Aqueous dipping insulating paint for insulation treatment of motor of electromobile and roll dipping process for motor of electromobile

A technology of insulation treatment and impregnated insulation, which is applied in the field of water-based impregnated insulating varnish, which can solve the problems of affecting the bonding strength and insulation resistance of motor windings, the rolling dipping process of battery car motors, and the uneven drying of paint films, etc., so as to reduce the number of employees and Impact on the surrounding environment, material cost reduction, long storage time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

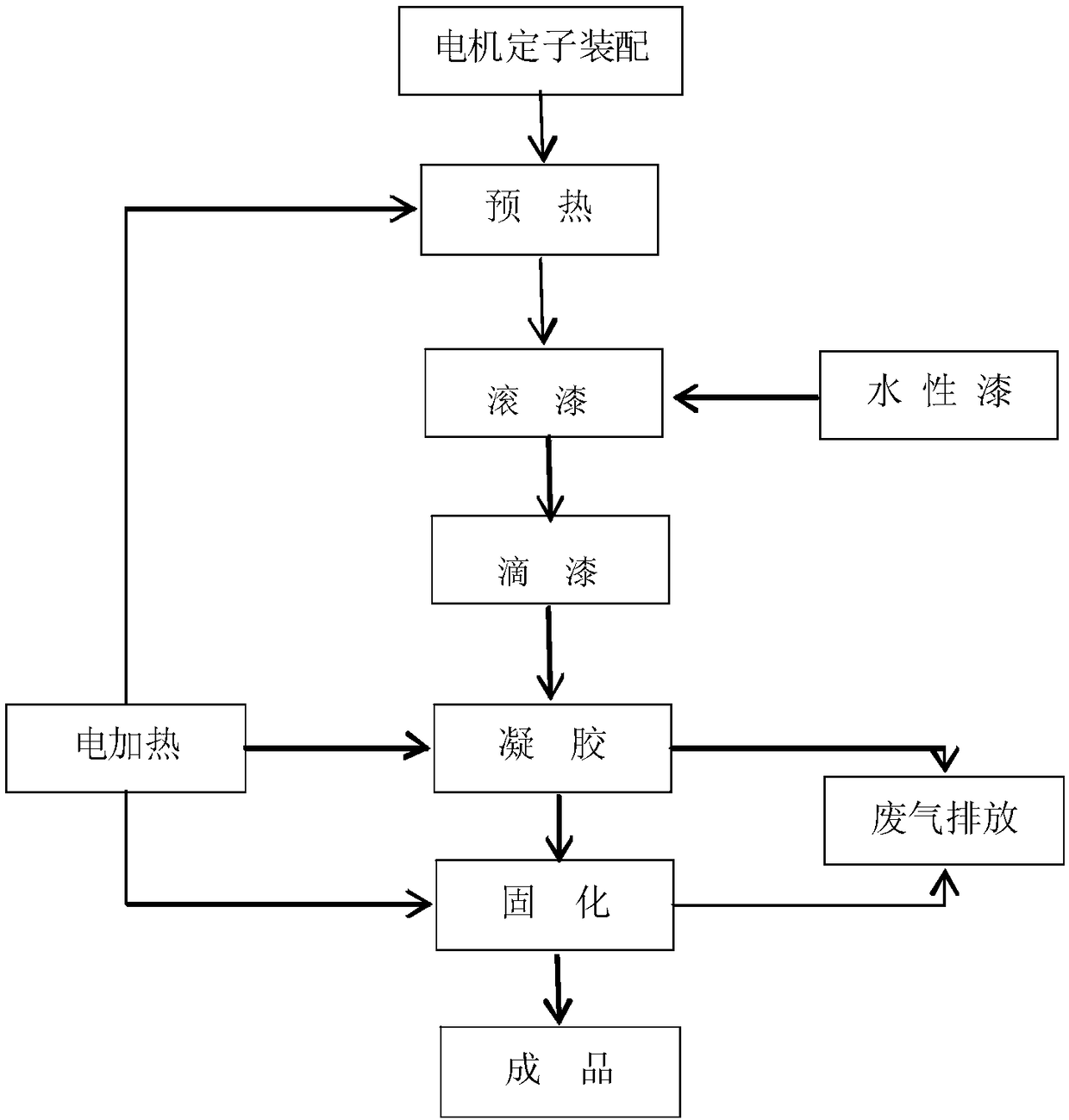

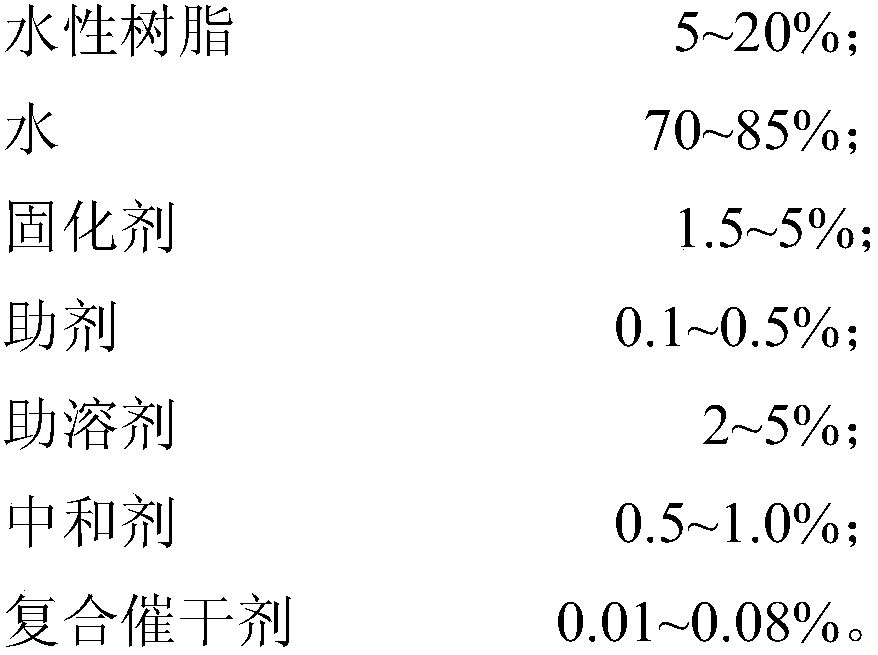

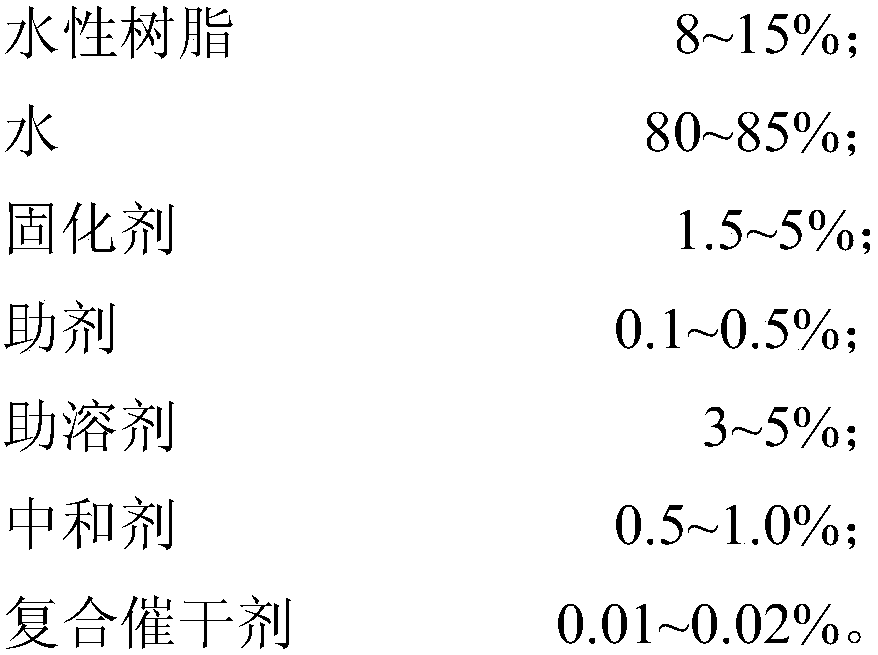

Method used

Image

Examples

Embodiment 1

[0046] 15g polyester resin, 5g 325 amino resin, 5g ethylene glycol monobutyl ether co-solvent, 0.2g defoamer + leveling agent, 126g natural water, 1g triethylamine neutralizer, 0.02g composite drier .

[0047] In this embodiment, the polyester resin is prepared by self-production, and the specific preparation process is as follows:

[0048] Put 60.3g of trimethylolpropane, 37g of phthalic acid, 28g of linoleic acid, and 24.9g of isophthalic acid into the reaction kettle together, start to heat up to 180°C, and start to keep warm. During the heating period, start stirring according to the situation, and keep warm at 220°C at a heating rate of 10°C per hour until the acid value is 40-50mgKOH / g. When the temperature is lowered to 200±5°C, finally add 4.5g of polybasic acid trimellitic anhydride and keep warm at 180-190°C To acid value 40±5mgKOH / g.

[0049] The composite drier used in this example includes zinc isooctanoate, calcium isooctanoate, and chelated cobalt drier (HLD06...

Embodiment 2

[0063] 20g of polyester resin, 5g of 325 amino resin, 7g of ethylene glycol monobutyl ether co-solvent, 0.2g of defoamer + leveling agent, 158.6g of natural water, 1.2g of triethylamine neutralizer, composite drier 0.025g.

[0064] In this embodiment, the polyester resin is prepared by self-production, and the specific preparation process is as follows:

[0065] Put 62g of trimethylolpropane, 44.4g of phthalic acid, 28g of linoleic acid, and 16.6g of isophthalic acid into the reaction kettle together, start to heat up to 180°C, and start to keep warm. During the heating period, start stirring according to the situation, and keep warm at 220°C at a heating rate of 10°C per hour until the acid value is 40-50mgKOH / g, and when the temperature is lowered to 200±5°C, finally add 5.0g of polybasic acid trimellitic anhydride and keep warm at 180-190°C To acid value 40±5mgKOH / g.

[0066] The composite drier in this example is the same as that in Example 1.

[0067] After the compone...

Embodiment 3

[0071] 25g polyester resin, 6g 325 amino resin, 10g ethylene glycol monobutyl ether co-solvent, 0.3g defoamer + leveling agent, 205g natural water, 1.5g triethylamine neutralizer, 0.030g drier .

[0072] In this embodiment, the polyester resin is prepared by self-production, and the specific preparation process is as follows:

[0073] Put 55.8g of trimethylolpropane, 51.8g of phthalic acid, 28g of linoleic acid, and 8.3g of isophthalic acid into the reaction kettle together, start to heat up to 180°C, and start to keep warm. During the heating period, start stirring according to the situation, and keep warm at 220°C at a heating rate of 10°C per hour until the acid value is 40-50mgKOH / g. When the temperature is lowered to 200±5°C, finally add 4.5g of polybasic acid trimellitic anhydride and keep warm at 180-190°C To acid value 40±5mgKOH / g.

[0074] The composite drier in this example is the same as that in Example 1.

[0075] After the components of the above formula are mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com