Anti-backward-flow method and system applied to drainage port

An anti-backflow and outfall technology, which is applied in the direction of waterway system, sewage discharge, drainage structures, etc., can solve the problems of electric shock hazard, difficult power supply, easy leakage and other problems, and achieves no occupation of height space, mature and reliable price, and anti-clogging powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

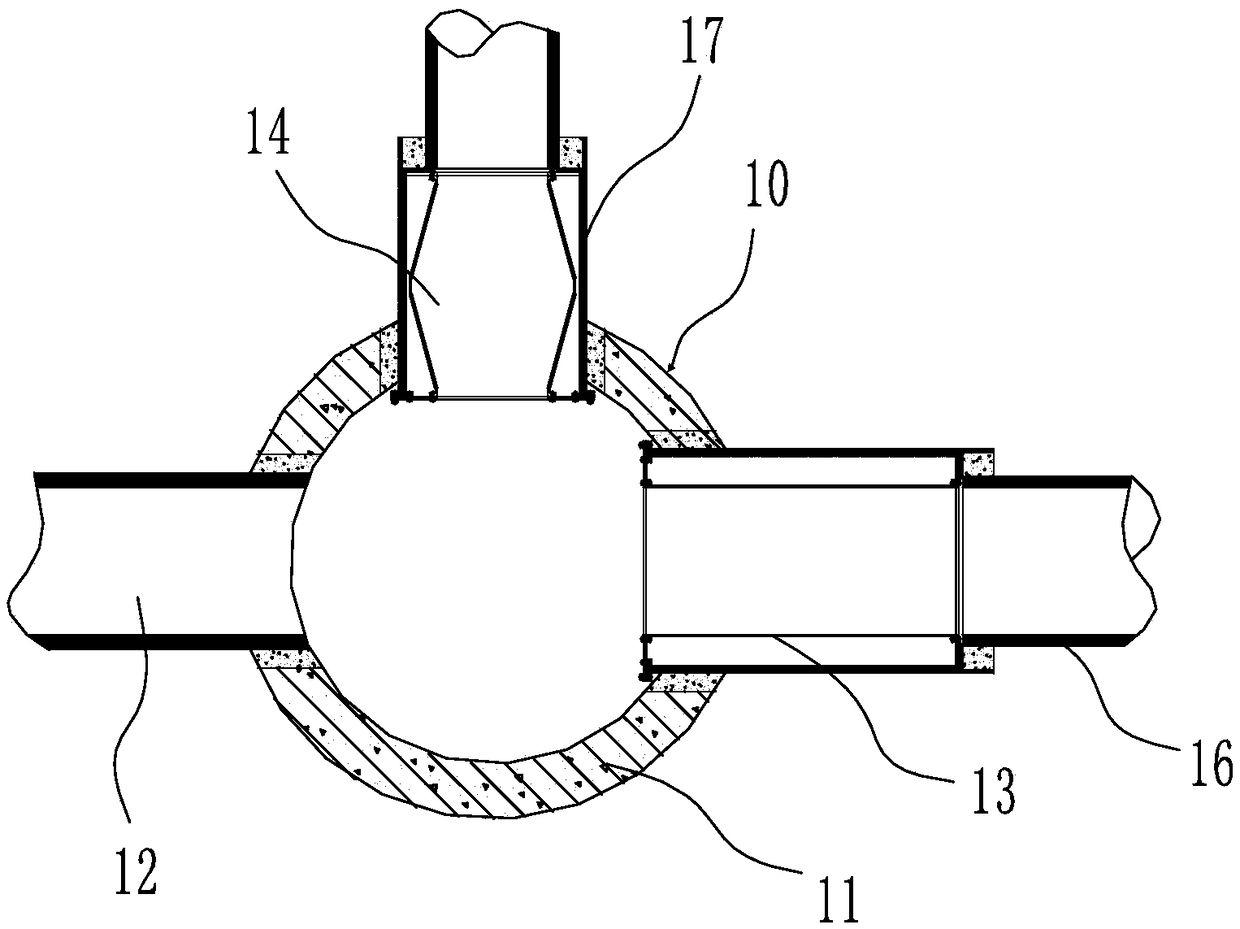

[0069] This embodiment provides an anti-backflow method applied at the outlet,

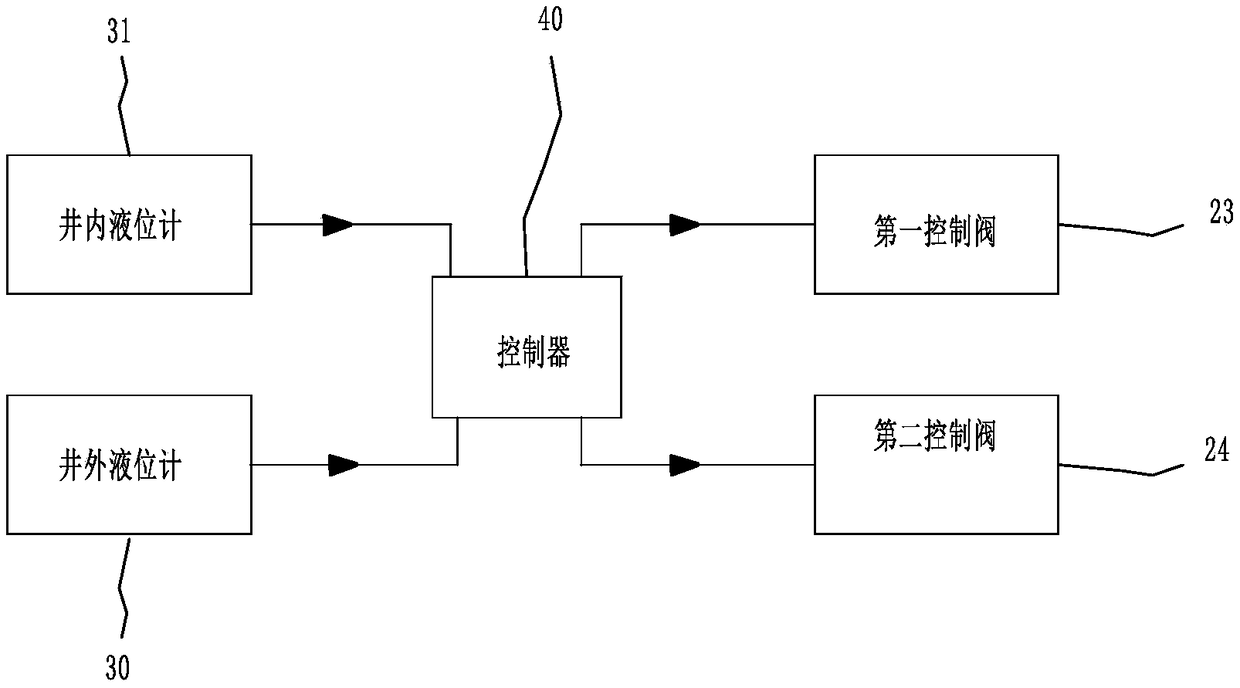

[0070] The well liquid level value H1 in the discharge well body 11 collected by the liquid level gauge 31 in the well, the liquid level value H2 outside the discharge well body 11 collected by the liquid level gauge 30 outside the well,

[0071] When H2>H1, execute the anti-backflow program: the first control valve is activated, the first pneumatic shut-off device is inflated, and the first outlet pipe is closed to prevent the fluid in the natural water body or rainwater pipe connected to the first outlet pipe from passing through the first outlet pipe. The water pipe is poured into the discharge well;

[0072] When H2=H1, the first controller acts, the first pneumatic shut-off device starts to inflate, and the first water outlet pipe starts to close gradually, after that,

[0073] If H2≥H1, the first pneumatic shut-off device continues to inflate until the first water outlet pipe is closed;

...

Embodiment 3

[0090] The difference between embodiment 3 and embodiment 2 is that only the first outlet is provided in the discharge well, and the first pneumatic shut-off assembly is provided on the first water outlet pipe.

[0091] When exiting the anti-backflow program, the first control valve acts, the first pneumatic shut-off assembly deflates, and the first water outlet pipe conducts.

Embodiment 4

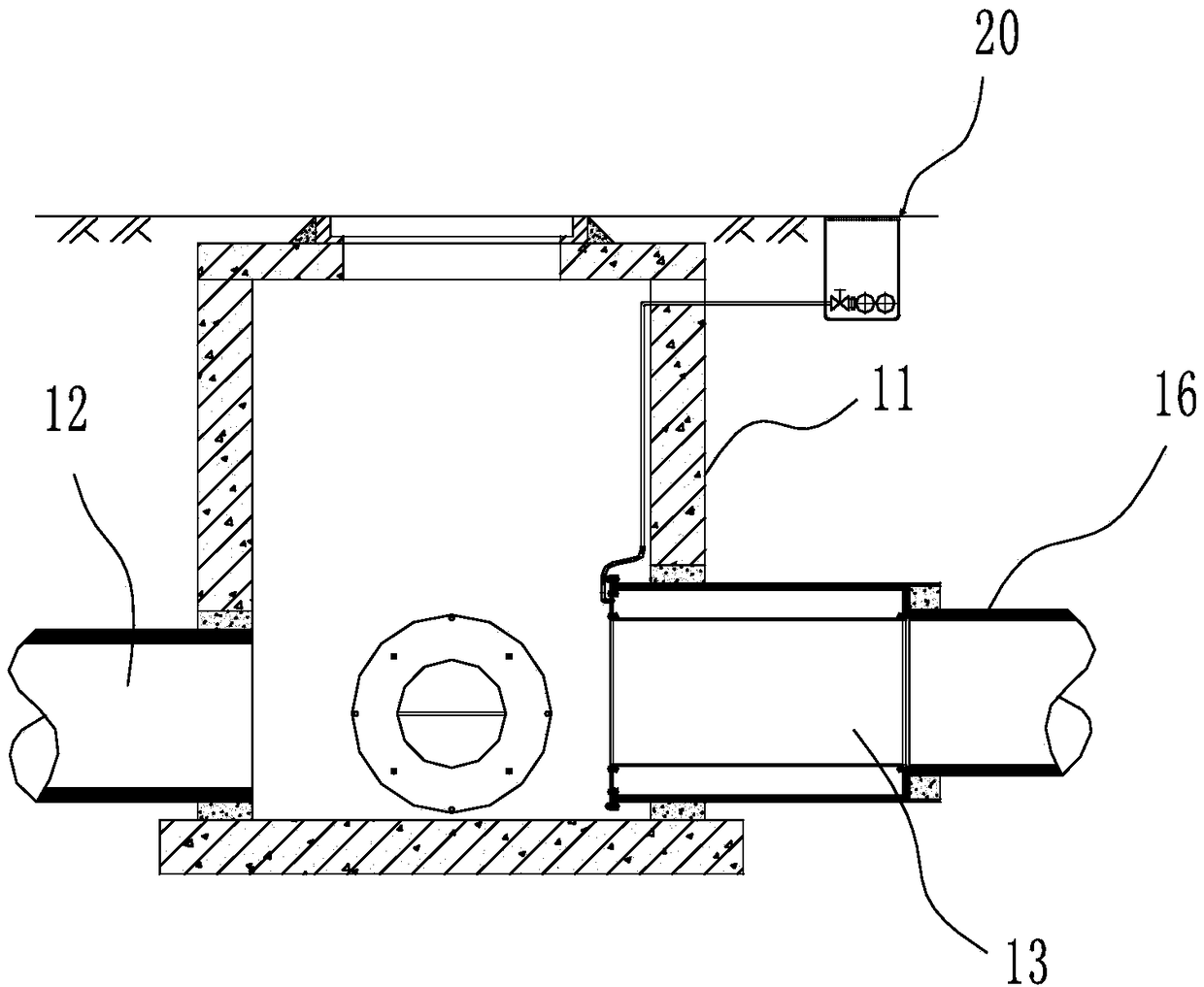

[0093] Embodiment 4 On the basis of Embodiment 2, the system is also provided with other measuring instruments for detecting the measurement information inside or outside the well 10. The measuring instruments include rain gauges, flow meters, water meters, timers, water quality One or more of the monitors. Correspondingly, the measurement information includes one or more of rainfall, instantaneous flow, cumulative flow, rainfall time, and water quality.

[0094] Wherein, the rain gauge is arranged outside the discharge well 10, and what is monitored is the rainfall rainfall, and the rainfall rainfall monitored during sunny days is 0;

[0095] The flow meter is arranged on the first outlet and the second outlet of the discharge well 10, and is used to monitor the instantaneous flow value passing through the first outlet and the second outlet, and calculates the instantaneous flow entering the discharge well 10 according to the instantaneous flow value;

[0096] The water meter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com