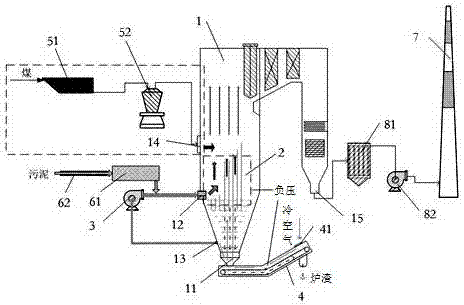

Slag heat drying sludge incineration treatment system and treatment method

PendingCN107365040AReduce heat lossImprove heat utilizationSludge treatment by de-watering/drying/thickeningSolid fuel pretreatmentCold airSlag

The invention provides a slag heat drying sludge incineration treatment system and a treatment method. The system comprises a boiler and a sludge sowing fan; a furnace slag discharging port is formed in the bottom of the boiler, a sludge feeding port is formed in the side wall of the boiler, an air outlet of the sludge sowing fan is communicated with the sludge feeding port by means of a sludge sowing pipeline, a hot air outlet is also formed in the side wall of the boiler, a set of furnace slag treatment equipment is connected to the furnace slag discharging port, a cold air suction inlet used for sucking cold air and realizing cooling of furnace slag in the equipment is formed in furnace slag treatment equipment and is communicated with the furnace slag discharging port, and the hot air outlet is communicated with an air inlet of the sludge sowing fan. The slag heat drying sludge incineration treatment system and the treatment method provided by the invention have the beneficial effects that air heating is completed by utilizing the incinerated furnace slag, and then sludge drying is completed by utilizing heated air; the heat energy utilization rate is high, the technological process is fully simplified, and the production cost is reduced.

Owner:JIANGSU GREEN WAY ENVIRONMENTAL PROTECTION TECH

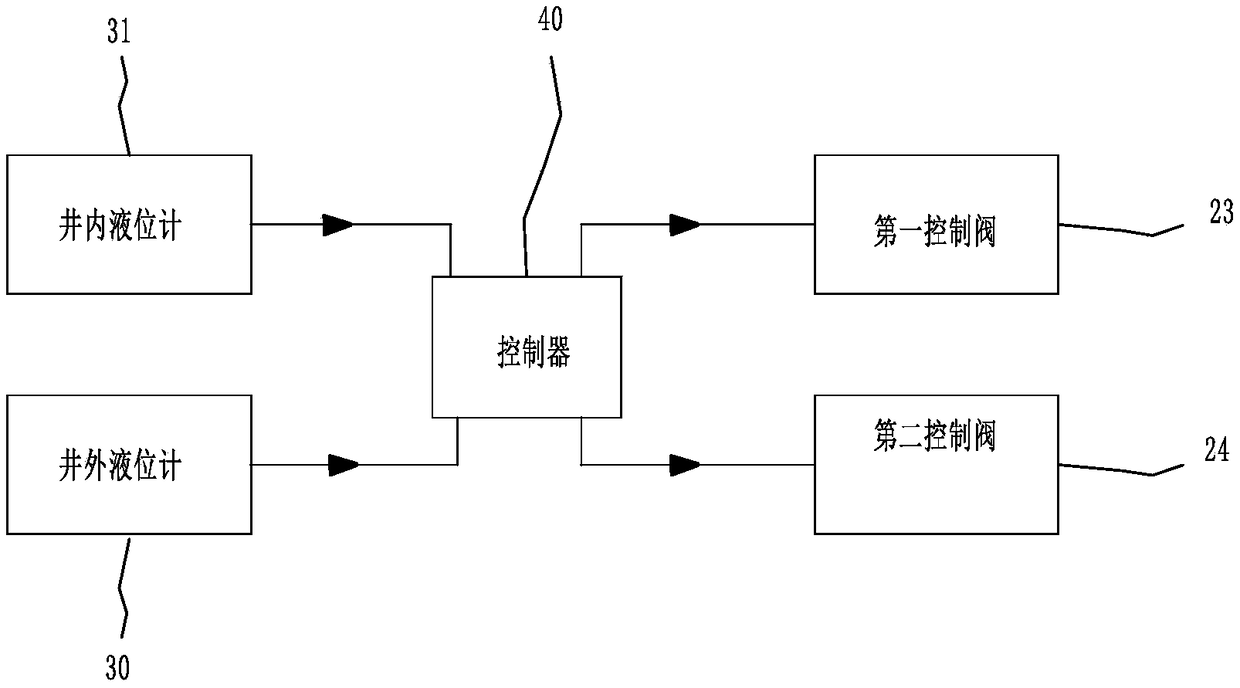

Anti-backward-flow method and system applied to drainage port

PendingCN109339190ALow costReduce work stressSewerage structuresSewage drainingEngineeringControl valves

The invention discloses an anti-backward-flow method applied to a drainage port. The method comprises the steps that an in-well liquid meter and an out-wall liquid meter are used for transmitting collected in-well liquid level information H1 and out-well liquid meter liquid level information H2 to a controller, and the controller is used for controlling action of a control valve according to the relation between the in-well liquid level information H1 and the out-well liquid meter liquid level information H2; when the out-well liquid meter liquid level information H2 is larger than or equal tothe in-well liquid level information H1, an anti-backward-flow program is executed; the control valve operates, a first pneumatic cut-off device is subjected to air inflation, a first water outlet pipe is closed, and natural water connected with the first water outlet pipe or a fluid in a rainwater pipe is prevented from flowing backward into a drainage port well through the first water outlet pipe; when the out-well liquid meter liquid level information H2 is smaller than the in-well liquid level information H1, the anti-backward-flow program exits.

Owner:WUHAN SHENGYU DRAINING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com